The design of a chainsaw carburetor is simple and accessible

As with other chainsaw components, before repairing the carburetor, you should study its design in detail. This will help determine the true breakdown and quickly fix it. The design of a chainsaw carburetor consists of the following elements:

- Tube - equipped with a transverse damper that regulates the entry of air into the system;

- Diffuser – located next to the fuel inlet. As the diffuser narrows, the air flow rate into the system increases;

- Fuel needle - serves to distribute fuel;

- Float chamber - regulates the fuel level at the point of entry into the channel.

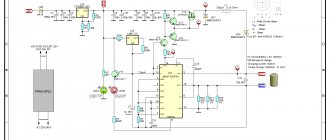

To better understand the design of the unit, you will need a diagram of a chainsaw carburetor. It clearly demonstrates the location and method of connecting the main elements of the unit.

The operating principle of a chainsaw carburetor is quite simple. The needle sprays fuel into the float chamber, after which the fuel is mixed with air. Next, the finished mixture enters the engine cylinder. The more fuel supplied to the engine, the higher the engine speed.

Regardless of the manufacturer and model of the chainsaw, each of the modern tools is equipped with carburetors that have an almost identical design and operate on the same principle. The main differences lie in the materials of the spare parts and their location in the carburetor structure.

Chainsaw engine malfunctions

The engine is the main component of the chainsaw, and most of the breakdowns that occur in it are associated with the gasoline drive. Correct diagnostics can determine the causes and troubleshooting methods even for an untrained user.

The main problems with starting the engine may be the following:

- the engine does not start;

- works unsteadily;

- startup occurs, after which the unit immediately stalls;

- stalls under load.

Ignition system malfunctions

First of all, the reason that the chainsaw does not start must be looked for in the ignition system of the unit. You need to start by checking the spark plug, since there is a possibility that the spark has disappeared.

By the state of the unscrewed spark plug, you can determine how the fuel system works. The spark plug is unscrewed with a special key.

The following figure shows 3 possible spark plug conditions.

A spark plug splashed with fuel indicates an excess of fuel in the cylinder. If the spark plug is flooded, then most likely the carburetor is incorrectly adjusted, or the rules for starting the engine were violated. The candle must be thoroughly wiped and dried. You should also drain the combustion chamber:

- shut off the fuel supply;

- With the spark plug unscrewed, pull the starter several times to remove all gasoline from the cylinder:

- Reinstall the spark plug and adjust the carburetor according to the instructions.

A large amount of soot on the spark plug is caused by an incorrect ratio between oil and gasoline during preparation of the fuel mixture, as well as problems in the fuel supply system. If the mixture is prepared correctly, using high-quality oil, then the carburetor should be adjusted. A spark plug with carbon must be cleaned by rinsing it in gasoline. After that, you need to wipe it dry, remove any remaining burnt residue with a needle, and clean the electrodes with fine sandpaper.

If the spark plug is dry, you need to check for a spark at its electrodes to rule out a malfunction of the ignition system.

- Place the cap with the high-voltage cable on the spark plug.

- Holding the cap, attach the spark plug threads to the cylinder.

- Pull the starter handle several times and see if a spark jumps between the electrodes. Normally, the spark should be bright. A weak spark indicates a possible problem with the ignition coil or the spark plug itself.

If there is a spark, then the problem needs to be looked for in the fuel system. There is no spark - the reason may lie in the spark plug itself (needs to be replaced) or the ignition system. The absence of a spark may cause a damaged cable, which should be checked by “ringing” the tester. If the wire is in good condition, you need to move on - check the ignition module. A malfunction of the ignition coil or an incorrectly set gap between it and the magnet can also cause the spark to disappear.

Adjusting a chainsaw carburetor - when is the procedure required?

- The engine does not start at all, or stalls immediately after starting - the reason for this may be a shortage of fuel coupled with an excess of air;

- Increased fuel consumption - in this case, the amount of exhaust gases rapidly increases. The reason for this situation should be sought in an increase in the amount of fuel and a decrease in the amount of air;

There are also a number of mechanical reasons that lead to the need to adjust the carburetor. These include:

- Strong vibration - it leads to damage to the protective cap, resulting in loss of fixation of all three adjusting screws;

- Wear of the piston part of the engine - in such a situation, adjusting the carburetor will only temporarily prolong the operation of the tool. To completely eliminate the problem, you will have to completely replace the piston group;

- The formation of blockages - they appear as a result of the use of low-quality gasoline, damage to the filter or scale. In such cases, it will be necessary to dismantle, disassemble and clean the carburetor.

In any of the above cases, it is better not to delay the procedure for adjusting or flushing the unit. Otherwise, this will lead to damage to other equally important elements of the chainsaw.

How to properly adjust the carburetor on a chainsaw?

Before adjusting the carburetor on your chainsaw, you will need to learn the meaning of the three screws required for adjustment. These screws have certain markings and names:

- Screw “L” is necessary to adjust low speed;

- Screw “H” is required when tuning the motor to operate at high speeds;

- Screw "T" is needed to adjust the idle speed.

It is worth noting that some chainsaws are equipped with only one “T” screw, so the carburetors of such models are adjusted by manipulating only this screw.

No matter how many screws there are on the chainsaw, the factory carburetor settings are the most optimal for its operation. The screws themselves are initially used to configure the chainsaw to work in certain weather conditions.

The carburetors of chainsaws with three screws should be adjusted using screws “L” and “H”. To increase the speed, they should be turned clockwise. In order to lower the speed, the screws turn against it. To adjust the carburetor, you will need a special screwdriver for adjustment - it will not slip off the screws and damage the threads on their “caps”.

The carburetor adjustment process consists of two stages: initial and main. The adjustment algorithm is as follows:

- During the first stage, screws “L” and “H” must be tightened clockwise to the very end;

- After this, these screws need to be turned 1.5 turns in the opposite direction;

- At the second stage, you need to start the chainsaw and leave it for 10 minutes to completely warm up;

- Then start turning the screw “T” until the chainsaw motor starts to run stably and the chain on the bar does not rotate.

Video

You can learn how to set up the saw's carburetor in the video below. In this video, the master shows how to step-by-step adjust a Chinese-made chainsaw without using a tachometer. Conducts post-adjustment checks in various modes.

- Do-It-Yourself Chainsaw Carburetor Adjustment Caliber

Adjusting a chainsaw carburetor, although it looks like a fairly simple process, requires a very careful and responsible approach. The article describes the process in sufficient detail, but if you have never adjusted a chainsaw, you should turn to specialists, this will help save time, nerves and money.

HomeTips for buildersAdjusting a chainsaw carburetor. Or how not to pay repairmen!

Owning a chainsaw makes life easier even for an amateur in many ways, and in some professions this tool is actually indispensable. However, like any relatively complex device, a chainsaw requires periodic maintenance. Due to untimely or poor quality maintenance, as well as as a result of exposure to both planned and excessive loads, various types of malfunctions may appear. For professionals, interruptions or unstable operation of the saw reduce work efficiency or can cause a ruined work day. One of the quite common malfunctions is the incorrect setting of the chainsaw carburetor, which gets lost due to unsuccessful attempts at adjustment or displacement of the adjusting screws for other reasons.

How to check a chainsaw carburetor?

After adjustment, you need to check the acceleration, maximum speed and engine idle. While checking the first parameter, you should sharply press the gas trigger. If the motor does not begin to gain speed, then you need to turn screw “L” counterclockwise. In this case, one turn should not exceed 1/8 of the full circle of the screw.

Read also: Jjd 45 2a what is it

To measure the maximum revolutions, you will need to engage the “H” screw. To increase the maximum number of revolutions, the screw is turned clockwise. To reduce the indicator, the screw must be turned in the opposite direction. It should be remembered that the maximum speed should not exceed 15 thousand.

For a final check of the chainsaw while idling, you need to start the tool and place it on a level place. Let the engine warm up and pay attention to the following elements of the chainsaw:

- The chain should not move;

- Engine - when you press the gas trigger, it should confidently gain speed until the set maximum limit is reached.

An important tip is that if the carburetor is configured correctly, the sound of the chainsaw engine will closely resemble the sound of a 4-stroke engine.

The carburetor of a Chinese chainsaw is adjusted and checked in a similar manner. The only difference is that the process of setting up such tools can take much longer - on average, about an hour. In addition, it should be remembered that adjustment of Chinese chainsaws is required much more often - it often needs to be done immediately after running in a new tool.

Fuel supply

In addition to the above-mentioned clogged breather, other problems may arise during the fuel supply. The main obstacles may be:

Clogged fuel filter. To check the device for this malfunction, you need to disconnect the fuel hose and see how the fuel flows. If the flow is weak, the filter may need to be cleaned. The filter device is removed through the filler hole of the tank and cleaned; if the contamination is too strong, it is replaced.

Professionals recommend changing the filter every few months, regardless of contamination.

Lack of fuel. In this case, the problem may lie in several factors. The first is a dirty air filter. The problem is that enough air is not delivered to the carburetor, causing the engine to run poorly. The filter must be removed, cleaned, washed and dried, and then put back.

How to remove a carburetor from a chainsaw?

Before cleaning the carburetor or repairing it, this element of the chainsaw will need to be dismantled and disconnected from other components. To do this, you must follow a certain procedure. The dismantling algorithm looks like this:

- First, remove the top cover by unscrewing the 3 bolts around its perimeter;

- Remove the filter shaped like a foam pad;

- Disconnect the fuel supply hose;

- Remove the drive rod;

- Disconnect the cable end;

- Carefully remove and completely pull out the fuel supply hose.

Try to perform each action as carefully as possible. Otherwise, there will be a risk of damage to important elements of the chainsaw.

How to clean the carburetor on a chainsaw?

It is necessary to flush the carburetor of a chainsaw in cases where low-quality fuel is used to refuel the tool, or the tool is used at extremely low temperatures. During the work, you need to try not to damage or lose small parts of the assembly. Cleaning the carburetor is performed in the following order:

- Remove the screws holding the carburetor body;

- Open the lid, remove the small parts of the assembly and place them on a towel;

- Carefully treat the walls of the case and all existing parts with compressed air from a can;

- If carbon deposits remain on the parts, wipe them with a rag moistened with a degreaser;

- Dry the body and parts;

- Assemble and install the carburetor on the chainsaw.

The internal combustion engine of a chainsaw requires special attention due to harsh operating conditions, and this is especially true for the carburetor. Without periodic maintenance, no motor system will last long. Today we will talk about the process of adjusting and eliminating various malfunctions.

Partner 351: owner reviews

Petya : I’m just mastering the Partner 351 chainsaw, I was pleased that the price is quite affordable and the manufacturer is Sweden. After a couple of days of work, I didn’t see any complaints, it started the first time, and it doesn’t let me down in the cold either. But it’s better to warm it up for at least half a minute or a minute. I plan to work with model 351 on a construction site, they say it is excellent for these purposes.

Pavel : I have been using a chainsaw since 2013, when I bought it, I was confident in the tool. It worked stably for the first year or two, then apparently parts began to wear out and some problems began. I immediately adjusted the carburetor, then changed some spare parts during the work process. More than suitable for its price, the characteristics are fully confirmed.

Sergey : I’ve been working with a chainsaw for 4 years, of course not Husqvarna or Shtil, but the device is worthy of attention. Ideal for construction, cutting wood or gardening, it is quiet and fits compactly in the hand. I don’t like that the engine is sensitive to fuel; if it’s a little worse than usual, starting will be a problem. But again, take care of the instrument and there will be appropriate returns.

Video

Chainsaw carburetor design

To independently adjust the carburetor of a chainsaw, you do not need to be a professional motor technician. However, you will still have to memorize some aspects of the carburetor’s operation regarding the process of preparing the fuel mixture.

The vast majority of chainsaws are equipped with Chinese-made Walbro carburetors. In their design they are simple, if not primitive. There is a monoblock pass-through type housing with a through hole. Inside the hole there is a diffuser - a narrowing of the passage with a fuel injection channel. There are valves on both sides: the smaller one is the throttle valve; it regulates the amount of fuel mixture supplied to the cylinder. The larger air damper serves to limit air flow during a cold start.

Walbro carburetor design: 1 - fuel inlet fitting; 2 - pulse channel of the membrane pump; 3 — inlet valve; 4 — fuel pump membrane; 5 — exhaust valve; 6 — filter mesh; 7 — air damper; 8 — throttle valve; 9 - fuel channel; 10 — idle speed adjustment screw; 11 - needle; 12 — idle jets; 13 - control membrane; 14 - fuel chamber; 15 - main jet; 16 — diffuser; 17 - main adjusting screw

All the magic of fuel preparation happens in the hidden channels and chamber of the diaphragm pump. When you turn the throttle valve, the cross-section of the channel through which fuel is injected into the mixing chamber increases slightly and fuel enters in a larger volume. In this case, the carburetor has two kinds of valves: for supply at low and high speeds. When changing the throttle position, the fuel flow changes proportionally between these two valves.

The need for such a device is that the quality of the mixture should be different at idle and under load. At the same time, the channel through which fuel is supplied to the mixer at idle does not close completely when the engine accelerates, and vice versa - the maximum speed channel is slightly undercut at idle.

Tools

To adjust, you will need the following tools: tachometer, screwdrivers, and in rare cases, special keys. Let's look at their purpose, necessity of availability and cost.

| Tool | Purpose | Price | Availability |

| Tachometer | Allows you to accurately determine engine speed and adjust them according to the requirements of the manufacturer. You can do without it by tuning by ear, but you need to understand that the tuning will not be done accurately. | 900 – 2000 rubles | Recommended |

| Screwdriver set (slotted screwdriver) | On most chainsaws, you will need a simple flathead screwdriver to turn the adjustment bolts. | 300 – 700 rubles | Necessarily |

| Special adjustment key | For example, to adjust the carburetor on Husqvarna chainsaws, you will need a special key; it is available only in certified service centers authorized for repairs by the manufacturer. This measure is aimed at reducing breakdowns due to incorrect settings by inexperienced users and those who carry out repairs without official permission to do so. | Out of stock | Depends on the chainsaw |

If possible, setting up a chainsaw should be carried out in official service centers that have a manufacturer’s certificate and appropriate permission to carry out repair work.

Is disassembly necessary?

You can adjust the carburetor of a chainsaw without any disassembly at all; in rare exceptions, you only have to remove the air filter cover. There is a considerable amount of contradiction here: on the one hand, the chainsaw is designed for unhindered access to the adjustment mechanism, on the other hand, it is recommended to access it as little as possible.

Read also: Designation of the limit switch on the diagram

True, experienced fellers and sawers always carry a flat-head screwdriver with a long blade and periodically adjust the carburetor. This is explained simply: during the manufacture of a chainsaw, its carburetor undergoes rough adjustments designed for a certain composition of air and fuel. It is clear that the conditions at the work site are different from those on the bench.

When changing the brand of gasoline or, for example, increasing air humidity, an experienced chainsaw user will always adjust the quality of the mixture for greater performance and less wear on the piston part. But this, we repeat, requires considerable experience in working with a specific chainsaw and knowledge of the peculiarities of its behavior. In addition, the adjustment is incredibly fine - the screws are tightened only 1/10. 1/20 turn.

Another reason for adjustment is carburetor repair or replacement. In any case, adjustment of the mixture quality should be carried out only if the serviceability of the carburetor is reliably known (no debris, gaskets are not poisoned), the air filter is clean, the spark plug, clutch and ignition system are in perfect order. Otherwise, there is a high probability that the malfunction will be eliminated in a moment and the adjustment will suddenly become incorrect, and the engine will begin to wear out.

We repair a chainsaw according to the instructions - everything you need to know

A chainsaw is an indispensable and reliable assistant in every household. The ease of use of the tool makes it even more popular, but the occurrence of various types of malfunctions can never be ruled out. If various types of chainsaw malfunctions occur, then to eliminate them you will need to resort to repair measures. You can repair a chainsaw yourself, but first you need to determine the malfunction. The material will discuss not only all kinds of malfunctions, but also the features of their elimination.

Main adjustment screws

There are only three organs for adjusting the carburetor; these are screws shunted by springs for a flat-head screwdriver. There is a pair of screws at the bottom, L on the left, H on the right. A little higher is the T (or S) screw. So here's what they are for:

- Screw L is the same valve that regulates the cross-section of the fuel channel when operating at low speeds.

- Screw H, by analogy with the previous one, is a channel flow regulator for high speeds.

- Screw T is the throttle valve adjuster. It determines its position when the accelerator lever is fully released.

The design of the first two adjusting screws is extremely simple: at their ends there are needles inserted into spools of variable cross-section (cones). All threads are right-handed, so by tightening the screw clockwise, you drive the needle deeper and reduce the flow. When rotating counterclockwise, the exact opposite happens.

In this way, the quality of the mixture is regulated in different operating modes. If the fuel content increases, the gasoline does not have time to burn completely and the engine develops less speed. When the mixture becomes leaner, the speed, on the contrary, increases, and at the same time the engine temperature increases. It is worth noting that even when the screws are tightened all the way, the flow of both channels is not completely blocked, unless there is a blockage.

Regulation rules

The carburetor adjustment diagram and the recommended position of the adjusting screws are indicated in the instructions for each specific tool. When getting acquainted with a new saw, it is recommended to tighten the screws all the way, counting the number of revolutions, so that later you can return the factory settings. The general principles of adjustment are as follows:

- Before making adjustments, the engine must be warmed up at idle speed for 10 minutes.

- By rotating screw L, you need to achieve such a mixture quality that at idle the engine runs evenly at 1500–2000 rpm. In this case, acceleration (acceleration) when pressing the accelerator lever should be fast, but uniform. A dip in the speed increase indicates that the mixture is too lean; the screw must be unscrewed until this phenomenon disappears.

- After adjusting the low speed mixture, screw T is tightened until the chain begins to rotate, and then backed out 1/2. 1/3 turn. Here it is important to monitor the serviceability of the clutch mechanism.

- The H screw is not adjustable in makeshift conditions.

The danger of independently adjusting screw H is that too lean a mixture at high speeds, and especially under load, leads to rapid wear of the piston and failures in the ignition system. You can attempt to adjust high speeds only if three conditions are met:

- The chainsaw obviously does not produce the required power when cutting.

- The person performing the adjustment has general knowledge of carburetor engines.

- A means of measuring engine speed is available.

The latter can be either a tachometer or a multimeter with a built-in oscilloscope. To connect the multimeter, you need to wrap 3-4 turns of thin copper wire around the spark plug wire.

The main task of screw H is to compensate for over- or under-revving due to a change in fuel type, oil concentration or air composition. Also, the “upper” setting can be disrupted by insufficient precision in adjusting the low speed screw. The adjustment scheme is simple - the screw is tightened or unscrewed until the saw engine at maximum gas produces 14.5–15 thousand rpm or the value specified in the operating instructions.

If you use an oscilloscope, its readings (spark discharge frequency) should be in the region of 230–250 Hz. Take into account the accuracy class of the measuring instruments and the fact that under load the speed drops by 10–15%. It is better if the engine runs at low speeds than at high speeds, even if only slightly.

Troubleshooting

As a conclusion, we will describe typical malfunctions associated with incorrect carburetor adjustment and methods for eliminating them:

- The engine does not start or starts and stalls after a few seconds. Obviously, the reason is the incorrect adjustment of the mixture quality at low speeds; it is too lean. If the carburetor is working properly, you need to enrich the mixture a little by unscrewing screw L 1/2 turn, and then complete the adjustment with screw T.

- The engine noticeably loses power under load. In this case, the carburetor produces a mixture that is too rich at high speeds. Screw H needs to be tightened 1/8 of a turn; if the engine load is still not sufficiently supported, but progress is noticeable, tighten it a little more.

- The engine “sings” at maximum acceleration without load. The mixture at high speeds is too lean, the speed is too high.

- The engine stalls if you apply gas after idling. The mixture is too lean or rich, or more precisely, you can tell by the condition of the candle.

Read also: Lm358 connection circuit in the charger

Please note that carburetor settings may be lost due to strong vibration. For this reason, a successfully selected adjustment must be remembered by counting the turns and position of each adjustment screw. If you have determined the best type of gasoline and oil ratio, save a small portion of this mixture so that in case of problems you can check whether the problems are related to the quality of the fuel and incorrect adjustment, or whether the cause is a malfunction of the chainsaw.

Reliable Chinese chainsaw Patriot PT 3816

Let's talk about the Patriot 3816 chainsaw, consider its purpose and characteristics. After reading the article, you will learn how to independently adjust the carburetor and troubleshoot problems that may occur in the chainsaw during operation.

IMPORTANT. An experienced electrician leaked the secret to the network on how to pay half as much for electricity legally. Read more

Repair: description of popular faults and their elimination

The chainsaw engine does not pick up speed and stalls. It is necessary to check the position of the air damper, check whether it fits tightly to the body. Check and clean the air filter if it is clogged.

In some batches of Patriot 3816 chainsaws, the intake hose was incorrectly positioned in the gas tank. Accordingly, when the tank is not full, fuel consumption is observed. During horizontal cuts, the chainsaw refuses to work. You can solve this problem yourself. It is enough to lengthen the fitting in the gas tank and point it in the desired direction. Manufacturers have corrected this deficiency on new models.

If, during long-term operation, you suddenly lose traction at high speeds, and adjusting the carburetor does not help, then you need to replace the CPG (cylinder-piston group).

This is what a failed chainsaw piston looks like

Application of Patriot PT 3816

Patriot PT 3816 is a non-professional chainsaw model and is intended for private use. For example, Patriot 3816 will cope with tasks such as annual collection of firewood in small volumes, trimming tree branches in the garden, and reducing waste. In addition, the saw is used in fence construction to cut wooden posts.

The Patriot 3816 saw cannot be used by deforestation professionals due to resource constraints. The chainsaw parts are made well, but they are not designed to work in harsh conditions for long periods of time. The engine cylinder is entirely aluminum, which means it is resistant to long-term operation and even slight overheating. If the Patriot 3816 installs a chrome plated cylinder, the engine life will increase from time to time.

If you take a close look at the Patriot 3816, you will immediately see its resemblance to typical Chinese chainsaws.

We invite you to watch a video about the Patriot PT 3816 chainsaw, in which the owner shows the equipment and explains the main characteristics.

Patriot chainsaws: model features, technical specifications

The American brand Patriot has become popular far beyond the United States. Since 1973, the company has produced hundreds of models of garden and professional tools. Particularly interesting are her chainsaws.

The products are designed to perform household, semi-professional and professional tasks. The country of manufacture of the saws is the USA, so they are of high quality, have excellent strength and the highest level of safety. All spare parts for tools are freely available, and maintenance and repair of saws can be done with your own hands.

Chainsaw Patriot 4518

The household model is used in the garden, vegetable garden and summer cottages. It is intended for light loads. The saw has a comfortable handle and compact dimensions.

Main characteristics:

- The power of the model is 2100 W;

- saw part size – 4.5 cm;

- lubricant reservoir - 0.26 l;

- fuel tank – 0.55 l;

- weight – 6.5 kg.

The Patriot PT 4518 chainsaw has a large bar that can handle even voluminous wood. The easy control mode will allow beginners to use the saw. Zip-Start technology ensures a smooth and stable launch of the product.

Chainsaw Patriot PT 5220

The Patriot professional saw can work in any conditions. It has a long service life and can withstand heavy loads. The headset of this saw is stable and durable.

Specifications:

- motor power is 2500 W;

- the cutting part has a size of 5 m;

- gasoline tank – 0.55 l;

- lubricant reservoir – 0.26 l;

- weight – 6.5 kg.

The Patriot 5220 chainsaw provides a high level of operator safety. It has an inertial brake, which stops the operation of the product if there is a threat of chain failure. There are rubberized handles, the weight of the model is light. The anti-vibration system ensures comfort in performing tasks.

Chainsaw Patriot 3818

The household model is used for caring for parks, gardens, and hedges. It saws trunks with medium and small diameters, thins bushes, and cuts firewood.

Specifications:

- tool motor power – 1500 W;

- tire size – 4.5 m;

- oil tank – 0.21 l;

- gasoline tank – 0.31 l;

- weight – 5 kg.

The Patriot PT 3818 chainsaw is equipped with a powerful engine, has an anti-vibration operating system and a balanced body. Comfortable handles and low weight reduce the load on the operator's spine and arms. The inertia brake makes working with the product safer.

Chainsaw Patriot PT 4016

Garden model, which is equipped with a primer. It can be used in summer and winter, regardless of external conditions. The tool effectively cuts branches, saws trees and firewood. He does a good job when designing landscape designs.

Specifications:

- saw motor power – 2 l. With;

- tire size is 4 m;

- oil tank – 0.21 l;

- gasoline tank – 0.31 l;

- weight – 4.9 kg.

The Patriot 4016 chainsaw uses gasoline economically and emits a reduced amount of harmful particles into the air. It has a smart design with Easy Start technology for easy starting. Allows easy access to all components of the chainsaw.

Chainsaw Patriot PT 6220

Low power model for home use. It can cut wood of any thickness, trim branches or prepare firewood for the winter. Excellent for working in garden areas.

Main characteristics:

- engine power – 4.35 liters. With;

- tire length is 5 m;

- oil tank – 0.35 l;

- gasoline tank - 0.88 l;

- weight – 7.5 kg.

The Patriot RT 6220 chainsaw is equipped with an anti-vibration system, which makes working with the device more comfortable. The pump automatically pumps fuel, so the saw can be started without the need for heating. There is simplified access to all structural parts of the product.

Chainsaw Patriot PT 554 PRO

The Patriot professional tool has proven itself well in gardens, in private households and in mini-carpentry. Operators will love the simple controls and easy starting system. The product can be used at any time of the year.

Specifications:

- model power 2500 W;

- saw chain size is 5 m;

- fuel tank – 0.52 l;

- oil tank – 0.26 l;

- weight – 5.1 kg.

The Patriot tool is equipped with the Easy Start system, a primer and a high-quality cutting set. The saw can operate even at extremely low temperatures and starts without heating. An automatic oil supply system is provided.

Chainsaw Patriot PT 2512

The professional Patriot model can cope with trunks of any size, preparing firewood and working in the garden. It can be used during logging or on sawmills. One-handed grip is provided.

Main characteristics:

- The power of the product is 1.3 liters. With;

- gasoline tank – 0.2 l;

- oil tank – 0.2 l;

- tire size – 3 m;

- weight – 2.9 kg.

The compact Patriot saw does an excellent job of cutting young trees and old stumps. It has an automatic lubricant supply system. The handles of the device have a well-thought-out design.

Characteristics of Patriot PT 3816 and its description

The number 3816 is indicated in the marking, this means that the chainsaw has a 38 cm 3 engine and the bar length is 16 inches (40 cm).

This volume is enough to produce two horsepower, which together with 12,000 rpm gives good performance. The Patriot 3816 is equipped with a carburetor with the ability to adjust the quality of the mixture and a good air filter that, if necessary, can be washed in soapy water, and nothing will happen to it.

The slot width for installing the chain is 1.3 millimeters, the chain and drive sprocket have a pitch of 3/8 inch, the length of the chain. 57 links.

Bar and chain

The main components of the Patriot PT 2512 saw set are the bar and chain. The guide groove of the tire has a standard width of 1.3 mm. The length of the bar determines the length of the cut, i.e. distance from the toothed stop to the toe of the tire.

Chain: Patriot 91VS-44E. Chain pitch is 3/8″. Number of links - 44.

It is believed that the service life of a tire is approximately three times the service life of a chain.