One of the most important components of a chainsaw is the clutch or clutch mechanism. When using the tool, this part may fail, which will make it impossible to carry out work on sawing wood. If the clutch mechanism fails, then the question immediately arises of how to remove the clutch on a chainsaw. This need arises when a device needs to be repaired or replaced. How to do this is described in the material.

The design and operating principle of the chainsaw clutch mechanism

Most sawers do not understand how the chainsaw clutch mechanism works. When working, it is not necessary to know the operating principle, but when malfunctions occur, in order to eliminate them, you will need to find out the design and operating features of the chainsaw clutch.

Modern chainsaws are equipped with centrifugal clutch mechanisms. Centrifugal clutch - this means that its performance depends on the torque of the engine. The main purpose of the clutch on a chainsaw is to ensure the transmission of torque from the engine crankshaft to the saw set (chain). The device operates in automatic mode, and we will find out in detail how this happens.

The clutch mechanism consists of the following structural elements:

- A drum with a removable or non-removable sprocket is a transmission mechanism

- Friction linings - move under the influence of centrifugal force, engaging with the drum

- Spring - ensures that the linings are pressed against the crankshaft

Now about the principle of operation of the chainsaw clutch.

When the two-stroke engine of the tool starts, the crankshaft begins to rotate. A coupling is attached to the shaft, to which the chain is connected using a sprocket. When the chainsaw is idling (shaft rotation speed up to 2700 rpm), that is, the accelerator trigger is not pressed, the spring presses the friction linings, as a result of which torque is not transmitted to the drum.

As soon as the sawyer picks up the tool and begins to increase the speed (maximum up to 14,000 rpm), the chain begins to move along the bar. This happens due to the fact that the speed of rotation of the crankshaft increases. Due to the force of inertia, the friction linings (also called counterweights) move and engage with the inner walls of the drum. As a result, the drum moves, which is connected to the sprocket. The rotating sprocket drives the chain.

The principle of operation of the mechanism is simple, which is due to its simple design. If this part fails, then the chainsaw will not work. A detailed description of the operating principle of the chainsaw clutch mechanism is described in this material.

This is interesting!

The clutch serves not only as a transmission mechanism, but also as a protective device. It protects the chainsaw engine from premature failure when the chain gets jammed in the wood being cut.

Preventive measures

In order to reduce the likelihood of various oil leaks during operation of the saw, periodic maintenance should be carried out. During this process, you need to monitor the tightness of all hoses and gaskets. If they are detected, the connecting elements should be pulled.

It is imperative to check the quality of the oil being poured. It must be of high quality and used in strict accordance with the characteristics indicated in the product passport. In this case, in no case should you use mining, since it has a heterogeneous structure. It is also imperative to periodically purge the oil pump. This will help prevent debris from coking in its working channels.

In addition, if lubrication is poor, the chain may fail, replacing which will be a rather expensive procedure.

After performing sawing work, it is necessary to clean the saw from any sawdust that has fallen on it. During long breaks in work, the chainsaw should be hung in a vertical position. This will allow the oil liquid to spread evenly throughout all channels of the tool. This even distribution will avoid vacuum plugs, which can cause oil pump malfunctions.

When the saw chain of a chainsaw moves in the groove of the bar due to friction, a large amount of heat is released. If oil does not flow to the chainsaw chain, it is necessary to stop work and take all measures to eliminate the malfunction of the lubrication system. The combination of heavy loads and overheating of the headset is accompanied by its accelerated wear and early failure.

- Without exception, all chainsaws and their electric analogues are equipped with systems of the same operating principle, through which the lubrication of the bar, saw chain and its drive parts is carried out.

- The standard composition of this device includes a reservoir from which chain oil is supplied to the inlet of a pump with a fixed or adjustable capacity.

- Next, the working fluid in a dosed amount enters the groove of the bar, in which it is evenly distributed by the shanks of the saw chain over the entire headset and the working surface of the drive sprocket crown.

Performance tires with a length of 400 mm or more are equipped with a driven sprocket. Periodic lubrication of the bearing is carried out individually, after 6-8 hours of operation.

When is a clutch replacement necessary?

Removing and replacing the chainsaw clutch is carried out if a malfunction of the mechanism is detected. Such malfunctions include:

- Spring damage.

Depending on the model of the tool, the spring can be of two types - coil (band or single) or steel plate. The spring is damaged by stretching, separation, or mechanical failure. To determine the cause of the malfunction of the entire mechanism, you will need to remove the protective casing and drum - Drum damage and wear.

Failure of this part is often associated with pieces breaking off. If such a malfunction occurs, the drum will need to be replaced. The inside of the drum also wears out, so the part also needs to be replaced. If the drum is blue, this indicates that it has been overheated and cannot be used for further use. - Development of the mechanism.

It is connected primarily with the stretching of the spring, which can be replaced. The threaded connection also wears out. If such a breakdown occurs, the entire coupling will need to be replaced. - Sprocket wear.

Depending on the type of sprocket (collapsible or non-dismountable), it is replaced along with the drum and, if necessary, a coupling

The service life of the clutch mechanism depends not only on the quality of the components, but also on the correct operation of the tool. To extend the life of the chainsaw clutch, you need to pay attention to signs that reduce the resource. These signs include:

- Frequent snagging or biting of the chain in the wood. In such situations, the clutch takes on the entire load, thereby protecting the engine from jamming

- It is forbidden to increase the speed when the handbrake is on, which also leads to wear on the mechanism due to overheating

- Use of low-quality oil, incorrect choice of tire, chain, etc. All this also affects the clutch, increasing the load, and thereby reducing the service life

Determining a device malfunction is quite simple. To do this, you need to cut the workpiece. If during the sawing process the rotation speed of the chain decreases or it stops when the load increases, then it’s time to check the clutch. We will consider in detail how to remove and replace the clutch on a chainsaw in the next section.

This is interesting!

You can check the suitability of the compression spring by connecting a tachometer to the tool. At idle, you need to turn up the number of 2500-2700 revolutions per minute on the tachometer. At this value, the chain on the chainsaw should not rotate. If a different picture is observed, then this indicates a decrease in the compressive properties of the spring. It is recommended to replace it. Based on this, it should be noted that the chainsaw clutch is in close relationship with the carburetor. If you cannot adjust the idle speed on the chainsaw by adjusting the carburetor, then you need to check the serviceability of the clutch.

Oil pump malfunctions

Regardless of the manufacturer, any chainsaw model experiences problems with the lubrication system.

Chainsaw oil pump assembly

The nature of malfunctions in the lubrication system can be different, and therefore, before starting repairs, it is necessary to accurately determine the cause of the oil leak or its failure to reach the tire. If we exclude the possibility of mechanical damage, the following breakdowns of the lubrication system can be identified:

- The connection between the line and the output channel of the chainsaw oil pump is not airtight;

- Not a tight fit of parts in the plunger system;

- Inconsistency between the parameters of the discharge chamber and the dimensions of the plunger;

- Lack of tightness of the oil line with the inlet fitting of the oil pump.

It is quite easy to eliminate oil leaks from a chainsaw if it is not used for a long time. To do this, you will need several screwdrivers and locksmith keys.

Removing and replacing the coupling with your own hands according to the instructions

Not many sawmills know how to remove the clutch on a chainsaw. The design of the mechanisms on different models of chainsaws differs, but the principle of operation is the same everywhere. The dismantling procedure is also almost identical, so next we’ll look at how to unscrew the clutch on a chainsaw with an internal sprocket.

First you will need to prepare the necessary tools:

- A special key called a puller. It often comes with a chainsaw

- Screwdriver for removing the screws that secure the protective cover

- Spark plug wrench - used to unscrew the fastening of the casing and tire (included with the tool)

- Rope - to stop the crankshaft. It is better to use asbestos, but any will be suitable for this purpose. A rope is used in case the tool does not come with a special piston locking wrench.

If dismantling is carried out for the purpose of replacement, then accordingly you will need to prepare a new mechanism in advance. When purchasing a new coupling, you only need to know the exact brand of chainsaw, since the devices differ in outer diameter, thread and design of the working mechanism. Instructions on how to remove the clutch on a chainsaw are as follows:

- Initially, you need to unscrew the fastening nuts of the casing and tire

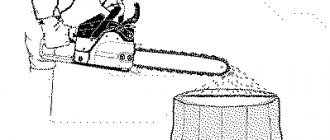

- Remove the handbrake housing, as well as the chain and bar

- After that, we proceed to removing the plastic cover to get to the spark plug. To do this, use a screwdriver to unscrew the fasteners and remove the cover along with the air filter.

- The spark plug of a chainsaw is unscrewed using a spark plug wrench

- You need to insert a rope into the spark plug hole of the cylinder (install a special key if available). This is done in order to lock the crankshaft. If the diameter of the rope is several times smaller than the size of the candle hole, you can make knots on it

- Next, we proceed to unscrewing the coupling itself. To do this, we take a special key, which should be included in the kit. If you don’t have a key, you can use a tool from an angle grinder or make your own puller, which is also not difficult

- The key splines must be installed in the coupling holes, and then begin rotating the part. Rotate in a clockwise direction. Manufacturers usually indicate the directions for unscrewing in the form of an arrow.

- As the clutch rotates, the piston will reach top dead center and then lock the crankshaft. Then, by applying a little force, the clutch will break off, followed by unscrewing the mechanism.

- The unscrewed clutch is removed from the chainsaw. If necessary, the drum with the sprocket is also removed

The procedure is not at all difficult and does not take much time. Assembly is performed in the reverse order of removal. To avoid any malfunctions, it is recommended to install a completely identical clutch on the corresponding tool model.

This is interesting!

The procedure for removing and replacing the clutch is carried out in a similar way for all brands of chainsaws: Husqvarna, Partner and others.

Alternative solutions

The sequence of operating moments is identical for almost all known models on the domestic market of chainsaw equipment. Experts advise using a branded part for replacement.

If we are talking about modernizing this unit, the feasibility of such a change should be clarified by consulting an experienced specialist.

The best option is to purchase a repair kit, which also includes a replacement bearing. In addition to the key, you may need a clutch drum puller individual for each model, a metal or plastic stopper to fix the piston in a given position.

Removing the clutch on Shtil and Dolmar chainsaws

You've probably noticed that chainsaws can have different designs of transmission devices. Above are instructions for removing the coupling with a drum on which the sprocket is located on the inside. Most chainsaws have such a device, but not Stihl tools. Chainsaws from a well-known manufacturer are equipped with a drum that has a sprocket on the outside. It looks like this, as shown in the photo below.

A different sprocket location does not mean that the tool is equipped with a different clutch mechanism. However, this suggests that the principle of removing the clutch differs from the instructions described above. Therefore, we will find out how to remove the clutch on chainsaws Stihl, Dolmar and others, on which the sprocket is located on the outside.

- To begin, you must also remove the casing and tire to provide access to the clutch.

- Unscrew the spark plug and lock the piston using a special wrench or cord

- Next we proceed to removing the sprocket and drum. To do this, use a screwdriver to pry up the retaining ring and remove it.

- The drum with bearing is dismantled

- Using a “19” wrench (included with the tool), you need to unscrew the nut with a left-hand thread connected to the mechanism. Unscrew in a clockwise direction

- The appropriate repair or replacement of the part can then be carried out.

Installation of a new or repaired part is carried out in the reverse order of removal. The procedure is almost identical to the first option, with the exception of some features. If it is necessary to replace only the drum or sprocket, then you will not need to dismantle the coupling, unlike the option with an internal sprocket arrangement.

This is interesting!

If the drum is replaced, it is also recommended to change the clutch mechanism itself. If the drum is changed due to overheating, then there is a high probability that the mechanism also has properties of damage from exposure to high temperature.

Starter problems

The starter often fails. In this case, to repair the Partner 350 chainsaw with your own hands, you must start with the following: unscrew the side cover located next to the gearbox. The starter on the saw is located next to the engine. To check this part, the air damper is first removed.

Then you need to disable the carburetor. The starter in this model is connected to the throttle. To separate them you need to use a screwdriver. If the starter shows an increase, this part must be completely replaced. In this case, a standard modification is installed, and it is not difficult to find it in the store. However, it is best to buy spare parts for the Partner 350 chainsaw in specialized workshops. After replacing the starter, all that remains is to re-tighten the throttle and put the carburetor and cover back on.

Clutch mechanism repair - spring replacement

Do not rush to change the entire mechanism, since a clutch malfunction can be eliminated by replacing the faulty part. Most often, the cause of the malfunction is a spring that stretches and can become damaged. An already stretched spring is faulty. If the spring is damaged, it can be replaced to restore the functionality of the tool. Replacement instructions depend on the design of the mechanism, since compression devices come in different types, but all of them can be replaced. This procedure is not so much complicated as it requires special care and adherence to the sequence of actions. How to replace the spring on a chainsaw clutch is shown in detail in the video clip.

If the friction lining is damaged, this part can also be replaced. Part replacement is also necessary if the threaded connection wears out, which happens when the coupling is frequently removed and replaced. To understand the cause of a part malfunction, you will first need to perform a visual inspection. If the sprocket teeth are worn, it should be replaced. Fixed sprockets must be changed along with the drum.

This is interesting!

The clutch does not have a specific service life, and its service life depends on the correct use of the tool.

Owner reviews

Vladimir Khlestov, 44 years old, Armavir

“After six months of use, the chain on the chainsaw began to spin constantly. I decided that there was a problem with the idle speed. No amount of carburetor adjustments helped. They took it apart in the workshop - it turned out that the spring on the coupling had burst. They changed everything in 10 minutes, and I couldn’t find the fault for two months. The main thing is correct diagnosis of the malfunction.”

Yaroslav Nedelko, 31 years old, Vinnytsia region

“I cut mostly hardwoods. Quite often you have to sharpen the chain, and the drive sprocket wears out. The first time I removed the clutch, I had to work hard. The metal is tightly stuck and cannot be unscrewed. I sprayed it with kerosene - it didn't help. Only after using Deshki was it possible to tear it off. And all because the oil was leaking somewhere, so the coupling was welded to the sprocket. I think so."

Andrey Kosoglazov, 23 years old, Primorsky Krai

“After three months of using the chainsaw, a longitudinal groove appeared in the sprocket - everything works, but the chain does not rotate. They said the problem was in the clutch. It is not at all difficult to disassemble it, the main thing is to find a puller and do not forget that the coupling nut has a left-hand thread. In short, I unscrewed and changed everything without any problems. It works great, and there was nothing complicated there, you just need to be careful.”

What does adjusting the chainsaw clutch mean and how to do it

If you have ever heard that the clutch on a chainsaw needs to be adjusted, then the question probably arose, how to do this? On a chainsaw, the clutch does not need to be adjusted, since it works automatically, unlike devices from older brands of tools. The compression force of the spring or springs cannot be adjusted, and if this part is damaged, it should be replaced.

When the chainsaw clutch is installed in place, there is also no need to adjust anything. The coupling is tightened all the way using a special wrench and a locked piston in the cylinder. Some chainsaw models have a washer or spacer bar. It can be located between the shaft and the sprocket or the drum and the sprocket. This washer regulates the centering of the sprocket with the tire. If there is such a washer on the chainsaw, then it must be put in its place when carrying out repair work or replacing the mechanism.

How to remove and adjust the clutch mechanism on chainsaws of the Ural and Druzhba brands is shown in detail in the video clip.

To summarize, it should be noted that the clutch on a chainsaw plays an important role. This mechanism not only ensures the transmission of torque from the engine to the chain, but also protects the motor from premature failure. Imagine a situation where the sprocket is rigidly connected to the crankshaft. If the chain gets stuck in the material being cut, simultaneous wear of engine parts, sprocket and chain will occur. Understanding the purpose and principle of operation of the mechanism, it is necessary to always monitor its serviceability, and at the first sign of failure, remove, repair or even replace it.

Oil pump malfunctions

Regardless of the manufacturer, any chainsaw model experiences problems with the lubrication system.

Chainsaw oil pump assembly

The nature of malfunctions in the lubrication system can be different, and therefore, before starting repairs, it is necessary to accurately determine the cause of the oil leak or its failure to reach the tire. If we exclude the possibility of mechanical damage, the following breakdowns of the lubrication system can be identified:

- The connection between the line and the output channel of the chainsaw oil pump is not airtight;

- Not a tight fit of parts in the plunger system;

- Inconsistency between the parameters of the discharge chamber and the dimensions of the plunger;

- Lack of tightness of the oil line with the inlet fitting of the oil pump.

It is quite easy to eliminate oil leaks from a chainsaw if it is not used for a long time. To do this, you will need several screwdrivers and locksmith keys.

Malfunctions of the plunger oil pump of a chainsaw and their elimination.

It often happens that oil is not supplied to the saw chain, even when the adjusting screw is set to maximum oil supply. There are not many reasons:

After disassembling the oil pump, the adjusting screw is set at 180° relative to its original position.

It is enough to rearrange the adjusting screw or leave it as is. Then the screw positions for maximum and minimum oil supply (<+…->) will change places.

The profile surface of the annular protrusion is worn out and no longer looks like a profile, but is flat. The plunger does not move along its axis.

We change the oil pump or form a profile and sharpen the central protrusion at the end of the plunger shaft. In this case, the volume of the pump working chamber will increase slightly.

When adjusting the profile and the protrusion, it is necessary to maintain the same maximum dimensions in height relative to each other, so that when the adjusting screw is positioned in the minimum mode, the plunger pumps up the oil a little. The new pump has a central protrusion at the end of the plunger shaft above the level of the annular profile by about 0.3...0.6 mm, and in the position of the adjusting screw with a minimum oil supply, the oil pump does not work.

Wear of the inner surface of the pump plunger chamber and the outer surface of the plunger.

This usually manifests itself with a previous defect or with what I will describe below. We change the oil pump or sort out kits based on used sizes.

Important How to make a mini tractor with an Oka engine with your own hands

Watch a video about the design and operating principle of a plunger-type oil pump for chainsaws.

Violation of the tightness of the working plunger chamber.

Oil can be gradually supplied to the lubrication point, but there is a lot of oil on the saw housing on the chain drive side.

The last example talks about the plunger collar, which in many cases is installed in the opposite direction, with the collar facing outward. Some masters claimed that this is a cuff that captures oil into the pump chamber. But how will this cuff behave when inflated? Will the oil pass through?

Some people choose rubber rings instead, but believe me, this is not easy and is very careful for those who are not experienced. This method is good, but you need to take into account the density of the sealing ring. If the ring fits tightly into place, then the plunger spring will need to be replaced, and there will be increased wear on the interface between the adjusting screw and the plunger shaft. There will also be additional wear on the plastic hub of the worm drive pair of the pump.

The ease of movement of the plunger is maintained by the use of a cuff, which does not interfere with the reverse motion when the plunger captures oil and maintains sufficient tightness of the working chamber when pumping oil.

At the first opportunity, when chainsaws come to me, I always disassemble the oil pump in order to be completely sure of the condition of the plunger and its seal. In the case where the cuff is installed with the collar facing outward, I reinstall it the other way around, with the collar facing the working plunger chamber of the oil pump.

Watch a video about repairing a chainsaw oil pump.

This is my method, which always pays off, provided that no one interfered with the design of the oil pump and oil was supplied to the pump through an oil filter.

Can The Saw Work Without Primer Cap

Chainsaw malfunctions and repairs

A chainsaw is not such a complicated device. But for which the fault detection design is intended, you need to have at least basic knowledge in order to find and remove the defect that appears.

It is necessary to consider the main malfunctions of chainsaws, find out what they are connected with, and also analyze the main steps to correct the breakdowns.

And the most important thing before starting repairs is to correctly identify the fault. And there may be several reasons for the inoperability of each element. Therefore, before you start disassembling the chainsaw, you need to try to find what is causing the refusal of work.

You know, a failure during operation of chainsaws can be caused by a malfunction of the motor or the appearance of breakdowns in its other components.

Motor malfunctions include:

- ignition fault;

- problems in the fuel supply system;

- piston malfunction as it is also called cylinder.

In other components, in most cases, malfunctions appear due to failures of the brake mechanism and lubrication system

, operation of the clutch, tires, etc.

It is necessary to consider both groups of defects so that you can, if necessary, find the cause of the breakdown on your own without contacting a repair shop.

Engine malfunctions

When operating the motor, in most cases the following disadvantages are observed:

- the engine does not start at all;

- starts, but immediately stalls;

- does not develop suitable power;

- works unstable.

To find the cause of the problem, it is necessary to analyze the probable preconditions all in order using the method of elimination. Let's go through this chain so that you know how to find a flaw in the chainsaw for which the design of its occurrence is intended.