Articles

All photos from the article

Wood milling is one of the main procedures necessary for the production of wooden products, creating profiles, grooves, edges, pockets and other shaped elements. Processing can be carried out for utilitarian or artistic purposes. We will look at milling equipment and the features of working with it.

A wood milling machine allows you to carve complex surfaces and patterns.

Tools for hand wood carving

To carve wood with your own hands, you will need quite a lot of tools, and each master has his own special ones that are more convenient and practical for work.

Among the most basic and necessary even for a novice master are the following tools:

- Cutters, also called cutters, are one of the most basic tools in wood carving. The dimensions of the cutters themselves may vary, depending on what they are intended for, but all of them have a cutting blade of 35 degrees Celsius.

- Shoals are special knives in which the cutting edge of the blade is 60 degrees Celsius. As a rule, jambs are used when creating flat-relief carvings, when creating contours and cutting some lines.

- Semicircular chisels - used for sculptural and flat-relief carvings. This chisel can have different widths and bends.

- Straight or flat chisels - level the surface to perfect smoothness, used to sample the background. Produced with different cutting edge widths.

- A rivet is a tool that is used in wood carving in hard-to-reach areas. The sharpening shape can be made like a sword, a leaf, or a nail.

- Geismus or corner chisel - the tool has a bending angle of the cutting blade of 45 degrees Celsius.

- Stichel - used in almost every wood carving technique. Such a tool can be made in different types, but all have a bend of the cutting blade of 15 degrees Celsius.

- Clukars are original tools for wood carving; when working with them, it is impossible to touch the working area with the handle. This tool has a pair of bends of 120 degrees Celsius.

- Spooner - Used to remove a significant amount of wood from a hole. As a rule, such a tool is necessary to create wooden utensils.

Where to begin

In order to “make friends” with a router, you need to practice on simple products. Working according to the template will help you get better. Take a pre-prepared blank and apply a drawing, trying to maintain the proportions. Finding templates is easy. There are options on the Internet that are easy to transfer with a pencil.

Drawings for inspiration:

Patterns on products may vary. Everything depends on the imagination of the creator, because the one who creates sees the work in his own way. Beginners, having mastered the basic rules, proceed to complex ones. You can learn to adjust the depth of the cut by adding patterns with different cutters. To make the work unique, craftsmen add notched carvings to the products.

Effective work

Using a hand-held electric router is suitable for artistic carved furniture. Artistic carvings look especially beautiful on furniture. Cutters of different sizes and profiles easily perform various tasks. Unfortunately, it is impossible to make triangular-notched work with a router. This task is suitable for chisels or knives. Bas-relief, contour cutting on wood - all this can be done with a hand router.

We can say that the functionality of the tool depends on the configuration. Various devices can work wonders, improve the product and make the work of the master easier.

Stencils are suitable not only for conventional tools, but also for a hand router. Examples can be seen below:

What else can you use a hand router for? Craftsmen can transform the interior of a home using this tool.

Designer items and interesting objects often attract attention. If you want to change something in the house, then a router is especially for this! He is able to revive old things

A beautiful pattern has never detracted from the look of a tree!

To carry out this kind of task, there is a figured carving that embodies unusual solutions in interior design. It can be used to decorate furniture, parquet floors, and make new decorations. This carving predominates in the Slavic style. Nowadays, it is coming back into fashion and hand-milled products are highly valued on the goods market.

For inspiration, you can look at photographs of works that are most often found on the Internet:

Manual carving router

In order to facilitate the process of wood carving, you can use a special manual milling machine.

- With the help of such a tool you can work in almost all techniques and speed up the work process itself.

- The main elements of a manual milling machine are cutters and attachments that have various shapes.

- Each cutter shape is designed to perform a specific function.

- Wood carving can be done with one milling machine or supplemented with elements that are made with other hand tools.

It is worth noting that the router can be horizontal, edge or vertical type. A vertical type milling machine is considered universal.

It can be used for cutting through holes. An edge router is used for processing the ends of products, and a horizontal router is designed for processing the side walls of a product.

What can you do with a router yourself?

The main types of work that are done with the help of a router are a selection of profiles of different configurations - semicircular concave and convex, curly, slotted straight, etc.

- figured profile along the edge of window sills, table tops, stool seats, book, telephone and other shelves, cutting boards, railings and stair railings, any pieces of furniture and interior design;

- grooves and tenons for connection along the entire length like a lining, at the ends in the corners, in the middle (under jumpers - drawers);

- applying patterns and ornaments with a cutter with a semicircular tip (fillet) or with another profile;

- selection of recesses for fitting door and frame hinges, handles and locks;

- processing of straight and curved edges, for example, cut with a jigsaw, a milling cutter of any profile with a limit bearing at the end.

Milling cutters

In order to carve wood using a manual milling machine, you should prepare several types of cutters.

The most popular and in demand cutters:

- Profile - to create a shaped configuration of the edges of the product.

- Conical - used to remove chamfers from poses at an angle of 45 degrees Celsius.

- A disc or rebate cutter is designed to create a groove in an edge.

- Galtein - designed for cutting round grooves on the edge of a figured product.

- Edge - used to form spikes and grooves.

Wood milling prices

| Thickness, mm: | Prices for wood milling, rub/mp | |||

| up to 500 | up to 1000 | up to 3000 | up to 5000 | |

| 6-10 | 45 | 35 | 25 | 20 |

| 11-15 | 55 | 45 | 35 | 25 |

| 16-25 | 80 | 70 | 60 | 45 |

| 26-50 | 120 | 100 | 85 | 65 |

| : | =»color:> |

| +7 926-301-80-59 | | |

| Prices for CNC wood milling are indicated in Russian rubles excluding VAT per linear meter, excluding the cost of the material. The cost of milling is calculated as the sum of the lengths of all cutting lines in the layout in meters, multiplied by the cost of 1 meter with the corresponding thickness of the material. | |

Types of wood carving

Wood carving can be done using various techniques, so this process is divided into types that have their own characteristic features and rules of execution:

- Brownie - used on coniferous trees. This type of carving is considered the largest and serves as decoration for the exterior of the house. In this type of carving, the technique of openwork carving or applied carving is used.

- Three-dimensional or sculptural is one of the most complex types of wood carving. To manufacture a product of this type, a significant number of tools and special skills are required. As a rule, the lower part of the tree is used for this process.

- Contour or ornamental - wood carving, which visually very much resembles engraving. As a rule, carving of this type requires a special knife, a curved chisel.

Geometric carving is one of the simplest and fastest types. The following tree species are best suited for this type of carving: linden, aspen, pine, larch, spruce. Can be done in several techniques:

- Stapled - due to semicircular tools, a chisel of different diameters;

- Two, three, tetrahedral - due to recesses with several edges.

Flat-relief - characterized by carving in one plane, while the background deepens, and the relief itself stands out more clearly. The created ornament must be the same height.

Relief carving is considered the most expressive and beautiful compared to other types. This type of wood carving is most often used for decoration. As a rule, it is best to use hard woods for relief carving: oak, beech, cedar.

Carving on gingerbread boards is one of the earliest types of wood carving. This type of carving is characterized by large inscriptions on all sides and a funny design in the center in relief.

Devices and how to use them

Two simple devices are used together with the router - a rip fence (guide) and a compass. They are included with most models.

Rip fence

This is a bar that is mounted on two plates or round rods that are inserted into the lugs on the router's support platform and secured with wing screws. The plank moves along one side of the workpiece, the cutter processes the other side.

The bar prevents the router from moving to one side, outward. In this case, the milling cutter can “dive” deep into the workpiece if the cutter is without a limit bearing at the bottom.

The parallel stop (guide) is used only when processing workpieces with straight sides (edged board or block). There are restrictions for use on the width of the workpiece:

- there is not enough plate length for a workpiece that is too wide;

- on narrow workpieces that do not extend beyond the edge of the platform, the bar does not reach the workpiece.

Therefore it is used quite rarely.

Compass

It is inserted into the platform eyes in the same way as the parallel fence, but has not two, but one platinum (pin). At the end there is a centering sharpened cone (needle). Used for surface sampling of circles and semicircles.

Sometimes a through cut is made with a milling cutter, that is, the circle is cut out completely in several passes, and then the circle is processed with an edge or profile cutter. The method is suitable for making door and other arches, applying ornaments with semicircular and round elements.

When the length of the plate (pin) is not enough to work with large diameters, make homemade compasses of the required length.

Sometimes the router is used in a stationary position, mounted in a table with the cutter facing up. But the table cannot be considered a fixture; it is a separate structure.

Rules for working with a hand router

In order to facilitate the process of wood carving with a manual milling machine, you should pay attention to some tips from experienced craftsmen:

- Only sharp tools should be used in this work.

- The material on which the carving will be made must be well fixed.

- You cannot remove the entire surface at once in one pass, this will greatly increase the load on the cutter, on the engine itself and the processing speed will decrease.

- You need to replace the router only with the machine disconnected from the network.

- When functioning correctly, the milling machine should not vibrate.

Creativity without limits

Milling equipment is indispensable when processing wood. With its help, you can turn a wooden blank into an elegant decorative product. This equipment is most often used by professionals, but experienced amateurs can also master it. Using mechanisms is not an easy task, so before you start working with them, you need to ensure your comfort and safety. Organization of the workplace is very important. The home craftsman must remember that during work there is a possibility of damage not only to the cutter or mechanical device, but also to health.

Woodworking is not only about working at the machine, but also about preparing the workplace and planning the sequence of work to be performed. Before you start milling, you need to select the appropriate type of cutter for a specific task, taking into account its shape and size. You should select the speed of the machine and the cutting depth and do not forget that the material being processed must be securely attached to the table.

Depending on the specific type of milling device, the rules for their use are different in many aspects. Today, vertical milling machines in which the spindles are located above the work table are widely used. They have proven themselves to be excellent in operations such as wood milling, processing the edges of shelves and round tabletops, making a groove, and joining wooden parts. When processing round structures, an indispensable addition is a special compass with a support plate, which ensures precision processing.

When working with a router, you need to learn how to move it calmly and smoothly. The key is to move the material being processed correctly and safely. This should not be done too slowly, as burn marks may appear on the wood, which can lead to damage to the material.

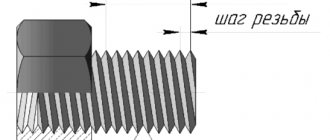

Chips appear when milling woodworking against the direction of the wood grain. In one pass it is necessary to mill to a depth of up to 8 mm; some models allow adjustment with an accuracy of 0.1 mm. Deep grooves and quarters need to be milled in several passes.

Photo of wood carving using a hand router

CNC milling, milling cutting, plywood, MDF, composite milling

Milling of plastic and plexiglass in Moscow, milling products Decorative partitions and openwork grilles Milling of artificial stone, inlay

CNC milling and figure cutting are used for precise milling cutting in the manufacture of products that often cannot be made by other methods of working with materials. Milling cutting on a CNC machine allows you to perform various milling options: chamfering, making a groove, figured cutting and much more. CNC is numerical control and it gives almost unlimited possibilities for executing complex orders that cannot be completed in the usual way.

We carry out the following milling work:

- Milling cutting and milling;

- Milling of parts, chamfering, shape cutting and cutting;

- Manufacturing of products.

The list of materials available for processing in our company is quite extensive:

- PVC;

- plastic;

- MDF;

- composite materials;

- plywood;

- wood;

- laminated plywood;

- plexiglass and acrylic;

- polystyrene;

- foam board;

- brass;

- artificial stone, possibly with inlay;

- aluminum;

- caprolon and other materials. — Milling of all materials is affordable and all this can be ordered from us. We are located in Moscow, you won’t have to travel far.

Our machine can mill thick plywood. Milling plywood 40mm thick can be done without problems, the results are in the pictures. Milling the plywood could have been made thicker, but so far there was no need.

Plywood products are made as follows. First, the plywood is milled, often according to the customer’s files. Then painting is done, if necessary. Plywood can be painted according to RAL. Then comes the assembly of products. Sometimes the assembly of plywood products is done by the customer himself.

We also mill laminated plywood. To mill this material, we use special cutters to eliminate possible chips of the laminate.

Milling plywood is often used for interior decoration, in advertising structures, and in the manufacture of toys.

MDF milling is used in the repair and manufacture of furniture, for various crafts, and for solving various advertising problems.

The difference from plywood is that MDF is a more homogeneous material and when milling MDF, the quality of processing is higher. MDF allows you to bring to life the exclusive ideas of designers: unique bas-reliefs, complex lattice partitions in the form of cut-out figures, and more.

We do MDF milling on MDF boards of any thickness. The dimensions of the products are limited only by the MDF sheet format and your imagination.

We use MDF milling to make ceiling panels. We paint the panels in the desired color, possibly according to RAL.

Milling of PVC and other plastics, especially milling of plexiglass and acrylic, is used for signs, POS materials, making all kinds of bent stands, three-dimensional letters. CNC milling is very popular for PVC, because... Laser cutting of this material is not allowed due to the release of chlorine, which has a detrimental effect on both the operator and the machine. But PVC milling solves all problems, the material is easy to process, and milling is fast.

Milling plexiglass and acrylic gives a matte edge after cutting with a milling cutter.

This must be taken into account, because If a glossy shiny edge is required, we use laser cutting of plexiglass or additionally process the matte edges with a torch.

CNC milling of plexiglass allows you to make cuts, grooves, and holes in products with high precision.

Milling of foam board is often carried out for the production of life-size figures, inscriptions and figures, stars and other design elements, for example, shop windows. We mill foamboard and this is what we get.

Composite milling is used in the production of advertising signs, often with inlay, and in the production of building cladding. The composite is a plastic material with thin aluminum sheets on both sides. Aluminum in a composite panel comes in different thicknesses, from 0.21 mm to 0.4 mm, the price varies greatly, and the desired panel option is used based on the task at hand. Milling of the composite is done with two cutters: one for straight cutting and the other, conical, for subsequent bending of the material.

Thanks to the ability to bend the material after milling the composite, we can obtain various three-dimensional advertising structures.

Milling aluminum, including thin aluminum, allows you to produce interesting products. For example, in the photo below, thin aluminum “gold-look”, 0.4 mm thick, was used to make leaves for a New Year’s tree.

CNC milling of brass is done to make signs, often followed by pouring paint. When milling brass, we remove the chamfer, then we have to polish the finished product. Polishing of all this is the most labor-intensive process, but the result is a beautiful product.

By milling brass you can make not only signs, but, for example, personal medallions, zodiac signs or other products based on your drawings.

Milling artificial stone of different colors allows you to obtain interesting and unusual types of products.

These can be three-dimensional letters, figures, anything.

Wood milling.

CNC milling: advantages

- high precision of cutting elements;

- there is no high-temperature effect on the edges, as with laser cutting;

- no charring of edges;

- milling plywood of any brand, regardless of the composition of the impregnation between the layers;

- possibility of PVC milling;

- milling of plastic, any kind, as opposed to laser;

- a CNC machine makes it possible to produce almost any non-standard products from PVC, plywood, MDF, composite, plexiglass, artificial stone and many other materials;

- strictly vertical cutting of the material, not associated with beam deflection when the optical environment changes;

- the ability to make a selection of grooves, make a chamfer;

- cutting and milling of composite, brass, copper, aluminum.