How to shorten a chainsaw chain with your own hands?

Long-term use of the headset leads to its gradual sagging.

Faced with this for the first time, many inexperienced fellers do not know what to do if the chain on the chainsaw stretches. To solve the problem, the first thing you need to do is assess the level of sagging. After this, you can begin to prepare tools that will help shorten the chain on the chainsaw. The subsequent procedure should look like this:

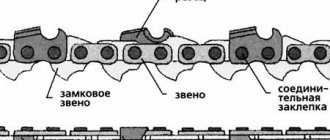

- First, you will need to carefully disconnect the links in the sagging part of the headset. Doing this with a grinder will be quite difficult and dangerous, especially if you are repairing a hard diamond chain. It is best to disconnect the links using a needle file or an ordinary file. When performing the procedure, it is necessary to grind off each side of the links. Then you need to unscrew the ground rivets using the prepared beard;

- Immediately after the operator has been able to carefully rivet the chain, it is necessary to set aside the disconnected part of the headset. There is no need to throw them away, as they may later be needed to replace worn links;

- After this, the operator must rivet the chain evenly. To do this, you need to count the teeth in the saw element in advance and carefully connect the remaining links together using a rivet. To do this, you need to press the side parts of the links tightly against the rivet being used;

- Then you can proceed to welding the links. The elements welded to each other will need to be carefully cleaned with a file, otherwise the bulges and other welding marks will severely scratch the surface of the tire;

- Before riveting the chainsaw chain, you need to let the headset cool. After this, a household drill must be equipped with a pre-prepared 7-centimeter steel blank, machined from an ordinary nail;

Quite often, instead of a blank and 2 needle files, a special riveter for chains is used to shorten the headset at home. It allows you to connect the links faster and more accurately without the need for further processing with a file.

Removing and disassembling the motor

The engine is held in place by 4 screws installed on the bottom of the Shtil 180 chainsaw. To remove it, you need to unscrew them, then carefully pull the engine out of the seat and the rubber carburetor pipe.

To disassemble the engine, 4 crankcase screws are unscrewed and it is removed; then there is the option of removing the crankshaft assembly with oil seals, bearings and piston rings.

Removing bearings and seals usually does not require additional tools; if the bearings were pressed onto the shaft with force, then a special puller will be useful for dismantling.

To remove the piston from the connecting rod, you will need to pull the lock ring out of the seat using a thin screwdriver, then press out the piston pin from the back side, after which the piston is removed to the side.

General concept of the chainsaw chain lubrication system

To understand how important the choice of chain oil is for a chainsaw, let’s consider the principle of operation of the lubrication mechanism itself using the example of the Stihl 180. This model was chosen as one of the most common modifications of chainsaws from.

The chain lubrication system of the Shtil 180 chainsaw consists of several main parts:

- expansion tank;

- lubricant supply tubes from the reservoir to the pump;

- oil pump;

- channels for supplying lubricant to the tire (on some saws, the intensity of pumping oil into the tire can be adjusted);

- channel systems inside the bar for distributing lubricant over the entire working surface of the saw set.

In general, the intensity of the lubricant supply for the Stihl 180 chainsaw chain is not manually adjustable. You can adjust the oil supply to the chainsaw chain in some other models (for example, on Husqvarna saws).

And in this saw a simple rule works: the higher the engine speed, the more intense the pump rotor rotates and the greater the quantity of lubricating fluid supplied to the saw set.

There are no finer settings without using methods not specified in the operating instructions.

Oil is poured into a special tank every time you fill up with fuel. The designers designed this chainsaw in such a way that after the fuel has been used up, there should still be a small amount of oil left in the expansion tank. That is, with proper operation, the likelihood that the chainsaw will run dry is eliminated.

The lubrication system works as follows. The crankshaft, through a kinematic connection, drives a rotary oil pump of the simplest design.

The oil pump creates a vacuum and sucks lubricant from the reservoir. Next, he drives it under pressure into the tire channel system. The oil enters the driven teeth of the chain and spreads throughout the headset. The chain, the working surface of the tire and its front needle bearing are lubricated.

Running in a chainsaw

All new and repaired chainsaws are tested. The peculiarity of a two-stroke engine is that parts and mechanisms should not be allowed to break in at idle speed. In this mode, the gasoline-oil mixture does not have time to burn completely and carbon deposits form on the walls of the cylinder and carburetor, causing the engine to become coked. This process quickly leads to breakdown of the unit.

The running-in of moving elements is carried out under light loads. During running-in, a chainsaw must be used to cut without applying significant physical effort. Recommended mode:

- a minute - one and a half - sawing with a slight load;

- 10-15 seconds in idle mode.

To break-in the parts and reach the engine's rated power, it is necessary that 7-10 full fuel tanks be used.

The moving elements of the saw set must also be run in. Before the first start, the chain is generously lubricated with oil or temporarily placed in a container with oil. When installing, the chain is tensioned so that it sits tightly on the bar, but can be turned by hand. The running-in of the headset parts occurs simultaneously with the running-in of the entire unit.

After each completion of work, the chain tension is checked.

When running in, do not give the saw a large load.

Troubleshooting Circuit Problems

During operation of the chainsaw, it is necessary to constantly monitor the lubrication of the chain. After all, it is this part that works in the most difficult conditions. The chain is constantly overheated and dust and abrasive particles become clogged with it. All this negatively affects its service life. A special lubricant will correct the situation. It is supplied to the chain from the tank, thereby ensuring unhindered operation.

If lubrication does not occur during operation, there is a high risk of overheating. When there is no oil flow, the chain begins to stretch. At the same time, there is still a possibility of it jamming or spontaneously jumping off, as a result of which a person can receive serious injury.

The channels through which fuel is supplied can become clogged with small particles, so it is advisable to clean them periodically

It is also important to monitor the oil level in the tank. Debris in the channel is a common cause of chain brake failure.

This may have a negative impact on your work.

But what to do if all the recommendations are followed, but the oil still leaks. It is necessary to ensure that the chainsaw is operating correctly. It is likely that it was assembled incorrectly. If the breakdown has not been identified, it is recommended to take it to a workshop. In some cases, it is necessary to replace the pump, but this should be done if the saw is new. Old tools leak due to worn out reservoir.

Only a specialist can assess the current condition of the chainsaw. If you lack knowledge or lack confidence in your own abilities, it is advisable to entrust instrument repair to a professional.

Each chainsaw, regardless of its model, brand, or class, has approximately the same structure. It consists of several important components, including the lubrication system. Without the latter, the operation of the power unit is impossible. Due to the functioning of the forced lubrication system, the tool chain reduces the risk of severe wear, which is guaranteed in conditions of constant friction of the carved element against the guide bar and inevitable heating. When the chain mechanism is lubricated, friction is softened; the chainsaw operator needs to repair this element or completely replace it much less often.

How to remove the clutch on a chainsaw of any brand

One of the most important parts of any device model is the clutch. This mechanism requires constant monitoring for correct operation. It must be removed periodically for inspection and necessary repairs. How to remove the clutch on a chainsaw of any brand correctly and how it works will be discussed below.

Chainsaw clutch

How does a chainsaw work?

All types of units are driven by a gasoline internal combustion engine. During assembly, single-cylinder engines are installed, which are filled with high-octane high-quality gasoline.

Instead of a gearbox, a single-stage transmission is used, which makes the chain move. The structure of the unit, due to its simplicity, allows it to operate reliably in any conditions.

The unit structure consists of the following parts:

- Single-cylinder internal combustion engine;

- Gas tank;

- Carburetor;

- Crank mechanism;

- Clutch;

- Saw chain and sprocket that drives it.

In addition, there are the following components:

- Air purification system supplied to the carburetor;

- Ignition mechanism;

- Exhaust muffling system;

- Emergency shutdown system activated in emergency situations.

In the photo you can see a variety of models from manufacturers Shtil, Husqvarna, Partner, Goodluck.

How does a chainsaw engine work?

Recently released devices have a single-cylinder, two-stroke, carburetor-type engine. It includes several mechanisms that work harmoniously. Main components of the engine:

- Flywheel;

- coupling;

- Incendiary module;

- Muffler;

- Mounting sleeve.

The engine installed in the saw operates at a frequency of 13.5 thousand revolutions/minute, and therefore it requires treatment with high-quality oil. A high level of system cooling is required during operation. The engine of the unit is equipped with a cooling system that supplies air to cool the systems.

Chainsaw clutch

The wood processing device's clutch is centrifugal and operates automatically when the engine crankshaft speed changes.

If the revolutions are small, then the elements of the mechanism are pressed against the shaft. This way the rotational motion is not transferred to the sprocket.

A characteristic property of this type of device is braking when the chain slows down. This way you can avoid some breakdowns. But still, this system is subject to enormous load, so it is necessary to systematically carry out preventive inspection and repair.

How to remove

The drive sprocket also serves as a drum. One of the main reasons for the breakdown of this block is the grinding of the sprocket teeth.

In a monolithic drum version, the chain can cut through the sprocket during operation. This mechanism requires replacement.

If the drum has a replaceable crown, it must be removed and replaced during maintenance. After this, the drum can continue to function.

When the need for repairs arises, you need to seek help from a service center staffed by experienced specialists.

But if there is no one nearby, the question arises - how to remove the clutch yourself? If you have the necessary set of tools, you can easily implement your plans.

Of course, there are some differences in models from different companies, but the disassembly scheme remains the same:

- First, remove the chain brake cover by turning the lever. Lightly unscrew the nuts to release the tension on the chain. After loosening, you can completely unscrew the nuts and remove the cover;

- The chain and guide bar are disassembled, as well as the mechanism is cleaned of dirt;

- The cylinder head spark plug is turned out and the piston is fixed. To do this, the crankshaft must be rotated until the exhaust port is blocked, and then a piece of rope is placed in the cylinder to lock the piston. After completion of the work, the rope is removed from the mechanism;

- The nuts on the clutch are unscrewed using the special wrench included in the kit. In this mechanism they are made with a left-hand thread, and this must be taken into account when dismantling. After this, the mechanism is disassembled and all its parts are inspected for damage. Worn parts must be removed and replaced with new ones.

Semi-synthetic oil of the Stihl brand

Very often, owners of such chainsaws wonder what kind of oil can be used for the saw. Its operation may be affected by:

- cutting set;

- climate;

- wood species

To solve this problem, the Shtil company developed a universal semi-synthetic oil. It is suitable for all high-speed chainsaws. Under any conditions, chains can be lubricated with this oil. The tool will work flawlessly.

Since Shtil semi-synthetics are intended for chains, they are made from special high-quality materials and do not contain various toxic substances that can cause cancer. The oil fully meets the most stringent environmental requirements.

The Russian climate is quite harsh. There are areas in our country where frosts often exceed -20°C. The latest Stihl chainsaw chain oil has been specially developed for use in cold conditions. In such frost it demonstrates excellent fluidity.

Special additives included in the oil prevent the cutting set from becoming oily; they will extend the life of other lubricated parts. A saw with this oil starts easily even after long-term storage.

The use of such chain lube reduces wear on the saw chain. Due to the high endurance of the oil at high temperatures, the cutting set is ideally protected. This oil is not afraid of peak temperature loads. Smoke almost never appears.

Of course, anyone who owns a chainsaw knows how important good quality oil is. And, everyone dreams, there is no need to say what it really is, that this is the typical “life force” of a given device for producing real and effective work

Today there is an unlimited number of oils and, as the saying goes, the choice is very large.

But, often, not every owner of electrical equipment of this kind knows what kind of oil to use for his steel friend, so that the operation of the chainsaw is not only easy, but also productive. Therefore, below we will discuss the issue regarding the correct choice of the manufacturer of the calm. Also, what it is to help the chainsaw in its time of its specific activity, and not harm. Let's get started with what we need.

Read also: Bimetallic crown for wood

Removing the clutch and oil pump drive

Before disassembling the clutch, you need to remove the driven sprocket. For this purpose, carefully remove the lock washer from the grooves on the shaft and remove the sprocket and needle bearing.

With the tallest head at 19, you need to unscrew the clutch. It has a left-hand thread, so it unscrews towards the bar, and not towards the rear of the Shtil 180 saw.

Having unscrewed and removed the clutch, you need to immediately remove the reflecting plate and the oil pump drive; this is easy to do, since they are mounted on the shaft without any fastening.

Currently reading: Chainsaw Hooter BS 52 characteristics

Tags: chainsaw repair calm

Comments 40

Yesterday, for some reason, the crankshaft bearings jammed during startup. I sorted out the dirt there and washed and lubricated everything. everything started spinning. assembled in reverse order. The saw does not start, there is a spark, there is gas. there is a current one BUT. assembled using transparent silicone sealant. I assembled it and after an hour I started trying to start it. is silent. and also poured zero under the candle. Maybe it won't start because the sealing is bad? The new saw was used 5 times in total.

dirt in the bearing means dirt in the gasoline! I don’t even know, try a different sealant. But that’s probably not the reason!

in the first part in the photo you can see a bottle with 80% oil that they are scorched because of this and are scuffed

How did you determine that it was scorched?

Container color print quality. Well, a great video right away.

Well, you are an “expert”! 1) The label is not really visible in the photo, but you saw the quality of the print and identified a fake, or rather, YOU SAW IMMEDIATELY) 2) The color of the bottle can distort the camera in any way, depending on the white balance settings and the sensitivity of the camera itself. 3) The oil was not bought on the market, but from an OFFICIAL STIHL DEALER along with the saw!

They even repair chainsaws here))). And they say it’s a car site. I also have a calm, 290 ms, and I took apart the current oil hose and changed it

Nice chainsaw. It has been working for me since 2008 and there are no problems. I cut about 12 cubic meters a year to heat my house.

This is what it looks like, more or less, it’s just a mini bikini

The best household models

Manufacturer Shtil is distinguished by a good set of even the most inexpensive products. The gasoline engine of any model is reliable and has sufficient volume for the declared power. The components have proven themselves well on the global market:

- Patented chain mechanism. The quick chain tension system allows you to tighten the chain with one hand.

- The manual fuel pump makes it easy to start the saw even after a long period of inactivity. One click and you can start cutting.

- Anti-vibration system. It's no secret that resonance can cause a number of health problems. The company took care of its users. Chainsaws are assembled in such a way that they are able to dampen harmful vibrations.

- QuickStop - Instant chain brake stops the saw if the front palm rest is touched or there is a sudden kickback.

All this makes the STIHL brand the most popular and best-selling product since 1971.

MS 250 C-BE

Suitable for long term use. There is an ErgoStart starting device. The weight of the chainsaw without a chain is quite small (only 4.9 kg), and its performance is as much as 3.1 hp. This is enough for comfortable work with trees up to 30cm in girth. Characteristics:

- vibration – 5.2/7.2 m/s2 left and right, respectively;

- specific gravity – 2.2 kg/kW;

- tire – 40 cm long.

MS 230 C-BE

The gasoline engine is less powerful (2 kW) than that of the ms 250. Therefore, the unit sounds quieter. The optimal thickness of wood for cutting is up to 30 cm. Technical data:

- vibration left/right – 5.2/7.2 m/s2;

- specific gravity – 2.5 kg/kW;

- tire length – 40 cm.

The saw is good for home use: splitting firewood, trimming trees, removing unnecessary wooden buildings and adjusting beams of different lengths to a single value.

MS 211 C-BE

A medium-power unit with a sufficient engine capacity will help with daily chores around the house. Reviews talk about convenience and ease of use. The advantages are undoubted:

- extremely low vibration level;

- reduced fuel consumption – savings of 20%;

- The two-stroke air filter reduces the harmfulness of exhaust gases by 70%.

Specifications:

- power – 1.7 kW;

- vibration level left/right – 3.5/3.5;

- specific gravity – 2.7 kg/kW.

MS 193 CE

Perhaps the lightest chainsaw. The small engine volume helps to produce firewood comfortably and solve other household tasks with ease. Specifications:

- power – 1.3 kW;

- weight – 3.5 kg;

- tire length – 35 cm.

- fuel tank volume – 270 ml.

Lightness in the hand has an undeniable advantage, so the price of MS 193 CE is slightly higher than its analogues.

MS 181 C-BE

Like the MS 211 C-BE, this saw has low vibration and noise levels. A good engine saves a lot of fuel and is good for the environment. Technical data:

- weight – 4.6 kg;

- power – 1.5 kW;

- tire length – 35 cm;

- Fuel tank capacity – 270 ml.

Starting ErgoStart starts the engine easily and comfortably even after a long period of inactivity (for example, after winter). Branded equipment makes it possible to effortlessly manage household and garden work.

Why does the chain fly off and break?

If the chain falls off the chainsaw or it breaks, this means that there is some kind of problem with the device; under normal conditions it should not do this. There are three reasons why a chain falls off:

- Tire problems. They lead to loosening of the tension, which can lead to the chain breaking. Most often, this problem occurs in the groove between the outer plate on the chain set housing and the inner plate on the motor housing. The casing with the tire is secured with a bolt, which can become loose during operation of the chainsaw, as a result of which the tire begins to move or vibrate. To solve this problem, you need to find and lower the chain brake, for which you need to turn the tension screw, which is located next to the tire, until it is fully tensioned.

- The chain has stretched. Sagging may indicate a malfunction of the chainsaw mechanism. During operation, the metal is deformed, which means it can become 0.5-1 cm longer. In this case, it is recommended to replace or shorten the chain.

- The drive sprocket is poorly secured. To secure it, you need to remove the engine protective cover and spark plugs, and then pull out the air filter. The spark plug itself also needs to be unscrewed, after which a special stopper is installed in its place to secure the piston. Turn the fastening disk clockwise until the piston stops in the uppermost position. A thick rope folded several times can act as a stopper. After fixing the piston, clamp the drive sprocket. Reassemble the chainsaw, installing all parts in the reverse order.

Read also: Finding hidden wiring and communications

Most problems can be solved by repair. Only in exceptional cases will it be necessary to change it.

Carburetor, muffler and ignition coil

To remove the carburetor, you need to have an 8 socket and an extension, which can be used to comfortably unscrew the carburetor and air filter mounting nuts. While dismantling the carburetor, you need to disconnect the ignition wire and the choke rod from the engine control lever and remove the lever, only after which the air filter and carburetor are removed.

The Shtil 180 muffler is secured with 2 nuts, after unscrewing them you need to pull it towards yourself, it will simply be removed.

The coil is secured with two screws; to remove it you just need to unscrew them.

Supplying Oil to the Chain of Shtil 180 Chainsaw

Construction and Dacha in clear language

Repairing the oil supply of chainsaw Shtil 180

Every year, technology becomes more advanced, which significantly simplifies the work of modern workers. New and improved models are constantly appearing on the market. Why is the spark plug in the chainsaw flooded? For the latest disassembly of the chainsaw, Calm 180. But any tool requires proper care. Chainsaw Shtil 180 is no exception. In this article we will talk about how to properly repair this tool.

Chainsaw repair Shtil 180

In order to carry out repairs correctly, you need to understand the internal mechanism. This rule applies to any instrument. Let's look at more popular difficulties that may arise when working with a chainsaw.

1.Owners often encounter oil leaks, which usually lubricates the chain. It is necessary to remove the flywheel of the chainsaw Shtil 180 carburetor from the chainsaw. This may be a consequence of poor tightness at the connection points between the hose from the oil tank and the pump.

To remove this problem, the tool should be completely disassembled. Then you need to check the connections and, if necessary, replace the hose with a high-quality analogue.

If you cannot purchase a new hose, you should remove the old one and degrease the landing site and the hose itself. Then you need to install self-tightening clamps, which firmly ensure the tightness of the connections. This approach will solve this problem.

In addition, it is recommended to check and clean the oil filter.

Shtil 180 oil supply repair

Stil 180 oil supply repair should be carried out if you see that your chain is dry. Carefully inspect the channels through which the oil is supplied and clean them thoroughly. Clogging of channels occurs quite often.

Diagnostics of the chain lubrication system of the Stihl MS180 chainsaw

Self-repair of stihl ms

180

.

chain

is not lubricated . Dismantling chainsaw calm 180 part 1 vasiliy. Disassembling the Shtil 180 chainsaw part 3. Finding and eliminating the cause of the problem

For better clarity, we recommend that you watch the Shtil 180 oil supply repair video.

Shtil 180 oil supply repair video user manual for STIHL MS180 chainsaw

2. If the saw does not start, you should conduct a thorough diagnosis of the tool. First you need to check the air filter and the performance of the spark plug. To do this, unscrew it and dry it.

If a fuel mixture is detected on the spark plug, it means there is an excess of fuel. Chain (14″; 1.3 mm for saws stihl 180 14 rezer ps-9-1,3-50 low price, chainsaws (536. The reason may be a poorly adjusted carburetor or a violation of the starting rules. See if the access through which gasoline is supplied is open .

To do this, open and close the gas tank cap. It is also necessary to check the combustion chamber. After the work done, check the serviceability of the spark plug and change it if necessary.

3. Description of common malfunctions of the Shtil 180 chainsaw and methods for eliminating them. The cause of the breakdown may be a clogged breather. Here I tell and show the proportion of mixing oil and gasoline for the Shtil MS 180 chainsaw. I not only tell you, but also show you. Thus, during operation, a vacuum is formed in the fuel tank, which affects the fuel supply. This may occur due to an unadjusted carburetor, a clogged carburetor, or a clogged air filter.

To correct the problem, you should repair the valve, which equalizes the pressure when fuel is supplied. To do this, the breather should be carefully cleaned with a needle.

To adjust the carburetor, you need to use three screws - the highest and lowest speeds. The adjustment should be carried out strictly according to the instructions for repairing the chainsaw.

Carburetor repair Shtil 180

Carburetor Shtil 180, we will look at its repair in more detail. To do this, you should clean the filter mesh and channels, and also check the integrity of the membrane.

Remember that the carburetor is a very complex device, since it consists of many small parts, so cleaning and disassembling it should be approached very responsibly.

If you want your saw to work properly, you should regularly care for it. Do not forget to regularly clean the air filter and lubricate the tool chain only with clean oil. When storing the tool for a long time, be sure to remove gasoline and chain oil from it. Then the saw will serve you for a very long time.

Features of fuel selection

A special feature of a two-stroke carburetor engine is the absence of a lubrication system for moving elements. Its role is played by fuel: a mixture of gasoline and oil. Therefore, if you use pure gasoline, the chainsaw will fail.

The operating manuals for Shtil units prescribe the use of gasoline with an octane rating of at least 90. In Russian conditions, the best solution is the AI-92 brand. Using high performance fuel is risky. Often high-octane gasoline is obtained by adding additives that lead to engine malfunctions of the saw. Gasoline with an ethanol content of more than 10% is also excluded.

To obtain a fuel mixture, gasoline is mixed with oil in a ratio of 1 to 50: for 1 liter of gasoline, 20 ml of oil.

Recommendations:

- Use a clean container for cooking;

- Use the finished mixture within a month;

- do not expose the finished mixture to low and high temperatures;

- Avoid exposure to direct sunlight when stored in transparent containers;

- Shake the mixture thoroughly before filling.

Troubleshooting Chain Service Issues

During the operation of the chainsaw, you need to constantly monitor the lubrication of the chain. Because this part works in the most demanding conditions. The chain is constantly overheated, dust and abrasive particles become clogged there. All of the above negatively affects its service life. A special lubricant can correct the situation. It is supplied to the chain from the tank, thereby ensuring unhindered operation.

If lubrication does not occur during operation, there is a high risk of overheating. When the oil

does not arrive, the chain begins to stretch. At the same time, the possibility of its jamming or spontaneous jumping off remains, under the influence of which a person can receive severe injury.

The channels through which fuel is supplied can sometimes become clogged with small particles, so it is advisable to clean them from time to time. It is also important to monitor the oil level in the tank. Debris in the channel often causes the chain brake to fail. This can have a negative impact on the workplace.

Regular cleaning of the channels and general care of the chainsaw will allow the tool to work for a long time.

But what should we do if our client remains following the advice, but the oil flows indifferently? You need to make sure the chainsaw is working properly. It is entirely possible that it was assembled incorrectly. If the breakdown has not been identified, it is recommended to take it to a workshop. Sometimes you need to change the pump, but this must be done in this case if the saw is new. Old tools leak due to worn out tank.

Only specialists can assess the current condition of the chainsaw. If you lack knowledge or, in other words, lack confidence in your own abilities, it is better to entrust instrument repair to a specialist.

Chainsaw Husqvarna 142 - a branded tool of an economical group

Husqvarna brand chainsaw products are among the top three most popular models in Europe and the CIS countries. The Husqvarna 142 chainsaw is considered in the category of household tools, but due to its features it can be used for many semi-professional jobs.

The design of the product is developed on the basis of traditional assembly using modern machine-building and assembly technologies. When developing the model project, emphasis was placed on increasing the comfort of work, extending the life of critical parts and assemblies, and the safety of performing complex types of work.

Photo: Husqvarna 142 chainsaw

Description and purpose of the saw

The creation of German engineers - the Stihl 180 chainsaw, was developed specifically for performing light tasks in garden plots, alas, practice shows that its use is also well suited for solving more complex tasks.

For example, the saw can easily cut ten cubic meters of wood into logs, and at the same time it will consume much less fuel than is needed for the more massive models of Shtil chainsaws. Stihl 180 chainsaws are equipped with tires of different sizes. In the configuration, the standard is equipped with a 14-inch long tire, but if desired, a 16-inch tire can be installed. This increases the speed of work, alas, it can affect how long the tool will not require engine repair, due to the increased load there.

The chainsaw engine is two-stroke, single-cylinder and uses a mixture of gasoline and oil to perform work. The consistency proportion is 1:50, i.e. for making 5 liters. The finished consistency will require only 100 ml of oil.

The body of the Shtil 180 chainsaw is made of impact-resistant plastic and does not even have iron parts, which allowed the manufacturer to significantly reduce weight compared to similar saws from other brands.

STIHL MS 180 oil supply repair

Owners of this model of tool should be prepared for the fact that they may encounter such an unpleasant moment as a leak of oil to lubricate the chain. Oil can leak out while working with the tool and even when it is just lying idle.

What is the reason for this phenomenon? The fact is that oil leaks due to leaks in the area where the hose from the oil tank and the pump connects.

Interesting! Another article about oil supply repair is here!

In order to solve the STIHL MS 180 problem associated with the oil supply, it is advisable to disassemble the device.

Solution to the problem:

- Check the hose, if it is damaged, replace it with another one. Or try degreasing the hose, rinsing it, and putting it on sealant, it should work.

- Check the filter oil for damage, clean it (if you filled in waste oil)

- It may also be due to a clogged priming, which creates a vacuum in the fuel tank and affects the fuel supply. The problem may be in the adjustment of the carburetor and the channels, or the air filter, may be clogged; you need to thoroughly clean the filter and carburetor channels.

In general, the main problem is due to bad oil.

It is not recommended to pour oil into a chainsaw that is not intended!

What kind of oil to fill for the Stihl 180 chainsaw (stihl 180)

- Don't spare money on original oil. Stihl HP 2-stroke oil costs a little more, but cleaning costs even more.

- You need to pour high-quality fuel into the fuel, you can use Mobil 1, and three-phase is suitable for lubrication; under no circumstances should you pour waste oil into it.

- Of the inexpensive options, mineral oil is 15-40, in winter 10-30. You can use M8, for example, or M10.

Remember personal safety when working with a chainsaw.

Remember that the performance of the chainsaw is affected by the quality of the oil being poured. Poor quality oil can cause the tool to operate ineffectively and adversely affect its parts.

To ensure that the STIHL MS 180 oil pump delivers oil without difficulty, check and clean the pump periodically. Thus, the oil supply process will be normal.

Carburetor STIHL MS-180

The STIHL MS-180 carburetor is equipped with one idle speed adjustment screw. The full load jet is not adjustable, meaning it cannot be changed.

You need to know the basic rules for setting the idle speed:

1) check the air filter, if necessary, change it;

2) check the spark-proof grille, if necessary, change or clean it. You can then turn on the engine and then warm it up.

STIHL MS 180 carburetor repair

Repairing a STIHL MS 180 carburetor is a very difficult process. Note that during repairs there is practically no risk of sudden changes in the cylinder-piston group.

If the chainsaw does not start, then follow these steps:

1) open and close the gas tank cap;

2) it is advisable to remove the candle and then dry it;

3) ventilate the combustion chamber.

If after this there are no positive results, then it is better to check the condition of the air filter, the gasoline supply process and the functioning of the spark plug.

This problem is associated with a valve (slepun), which becomes clogged, and as a result a vacuum is formed. To eliminate this inconvenience, you need to clean the valve (slepun) with a needle.

Systematically check the filter; if the muffler is clogged, the device will not be able to deliver the power that is put into it.

If the chainsaw was purchased with a warranty (as a rule, there is no other option), immediately take it to the service center.

Thus, the STIHL MS 180 chainsaw is very easy to use, has good ergonomics and a number of significant advantages.

Removing the handle

Specific disassembly of the Shtil 180 begins with removing the handle, which is attached to the chainsaw body using 3 rubber shock absorbers. To remove, you need to remove the plastic plugs from the internal cavity of the shock absorbers, then using a strong screwdriver, first squeeze out the upper shock absorber, then the one closest to the rear handle.

At the back of the handle there is a throttle trigger, which is connected to the carburetor through a wire rod. If you set a goal to disconnect the rod from the throttle trigger, you need to unscrew two screws and disassemble the handle.

When the handle remains on one shock absorber, you need to unscrew the chainsaw body from the inside of the handle and, bending it to the side, remove the body from the last rubber band.

Currently reading: Do-it-yourself trimmer engine repair: electric, gasoline

Lubrication system design

Depending on the brand of chainsaw, the parts of the lubrication system may vary slightly in design, but their total number and connection diagram remain the same.

The main components of the lubrication system are:

- an oil tank located, as a rule, in the engine crankcase.

- The filter element is installed in the tank.

- The oil line is a small diameter hose made of oil-resistant rubber.

- The heart of the system is the oil pump.

- The worm gear transmits force from the engine to the pump.

- The chainsaw tire can also be considered an element of the lubrication system, since it has special holes for supplying oil. By the way, the chain itself is involved in transporting oil and, accordingly, also has some elements designed specifically to provide lubrication.

Modifications

Taking into account the wishes of users, two technically advanced versions were developed on the basis of the main model. The MS 180 C-BE chainsaw is distinguished by the presence of the STIHL ErgoStart easy start system, a device for quick chain tensioning located in the carburetor of the fuel compensator.

The characteristics of multi-channel mixture formation of the engine and vibration damper have been significantly improved, and operator comfort has been increased due to the single-lever control circuit.

Another version of the Stihl MS 180 Picco takes advantage of the operational benefits of an automated lubrication system. This model is equipped with only 14 inch tires and saw chains with 50 links.

Basic malfunctions and repairs of the chain lubrication system

Let's look at common malfunctions and repairs of the chain lubrication system of modern chainsaws.

If the chain is not lubricated

The tank is full, but the oil does not flow to the chainsaw chain. There could be several sources of the problem here.

Oil pump drive failure. Quite a common malfunction. On Stihl chainsaws, it is common to cut off the flange of the plastic drive gear. Or the splines are worn out. The gear does not rotate at all or rotates but does not engage the pump drive. Clogged lines. Observed when using unsuitable oil, including waste oil. Violation of the tightness of the tank, rubber tube or line connections

In addition to mechanical damage to the integrity of the oil channels (a tube coming off its seat, a crack in the tank or in another part of the line), sometimes the lubricant supply hose is destroyed under the influence of aggressive synthetic oils. Please note So which chainsaw chain oil is best? In this case, the answer is clear: the best solution would be to purchase lubricants from the equipment manufacturer.

Incorrect adjustment of the lubricant supply to the chain. With unqualified intervention, you can completely shut off the supply of lubricant to the chain using the adjusting screw.

Oil pump

Pump failure

This problem occurs extremely rarely and mainly on cheap saws from little-known Chinese manufacturers. For example, on Stihl chainsaws the oil pump has such a service life that, according to statistics, there are practically no cases of its replacement due to breakdown. Most often, the pump is simply cleaned of contaminants by regular blowing.

Uneven supply of lubricant

The chain receives too much or too little lubricant. When oil does not flow to the chain or is poured too much, it causes discomfort during operation and can damage the saw. This problem is a little less common, but also quite widespread. There may be several reasons.

Leaking lubrication system pipe

- Incorrect adjustment. It is better not to touch the oil supply adjustment screw on some saws without understanding the adjustment process.

- Use of lubricants of unsuitable viscosity. The pump pumps lubricants that are too thick less readily, and they are less easily distributed by the chain along the tire. With liquid oils the opposite is true.

- Reduced tightness in the chain lubrication system. Sometimes the oil supply tube to the pump comes off or is damaged. This causes oil starvation. A similar problem manifests itself in lubricant leaks at the bottom of the chainsaw.

Why doesn't the Stihl saw start?

The principle of starting the unit consists of a chain of interconnected processes. If one link in the chain fails or is missing, this not only negatively affects the operation of the equipment, but can also lead to its breakdown or problems starting the device.

Operation of the tool involves the following steps:

- Supply of compressed fuel mixture. It is needed for the engine to operate;

- Spark supply. Necessary for ignition;

- The launch and operation of the device is a consequence of previous processes.

If, despite the procedure described in the instructions, the unit does not start, it means that one of the processes has been disrupted in one of the chain links.

Reasons why a chainsaw may not start:

- Malfunctions associated with the fuel system: low fuel quality, lack of fuel mixture supply.

- Clogged main filter elements. A dirty gas filter prevents the supply of fuel to the carburetor of an internal combustion engine, which immediately negatively affects the operation of the equipment. A clogged air filter, in turn, cannot provide a full supply of air, without which the engine cannot be started.

- No spark. The reason for this may be a poor quality or damaged spark plug.

- Engine overheating.

Monitor the quality and correct proportions of the fuel mixture. The presence of water or large amounts of oil in the fuel can cause malfunction or problems starting garden tools. The optimal shelf life of the gasoline-oil mixture is 1 month, after which coking resinous deposits form in it, which negatively affect engine performance.

If the saw does not start when you first try to start it, you can first stop it for 10 minutes, then try to start the unit again. If trying again does not work, you will have to look under the body of the garden machine: check the condition of the filters, inspect the carburetor and spark plug. You should try to clean dirty filters, rinse them in soapy water, and then dry them. Running filters will have to be replaced. If the spark plug is wet and does not produce a spark, you can try to dry it, but it is advisable to replace it too.

What oil should I use?

It is widely believed that high-quality branded chain saw oil should only be used in the gasoline-oil mixture of the engine. Nevertheless, choosing a lubricating oil is not a difficult matter. Anything will do, as long as it goes where it needs to go.

But applying lube to the chain is half the battle. It needs to stay on the metal and remain on the lower edge, which is used to saw the wood. For this purpose, substances with increased adhesion are used, that is, the ability to stick to a surface and stay on it. Oil with weak adhesion will fly off the rapidly rotating chain, splashing everything around to no avail. Of course, some part will remain, but it is unknown whether this will be enough to prevent the circuit from overheating during intensive work.

Important! When using a chainsaw all-season, you need to take into account the dependence of the oil supply conditions on the time of year and air temperature.

Mineral materials that provide chain and bar lubrication at above-zero temperatures crystallize and thicken in the cold. This leads to the fact that lubricant will be supplied with difficulty and the load on the oil pump will increase. Its service life is reduced and it may fail prematurely. In winter, you need to choose synthetic materials with special additives that provide reliable lubrication in frosts down to -40 ℃. In mild frosts and temperatures around zero, semi-synthetics are used.

Estimates of the use of different oils for lubricating chainsaws boil down to the fact that the wrong choice can increase the load on the engine by up to 10%. The service life of the chain and saw bar itself is further reduced.

Due to the recent emphasis on the environment, branded oil products are increasingly being made from biodegradable substances. But during long-term operation, the consumption of chain lube can be measured in liters. And for people who care about nature, this will be another reason to choose an environmentally friendly product. If you care what your area is splashed with and what marks remain on the wood after cutting.

Product manufacturer STIHL

The history of the STIHL brand dates back to 1926, when Andreas Stihl founded. Initially, the company specialized in creating working boilers and the first “washing machines”, and later, with the money earned, the first model of a chainsaw was created. This unit, despite its enormous weight (48 kg), quickly conquered the market and began to be sold very successfully to countries near and far abroad.

The 90s marked the beginning of a family business for the company. Almost all members of the Stihl family began to take part in the life of the company.

In 1995, the AG&Co Holding was created , the main base of which was in Waiblingen and Diesburg.

Manufacturing company STIHL

Since 2002, a complete stranger has become the head of the board of directors of STIHL AG. At that time, boss Hans Peter Stihl headed the company's supervisory board and took over the chairmanship of the commission of STIHL Holding AG&Co.

After another 2 years, the company’s modern development center opened, and already in 2006, a new assembly plant started in China.

Today, the company is successfully developing , introducing new ideas and even more practical approaches. STIHL's inventions top the chainsaw ratings in terms of reliability.

How to replace expensive oil

The disadvantage of special branded chain lubricants is their high price. Buying a liter of another expensive oil is not burdensome. And if there is work to be done that requires several liters, or even tens of liters, thoughts about saving will probably arise. The main thing is not to go to extremes when considering options. You can save on oil to such an extent that you will have to change the chain several times, or even the tire itself or the oil pump.

There are three replacement options. Firstly, you can use specialized products from little-known manufacturers to lubricate the chain. But we still need to look for such oils. In addition, there is a risk of stumbling upon a low-quality product.

Application of oils for automobile engines. They can be used as a temporary replacement, but they cannot boast of high adhesion, so the quality of their work will be clearly worse than special ones. For this reason, it is not recommended to use spindle and diesel oils - the worst in terms of adhesion.

And we definitely need to talk about one more option - working out. This is the name of oil that has spent its life in the engine and is drained from it when replaced.

In fact, this is not an option at all. Metal particles are always present in the waste. And if they may not damage the chain itself, then they certainly will not damage the oil pump and the entire lubrication system. On forums on the Internet you can find a “killer” argument in favor of testing - that the Soviet chainsaw “Druzhba” did not have chain lubrication at all and worked. So you can pour whatever you want - and it will do. Well, “Shtil” will also work with a working off or even with a non-lubricated chain. The question is how long it will work and how many chains will have to be replaced during this period.

A warning to those whose chainsaw is under warranty. Warranty workshop technicians are able to identify cases of poor-quality chain lubrication. Especially when using mining. Repairs under warranty will be rejected immediately.

Tips for choosing a device

The chainsaw you purchase must fully comply with the tasks being solved and the conditions of use. Advice to the buyer is extremely simple:

- The required model is selected from products of the appropriate class: household - for gardens and farmsteads, semi-professional - for intensive work, professional - exclusively for logging and industrial wood processing;

- The length of the bar must exceed the maximum thickness of the material being cut;

- If you need to work in an open area in winter, you will need a saw with a heated carburetor and handle;

- The tool should be comfortable for you and not overweight;

- STIHL chainsaws are not cheap. Beware of fakes. Find out in advance how to distinguish a real STIHL chainsaw from a crude Chinese imitation. It is better to make such a purchase in a specialized store.

Watch a video on how to distinguish a copy of the STIHL 180 from the original