A horizontal boring machine, the models and technical characteristics of which may vary, has the following purpose:

- Boring holes.

- Drilling.

- Turning parts with a cylindrical shape.

- Processing of product ends.

- Milling.

- Countersinking.

- Thread cutting using a product designated 2620V.

And this is not a complete list of operations performed by the installation of a horizontal boring machine. Thanks to this, it is possible to use only one type of equipment to carry out a full cycle of manufacturing parts from blanks. For multi-batch production, this is a very convenient option; no additional equipment is required.

The presence of a spindle is one of the distinctive features. This part of the structure can be horizontal or vertical. 1 horizontally located element is most common.

The spindle is used to hold cutting action attachments on the 2620 horizontal boring machine, including:

- countersink;

- drill;

- incisors;

- cutters and so on.

During operation, the parameters are determined by the diameter of the spindles. The same applies to the overall dimensions of the machines, including the 2620V version.

About the design features

The design features and the workpieces used make it possible to distinguish the installation for a special, universal purpose.

Horizontal boring machines 2620 are:

- Diamond boring machines.

- Jig boring machines.

- Horizontal view.

The horizontal machine has three versions:

- with two directions of movement;

- with movement in one direction;

- lack of movement.

The spindle is moving, which means that work is starting, shaping is taking place, when workpieces are processed using a horizontal boring machine 2620. Both the tool itself and the workpiece can be fed. The specific option is determined by the technology used. Processing is not complete without additional movements:

- Using guides when moving the steady rest.

- Connection between the rest and the rear pillar.

- Movement of the table across or along.

- Spindle head running vertically. 2620V designs also have this option. This makes the technical characteristics high, and relative to the 2620a option.

Most of the machines are equipped with a rotary table, with spindles of 125 mm diameter. The tables move both transversely and lengthwise. Among the important additions are the A-pillars, which have no movement.

With a 125 mm spindle diameter, the racks move without problems in one or several directions. But most often there are models of horizontal boring machines 2620 with stationary components.

2M614 Block diagram of the power supply of the main circuits of the electrical equipment of the machine

- ДШ — spindle electric motor — А02-52-6/4С1 ~4.5/6.7 kW, ~380 V

- MSM - lubrication pump electric motor - AOL-11-4 ~0.12 kW, ~220/380 V

- ML - steady rest electric motor - AOL-12-2 ~0.27 kW

- MSM - table rotation electric motor - AOL-11-4 ~0.12 kW

- DP - feed electric motor - PBST-42 = 2.1 kW

- TG - tachogenerator - PT11 =0.015 kW (Built in PBST-42)

- EMU - electric machine amplifier - EMU-50A3 = 4.0 kW

- MA - electric motor EMU ~5.9 kW (Built into the electric machine amplifier EMU-50A3)

Work – what principle is it based on?

Feed movements are the main operating feature of these devices. Several important elements and principles need to be described here:

- Fastening of cutting tools occurs with the participation of a faceplate support or spindle. This is where the rotation begins. The principle continues in the 2620a models.

- Placement on the surface of a movable table, using a special device.

- When working, the table moves, lengthwise or crosswise. 2620V models have the same capabilities.

The front post is involved in the movement of the spindle head, while maintaining the vertical direction. The support steady rest is combined with the stand at the rear. The movement of two parts occurs simultaneously.

When holes are bored or internal threads are cut, a translational movement is carried out by a boring spindle. When a part is processed using a 2620 horizontal boring machine, the faceplate with the caliper moves only in the radial direction.

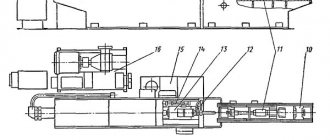

2M614 Arrangement of components of a horizontal boring machine

List of components of the horizontal boring machine 2M614

- Bed 2M614.11.000

- Front strut 2М614.12.000

- Spindle head 2M614.30.000

- Rear stand with steady rest 2М614.13.000

- Faceplate 2М614.32.000

- Table 2M614.22.000

- Distribution box 2М614.51.000

- Lubrication station 2М614.14.000

- Electrical equipment cabinet 2M614.92.000

Model 2620 Features

This CNC horizontal boring machine also has a number of modifications - 2620G, 2620V, 2620A, 2A620, 2620. When using them, it was previously possible to process parts with bodies of medium or larger sizes. Machines are not produced without retractable spindles.

It is characterized by the presence of faceplates inside, 90 mm in diameter. Parts weighing less than 3 tons are processed. This is confirmed by the passport is2a636f1.

The differences between the models are as follows:

- 2a620G – no rear pillar;

- 2А620В – rear pillar present;

- 2a620F1 – with a device that provides digital identification.

Information about the manufacturer of the horizontal boring machine model 2M614

Manufacturer of horizontal boring machine 2M614 Charentsavan Machine Tool Plant .

Machine tools 2L614, 2L615, 2A614-1, 2A615-1, 2L614-1, 2L615-1, 2M614-1, 2M615-1, 2N614-1, 2N615-1 were also produced at the Charentsavan Machine Tool Plant.

Machine tools produced by Charentsavan Machine Tool Plant

- 2A614

horizontal boring machine Ø 80 - 2L614

horizontal boring machine Ø 80 - 2M614

horizontal boring machine Ø 80 - 6540

vertical milling machine with cross table 400 x 1000 - 6550

vertical milling machine with cross table 500 x 1250

Information about modifications 2A622F4 and 2A622

This is a new type of CNC horizontal boring machine, replacing obsolete analogues.

The devices are designed to process parts in a cantilever manner, even with large-sized housings. Their weight can reach up to 4 tons. Processing should not be a hassle, even if there are holes that require precise parameters. And when certain dimensions are saved for connecting the axes. Sometimes products with the number 2L614 are designed this way.

An obligatory part of the equipment is a rotary table and a front stand that maintains a fixed position. But the table itself moves, lengthwise or crosswise. On machines of this series it is easy to mill workpieces following an octagonal contour. Let's assume an option with a circular table feed. One of the available modifications is is2a636f1.

The design also includes a retractable spindle with a diameter of 110 millimeters. The plates are mounted in one position on the spindle headstock, at the end of the wall. This is how the horizontal boring machine model 2a614 works.

Among the main characteristics it is worth noting high rigidity and the ability to resist vibrations. Due to this, the service life of the spindle device is increased. Console technology increases efficiency. Machining the end surfaces of parts is made possible thanks to a removable faceplate. Boring large diameter holes is simplified. The 2L614 variants have this property.

The type of design determines the presence of certain additional parts:

- CNC option.

- Digital identification technologies.

- Coordinate readings are in digital form, this is important for the processed part.

2a614 - how does the model differ?

The main purpose of the model with the designation 2a614 is case-type parts, weighing up to 2 tons. It simplifies the work with structures where there are holes of precise dimensions with connections that require compliance with the parameters between the axes. Boring machines of the 2A614 series are universal devices that provide access to the following capabilities, just like the 2L614 products:

- Machining grooves of a ring device.

- Grinding the surface at the ends.

- Work with sampling, milling.

- Reamed holes.

- Countersinking.

- Boring holes. Horizontal boring machines 2a622 also cope with this function.

- Drilling.

The manufacturer can additionally install a thread-cutting device if necessary. Even for the 2L614 design.

A mandatory addition is the clamping of tools using a mechanized method. The device is characterized by high resistance to vibration influences. The level of productivity is so high and the controls are so convenient that work requires a minimum of effort and investment. The level of accuracy will also be pleasantly surprising. But horizontal boring machines 2a622 can also boast of this.

A table with a turn can be built into any design. It moves along and across the spindle part. Characteristically, there are pillars in front that do not change position. Like the model 2L614.

The work is also carried out due to the built-in faceplate, with a radial support. The spindle and faceplate would not be able to move without the participation of an alternating current electric motor. For this, a high-speed box with a gear device is used. The gear selector mechanism also becomes an indispensable assistant.

The DC motor is responsible for organizing the feed. The breadth of the regulatory spectrum is sufficient to ensure that resolving the issue does not cause additional problems. The feed amount can be changed at any time without stopping the movement. This opportunity is also provided in models of horizontal boring machines 2m614.

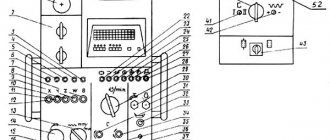

2M614 Location of horizontal boring machine controls

List of controls for horizontal boring machine 2M614

- Feed rate setting handle

- Handle for dialing spindle and faceplate speeds

- Headstock Clamp Handle

- Faceplate rotation handle

- Handwheel of the mechanism for manual movements of all movable bodies (Steering wheel)

- Feed drive signal lamp

- Signal lamp for reaching the limit switch

- Local lighting switch

- Optics backlight button

- Button for jog turning the spindle and faceplate clockwise

- Button for jog turning the spindle and faceplate counterclockwise

- “Start” button for the spindle and faceplate drive electric motor. Direction of rotation clockwise

- “Start” button for the spindle and faceplate drive electric motor. Direction of rotation counterclockwise

- "Stop general" button

- Button for quick movements of movable working parts

- Button for quick movements of movable working parts

- “Start” button for the feed drive when the main drive is turned on

- “Start” button for the feed drive when the main drive is turned on

- “Start” button for the feed drive when the main drive is turned on

- “Start” button for the feed drive when the main drive is turned on

- "Stop general" button

- Feed stop button

- Table cross selection button

- Headstock selection button

- "Table along" selection button

- Spindle selection button

- Faceplate support selection button

- Steering wheel button

- Toggle switch for switching operating modes of the steering wheel

- Subtle movement of any organ

- Rough displacement of any organ

- Switch for cycle operation - Contour continuous milling

- Button for turning on the working feed when working in a cycle

- Table cross slide clamp handle

- Handle for manual rotation of the upper (rotary) table

- Turntable Clamp Handle

- Table slide clamp handle

- Table quick adjustment button

- Table quick adjustment button

- Handwheel for fine manual feed of the rear pillar rest

- Buttons for quick installation movements of the rear pillar rest

- Buttons for quick installation movements of the rear pillar rest

- Rear pillar steady rest clamp handle

- Rear pillar longitudinal movement handle

- Rear strut clamp handle

2L614 – about equipment characteristics

This machine also represents a group with universal products. It is used when processing body parts weighing no more than 1000 kilograms. Other features are also characteristic:

- Equipped with a built-in rotary table. Standard movements - using longitudinal, transverse directions. They are also followed in product 2a622f4.

- It is worth noting the presence of a front pillar, which is motionless.

- Among the main units is an alternating current electric motor, which is responsible for organizing the rotational movement, which is carried out with the participation of the spindle and faceplate.

- It is easier to control the process when using a gear selection mechanism with a handle. As in option 2a622f4.

The 2l614 modification machine is always supplemented not only with a built-in type of faceplate, but also with a radially moving caliper. The list of operations performed is larger thanks to the radial caliper.

When machining, you can use the so-called retractable spindle. Then milling work makes it possible not to use a radial type caliper.

The machines will benefit enterprises in the field of mechanics and tool production. In terms of accuracy, there is correspondence to the category designated H. Products 2a622F4 are designed differently.

Video: CNC horizontal boring machine.

Electrical equipment of the machine 2M614

The electrical equipment of the machine is designed for power supply from a three-phase alternating current network of industrial frequency (50 Hz) with a voltage of 380 V.

Description of the electrical circuit

The main drive - the spindle drive (faceplate) is carried out from a two-speed asynchronous electric motor through gearboxes (Fig. 20).

The main electric motor produces:

- rotation and installation rotation of the spindle (faceplate) in both directions, automatic rotation of the drive gears during gear shifting

- rotation of the spindle (faceplate) using buttons located on the control panel, which is located on the spindle head of the machine.