Repair tools Shtil 180

To carry out a relatively high-quality repair of the Shtil MS 180 chainsaw yourself, you will need to have:

- air compressor (for cleaning the chainsaw and blowing out the main components and assemblies);

- a vacuum gauge is necessary to check the tightness of the crankcase and carburetor, as well as to identify defective seals;

- piston stopper to limit the stroke of the crankshaft;

- electronic tachometer in order to correctly adjust the chainsaw carburetor;

- T-key STIHL Torx 27 or equivalent;

- puller for crankshaft bearings.

Only if you have these tools, do-it-yourself repair of a Shtil 180 chainsaw can be done with sufficient quality.

The most common types of chainsaw malfunctions

The Shtil 180 chainsaw is operated in accordance with the instructions supplied with the tool. The user turns on the starting system after he is convinced of the presence of oil, gasoline, and makes sure that the chain tension is correct.

Work with the tool begins after it is securely fixed in your hands. If a failure of the tool is detected, it is necessary to determine what caused the malfunction of the Stihl chainsaw.

The reasons that caused to malfunction may be:

- the appearance of a leak in the oil system;

- formed breaks in the crankcase cord;

- carburetor malfunction;

- air entering the crankcase through the seals;

- worn condition of the worm gear in the oil pump;

- a spark does not appear at the ignition cross section;

- drive sprocket wear;

- violation of the integrity of the eye under the control lever.

To carry out independent repairs of a broken Stihl chainsaw, we use tools that are available to each consumer.

- screwdrivers;

- socket and wrenches;

- hexagons;

- a vacuum gauge used to determine defects in oil seals, carburetor, crankcase;

- an air compressor used for purging and cleaning components and assemblies;

- T-key STIHL Torx 27;

- a stopper that limits the stroke of the crankshaft;

- bearing puller.

How to Replace the Starter Cord

Quite often the starter cord needs to be replaced due to a break. Let's figure out how you can replace it without contacting a service center.

Removing the starter from the Shtil 180 chainsaw is quite simple, without even removing the handle block; to do this, you will need to unscrew the mounting screws and remove the covers of the oil and fuel tanks. Then, slightly lifting and turning the starter, remove it from its seat.

The starter cord is wound on a special drum, which is installed in the body of the part. To replace the cord, there is no need to remove the drum; just remove the broken cord and wind a new one.

After the cord is wound on the drum, it is necessary to pass it through the starter body and install the handle and secure it with the help of several knots made one after another. Next, the working stroke of the starter is checked, and if everything is in order, the part is installed in place.

A video showing how to replace the starter cord yourself can be viewed below. The master comments in detail on all stages of the replacement, starting from removing the starter and ending with installation.

Chainsaw starter device

The principle of operation of a starter for a chainsaw is as follows. A handle is installed in a groove in the housing, through which a cable is passed. If the handle is sharply raised, the cable is pulled out and engages the drum of the ratcheting mechanism, which transmits the movement to the drum with splines provided on the shaft. In this case, the crankshaft makes several revolutions, and the working mixture in the space between the piston and the cylinder head is compressed. Accordingly, when the handle is lowered, contact between the ratchet and the splines is lost and the shaft stops.

As engine volume increases, the required amount of fuel-air mixture required for its subsequent ignition also increases, so the number of pulls on the starting cable for high-power saws increases. Therefore, in order to speed up the return of the drum, involuntary return springs made of steel with high elastic properties are used.

Making it easier to start a chainsaw is done in the following ways:

How to install a spring on a chainsaw starter?

Fitting the starter spring into the correct groove is not an easy task even for an experienced user. First, the spring should be twisted to its previous diameter and installed in the cavity of the drum hub. The outer end of the spring is fixed by the limiting protrusion, and the outer end should be positioned opposite the hole in the lock using a screwdriver. Using a screwdriver, align the loop at the inner end of the spring with the hole, after which the disk is lowered. By rotating the disk, check whether the ratchet pawl is in place. Next, the ratchet itself is assembled.

After installing the spring, it is necessary to adjust its tension. To do this, a cable is inserted into a groove on the circumference, and a return spring is twisted around it. After removing the slack, it is better to wind the spring an additional few turns to ensure the required tension on the part.

How to set the ignition

You need to turn on the ignition on the chainsaw. Ignition adjustment is carried out as follows:

- unscrew the spark plug and evaluate its appearance;

- specify the distance between the magnets and the coil (up to 0.2 mm);

- check the spark.

Pouring a candle

If you notice that the spark plug on your STIHL chainsaw is flooding, then there may be a malfunction in the fuel system. The engine must run on a mixture of gasoline and oil. If the mixture is lean, then the power decreases, the cylinder overheats and the saw systems wear out. A wet spark plug on a STIHL chainsaw occurs due to an imbalance in the fuel mixture. Lack of air in the mixture prevents the emulsion from burning properly.

Using low-quality gasoline can cause engine wear.

Oiling of the spark plug also causes the use of oil for 4-stroke engines and wear of the pistons. If such a malfunction occurs, you need to remove the gas tank cap and adjust the fuel supply. The air intake should be in good condition. A clogged filter must be blown out with air, or better yet, replaced. How to clean the filters is described in the operating instructions for the chainsaw.

The quality of the mixture can be determined using a spark plug insulator. If a brown color appears on it, this means that the quality of the mixture is normal. White color or soot indicates a poor or over-enriched mixture.

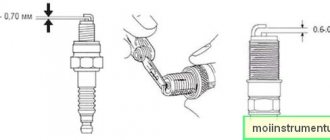

The cause of oiling is the candle. Interruptions in spark formation are observed when the gap is set incorrectly. The repair and operating instructions for the device give the distance between the spark plug contacts. If you do not have such data, then you can set 0.7-1 mm.

If the gap is smaller, then the efficiency of ignition of the mixture decreases; if it is larger, then interruptions in spark formation occur. To eliminate over-enrichment of the mixture, the engine is purged. In this case, you need to remove the spark plug and turn the crankshaft several times with a manual starter.

Replacing the piston

Let's look at how to diagnose and replace the piston group. It is necessary to check the condition of the cylinder and the degree of wear of the piston. After dismantling the engine, unscrew the pan and remove the crankshaft and piston from the cylinder. Unscrew the piston pin stoppers. If the piston is faulty, it must be replaced. The retaining rings are fixed with the cut down. Before installing the piston group into the cylinder, lubricate the piston with oil. Before installing the crankcase, degrease its surface and apply sealant.

Operational and technical characteristics

As for the technical and operational characteristics of this chainsaw, they are in many ways superior to all modern market analogues. Find out how to properly break in a chainsaw here.

The design of the Stihl 180 chainsaw is manufactured in such a way as to achieve maximum impressive results, without causing any discomfort during operation. The device is completely vibration-free and does not tire the operator’s hands.

STIHL MS 180

The handle that surrounds this tool sits tightly on 3 shock-absorbing blocks made of rubber, which is also very convenient for using a chainsaw.

Chainsaw Shtil ms 180 has the following specific characteristics:

- The maximum working volume is 31.8 cm³;

- Nominal weight is only 3900g;

- Power level is 1.5 kW / 2.0 hp;

- Tire 0.35 m long;

- Characteristic Oilomatic type chain with a pitch of 3/8 “P (PMC3);

- Tank with a volume of 250 cm³;

- Idle speed is 2800 rpm;

- Specific gravity – 2600 g/kW;

- The permissible vibration level is 6.6 to the left and 7.8 m/s2 to the right;

- Sound pressure is 97.0 dB;

- Sound power – 106.0 dB.

It is easy to operate and does not require additional maintenance other than timely lubrication (if you do not take care of the lubrication in time, it is quite possible to “kill” both the tire and the chain itself).

It is worth noting that the two-stroke engine of this unit is designed in such a way that it runs on a gasoline-oil mixture. It is necessary to add only high-quality oil to gasoline for STIHL chainsaws. You can read about which oil to use for a Stihl chainsaw here.

The quality of these operational elements will largely determine the impact on the operation and service life of the entire system.

Chainsaw Shtil 180 instructions provide for strict adherence to all rules of its operation

This is important for warranty repairs and also for extending the service life of the chainsaw. It is very important to use good chainsaw chain oil.

Operating principle of the oil supply pump

Before removing the chainsaw pump, it is important to understand on what principle it functions. The force generated on the drive is transferred to the plunger through a worm-type transmission (the force transmits rotational motion). The latter begins to spin, repeating a reciprocating motion.

This type of movement is guaranteed due to the specific shape of the plunger, the adjusting screw, its thrust spring and the eccentric. When the plunger begins to move back, oil enters the reservoir through a small hole (we also see this principle in a regular syringe).

The forward movement forces the oil out through the same hole. It is easy to guess that according to this principle, the unit works only due to the tightness created by the rubber cuff. May not be indicated on the working diagram.

In addition, according to this principle, the pump only works if two holes are not open at the same moment. To prevent this from happening, the developers provided a segmented cutout at the tip of one plunger. While moving backwards, it turns towards the inlet. This hole closes when forward movement occurs. At the same time, the outlet hole is open, because the cutout is turned towards the last hole. One rotation of the plunger occurs with one reciprocating movement.

At the same time, manufacturers of saw main units can change the stroke of the plunger, which requires an eccentric and an adjusting screw. The first is visually just a cylinder integrated into the adjustment screw housing. The main axis of this part will not coincide with the axis of the adjustment screw even when the screw rotates.

The cylinder will move closer and further away in relation to the ribs of the plunger. This is necessary to know in order to understand the essence of the work and functions of the eccentric. This type of displacement of this part is the reason why it came to be called a “cam”.

If the plunger gets as close to the cam as possible, the oil will not be able to be pumped. Otherwise, the plunger will move the oil to maximum (pump at full power).

Also be sure to look at the article about how the chainsaw chain lubrication system works. Information is also related to oil and its supply to working parts.

How does the plunger move?

Its movement is possible due to special processing of the end, which rests with a protrusion in the center against the eccentric. The edge of this end resembles a regular ring, surrounded by a protrusion located in the center. This ring is located at an angle, and not perpendicular to the axis of the plunger. Having formed a bevel, this part allows the plunger to protrude slightly.

In this case, the edge of the plunger and the adjustment screw are connected specifically. This makes it possible for the end to touch the screw during movement with different parts, protruding and not protruding. When the end touches the screw with the protruding part, the plunger rotates forward. And when the end touches the adjustment screw with the non-protruding part, a backward movement occurs. Reverse movement is possible thanks to a persistent spring.

Identifying Oil Pump Problems

If the operator knows how the booster pump works, he will be able to figure out how to remove the chainsaw pump. A minimum of plumbing skills and a minimum of tools are enough to do this and then repair the unit.

Please note that identifying the problem of the oil supply pump will allow you to understand what kind of component dismantling needs to be done, complete or partial. If you are afraid that you will not be able to cope with complete dismantling, contact a service workshop, where specialists will use their technical potential for this purpose. Of course, many parts that you can damage when dismantling a component can be replaced, but this replacement will cost you a pretty penny.

Please note that when the oil reservoir is full, but no oil is supplied to the saw set, the cause of this failure may not always relate to the oil pump. Sometimes, during the process of disassembling the saw, you will be able to detect a malfunction of other elements not related to this unit. Most often, replacing them solves the main problem.

In addition, before blaming the oil pump for all your troubles, check the oil filter, which, if heavily soiled, not only impairs the operation of the oil pump, but can also completely damage it. In order to check the oil filter, it is enough to hold a piece of paper over it, on which an oil streak will remain. The density of the latter will allow you to assess the condition of the filter and develop a plan for further action.

Important! Sometimes, after repairing the lubrication system, consumables do not flow to the saw set, then you need to look for the cause of the malfunction of the mechanism in the standard adjustments. This problem can also arise due to a mismatch between the viscosity index and the density index. On the other hand, the appearance of this problem through negligence or inattention can be caused by the operator installing an unsuitable guide on the power unit, for example, on an ordinary household guide or a guide from a professional powerful tool.

- How to Start a Stihl 180 Chainsaw

- How to Cut a Countertop at Home

- How to Clean the Carburetor of a Stihl 180 Chainsaw

- Which Circular Saw is Best for the Home

- Adjusting the Carburetor of a Stihl 250 Chainsaw with Your Own Hands

Repair of STIHL MS 180 chainsaw. No oil supply.

main reasons why not

Stihl

oil arrives .

Chainsaw fuel system: 1 – fuel filter, 4.5 – carburetor, 3 – manual preparatory pump.

If the carburetor is adjusted correctly, fuel will be consumed in the permissible amount. Otherwise, it will end very quickly.

Slowly reducing fuel during use of the saw is a common process. If it is missing, the chain is not lubricated correctly, so working with the chainsaw will be smooth. It is necessary not only to be able to eliminate breakdowns, but also to identify them without the help of others.

There is an option to change the fuel supply manually. The correct operation of the lubrication complex of accounting programs is determined by the method of applying the tire. If oil splashes appear, it means that all that remains for our client to do is set it up correctly.

Replacement oil pump Stihl one hundred and eighty

Diagnostics

Diagnostics should begin with inspecting and checking the oil receiver (filter) of the Stihl 180 saw. Typically, if the filter is very dirty, the oil supply may run out.

Next, you need to remove the drum sprocket and check the condition of the drive gear. The thread on it must be correctly expressed, not licked and not have any other flaws; also, with the gear removed, you need to check the wire lever. It must press the gear tightly and not turn; otherwise, the gear stands still and does not transmit force to the pump, as a result of which the oil supply stops.

If all the methods listed above to find and remove faults do not produce results, you need to use the last measures, i.e. dismantle the pump.

Features of disassembling and assembling a Stihl saw

Disassembling the Shtil saw involves several more nuances, one of which is the prohibited fixation of the flywheel from turning using screwdrivers, screws and other improvised means. This may cause its blades to break. Carry out fixation only in the manner indicated in the diagram. We talked about how to disassemble the Stihl 180, but there are also nuances of reassembling the chainsaw:

- We install a piston on the connecting rod, to the left of which is the side of the crankshaft where the flywheel will be;

- return the piston to the cylinder. Regarding elements such as a retaining ring, bearings or oil seals, we place them on the shaft and place them in the appropriate place in the cylinder;

- degrease the crankcase and its seating area, coat it with sealant and secure it with 4 screws.

These are the nuances of reassembling the engine itself, during which difficulties may arise (if you disassembled it), all other parts are assembled in the reverse order step by step. Don't forget to check the installation of the rod on the carb and the connection of the ignition wire. Also, all the nuances can be viewed on video. The KoshiKosa petrol tool store is pleased to offer all its knowledge to each of our readers and customers.

And also watch the video Disassembling the STIHL MS180 chainsaw

Good evening, I have the same problem. I saw a calm ms180c, I didn’t work much, the last time I sawed trees, the engine began to have interruptions. Then it stalled. what I didn’t do, 0, disassembled the blower, cleaned the carburetor, reassembled it, started up with half a turn, worked great, picked up speed, stalled, and again 0, replaced the spark plug. ignition coil, 0, disassembled carburetor, clean, blew, reassembled, started. and it worked again, the gas ran out, I poured a little, added gas, everything was 0 again, the spark plug was wet, there was a spark, tell me. I described how to solve this problem meticulously, so that it would be clearer, maybe someone has encountered this problem. Thanks in advance.

Hello, did you try it when you pulled the spark plug out? is there a spark? It happens that there is a spark and everything seems to be in order, but the saw still does not start. I actually had almost the same situation on another brand. It turned out there was no compression. I changed the seals and it seems to still be working (for the second year now). Another problem that happens is filters. did you change them? in general, a bunch, different answers every time, so as not to bother for a long time, try the service, if it’s too expensive, then...

Source: xl-info.ru

Practical recommendations

Lubrication hole layout.

Before you start using chainsaws, you need to check the lubrication system of the chainsaw chain. For this purpose, it is necessary to hold the end of the tire by placing a sheet of paper under it. When the speed increases, an oily strip should form on the sheet.

Proper lubrication of the chain greatly increases the life of the chainsaw headset. If there is not enough oil, the device will operate dry. The cutting set will quickly break. The friction of the parts should be minimal, so all guides and hinge joints should be covered with an oily film.

When the chain moves along the guide bar, the lubrication system must provide a constant flow of oil. This function is performed by the oil pump. With its help, the required amount of oil is supplied to the guide bar and its groove.

The driving links of the chain spread oil over the total length of the groove. A guarantee of proper chain lubrication is considered to be:

- fine tuning of the oil pump;

- completely filled oil tank;

- correct choice of oil.

Before starting work, it is necessary to constantly monitor the operation of the lubrication system. The correct supply of lubricant is determined by the sides of the chain; they must be lubricated at all times.

Basic parameters of a chainsaw chain.

The need for lubricants is always different. It all depends on what needs to be cut. When the length of the cut reaches large values, the tree has high hardness and thick bark, it is necessary to have a large supply of oil.

If the cutting set smokes or the chain stops, we can talk about a lot of heating. The main reason is lack of lubrication. Other reasons may be:

- dullness of the chain;

- strong tension.

Types of plunger pumps

Plunger pumps installed on modern chainsaws are:

Unregulated pumps are usually installed on household-grade tools, for example Yamamoto CS-4552, Husqvarna 135 Mark II, Kruger GCSK 35-45, Husqvarna 120 Mark II. Such units provide a stable supply of working fluid regardless of operating conditions. They have a simple but reliable design. Their disadvantages include the lack of adjustment of the supply of lubricant to the friction surfaces.

Adjustable pumps are installed on chainsaws of semi-professional and professional classes, such as powerful chainsaws from Energomash, American McCulloch, Procraft, Parma. They have a more complex design.

The adjustment function is necessary when the saw is operating under difficult operating conditions, when the amount of working fluid specified by the manufacturer is not enough to properly lubricate the saw set. In addition, it may be needed when the plunger is slightly worn, when the pump cannot provide enough oil to lubricate the bar and chain.

The photo shows 3 types of adjustable oil pumps

Oil supply system repair

If there is no oil supply to lubricate the chain, it is necessary to diagnose the entire system and determine the reason why the oil is not supplied. There may be several main reasons:

- Clogged oil filter or oil system;

- Missing thread on the oil pump worm gear;

- Blockage or malfunction of the pump itself;

- Depressurization of the oil system (there will be oil leaks on the bottom of the chainsaw).

To check the threads on the worm drive of the oil pump, you will need to remove the chainsaw drive sprocket and unscrew the clutch. To do this, the spark plug is unscrewed and a piston stopper is installed in its place, thereby ensuring reliable fixation of the tool’s crankshaft from turning.

Next, remove the cover from the side of the bar of the Shtil 180 chainsaw, and using a screwdriver, remove the retaining ring holding the drive sprocket, after which the sprocket itself is removed.

The clutch is untwisted using a 19mm socket and a wrench. It is necessary to unscrew the clutch clockwise, since the thread is left-handed. There is a reflective plate behind the clutch, this also needs to be removed. The next part is the worm drive of the oil pump. Having examined and discovered the absence of a plastic thread, you can safely throw out the part and install a new one in its place, since it is impossible to restore it. Assembling the Shtil 180 chainsaw is carried out in the reverse order.

If the gear is in normal condition, disassembling the saw continues; for this, the corkscrews are removed from the shock absorbers, the rear handle is untwisted and the throttle control rod is disconnected, after which the handle block is removed from the shock absorbers using a powerful slotted screwdriver.

It is necessary to remove the handles to provide access to the bottom where the oil pump is installed.

At the next stage, the oil hose coming from the oil tank is removed from its seat on the body and the line is checked for blockages by supplying air through the oil hose into the oil tank body. If a blockage is detected, it must be cleaned; if this is not possible, the faulty hose must be replaced.

Next, the oil pump is removed from the body of the Shtil 180 chainsaw and washed in gasoline.

After repair, we assemble the Stihl 180 chainsaw in the reverse order. An important point is to seal the oil hose at the installation site, into the seat on the housing. It is necessary to rinse the hose and the hole for its installation with gasoline, then blow with compressed air until completely dry and coat it with sealing oil-resistant sealant, and then install it in place.

Malfunctions of the pump and the system as a whole

As you know, nothing lasts forever in this world and everything has to be repaired over time. The oil system of the Shtil ms 180 is no exception, and has its own specific malfunctions. Let's take a closer look at them.

Signs of a malfunctioning lubrication system are as follows:

- the chainsaw chain is absolutely dry and does not shine;

- oil does not leave the oil tank;

- the chain stretches quickly and this happens constantly;

- the saw bar moves to the side when sawing;

- The tire also heats up in the area of the drive sprocket and the paint melts.

All these signs directly or indirectly indicate problems in the chainsaw chain lubrication system.

The first thing to do after you suspect that chain lubricating oil is not being supplied is to check its supply. There are two ways to do this. The first is described in detail in the instructions for the tool and consists in the fact that you need to start the chainsaw, increase the gas as much as possible and point it towards any obstacle.

If the lubrication system is working properly, the oil will fly off from the tip of the tire and a strip of oily drops will appear on the surface towards which the tire is pointed. If there are still violations in the system, the surface will remain clean.

The second way is to remove the tire from the chainsaw and start it. When the engine speed increases, oil will flow from the oil channel at the tire shank installation site; if this does not happen, it is necessary to look for the cause of the malfunction.

What kind of damage may occur?

Chainsaw malfunctions can be divided into groups:

- Engine malfunctions (ignition, exhaust and cylinder-piston systems, fuel supply).

- Failure of components such as the clutch, chain brake, lubrication system or tire.

Chainsaw engine failure is more common than others. Most of the time is spent on its detection and repair. As a rule, it comes down to such manifestations when the engine runs unstably or stalls altogether, the engine does not start, and does not develop power.

Before you start repairing your chainsaw, first check all the possible causes of problems in its functioning, or better yet, watch the video. Fortunately, today you can find any material of interest on the Internet.

Then you will have to prepare the necessary tools to repair the damage:

- device diagram (must be included in the delivery kit);

- keys, including spark plugs.

Ignition system malfunction

When the engine refuses to work, but there is a spark at the spark plug and fuel is flowing, you should check the ignition.

Checking it is not at all difficult: unscrew the spark plug, adjust the gap between the contacts, connect it to the wire and press it against the cylinder body. After this, watch for a spark to appear.

If any deviations occur, you need to adjust the ignition system. In general, this process is similar to adjusting the ignition in other two-stroke engines.

Main breakdowns of the Shtil chainsaw and repair stages

The most common faults you encounter:

- the saw does not start or constantly stalls both at idle and under load;

- there is a decrease in power;

- smoke is visible upon startup;

- the engine malfunctions and starts poorly;

- The motor runs but the chain does not rotate.

- No oil getting to the chain

To avoid premature failure:

- do not overload the equipment;

- use only high-quality gasoline and original engine oil in the correct proportion;

- timely filters, spark plugs and carry out maintenance at an authorized service center;

- do not saw with a chain with blunt teeth (we can either sharpen an old chain or buy a new one).

Stages of repairing a Shtil chainsaw:

- Before starting repairs, our technicians will perform a preliminary diagnosis of the Shtil chainsaw. This will allow you to accurately determine the source of the problem and decide on further actions. In this case, the client will receive complete information about the condition and reasons for the breakdown of his tool, as well as the cost of eliminating the fault. The diagnostic period when contacting our service center in St. Petersburg is only 1 day.

- Based on the testing results, damaged parts are restored or replaced. The client can choose original spare parts or their certified analogues, which will allow additional savings.

- After a Stihl saw has been restored, it is inspected in the presence of the customer. He makes payment and receives a guarantee for all work.

Do-it-yourself adjustment of the Shtil 180 chainsaw carburetor

Adjusting the Stihl MS 180 carburetor is necessary to ensure efficient operation of the saw when used at maximum speed, and to save fuel. To perform this procedure, you will need to clean the air and standard fuel filters.

The carburetor of the model can be adjusted using three standard screws. Screws L and H are needed to pre-set the air-fuel mixture ratio, which is regulated by different throttle valve positions. Screw S is responsible for fine-tuning the operation of the chainsaw at idle. The procedure for setting up the carburetor is as follows:

- First you need to start the tool and begin to alternately turn the screws H and L clockwise until it stops. Both screws will then need to be slowly turned 2 full turns in the opposite direction;

- After this, you need to find the maximum engine speed when the saw is idling. To do this, screw L should be turned alternately in different directions. In this case, the screws should not make creaking sounds. Once the base maximum speed has been found, you will need to slowly turn screw L a quarter turn counterclockwise;

Engine malfunctions

- the engine does not start;

- starts but stalls;

- works unstably;

- does not develop power, i.e. It runs fine at idle, but stalls under load.

When repairing a chainsaw with your own hands, you need to act by elimination - inspect alternately all the possible causes of a malfunction, starting with those that take the least time to check and eliminate (see here for information on the design and operation of a two-stroke engine).

Ignition system

. Almost all types of engine problems listed above can be caused by ignition system failures. Therefore, when they occur, it makes sense to start troubleshooting with a spark plug. replacement of the fuel hose for a Husqvarna 136 136 142 chainsaw, the hose of the pulse fuel filter was also replaced and adjusted. This is all the more justified since the state of the latter can provide useful information about the operation of the fuel system. So, if a problem occurs, you need to unscrew the spark plug and inspect it.

The wire is disconnected and the spark plug is unscrewed with a special wrench.

If the spark plug is dry, this means that the problem is most likely not in the ignition system, but in the fuel mixture not entering the cylinder. You can wrap the spark plug back and get to work on the fuel system. If the spark plug is heavily splashed with fuel mixture, it means there is an excess of it. This may occur due to carburetor misadjustment or violation of starting rules. The spark plug is wiped and dried, the cylinder is dried by turning off the fuel supply and operating the starter to ventilate the combustion chamber and remove excess fuel. Then install the spark plug in place and repeat the start.

The presence of a large amount of black carbon also indicates a malfunction in the fuel system.

The ratio between oil and gasoline in the mixture may be incorrect, the carburetor may not be adjusted, or low-quality oil may be used. Disassembly and replacement replacement of the fuel hose to replacement of the fuel hose on the chainsaw. The spark plug is washed in gasoline, cleaned of carbon deposits with a needle or awl, the electrodes are cleaned with fine sandpaper and replaced.

Removing and disassembling the engine

The engine is held in place by 4 screws installed on the bottom of the Shtil 180 chainsaw. To remove it, you need to unscrew them, and then carefully remove the engine from the seat and the rubber carburetor pipe.

To disassemble the engine, 4 crankcase screws are unscrewed and it is removed, then you can remove the crankshaft assembly with oil seals, bearings and piston rings.

Removing bearings and seals usually does not require additional tools, but if the bearings were pressed onto the shaft with force, then a special puller will be needed for dismantling.

To remove the piston from the connecting rod, you will need to remove the retaining ring from the seat using a thin screwdriver, then press out the piston pin from the opposite side, after which the piston is removed to the side.

Video: How to Replace the Piston on a Stihl 180 Chainsaw

The great thing about the CPG on the Stihl MS 180 is that it has two compression rings, while almost all of its main competitors only have one. According to the manufacturer, installing a pair of rings can better stabilize the piston during operation, increase its cooling and increase compression in the engine, thereby improving starting.

How to replace a piston with a Stihl 180 chainsaw

If you need to replace the old piston and install a new one, you need to know how to do it correctly and follow a certain algorithm. You also need to have a small slotted screwdriver, a special Stihl combination wrench, an electric screwdriver, a hammer, a soft drift, a compressor, and a Stihl piston stopper.

When replacing a piston or piston group, the chainsaw should be as clean as possible from contamination. Further work is carried out according to the following algorithm:

- The top cover is removed from the saw and the spark plug is lit.

- Remove the side cover.

- Using an electric screwdriver, the plugs are removed from the shock absorbers of the chainsaw, after which their handle is disconnected from the body.

- Next, remove the drive sprocket and starter.

- Install the piston stopper into the spark plug hole and loosen the flywheel retaining nut and clutch.

- Remove the flywheel, clutch gears and oil pump behind the clutch.

- Remove the two screws that secure the carburetor and air filter. Remove the filter, engine control lever and Stihl carburetor.

- Remove the ignition coil and muffler.

After completing all these operations, clean the file from dirt again, then turn it over and unscrew the four screws that secure the engine to the body of the chainsaw. After unscrewing the screws, the engine is separated from the housing and cleaned again.

With the engine removed, the pan is unwound and the pan is lifted, after which the piston and crankshaft assembly is removed from the engine.

When removing the piston from the cylinder, remember that it is located relative to the cylinder.

The piston pin snap rings are then removed with a small screwdriver and the crankshaft is disconnected from the piston.

In case you only need to replace the piston, you can install it on the crankshaft and then install the piston pin circlips, positioning them so that the circlip breaking point points downwards. This eliminates the possibility of the locking ring accidentally popping while the engine is running (according to the Stihl manufacturer's instructions). After this, the compression rings are installed, the cylinder is lubricated with engine oil and the engine is assembled.

Installation of the piston into the cylinder must be done as carefully as possible, since the clamping rings are fragile and easily break.

The crankcase is installed on the engine, sealant is used as a gasket, and then the four machine screws are attached and tightened in a crisscross pattern. Then the engine is installed on the chainsaw body. Subsequent assembly is performed using a reverse disassembly algorithm.

Why does my Stihl chainsaw not start after replacing the piston?

If the saw does not start after replacing the piston, it is necessary to check the fuel supply to the chamber and diagnose the ignition system. Very often, when installing the control lever on a chainsaw, craftsmen forget to connect the wires coming from the ignition coil, as a result of which the spark disappears and dust does not start.

The problem could also be hidden in a trapped fuel hose or if it's not connected at all. Of course, there could be many reasons, but you should remember that if all the work to replace the piston is done correctly, the tool should start and work normally without problems.

video

In the video you can see a detailed video tutorial in which the master showed in every detail how to properly disassemble the dust and install a new piston on it. You can also see in the video how to properly clean the saw during repairs.

Malfunctions of the chain lubrication system

Each instruction manual indicates the need to monitor the condition of the chain lubrication system.

Typically, system malfunctions occur due to clogged channels through which lubricant is supplied. If there is a slight oil leak, you can continue operation. But if the oil leaks are large enough, then you need to check the tightness of the connections of the tubes to the pump fittings. The leak can be eliminated using sealant or replacing the tubes.

You should also pay attention to the condition of the oil pump. If there are cracks in its body, replacement is necessary.

The oil pump repair video is shown below:

Device and circuit

The design of the Stihl 180 chainsaw (like the stihl ms 660 chainsaw) is quite complicated, and this is due to the peculiarities of the operation of this unit. In order to become familiar with the specifics of its operation, you need to study the operating instructions for the stihl ms 180 chainsaw.

Instructions for use

Here there is a selection of the schematic structure of a chainsaw, all the nuances regarding the component parts and the implementation of the first and subsequent launch are indicated. To keep the device in good condition and to be confident in its performance, you need to know the basics of its structure and the principle of operation. Also, for more efficient operation, it is necessary to adjust the chainsaw carburetor.

Serial equipment of the product consists of:

- Ematic type guide rail;

- Oilomatic saw chain;

- An adjustable oil pump that ensures even distribution of oil throughout the entire chain and guarantees excellent system operation;

- Carburetor with a special STIHL compensator that regulates optimal engine power;

- Air filter;

- Start lever (cold and hot);

- Control lever;

- Handle with a particularly anti-vibration system.

How to properly disassemble a Shtil chainsaw

Before directly disassembling the Stihl saw, a preparatory stage must follow. Prepare a comfortable table, dry rags, brushes for delicate wiping of parts, clean water, gloves and a dry place away from fire

It is also important to understand that there should be no fuel in the unit. It would be optimal to work it out rather than drain it and let the saw cool for several hours before disassembling it.

The procedure is simple and clear:

remove the chain, tire and side cover; using a compressor, if available, brushes, a dry sponge - clean Shtil from oil, dirt, dust, smudges, sawdust

Pay special attention to the drive sprocket - it may contain a lot of soot and dirt; if large accumulations of dirt are difficult to remove mechanically, then pure gasoline can be used; We look for three rubber shock absorbers and remove the handle. This can be done by removing the stubs

Using a strong screwdriver, first squeeze out the upper shock absorber, and then the one located at the rear handle; disassemble the back of the handle by unscrewing two screws. So we disconnect the rod from the gas trigger (it connects the carburetor and the gas trigger, which is in the handle); at the moment of fixing the handle only on the shock absorber - it’s as if we are turning out all the “insides” of the saw and twisting it to the side - we remove it from the last clamp like an elastic band; the starter is removed by dismantling the top housing cover and unscrewing the 4 screws on which it is attached. Next, remove the tank caps - fuel and oil. Under the starter there is often an accumulation of dirt and sawdust, which also needs to be cleaned; a 13mm head will help unscrew the flywheel. We block the crankshaft from turning by unscrewing the spark plug, namely through its hole we fix the piston stopper; if the piston is blocked, you can unscrew the flywheel nut; Before removing the clutch, disconnect the drive sprocket. The lock washer is removed from the grooves, as well as the needle bearing; disassembling the Shtil 180 chainsaw involves removing the clutch with a size 19 head. Next, remove the reflective plate and the oil pump drive; We disconnect the ignition wires and the air damper rod from the part called the engine lever, and remove the lever itself. Next, unscrew the nuts of the carb and air filter using a convenient 8-mm socket with an extension (if one is available); by unscrewing 2 nuts and pulling slightly towards yourself, you will remove the next part, the muffler; There are 4 screws in the bottom of the saw that hold the motor. When carefully removing it, do not forget about the rubber carburetor pipe, which can be touched.

Disassembling the engine of the unit is a separate diagram, but in general, we have looked at how to disassemble a Shtil chainsaw. Regarding other popular models, such as 250, the procedure should be carried out similarly. Like other parts, you can always order a file for sharpening chains at KosiKosa.

Principle of operation

Before identifying a malfunction and repairing the Shtil 180 chainsaw, you should study the principle of its operation and what structural elements it consists of. A chainsaw must contain its main element - a two-stroke engine. It is he who is responsible for the reliability and performance of the device. The engine is involved in starting the chain drive and maintaining its movement under the influence of the centrifugal clutch. In addition to the electric motor, the chainsaw includes:

- starter;

- flywheel, also known as a cooling unit;

- ignition unit;

- clutch and brake mechanism;

- carburetor with STIHL compensator;

- air filter;

- fuel and oil tank;

- muffler;

- anti-vibration system.

Fuel from the tank enters the carburetor, where it is mixed with air coming from the cleaning unit. From the carburetor, a mixture of air and fuel enters the engine. The saw carburetor has one adjustment screw that controls the idle speed. All device settings are made at the factory and ensure optimal supply of the fuel-air mixture.

The chainsaw uses a single-cylinder motor. A clutch is used as a protection mechanism, which allows the electric motor to switch to idle mode in the event of a chain jam. At the initial revolutions, special linings located in the radial direction are pressed by springs to the middle of the shaft, thereby preventing it from rotating. At high speeds, centrifugal force increases, which leads to compression of the springs. The linings are pressed away from the center of the shaft, the sprocket rotates and the chain starts.

The electrical circuit of the device is involved in the ignition system. Due to the use of a flywheel with magnets, an electromotive force (EMF) is generated during rotation, which leads to the appearance of current in the electronics unit. The block sends a signal to the spark plug, causing a spark to appear at its terminals. This spark ignites the mixture coming from the carburetor. After a successful start has occurred, the chainsaw begins to repeat all work processes in the cycle.

The device chain is made up of teeth and connecting elements. To protect the user from kickback, the device is equipped with a brake system. Oil supply occurs automatically under the action of a pump.

This is interesting: How to repair a chainsaw starter with your own hands: let’s look at it in order

Repair of STIHL MS 180 chainsaw. No oil supply.

the main reasons why stihl oil does not

180.

Chainsaw fuel system: 1 – fuel filter, 4.5 – carburetor, 3 – manual preparatory pump.

If the carburetor is adjusted correctly, fuel will be consumed in the permissible amount. Otherwise, it will end very quickly.

Slow reduction of fuel during operation

sawing is a common process. If it is missing, the chain is not lubricated correctly, so working with the chainsaw will be smooth. It is necessary not only to be able to eliminate breakdowns, but also to identify them without the help of others.

There is an option to change the fuel supply manually. The correct operation of the lubrication complex of accounting programs is determined by the method of applying the tire. If oil splashes appear, it means that all that remains for our client to do is set it up correctly.

Troubleshooting carburetor

If, as a result of pressure on the gas, the chainsaw begins to stall, then the problem lies in the carburetor. Also, a sign of a carburetor malfunction can be a prolonged start of the chainsaw and the inability to gain speed.

In most cases, such a malfunction appears as a result of wear of the rubber cuff, which is located on the fuel accelerator piston. As a result, when starting the tool, air leaks. Basically, such a breakdown appears after a couple of years of using the chainsaw.

Elimination of this malfunction is carried out in the following sequence:

- Remove the carburetor. Remove the screw that holds the cover with the membrane. Turn the carburetor so that the pin is visible. It is necessary to remove the retaining ring from it and disconnect the air damper spring. Then the throttle valve. To do this, you need to unscrew the screw that holds it. The next step is to remove the damper shaft.

- Pull out the accelerator with the spring. It has a cuff on it. Wear of this particular element leads to air leaks and the engine stopping after a recent start. The piston with cuff needs to be changed.

- Assemble the carburetor in reverse order and install it on the chainsaw.

Step-by-step disassembly of the carburetor

Now it’s clear how to fix common carburetor malfunctions. If you follow all the rules, you can simply do this work yourself.

Our next article will tell you how to repair the Partner 350 chainsaw.

Troubleshooting

If oil is supplied to the chain in excessive quantities, not only while the saw is running, but also at idle, manual adjustment should be made (if the pump design allows this possibility). This is done using a screw, which is located on the body near the guide bar, usually on the bottom or side. Tightening the screw reduces the oil supply, loosening it does the opposite. If the adjustment does not help, it is necessary to check the serviceability of the pump, and also inspect the tire - perhaps a gap has formed at the point where it connects to the body, through which oil flows past the chain.

Read also: Light bulbs in a circle in a suspended ceiling

Lack of oil can be caused by several reasons, each of which has its own solution:

- Oil pump malfunction. As a rule, it consists of an unsuitable gasket. In order to replace it, it is necessary to carefully disassemble the pump so as not to damage its moving parts. Next, a new gasket is installed, after which the pump is assembled and installed in place.

- Broken oil supply hose. If the pump gasket is in good condition, or if replacing it did not lead to results, you should check the tightness of the hose. If it is faulty, it needs to be replaced. Otherwise, it would be a good idea to clean it and seal it with sealant.

If the reason does not lie in a breakdown of the pump, it is necessary to inspect all conductive holes and channels for blockages, and, if necessary, clean them of foreign objects. This can be done with a jet of compressed air.

Don't want to tinker with a chainsaw but need to adjust the oil flow? Contact our specialists for help, who will diagnose and repair the chainsaw, and, if necessary, carry out repair work and adjust the lubrication level. Your saw will be like new!

Return to list

How to adjust the oil supply to a chainsaw chain?

Adjusting the oil supply level is necessary when operating the tool under difficult conditions. The supply level is controlled by a shaft with an eccentric mounted on it, which rests on the pump plunger.

Rotation of such a shaft displaces the plunger relative to the longitudinal axis. This allows you to increase or decrease the volume of the pump’s discharge chamber and quite accurately adjust the level of supply of the working fluid. To do this, at its lower end there is a groove with which adjustment is made.

As a rule, the screw is accessible from the bottom of the chainsaw. For example, in order to adjust the oil supply to the saw set of chainsaws of the Ural family, you must perform the following steps:

- At the bottom of the saw, next to the bar, find the adjusting screw. It is located next to the stamping, which shows the direction of its rotation;

- Use a screwdriver to turn the shaft in the direction of increasing or decreasing the oil supply level.

When performing these actions, remember that the shaft is designed to rotate up to 90⁰. Exerting too much force will lead to breakage of the screw retainers and possible interruption of oil supply to the friction surfaces.

Video instructions can be viewed by following the link

Repairing the Oil Pump of Chainsaw Shtil 180

The STIHL MS 180 chainsaw is an indispensable tool designed for harvesting wood and other wood construction work. It is one of the most recognized gardening devices that is armed with functional capabilities.

The weight of the tool is about 4 kg. The power reaches 1.5 kW, and the bus length is 35 cm.

How to Remove the StihlRead Trimmer Flex Shaft

Note that this saw model received electric ignition and a fairly fast chain tension from the semi-professional device. Additionally, the STIHL MS 180 saw has 4 tanks designed for gasoline and also for oil consistency.

One of the main features is reduced vibration.

This result is achieved thanks to 4 shock absorbers. It is no secret that high depreciation has a harmful effect on human health, and Europe has been fighting it for a long time.

It must be emphasized that it is not better to disassemble this saw without the help of others without special instructions; in solving this issue, it is better to entrust the device to specialists.

Owners of this tool model must be prepared to face such a nasty situation as a leak of oil to lubricate the chain. Oil can leak out while working with equipment and when simply lying idle.

What is the reason for this phenomenon? There is a possibility that oil leaks due to density problems in the area where the hose from the oil tank and the pump connects.

To be able to solve the STIHL MS 180 problem related to the oil supply, purposefully disassemble the device.

Solution to the problem:

- Check the hose; if it is damaged, replace it with another one. Or try to degrease the hose and wash it, and put it on sealant, our client should still earn money.

- Check the filter oil for damage, clean it (if you filled in waste oil)

- Also, perhaps the reason is a clogged priming, at the same time a vacuum appears in the fuel tank and affects the fuel supply. The problem is that the carburetor is adjusted better, and sometimes the channels are clogged, and in other words, the air filter, you need to carefully clean the filter and carburetor channels.

Product reserve

The Stihl MS 180 C-BE 16 40 cm chainsaw is an improved version of the Stihl MS 180 chainsaw - it has an ErgoStart ease-of-start system and lateral chain tension without the use of tools. The tool is suitable for collecting firewood, forming tree crowns, knots, erecting wooden structures, sawing tree trunks, as well as performing other simple household work. The Shtil chainsaw has high cutting capabilities, wide functionality and low weight. A high level of ergonomics ensures ease of use regardless of the complexity of the task. The device is equipped with a 16-inch tire (40 cm), providing the ability to work with trees with a diameter of up to 35 cm.

The STIHL MS 180 C-BE petrol saw has a modern vibration protection system. The anti-vibration system is located in the area of the saw handles and significantly dampens the vibration transmitted from the engine. The tool is equipped with a modern lubrication system that regulates the amount of lubricant supplied. The control button for cold and hot start, turning the tool on and off is represented by a separate lever. This makes handling the saw safe, since the operator's hand always remains on the handle.

Features and benefits of Stihl MS 180 C-BE 16 40 cm

- ErgoStart starting aid

- Side pressing of the chain without using a tool

- Light weight

- Convenience

- QuickStop chain brake

- Safety

- Quick chain tension

- Modern vibration protection system

- Modern lubrication system

Equipment

The QuickStop chain brake is a safety mechanism when working with chainsaws. The chain brake is activated by pressing the front palm rest and stops the saw chain in a matter of seconds. If the kickback is strong enough, the QuickStop chain brake engages automatically.

Strong vibration in the area of the handles can lead to chronic circulatory problems in the hands. That's why STIHL has developed a highly effective anti-vibration system (AS). For tools with AC, engine vibration transmitted to the handles is noticeably reduced.

The STIHL compensator - a regulating element in the carburetor - ensures almost constant engine power, exhaust quality and fuel consumption over a long period of time despite increasing contamination of the air filter. It is necessary to clean the air filter only when there is a noticeable drop in power. Long-term maintenance-free operation becomes possible.

The STIHL Ematic system consists of an Ematic guide bar, an Oilomatic saw chain and a variable-flow oil pump. The special design of the bar and chain ensures that every drop of oil reaches exactly where it is needed for lubrication. This allows you to reduce oil consumption by 50%.

The coil spring between the starter cable spool and the crankshaft compensates for peak forces, and now there is almost no shock felt on the cable. The result: STIHL ErgoStart reduces the force by half and the starting speed by approximately two-thirds compared to traditional jump starters.

Machine functions such as cold and hot start, operation and shutdown are controlled by a separate lever. This makes control especially convenient and safe, since the right palm remains on the handle.

The proprietary STIHL quick chain tensioning system (B) makes tensioning the saw chain child's play. You just need to loosen the nut securing the chain sprocket cover, and use the adjusting wheel to quickly and easily tighten the chain. No tool required for this.

If you find an error or inaccuracy in the text or product description, highlight it and press Shift+Enter.

Chainsaw carburetor malfunctions and repairs

All carburetors are cleaned the same way, the main thing is not to be afraid and not to lose anything. For repairs you will need to prepare:

Recent posts Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the soil

- any brush;

- Phillips screwdriver;

- head for 8;

- some gasoline.

First of all, using a brush, dirt and dust are cleaned. Then remove the lid and filter. The two air filter nuts are unscrewed and the air collector housing is removed. Now you can see the carburetor and the choke and accelerator rods. By lowering the throttle down with your finger, you will need to remove the accelerator lever.

To move the carburetor from its seat, you must first remove the choke lever and close it completely. Now you need to remove and pull the engine stop wire towards you. It is also necessary to remove the plastic lever on which the wire is attached. On the right it is inserted into the hole, and on the left it can be lifted.

The carburetor is freed and can be pulled out and cleaned. This is best done with a compressor, but if you don’t have one, the parts can be washed in clean gasoline.

Don’t forget about the fuel filter, which also needs to be removed and the fuel hose blown out. Everything is put together in reverse order.

If, after assembling the carburetor, the saw does not start well and smoke comes out of the muffler, then most likely the spring located under the needle lever has been lost. Due to the absence of this spring, the needle does not shut off the fuel supply, so the spark plug is “flooded” with gasoline. Of course, to fix this problem, you should find the spring and put it in place.

When repairing a carburetor, you should remember that it is a rather complex unit, which consists of various small rings and parts

Therefore, it is necessary to clean and repair it with special care and caution.

If the chainsaw does not start or stalls, then in addition to the carburetor itself, you should check the functionality of the spark plug. If it is faulty, it should be unscrewed and dried. Also, excess fuel must be drained from the spark plug through a special hole.

It must be remembered that drying must be done for at least thirty minutes, after which the candle is put in place and the tool is started.

The cause of the malfunction may be poor contact between the end of the spark plug and the high-voltage wire. If you don’t like the work of the candle at all, then it is better to replace it with a new one.

Parts of the Shtil 180 chainsaw, such as anti-vibration elements, chain, tire, and drive sprocket, wear out faster than others. Therefore, to quickly replace them, it is recommended to keep spare parts in the workshop.

Eliminating the causes of chainsaw malfunctions with your own hands will in any case cost less than repairing the tool in a service workshop. In order not to rack your brains over why the tool stopped working, you can watch video instructions for troubleshooting various breakdowns of the Shtil 180 chainsaw. However, in case of serious damage, it is better not to do the repairs yourself and entrust the work to a specialist.

Basic malfunctions and ways to eliminate them

The tool must be used in accordance with the instructions supplied with it. The start button should be turned on only after the chain tension and the presence of the fuel mixture and oil have been checked. Having secured the chainsaw securely in your hands, you can begin to work.

If the tool refuses to work, then first of all it is necessary to identify the cause of the malfunction. And the most common equipment for repairing a chainsaw is suitable: various screwdrivers, socket and wrenches, hexagons.

Chain oil leaking

Every tool owner will face this problem sooner or later. The cause of this malfunction is a violation of the tightness at the junction of the oil pump and the hose from the oil tank.

To fix this problem you will have to almost completely disassemble the chainsaw .

- If the hose is damaged, it is best to replace it with a new one. You can try filling it with sealant, after degreasing and washing it.

- Oil may leak due to a clogged or broken saw oil filter. It should be checked and cleaned or replaced.

If the chainsaw does not start

If you believe the experts, then in case of such a problem, the first thing you need to do is simply open and close the cap on the gas tank. After this, you need to ventilate the combustion chamber , and also remove and dry the spark plugs. These actions are often enough to get the tool started and working. If the malfunction remains, then the cause should be sought elsewhere.

- The fuel supply is affected by the breather. Therefore, if it becomes clogged, a vacuum forms in the fuel tank and the saw does not start. Repairing the breather is very simple - it should be cleaned with a needle.

- The Shtil 180 chainsaw may not work due to a broken cylinder. If there are chips or unevenness on the cylinder, then this is the reason.

- If the tool does not start, holds power for a short time, or stalls immediately after switching on, then the cause of the breakdown may be in the muffler. It may be clogged with any deposits that occur during operation during the exhaust process.

- The saw may not start well due to a faulty starter. To look at it, you should remove the cover from the carburetor and twist the special screen located behind the chainsaw drum. If the contact wire has come off the starter, it must be attached using a blowtorch. If the problem lies in an oil leak, then simply wipe the starter with a cloth.

The chainsaw engine runs intermittently

The cause of such a malfunction may be a breakdown of the cylinder-piston group , which can be easily repaired with your own hands.

To remove the cylinder from the tank, you need to unscrew the four bolts on its head. Then carefully check the piston, which should not have any burrs, scratches, or chips. If any are present, the piston will need to be replaced.

The optimal pressure in the combustion chamber is ensured by the piston and piston rings, which must fit fairly tightly on the piston body. If the piston inserted into the cylinder has free movement when rocking, this indicates its wear.

This defect can be eliminated by boring the cylinder and installing repair parts. However, the easiest way is to simply replace the entire set of CPGs.

Your main assistant should be the instruction manual. If you have lost it, you can contact the dealer of the company whose chainsaw you use; they will provide you with instructions in electronic form.

So, before each time you turn on a gasoline chain saw, be sure to check that the chain is in good condition, whether its teeth are sharpened, and whether it is well tensioned (does not sag, but is not too tight, it can be pulled a little away from the blade).

You can sharpen the chain using a special machine or a file with a special template (depending on the tooth pitch of the chain, there are different templates).

Every time after use, the chainsaw must be cleaned: the chain, bar, air filter, housing, cooling fins, cracks and other grooves are cleaned of sawdust. After using the saw, turn the bar over so that it wears evenly, lubricate the sprocket (if there are grooves for lubrication in the front of the saw).

During long-term storage, be sure to drain the fuel and oil! The chain and the bus form an electrochemical pair, so they rust together and must be stored separately.

Pump structure, lubrication system and principle of operation

The oil pump drive consists of two parts: a plastic gear with a worm gear and a wire lever that transmits force from the drum sprocket to the worm gear.

One of the main defects of the saw’s oil system is a defective thread on the plastic gear of the oil drive, therefore, no matter how hard it is, you need to keep its wear and the quality of the thread under control.

The lever is aggressively mounted to the gear and they are supplied as one piece. The tip of the wire arm has a corresponding bend, which is designed for the best grip on the sprocket drive drum. Repair of a stihl ms230 chainsaw, replacement with a Chinese one, replacement of an oil pump with. The drum has a special slot for installing the drive.

The Shtil 180 oil pump is one hundred percent made of metal and has a non-collapsible design. Replacing the starter cord disassembling the Stihl 180 chainsaw part 1 stihl ms260c recoil starter repair 2/2 how. On the pump body there is a receiving hole for oil and a groove-channel through which oil from the oil wire gets directly into the pump. The mechanism is installed in the body of the Stihl 180 chainsaw.

What does an oil pump consist of and how does it work?

The pump housing is located on the outside of the saw housing, under the centrifugal clutch drum of the gasoline saw. The drive mechanism of the oil pump is rigidly connected to the saw chain clutch. This means that the higher the engine speed, the more lubricant is supplied to the chain and chainsaw bar.

Unlike the plungers used on car pumps, the operating mechanism in chainsaws can be disassembled and reassembled without much effort. The pump body has two calibrated holes located opposite.

One hole is connected to the oil tank and serves to draw lubricant from the tank. The other communicates with the main line leading to the saw set. At the end of the plunger there is a longitudinal segmental groove to capture the working fluid.

Lubrication system malfunctions and how to fix them

The main malfunctions of the oil supply system on a chainsaw can be divided into two main types: these are general malfunctions inherent in all chainsaws and individual ones, which may vary depending on the type of pump and worm gear installed on a particular model. Let's begin to understand the faults in order.

Signs of a malfunction of the lubrication system, checking its performance

- The chainsaw chain is dry and has a pale tint without shine.

- The chain stretches relatively quickly.

- The tire is very hot and may even partially melt the paint.

- The oil from the tank is practically not reduced.

- Reduced cutting efficiency on a sharp chain

All these signs indicate that the lubrication process is not proceeding properly. In order to check the oil supply to the lubrication system, you need to remove the side tire of the chainsaw and start it. Next, you need to slightly increase the speed while observing the end of the oil line. If oil comes in, most likely the amount is not enough for normal lubrication and you need to clean or replace the filter and, if possible, adjust the flow. If it does not, the problem is more serious and requires further diagnosis.

There is a way to check the oil supply without removing the tires. To do this, you need to point the end of the bar towards, for example, a freshly cut piece of wood from the side of the cut and increase the speed as much as possible, while trying to keep the end of the bar at a distance of no more than 10 cm from the block. If oil spots begin to appear on its surface, it means the oil is being supplied.

Troubleshooting

Once it has been determined that oil is not being supplied, further diagnosis is only possible if the oil system is completely removed. Of course, in some situations replacing the filter helps, but this is very rare.

Most common faults

- Broken oil hose. It can sometimes be detected by visual inspection. The problem is solved by replacing the faulty part.

- There is no thread on the oil pump shaft; replacing it will help.

- A defective thread on the pump drive gear can be similarly solved by installing a new part.

- Lack of main shaft corkscrew (relevant for some instrument models, for example, Homelite). You can fix it by installing a nail of a suitable diameter instead of the original corkscrew, cutting it to the required length.

- Blockage in the line. Can be removed by blowing with compressed air or mechanically, using a wire of a suitable diameter.

- Filter element clogged.

- The Stihl MS 180 tool, whose pump is not dismountable, often gets clogged. You can try to wash it in clean gasoline, if that doesn’t help, replace it.

- In Chinese chainsaws (Gypsy), it very often cuts off the grooves on the main gear, through which the force from the sprocket is transmitted to it.

Individual malfunction of the Stihl MS 180 lubrication system

Due to the fact that the Stihl MS 180 is one of the most common models of chainsaws, I would like to dwell in more detail on one fault inherent only to it and describe a method for eliminating it without replacing parts.

Quite often, on the Shtil MS 180 chainsaw, depressurization of the oil line is observed in the place where the oil line coming from the tank is installed in the saw body. The malfunction can be determined by the characteristic lubricant leaks on the bottom of the tool.

To eliminate the problem, you need to remove the chainsaw handle, remove the hose from the mounting hole, clean and degrease. After all these manipulations, apply sealant to the hose seat and install it into the chainsaw body.

You can learn more about troubleshooting and complete diagnostics of the lubrication system of the Stihl chainsaw by watching a video that shows the step-by-step process of disassembling and repairing the lubrication system.

Actions if a malfunction is detected in various parts of the unit

Such unpleasant phenomena as loss of power, lack of connection, and idle support are common. The reasons for this behavior of the tool are malfunctions of the chainsaw carburetor. This is expressed in contamination with particles of dust and sawdust. Such a breakdown can be easily repaired on its own.

The carburetor is cleaned using:

- a small amount of gasoline;

- Phillips screwdriver;

- brushes;

- heads, size 8.

To begin repairing the carburetor, they begin by cleaning it from dirt and dust particles and small wood. A brush is used for this. When the surface is completely free of debris, the repairman removes the cover, and then the filter.

Diagnostics of the chain lubrication system of the Stihl MS180 chainsaw

Video about STIHL chainsaw

MS

180

for changing

pump

and pump oil.

STIHL MS180 oil pump and oil drive replacement

stihl 180 oil does not arrive

.

The air collector is released after unscrewing the air filter mounts. The user now has access to the accelerator and rods. The accelerator lever is removed as soon as the throttle is lowered by pressing down with your finger.

The carburetor moves away from its seat after the choke lever is removed and closed. Then the wire is removed and pulled towards itself to stop the engine. The plastic lever, which is the place where the wire is attached, is photographed.

It is raised from the left. As a result, the carburetor is freed, which makes it possible to pull it out and clean it. For these purposes, it is convenient to use a compressor. In its absence, the parts are washed in clean gasoline.

Disassembling a Stihl chainsaw - video

The saw carburetor assembly process is carried out in reverse order. If, after this process, smoke appears from the muffler and the saw engine does not start well, then you need to make sure that there is a spring located under the lever needle.

The spring cuts off the fuel supply. In its absence, a spontaneous “overflow” of fuel into the spark plug occurs. It is important to ensure that the spring is installed in its place and to ensure that the spark plug is working.

If a candle is filled with gasoline, it should be dried. To do this, the part is unscrewed and the excess fuel that gets inside is drained through the existing hole. The candle takes more than half an hour to dry. Then it is installed in place, and the chainsaw is brought into working condition.

Insufficient contact between the high-voltage wire and the end of the spark plug can also be one of the reasons for tool failure. stihl chainsaw parts can be done by replacing problematic parts.

For example, if a spark plug fails, it is replaced with a reliable one. Chains, sprockets, and tires are subject to rapid wear. They solve anti-vibration problems in the chainsaw device, so they are replaced urgently. It is recommended to keep such spare parts in stock.

Source: evdiral.ru

Divinol

This brand offers high quality chain lube that has good adhesive and lubrication properties, so that the lubrication is done efficiently and the hinges and chain loops are reliably protected from wear. The optimal combination of viscosity and temperature characteristics guarantees that this oil can be used at any time of the year and at any temperature.

Divinol offers various oils for chainsaws

What's the use of them? Zweitaktoel FF pays attention to economical consumption, connection to any fuel, prevention of aging of the fuel mixture and excellent corrosion protection. In addition, this oil can be used at any temperature.

Divinol Kettenol and Divinol Kettenol Bio can be used to lubricate chainsaws and chainsaws. With these connections, chain links and joints can be reliably protected from wear, while ensuring economical oil consumption. High-quality organic oils of this brand provide excellent lubricating and adhesive properties, so their use is not only simple, but also environmentally safe.

Replacing the fuel hose on a 3816 chainsaw

How to replace a fuel hose on a chainsaw

and what to do if oil leaks from a chainsaw? In this video we arrange.

Insufficient supply of the fuel mixture from the carburetor to the cylinder or a violation of the correct ratio between fuel and air mixed in the carburetor can occur for several reasons: due to a clogged air filter, unadjusted carburetor, clogged channels or filter mesh.

As a rule, repairing chainsaws is not complete without cleaning the air filter, since it gets dirty quite quickly. When this happens, the flow of air into the carburetor is reduced, and the fuel mixture leaving it becomes too rich, which disrupts the normal operation of the engine. replacing the fuel hose on a husqvarna 136 chainsaw - duration: does not start when cold. You need to carefully remove a dirty filter for cleaning so that dirt does not get into the carburetor. The filter should be cleaned or washed in water with some detergent, dried and installed back.

Carburetor misalignment can be corrected by adjusting it. Replacing the fuel hose on a Husqvarna chainsaw. This is usually done using three screws - maximum and minimum speed and the idle screw. Adjustment must be carried out in strict accordance with the instructions, failure to comply with which may lead to engine damage. Some saw manufacturers leave only one adjusting screw (idle speed) to prevent unwanted interference by inexperienced users with the operation of the carburetor. For an example of adjusting a chainsaw carburetor, see the article Working with a chainsaw.

If adjusting the carburetor does not help, you need to clean its channels and filter mesh, and at the same time check the integrity of the membrane. The carburetor is one of the most complex devices in a chainsaw, so you need to start disassembling and cleaning it with a full understanding of the responsibility of this operation. replacing the drive sprocket on a chainsaw; replacing the sprocket on a Chinese chainsaw. It consists of many small parts that have the ability to unnoticeably jump out of their places and get lost irretrievably, so that after disassembling this capricious device, you may not be able to reassemble it.

Below is a diagram of another chainsaw carburetor.

If you do not have experience and self-confidence, it is better to entrust the repair of a chainsaw carburetor to a service center specialist. Sometimes, to properly clean the carburetor, it is necessary to use ultrasonic cleaning.

Muffler

. Replacing replacing a fuel hose with replacing a fuel hose on a chainsaw. Often the cause of engine malfunction, especially when the engine runs normally at low speeds and stalls under load, is clogging of the muffler spark arrester with combustion products, which prevents normal exhaust. Repair in this case consists of removing the muffler, disassembling it (if it is dismountable) and wet cleaning it from carbon deposits using detergents. The non-removable muffler is dried with a hairdryer after washing. Remember that carbon deposits contain substances that are carcinogens, and dry cleaning, which could result in their inhalation, is unacceptable. When removing the muffler, plug the engine exhaust hole with a clean rag.

Chainsaw malfunctions and repairs

A chainsaw is not such a complicated device. But if a malfunction is detected, you need to have at least basic knowledge in order to find and remove the defect that has appeared.

Let's look at the main malfunctions of chainsaws, find out what they are connected with, and also look at the main steps to correct the breakdowns.

Replacing the sprocket

The most common cause of a malfunction in this element is jamming of the chain due to its misalignment or significant wear of the chainsaw sprocket itself.

If any signs of these deviations appear, it is necessary to carefully inspect the plane and teeth of the drive transmission element, paying attention to the depth of drift (it should not exceed 0.5 mm)