Do-it-yourself chainsaw carburetor adjustment

For an independent carburetor option, you need to familiarize yourself with its structure and understand the procedure for the work that is carried out to adjust the parts responsible for the proper functioning of the components of the device and parts close to it.

It is necessary to carefully handle items for the system option, and also to determine whether the set characteristics correspond to very acceptable values.

About the carburetor design

The carburetor serves to mix the flammable mixture with air while maintaining predetermined proportions. If clear doses are not followed, the proper operation of the engine is at risk. When a huge amount of air enters during mixing of the components, but there is not enough fuel, then such a mixture is considered “lean”.

Oversaturation should not be allowed, because with a larger amount of fuel compared to air, malfunctions or engine wear are also likely. Carburetor adjustment is needed not only before initial use, but also when any differences in its operation are detected. Before working with a chainsaw, do not forget to run it in.

Carburetor components

The carburetor design contains a standard set of parts, but may vary slightly depending on the manufacturer. Components:

- The basis. This is a special tube that is visually similar to an aerodynamic design. Air passes through it. In the transverse direction, a damper is located in the middle of the pipe. Its position can be changed. The more it is extended into the passage, the less air enters the engine.

- Diffuser. This is the constricted part of the tube. With its help, the air supply speed increases precisely in the segment from which the fuel comes out.

- Channels for fuel supply. Chainsaw Huter BS 45, Carburetor adjustment. On Huter BS 45 and Huter BS 52 chainsaws. The fuel mixture is contained in the float chamber, then passes into the nozzle, from which it flows into the sprayer.

- Float chamber. It is a separate structural element, reminiscent of the shape of a tank. Designed to constantly maintain the optimal level of fuel fluid before entering the channel from which air enters.

Don't know which chainsaw to choose? Read our article.

Are you looking for cheaper models, but reliable and time-tested? Pay attention to Russian-made chainsaws.

Or explore foreign chainsaw manufacturers such as Shtil.

What you need to have for setup

Each carburetor owner must have the necessary tools to adjust this system. There are three adjustment screws that are located on the body of the device. They have their own markings:

- L - screw for correcting low speeds.

- H - screw for adjusting high speed.

- T - regulates idle speed, in most cases used for experiments.

Chainsaw air filter

Before adjusting the carburetor, you need to prepare the device:

- The engine warms up, that is, it starts about 10 minutes before repairs, and turns off when starting work (see how to start a chainsaw).

- The air filter is checked and washed.

- The chain is stopped by turning screw T until it stops (see chain oil).

To carry out a safe repair, you need to prepare a flat surface where you can carefully place the device and turn the chain in the opposite direction. Need a tachometer. It determines whether there is a malfunction in the carburetor. When turning the screws, the sound should be perfect and absolutely smooth. If you notice squealing notes, the mixture is oversaturated.

Setup instructions

Carburetor adjustment is divided into two main stages. The first one is called basic. It is performed with the engine running. The second is performed when the engine is warm.

To carry out the carburetor setup procedure successfully, you need to read the operating instructions for a specific model in advance to identify additional features of setting up the device.

First stage

The adjusting screws for the highest and lowest speeds should be moved clockwise until the highest resistance is met. When the screws reach the stop, you need to move them in the opposite direction and leave them 1.5 turns.

Main stage

The engine is turned on at medium speed and warms up for about 10 minutes. The screw responsible for adjusting the idle speed should move clockwise. It is released only when the engine reaches stable operation mode. It is necessary to ensure that the chain does not move during this process.

Adjusting the carburetor on a Chinese chainsaw (practice)

Spare parts for Chinese chainsaws? How to adjust the carburetor on .

Gasoline chain saw Huter BS-52

Engine capacity, cm? 52 Power, kW 2.2.

In idling mode, the engine may stall (the reason is here). In this case, you must immediately turn the adjusting screw clockwise until it stops. Sometimes the chain starts to move. In this case, turn the adjusting screw in the opposite direction.

Checking acceleration operation

Need to do a little research. Acceleration of the device is initiated. It is necessary to evaluate the proper operation of the engine during maximum speed. When the engine is functioning correctly, it means that when you press the accelerator, the speed quickly increases to 15,000 rpm.

If this does not happen or the increase in speed is too slow, you must use the screw marked L. It turns counterclockwise. Moderate movements must be observed, since the turn cannot be more than 1/8 of a full circle.

Maximum number of revolutions

To limit this indicator, you need to use a screw marked H. To increase the number of revolutions, turn it clockwise, and to reduce them in the opposite direction. The maximum frequency should not exceed 15000 rpm.

If you make this figure larger, the device’s engine will wear out, which will lead to problems in the ignition system. When rotating this screw, you need to take into account the ignition processes of the device. If the slightest malfunctions appear, then the maximum speed value must be reduced.

Final check at idle

Before this procedure, it is necessary to carry out a full adjustment of the carburetor components when operating at maximum speed. Next, you should check the functioning of the device in idle cold mode. When the correct adjustment parameters are achieved, you will notice that the carburetor design closely matches the following criteria:

- When the idle cold mode is activated, the chain does not move.

Chainsaw accelerator

- When the accelerator is pressed even slightly, the engine accelerates at an accelerated pace. With gradual deepening of pressure, you can notice that the engine speed increases proportionately, reaching the maximum permissible values.

- When the engine is running, you can compare its sound to a four-stroke device.

If violations are noticed in the given parameters or the device has not been fully adjusted, you need to perform the main setup step again. Sometimes actions are performed incorrectly. In this case, the device may fail due to the loss of the correct node settings. In this case, you will have to contact a specialist.

Disassembling the carburetor if necessary to check or repair components

The design of different carburetor models is almost the same, so when working with them you can use the standard scheme. All elements must be removed carefully and then laid out in the order given below so that you can successfully place the items in place after the completion of the repair work.

Removing the Top Cover

- The top cover is removed. To do this, you need to unscrew the 3 bolts holding it in a circle.

- The foam rubber is also removed, since it is the upper component of the filter that conducts air.

- The fuel hose is removed.

- The drive thrust is output directly to it.

- The cable end is disconnected.

- The gasoline hose can be completely removed if you systematically pull it off the fitting.

To finally prepare the carburetor for major repairs or replacement of the smallest parts, you need to carefully disconnect it from the main system. Sometimes further disassembly is required. You should unscrew the components carefully and put the fasteners in groups, as these small parts are easily lost.

Instructions for Chinese

To correctly configure the carburetor of a Chinese chainsaw, you must first remember the factory settings of the device, then turn on the engine. Subsequently, you will have to leave it running for several hours in order to accurately set your own parameters. Sometimes work is carried out only after ten minutes of engine operation, but many Chinese-made models require special handling.

Chinese chainsaw model

Adjustment procedure:

- Activities begin in idle mode. Using the adjusting screws, you need to achieve a systematic increase in engine speed, so you should first let it run at low speeds. A deviation from the norm is the movement of the chain along the bus. In this case, you need to adjust the outer screws to the optimal position so that the chain remains motionless.

- The transition to medium speed speed is carried out. Sometimes the engine starts to smoke. This defect can be eliminated by tightening the screw to supply a leaner fuel mixture.

In this case, the smoke will disappear, but the engine speed will increase. You need to adjust the settings until you reach a level where, when you press the throttle, the engine smoothly picks up speed, and no sudden jerks or interruptions are heard.

- The device's engine is being checked. The chainsaw is switched to minimum speed, and then the lever is quickly pressed. When pressed maximally, it is held for 3 seconds. If there are problems with the engine, you need to gradually loosen the screw until the optimal position is reached.

- The chainsaw should work for several hours in real conditions. You need to cut wood, and then inspect all the elements involved in this event. If there are deviations, they must be corrected using adjusting devices. When all defects have been eliminated and the optimal settings have been established to supply correctly concentrated fuel, the device setup process can be considered complete.

- Take a look at the video:

Conclusion

In order for the chainsaw to work properly, you need to carefully carry out the work of adjusting the carburetor in exact accordance with their order. If any malfunctions occur in the operation of the device, you must completely disassemble it yourself. In most cases, replacement of any parts that have become unusable is required.

By constantly checking the quality of carburetor settings and taking timely actions to improve its operation, problems with the chainsaw will not arise.

Read about which chainsaw to choose here.

Huter chainsaw carburetors - design, adjustment and repair

The carburetor is a fundamental component of a chainsaw on which the high-quality performance of the tool directly depends. One of the most common defects on Huter saws is incorrect settings. Repeated adjustment is necessary to maintain good performance and extend the life of the tool.

What carburetor is installed on the Huter BS 45 chainsaw

As stated above, this model of the Huter is equipped with a Walbro diaphragm carburetor. The advantage of such a carburetor lies in the ability to dose the quality and quantity of the fuel consistency, and also, unlike float carburetors, in the ability to work in any position.

How to install a saw made in China?

The design of the carburetor on Chinese chainsaws is no different. The installation procedure and principle are also the same and are performed in the same order. The only difficulty that may arise during work. This determines the purpose of the adjusting screws. Typically the T screw is at the top and the H and L screw are located at the bottom of the carburetor body. There may be one extra screw there.

Figure 3. Location of control mechanisms

Usually their goal is determined experimentally, slightly changing the position and monitoring the result. Once the purpose of the elements is clearly defined, further configuration is straightforward and can be done in the usual way.

Adjusting the chainsaw carburetor is an important and necessary procedure that must be performed periodically to restore normal operation of the tool. This process does not create any fundamental difficulties, but requires the user to be careful, attentive and follow safety rules. Chainsaws are usually not removed because you need to keep an eye on their position. Therefore, it is important to always remember the possibility of triggering it and exercise the necessary caution.

The adjustment should be made smoothly, with slight changes in the position of the screws, so as not to cause too sudden changes in the mode of rotation of the shaft. The result depends on the care and diligence of the user, and a properly adjusted carburetor will extend the life of the tool.

Source

Huter BS 45, a popular inexpensive chainsaw. Many users prefer not to overpay, so they choose this model.

READ How to remove the oil tank on a Champion chainsaw

Advantages and disadvantages of the Huter chainsaw carburetor

The positive properties of this carburetor are quite significant:

- advice on using fuel and oil only of the highest quality (gasoline not lower than AI 92);

- the need to adjust industrial carburetor options.

The design and principle of operation of the carburetor

The carburetor is one of the important parts of the chainsaw and serves to mix fuel with air and supply this mixture to the combustion chamber of the engine.

For the independent option of the Huter carburetor, it is important to know how it works and understand its principle of operation.

Walbro carburetors are ordinary in design. They have a monoblock pass-through type housing with a through hole. Inside the hole there is a diffuser - a narrowing of the passage with a fuel injection channel. There are valves on both sides: the smallest one is the throttle valve; it regulates the amount of fuel mixture supplied to the cylinder. The larger air damper serves to limit the air flow during a cool start.

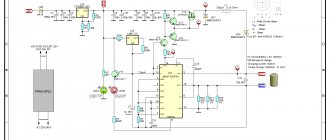

Huter BS-45 chainsaw carburetor diagram

A vacuum is created in the engine cylinder and fuel is dosed into the carburetor chamber through the channel of the diaphragm pump, thanks to the bending of the control membrane and the movement of the needle to the lower position. Valves and dampers open due to the pressure difference, thereby admitting and directing these elements through channels to the diffuser, where air and fuel are mixed, sprayed and entered the engine cylinder.

Design and principle of operation

Carburetor. This is a device in which fuel (gasoline) and air are mixed in specified proportions and then the finished mixture is fed into the engine cylinder. Almost all models of chainsaws have the same type of carburetors, so the design and operating principle are the same.

The main elements of the carburetor design are:

- Body which is cast in aluminum to reduce weight. Chainsaws are constantly moved from place to place and are held in hands while working, so reducing tool weight is a priority for manufacturers;

- Diffuser with an air damper located at the inlet;

- Jets , presentation of valves for metered fuel supply;

- Spray , ensuring the injection of gasoline into the chamber (in the diagrams it is designated as the main nozzle);

- Fuel (float) chamber.

Figure 1. Diagram of a carburetor chainsaw

The operating principle of a carburetor can be described as a cycle consisting of the following stages:

- The choke valve opens when the engine starts.

- The stroke of the piston creates a vacuum in the air channel, as a result of which air enters the diffuser, the amount of which is regulated by the position of the air valve.

- From the gas tank, gas enters the float (fuel) chamber. The speed of its entry is controlled by nozzles.

- Gasoline and air are mixed in the diffuser, resulting in the formation of an air-fuel mixture, which then enters the engine cylinder. The more mixture enters the combustion chamber of the cylinder, the higher the power and speed at the engine shaft.

DIY carburetor repair

The fact that the carburetor needs repair can be determined by the following signs: unstable engine operation, excessive fuel consumption, engine power surges, popping noises.

The Huter chainsaw is not considered a difficult piece of equipment to disassemble, therefore, if you have the initial skills of a mechanic, available tools and desire, it will not be difficult to replace the parts yourself.

READ Cut the inner corner of the ceiling plinth without a miter box

What can be changed in the carburetor without contacting a specialist:

- fuel filter (washing or replacing) - when the engine jerks and sneezes;

- needle valve - if the needle gets stuck in the valve or is stuck;

- fuel pump diaphragm - wear;

- The gasket under the main chamber cover is not tight.

- disassemble and wash the carburetor if the air filter is clogged;

- tighten the bolts if they lose their fixation due to intense vibration of the chainsaw.

The Walbro company produces extended repair kits for self-replacement, which include, in fact, all carburetor parts (fuel inlet needle, rocker, rocker axle, filter meshes, membrane).

A fundamental recommendation for avoiding carburetor malfunction: do not leave the fuel mixture in an inactive saw for more than 12 hours; such negligence can lead to blockage of the channels.

Is disassembly necessary?

You can adjust the carburetor of a chainsaw without any disassembly at all; in rare exceptions, you only have to remove the air filter cover. There is a considerable amount of contradiction here: on the one hand, the chainsaw is designed for unhindered access to the adjustment mechanism, on the other hand, it is recommended to access it as little as possible.

True, experienced fellers and sawers always carry a flat-head screwdriver with a long blade and periodically adjust the carburetor. This is explained simply: during the manufacture of a chainsaw, its carburetor undergoes rough adjustments designed for a certain composition of air and fuel. It is clear that the conditions at the work site are different from those on the bench.

When changing the brand of gasoline or, for example, increasing air humidity, an experienced chainsaw user will always adjust the quality of the mixture for greater performance and less wear on the piston part. But this, we repeat, requires considerable experience in working with a specific chainsaw and knowledge of the peculiarities of its behavior. In addition, the adjustment is incredibly fine - the screws are tightened by only 1/10...1/20 of a turn.

Another reason for adjustment is carburetor repair or replacement. In any case, adjustment of the mixture quality should be carried out only if the serviceability of the carburetor is reliably known (no debris, gaskets are not poisoned), the air filter is clean, the spark plug, clutch and ignition system are in perfect order. Otherwise, there is a high probability that the malfunction will be eliminated in a moment and the adjustment will suddenly become incorrect, and the engine will begin to wear out.

The best inexpensive chainsaw for about rubles

A tool for rare and careful use on a limited budget. It requires painstaking maintenance and often repairs. Cheap chainsaws usually last three to five seasons, depending on the activity of use.

- reliable grip;

- accidental start blocking;

- the chain catcher will protect the operator in the event of a rupture of the saw set;

- difficult, as for a new person, to install the tire;

- end chain tensioner.

2 PATRIOT PT 5220 Imperial 2500 W/3.4 HP

Powerful saw with a two-stroke engine with increased service life. It starts with little effort thanks to the Easy Start system. The overrun brake and starter covers are cast from magnesium alloy. The anti-vibration system reduces stress on the hands, extending the working session. Operator safety is enhanced by a chain catcher, an inertia brake, a safety device against accidental start and a guard. The filter and spark plug can be serviced without tools. Peculiarities:

- easier engine starting;

- multi-level operator protection;

- automatic oil supply;

- lateral chain tension;

- quick access to the spark plug and air filter.

A compact gasoline saw with a 35-centimeter bar, designed for processing wood in small quantities and clearing areas of unnecessary bushes and trees. A good choice for gardeners, considering the low cost. The motor speed is adapted for sawing all types of wood, including dry wood. The high-tech electric ignition mechanism and primer make it possible to start the engine with female hands.

- fuel pump;

- advanced vibration protection;

- equipped with Oregon saw set;

- shiny cylinder.

A tool with a long bar for repeated sawing of logs with a diameter of up to 75 cm. Owners recommend doing this less often, taking into account the cost. Armed with advanced safety mechanisms: engine brake in case of reverse impact, start blocker. Rubberized handles provide a secure grip with frozen hands and prevent the transfer of vibrations from the motor to the operator. The fuel pump makes starting the engine easier.

- a long tire for sawing huge trees;

- instrumental chain tension;

- work at low temperatures;

- Difficulty in reinstalling the lid.

For the garden and cutting firewood for barbecue, the cheapest chainsaw is enough. Harvesting firewood, lumber, construction, constant sawing and making garden sculptures requires a powerful tool from a renowned manufacturer.

When to adjust it yourself, and when it’s better to take it to a service center

adjust the carburetor if you have an idea of its operating mechanism and the sequence of the option method is accurately carried out. If, after adjustment at home, stability in the operation of the chainsaw is not achieved, you should contact a specialist to avoid irreversible damage to your Huter chainsaw.

Tires and chain

The bar guides the chain in operation; the greater the power of the saw, the longer the bar will be.

Low-profile chains are used for non-professional equipment. The main advantage is low vibration, but with all this, productivity decreases.

The components of a saw set (bar, chain, sprocket or drive sprocket) from different manufacturers are not compatible together. Having chosen a specific tool model and manufacturer, try to select the appropriate components from the same company.

Carburetor parts, preparation for tuning and safety precautions

Before adjusting the carburetor, you should definitely make sure that the air and fuel filters are clean. Also, make sure that there is no air leaking into the engine from the side, otherwise you will not be able to adjust the carburetor correctly.

Almost any carburetor in a chainsaw is adjusted using three screws:

- The main jet bolt, which is usually indicated by the letter "H", is used to set the maximum engine speed;

- The idle jet bolt, which is designated “L”, and is used to set low speed or idle speed;

- Idle speed adjustment bolt, which is designated differently: “S,” “LA,” “T”

Of course, you may find carburetors with fewer screws. Such carburetors, as a rule, are specially designed to protect their products from incorrect settings.

Modifications of the Partner 350 model

The Partner model range is represented by the following modifications, any of them will be considered separately:

- Partner P350S: 2 HP\140 W motor drives a 3.8-inch chain, moving at a speed of 22 meters per second, tensioned on a 400 mm long bar - these characteristics significantly increase productivity, making this model stand out among the analog. The fuel tank capacity is 250 ml. The Partner P350S model uses new approaches to user safety: an inertial chain stopper, blocking using a special switch, a chain catcher, which allows it to be braked using various methods. The design also includes a fuel pump, which also removes remaining air and fuel from the carburetor, allowing for a smoother start.

- Partner 350 XT CHROME: the chainsaw is equipped with an engine with a power of 1.3 hp\1300 W, which is perfect for carrying out work of medium difficulty. The highest performance characteristics are provided by a chain with a tooth pitch of 3.8 inches and a bar length of 400 mm. The fuel tank capacity is 400 ml - this guarantees maximum operating time. Parts that optimize the operation of the chainsaw include a vibration damping system, which is achieved by using long-lasting steel springs. Safety is ensured by a double brake system.

- Partner 350 Chrome: has an engine with a power of 1.9 hp\1300 W. The bar length is 400 mm, the chain pitch is 0.325 inches. This significantly increases the performance characteristics of the chainsaw. The fuel tank capacity is 400 ml. The model is characterized by the highest wear resistance, which is due to its shiny coating. Safety is ensured by an inertia-type chain stopper.

READ Carburetor Adjustment for Chainsaw Shtil MS 660 China

Checking the ignition system

The first thing you need to do if your chainsaw breaks down is to inspect the spark plug by disconnecting the wire and carefully unscrewing it with a special wrench.

Components of the chainsaw ignition system: 1 – flywheel with magnets, 2 – ignition module, 3 – spark plug, 4 – high voltage wire

The spark plug is unscrewed to check its condition

Her appearance speaks volumes:

- Dry. Most likely, the fuel mixture is not getting into the cylinder. The problem is not in the ignition system, so the spark plug is screwed back in.

- Heavily splashed with fuel. The reason for the excess fuel mixture lies either in violation of the starting rules or in incorrect carburetor adjustment. The spark plug is thoroughly wiped, the fuel supply is turned off and the starter is turned on to remove excess fuel and ventilate the combustion chamber. Then the candle is placed in place and the mechanism is started again.

- Covered with black soot. This may indicate the use of low-quality oil, an incorrectly adjusted carburetor, or an incorrectly calculated ratio of gasoline to oil. The spark plug should be washed, removed from carbon deposits with a sharp object (an awl or a needle), the electrodes should be wiped with sandpaper and placed in place.

Description

A chainsaw is a saw with a chain and an internal combustion engine for working with wood and other materials. It is completely autonomous and more comfortable to use compared to an electric one.

- Household. Suitable for small jobs in the garden and plot.

- Semi-professional. They allow you to do the job quite quickly and perfectly. Will handle trees, bushes and branches.

- Prof. The most massive and productive. Designed for professional tree felling.

What carburetor is installed on the Huter BS 45 chainsaw

As stated above, this model of the Huter chainsaw line is equipped with a Walbro diaphragm carburetor. The advantage of such a carburetor lies in the ability to dose the quality and quantity of the fuel consistency, and also, unlike float carburetors, in the ability to work in any position.

Huter chainsaws – real German quality

The Huter company (Hüter Elektrische Technik GmbH) was founded in 1979 in the small German town of Nordhausen. The new company began its production activities with the production of mini-electric power stations, and a few years later began the production of gasoline and diesel generators. Soon the range of products began to expand. To meet customer needs, Huter's shareholders decided to build another plant in Erfurt. From that moment on, the company firmly became one of the leaders in the market of gardening and farming equipment.

Hüter Elektrische Technik GmbH

At the beginning of the 21st century, part of the production capacity was transferred to China. By that time, the company had already received all international certificates, and its products were sold on all continents. In the catalog of manufactured products we find electric and chainsaws, trimmers and lawn mowers, snow removal equipment and boat motors.

An important factor that contributes to the popularity of Hooter equipment is its reasonable pricing policy. The company's products combine high quality and reasonable prices. Even a professional Huter tool can be purchased for very reasonable money.

So how much does a Huter petrol chain saw cost? We looked at the offers of the largest Russian online stores and found out that the price depends on the model and ranges from 5,000 to 7,000 rubles.

It is worth noting that the company quite often holds various promotions and sales, during which you can buy a chainsaw at a special price.

Carburetor adjustment

The Huter BS 45 and Huter BS 52 chainsaws are equipped with a membrane carburetor with the ability to adjust the properties and amount of consistency. After purchasing a tool, it is recommended to slightly enrich the fuel mixture in order to compensate for the loads that arise during the piston grinding process.

Fundamentally! After the saw has worked with the enriched consistency and the parts of the piston group have rubbed against each other, the quality of the consistency should be brought back to normal.

The screw (L) is responsible for the quality of the fuel consistency. To enrich the fuel consistency (increase the fuel supply to the cylinder), the screw must be turned a quarter turn counterclockwise. After running in, return to the starting position.

If carburetor is completely out of adjustment, its adjustment is carried out using the following method:

- on a muffled saw, screws L and H are installed 2.5 turns from the one hundred percent tightened state;

- the saw starts and warms up for 5-10 minutes;

- after warming up, slowly tighten screw L. you need to find the highest idle speed, then loosen the screw one quarter;

- screw H regulates the operation of the motor at the highest speed;

- After adjusting screws L and H, use screw T to adjust the idle speed. It needs to be set in such a way that the engine works stably and at the same time the saw chain does not spin.

Fundamentally! Adjustment of the highest speed should be carried out using a tachometer. If there is no such device, then the screw is tightened until the moment when the engine begins to work smoothly and uniformly, simply picking up speed.

It is worth keeping in mind that adjustment should be carried out only after a complete diagnosis of the saw has been carried out and faults such as crankcase depressurization, air leaks under the spark plug, and carburetor gasket have been eliminated.

Last year I bought a Huter BS 45M for myself and I can say that I have only great memories from it. The saw is powerful and responsive. It simply cuts even thick trees. I didn’t do a break-in after purchase, or rather, I didn’t adjust the carburetor to increase the amount of fuel, I just added a little more oil to the gasoline.

For almost a year of operation, I only changed the tire and chain, and that’s because I was sawing various rubbish and sorted them out myself.

In order to extend the service life of the saw, I try to use high-quality lubricants and always drain gasoline and oil from the tanks if I do not plan to use the saw for more than 1 month.

I am satisfied with the saw; it seems to me that its quality is quite consistent with the price.

I am the owner of a Huter BS-45 chainsaw. I have been using it on my own farm for more than 3 years. During this period of time, I changed the starter and springs a couple of times and adjusted the carburetor. Once I had to contact the service center because I couldn’t start the saw without the help of others. The service center carried out diagnostics and found that the injector valve in the carburetor was stuck. The reason is that I left the saw with gasoline. It evaporates and only the oil remains, which is what stuck to the valve. The mechanics said that I was just screwing up, because the oil could seal the carburetor channels and it would have to be changed.

I am satisfied with the saw, I recommend it to all my friends.

What you need to have for setup

Each carburetor owner must have the necessary tools to adjust this system. There are three adjustment screws that are located on the body of the device. They have their own markings:

- L - screw for correcting low speeds.

- H - screw for adjusting high speed.

- T - regulates idle speed, in most cases used for experiments.

Before adjusting the carburetor, you need to prepare the device:

- The engine warms up, that is, it starts about 10 minutes before repairs, and turns off when starting work (see how to start a chainsaw).

- The air filter is checked and washed.

- The chain is stopped by turning screw T until it stops (see chain oil).

To carry out a safe repair, you need to prepare a flat surface where you can carefully place the device and turn the chain in the opposite direction. Need a tachometer. It determines whether there is a malfunction in the carburetor. When turning the screws, the sound should be perfect and absolutely smooth. If you notice squealing notes, the mixture is oversaturated.

Advantages and disadvantages

The main advantage of the BS 45 and BS 45M chainsaws is their price, which is actually half the price of rival chainsaws. You can verify this by looking at Yandex’s offers, which indicate approximate prices.

Another positive point is the availability of warranty and post-warranty service. The craftsmen of the Huter company undergo special training, so when you send your saw for repairs, you can be careful about its quality.

In technical terms, the advantages of these chainsaws are their high power and long tires, which allow you to cut thick tree trunks without much difficulty.

Curious! The Huter BS-45 chainsaw has the ability to adjust the oil supply for chain lubrication, which allows you to increase the supply of lubricant when sawing dirty wood. Because of this, the service life of the saw set can be significantly extended.

READ Motor-cultivator carburetor regulator does not work

These chainsaws have few disadvantages, but they are quite significant.

- Build quality (after purchase, they need to be tightened with screws).

- Low quality plastic parts.

- The fuel and oil tank caps quickly wear out and begin to leak (it's easy to change, but it causes inconvenience and trouble).

- The motor has a short lifespan due to the poor quality of the parts from which it is assembled.

- Weight. Working with a Huter BS 45M (BS 45) chainsaw for a long time is quite difficult. Especially if you need to cut small growths.

All the disadvantages of a chainsaw are directly related to its price. If you remove them, it will cost even more.

How to recognize carburetor failures?

Operation diagram of a chainsaw carburetor

Carburetor settings may be affected by:

- lack of fixation of the adjusting screws;

- wear of the piston group;

- clogged fuel-air channels;

- damage to air filters;

- poor quality gasoline or oil.

Any problems found should be corrected immediately. But how can you determine that the problem is in the carburetor? To do this, watch how your tool works.

Typical signs that the carburetor settings are off include:

- Unstable motor operation

As a rule, the reason for this is the use of the wrong (lean) fuel mixture.

- Excessive fuel consumption

It is expressed in an increased release of exhaust exhaust, which turns black. This means that fuel is not completely consumed, i.e. the mixture is oversaturated.

The carburetor is adjusted correctly - the saw starts the first time

- Arbitrary changes in engine power

May be associated with damage to the fastening of the adjusting screws or the protective cap.

- Increased fuel consumption accompanied by vibrations and pops

This indicates critical wear of the piston group, so adjusting the carburetor will only postpone major repairs for some time.

- Sneezing and engine jerking

This picture is observed when the carburetor channels are clogged or its filters are faulty. In this case, adjustment should be carried out only after thoroughly washing the unit.

Chainsaw fuel filter

Despite the fact that the carburetor is the most complex part of the engine, you should not be upset if you detect malfunctions in its operation. Instead, you need to arm yourself with some tools, a design diagram of the unit and sound logic.

Chainsaw carburetor being repaired

User manual

The instructions that come with the Huter BS 45 saw are quite detailed.

- description of the saw;

- description of the equipment;

- safety tips;

- management of the launch and operation of inventory;

- description of maintenance;

- saw chain sharpening method;

- Annotation on making a fuel mixture and refueling a chainsaw.

Fundamentally! After purchasing the newest chainsaw, you should not ignore reading the instructions. The information contained in it will help you avoid common mistakes that lead to chainsaw failure. Remember that malfunctions caused by incorrect operation are grounds for refusal of warranty repairs.

How to disassemble a chainsaw correctly?

So, how to disassemble a chainsaw so that when you reassemble it, there are no unnecessary parts on your desktop?

Disassembly should begin by loosening the bolts securing the clutch cover. After this, the chain tension should be loosened. And only then remove the bolts securing the clutch cover. Next, remove the clutch cover, the bar along which the chainsaw chain moves, and the chain itself. The next step is to remove the top cover of the case.

Helpful advice: leave all screws securing body elements or individual parts of the chainsaw in their grooves. Firstly, this will remove the problem that arises during assembly: which screw should be inserted into which groove. And secondly, this, in principle, will save you a lot of time and nerves.

Next, we proceed to disassembling the internal components of the chainsaw. During the disassembly process, we strongly advise you to follow the disassembly video instructions for the model you own. Even if you are disassembling a Chinese copy of some prestigious model, there will still be differences in the method of fastening or the order of disassembly.

Therefore, we now want to draw your attention to some nuances that may not be heard from instructors during the process of disassembling the chainsaw.

- Usually the muffler element is removed immediately along with the muffler. If they are removed sequentially (first the muffler, and then the muffling element), then after removing them it is better to reconnect them together.

- Typically, the cross handle of a chainsaw is secured from the bottom with shorter bolts than the top bolts that secure the handle on the sides.

- Before you begin to remove the clutch, you should turn the crankshaft clockwise by the clutch, observing the movement of the piston through the exhaust gas outlet hole. As soon as it blocks the hole where the exhaust gases exit, we place a rope with knots through the spark plug hole into the combustion chamber.

- The clutch has a left-hand thread, so the clutch unscrews clockwise rather than counterclockwise. It is best to unscrew the clutch with a simple wrench, the “jaws” of which should coincide with the grooves of the clutch. For better fit of the “jaws” into the grooves, they should be bored out.

- To remove the flywheel, hit the free boss, i.e., the one on which the magnetic wire is not wound.

- Even after you have drained the gasoline, it will still remain in the gas line, and under slight pressure. Therefore, when removing the gas line, pinch its end with your fingers, and then let the gasoline drain onto the surface of the workbench.

- In order to remove the carburetor adapter, it must be pulled off the two pipes located between the adapter and the cylinder. The adapter is pulled upward and away from the cylinder.

- When disassembling a chainsaw, carefully inspect its parts. If there is significant visual wear, such parts should be replaced. And at the same time, in order not to get up twice, replace consumables, first of all, chainsaw oil.

In our online store you can also buy a chainsaw chain at the most attractive price in Ukraine.

Purpose

The Huter BS 45 chainsaw is a household tool; it is not recommended to be used for industrial logging, since it has a limited resource, due to the fact that manufacturers tried to save a lot when developing it. But, despite this, the chainsaw has established itself as a reliable household assistant, with the help of which you can prepare firewood for the winter, maintain the site, and saw off anything at a construction site. Provided timely maintenance is carried out, the saw can last for more than one year.

The Huter BS 45 chainsaw is not suitable for outdoor enthusiasts, as its weight and dimensions are above average.

The chainsaw manufacturer, the German company Huter, has been represented on the Russian market since 2000.

According to the manufacturer, the Huter BS-45 saw is German, but if you look closely, it becomes clear that this is another creation of the Chinese industry, imported into our country under the German brand.

Although this is a Chinese version of a chainsaw, the fact that it is sold under the Huter gives it some advantages. The saw is covered by a warranty; the company’s specialists also carry out post-warranty repairs; there are no problems with servicing the Huter 45.

A video review of the Huter BS 45 can be seen below. After watching, you will find out what the chainsaw looks like and how it is equipped. Familiarize yourself with the main components. The video also shows how to properly start a chainsaw in cold and hot weather and how it cuts.

Maintenance

Reviews of the Huter BS-45 chainsaw quite often help consumers make the right choice in favor of this model. If you have already become the owner of such equipment, you should become more familiar with the features of maintenance

It is important to keep the oil holes clean. They should not contain lumps of dirt, foreign objects and oil clots

Lubrication holes should be checked regularly and cleaned if necessary. Using a grease gun, the operator will lubricate the driven sprocket of the tire. This manipulation should be carried out before starting sawing. In order to regulate the amount of oil supplied to the chain, you should use a pump regulator. To increase or decrease the amount of oil, the bolt must be turned in one direction or another.

Equipment

The delivery set of this chainsaw is actually no different from that of its competitors and contains the following:

- chainsaw;

- saw bar;

- chain;

- adjusting screwdriver;

- combination spark plug wrench;

- protective cover for the tire;

- container for making fuel mixture;

- abstract in Russian.

Naturally, the equipment is not rich, but this is enough to start working with a chainsaw immediately after purchase.

Adjusting the carburetor on a Chinese chainsaw (practice)

Adjustment tools

To adjust the carburetor, you will need Phillips or slotted screwdrivers of varying lengths or thicknesses. The size depends on the design of this unit and the characteristics of the engine assembly. It should be noted that some manufacturers produce carburetors designed for use with special tools.

In particular, installation of Husqvarna carburetors and other imported tools may require a special screwdriver. It is advisable to clarify this issue even when purchasing a chainsaw, so that you can purchase the necessary additional equipment in advance.

In addition, washed gasoline or acetone will be needed to flush and clean the device. They are used to clean the external surfaces of the carburetor. All internal channels are washed with kerosene, diesel fuel or white alcohol. Before washing the carburetor, remove all rubber or plastic parts that may come into contact with aggressive chemicals.

Wrenches or ring wrenches are used to disassemble the carburetor. Washing of internal channels is carried out in specially designated baths; sometimes plastic syringes are used for this.

READ How to Tension a Chain on a Chainsaw Partner

Characteristics of BS 45

The chainsaw chain drives a single-cylinder two-stroke engine. Its volume is 45 cubic meters. cm, that’s why the name of the saw is marked 45. This volume allows you to produce 1.7 kW of power at maximum speed, which is slightly superior to the power of rival chainsaws, for example, the STIHL 180.

adjusting the carburetor on a Huter chainsaw

In the standard configuration, the saw is equipped with a long bar (45 cm) and a chain with a Husqvarna pitch of 0.325.

This length of the bar combined with good power allows you to comfortably cut tree trunks with a diameter of more than 30 cm.

The fuel consumption of the Huter 45 is slightly higher than that of the STIHL 180, this is due to the difference in piston volume. The fuel tank is 0.55 liters, enough to operate for 30 minutes.

The Huter BS-45 has an anti-vibration system and a critical chain brake system, which significantly increases the level of safety during operation. The springs of the 45th can be metal springs; there are also modifications with rubber-metal ones. It’s just that iron ones are a little more reliable, because rubber-metal ones quite often tear, they are not able to withstand the load.

The weight of the equipped chainsaw is more than 7 kg. It is quite difficult to work with such equipment for a long time. The heavy weight makes it difficult to implement it on construction sites. In terms of weight, the Huter BS 45 is very inferior to its competitors; the saw is also very noisy, producing more than 100 decibels during operation, so you must use headphones during operation.

Final check at idle

Before this procedure, it is necessary to carry out a full adjustment of the carburetor components when operating at maximum speed. Next, you should check the functioning of the device in idle cold mode. When the correct adjustment parameters are achieved, you will notice that the carburetor design closely matches the following criteria:

- When the idle cold mode is activated, the chain does not move.

- When the accelerator is pressed even slightly, the engine accelerates at an accelerated pace. With gradual deepening of pressure, you can notice that the engine speed increases proportionately, reaching the maximum permissible values.

- When the engine is running, you can compare its sound to a four-stroke device.

If violations are noticed in the given parameters or the device has not been fully adjusted, you need to perform the main setup step again. Sometimes actions are performed incorrectly. In this case, the device may fail due to the loss of the correct node settings. In this case, you will have to contact a specialist.

Modification Huter BS-45M

Huter BS 45 has one improved modification, which is sold under the Huter BS 45M label.

It differs from its older sister with a slightly higher power (1.8 kW) and a shorter tire. The length of the bus supplied with Huter BS is 45 m 40 cm. This model uses a chain with a pitch of 3/8, therefore the headset from the modified model is not suitable for BS 45.

Otherwise, the chainsaws are actually similar, except for the price. Usually, the modified model is little more expensive.

Sources:

https://rodinapress.ru/ogorod/karbyuratory-benzopil-Huter-8212-ustroysTVo-regulirovka-i-remont https://benzopilok.ru/brend/Huter/benzopila-bs-45.html

Reviews and prices

On the supplier’s official website, the HS-360 model is sold at a cost of 7,934 rubles; the more powerful HS-390 with a 3.9 kW engine can be purchased for 9,632 rubles.

Slava, 26 years old, Kharkov: “I bought an HS-360 chainsaw three years ago. I consider the Hunter to be a tool of euro quality, compared to the same Huter. I’ve been using it for three years now without any complaints, despite the fact that I work a lot and constantly.”

Taras, 34 years old, Kyiv: “The quality of metal and plastic is not bad. A big plus for the manufacturers for the equipment - Oregon tire and STIHL chain. The saw is comfortable, light in weight, perfect for pruning trees in the garden. The only negative is that the oil consumption is a little higher than that of other professional class saws.”

Igor Ivanovich, 55 years old, Saratov: “Friends from Ukraine brought the saw as a gift. I liked it. A tough workhorse. The handle is comfortable, the weight is light, you can work for two to three hours without feeling sluggish.”

Features of regulation and regulation

To learn how to adjust the carburetor on a chainsaw, you must learn to identify the three screws (some models only have one).

Screws L and H are similar only in appearance, in fact they are different

Each screw has its own letter designation:

- "L" is used to set low speed;

- "H" is required to adjust the maximum speed;

- "T" is required to adjust the idle speed (only one screw is present on single screw models).

The factory adjustment is optimal, and use the screws to adjust the engine operation in special situations (operation associated with different climate conditions).

The diagram shows the conclusions of the carburetor adjusting screws with the cover closed.

A special tool is used to install the chainsaw

Adjustment is carried out only by screws L and N. To increase the rotation speed, they rotate clockwise. Lower. Counterclock-wise. Screw sequence: LHT

If you are in doubt about the adjustment, it is better to contact a specialist, as incorrect adjustment can damage the engine.

Source