One of the main advantages of the 142nd model of the Swedish brand Husqvarna is the competent selection of its components and the high quality of the original assembly. The basis of the garden tool consists of a 2-stroke gasoline engine, the chrome-plated cylinder of which has a volume of 30 cm3. Starting a standard internal combustion engine is done by pulling the recoil starter cable. A proprietary Japanese Walbro brand carburetor with forged jets and an improved fuel injection system is responsible for preparing and enriching the fuel mixture with air in the internal combustion engine configuration. The manufacturer equipped the engine with a fuel and oil tank with a volume of 370 and 190 ml, respectively.

The Husqvarna 142 chainsaw is equipped with a durable clutch, which is responsible for the continuous connection of the engine with the saw set. All spare parts of the mechanism are made of durable steel, resistant to high temperatures and corrosion.

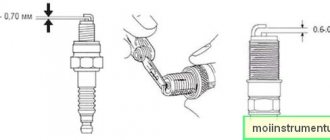

For instant ignition of fuel in the internal combustion engine cylinder of Husqvarna garden tools, a proprietary capacitor ignition system is used, which includes a Champion RCJ7Y spark plug. The distance between the flywheel and magneto electrodes in the operating state of the ignition system is 0.5 mm.

For sawing wood, the Husqvarna 142 chainsaw is equipped with a high-quality saw set made of wear-resistant alloy. It consists of a 38 cm long tire, as well as a chain with a pitch of 0.325". An oil pump operating in fully automatic mode is responsible for the continuous lubrication of the saw set. To allow chain adjustment without the use of hand tools, Husqvarna has provided easy access to the tensioner sprocket. The built-in inertia brake is responsible for the safe operation of the model, which is activated whenever the chain hits a wire, nail or any other solid object.

The Husqvarna 142 chainsaw stands out for its good balance and ergonomics. All switches and buttons necessary for operation are located at the rear of the instrument body. This simplifies the operation of the chainsaw in very limited space.

Structural Components

All engines, be it a car or another instrument using an internal combustion engine, have similar operating principles.

No exception, there are such famous chainsaws that are used with pleasure by consumers such as Goodluck, Shtil or Husqvarna.

The drive in them is the familiar internal combustion engine, respectively the fuel tank, the engine and the working element that directly performs the work, as well as other attachments that help with control.

Sometimes during operation some problems may arise with this fairly reliable tool like a chainsaw.

All engines, be it a car or another internal combustion engine tool, have similar operating principles.

It is no exception that there are such outstanding chainsaws and are used with pleasure by such consumers as Goodluck, Calm or Husqvarna.

Drive into them. This is all familiar, respectively, the fuel tank, the engine and the working part, which does the work itself, as well as other articulated parts that help with control.

Sometimes, during operation, some problems may arise in this fairly reliable tool, such as a chainsaw.

DIY carburetor repair

If, during a full diagnosis of the Husqvarna , carburetor defects were discovered, then some of them can be removed without calling the Husqvarna AB service center. For example, without the help of others you can:

- change the gaskets under the covers of the main chamber and fuel pump;

- clean or change the mesh filter;

- change the diaphragm or needle valve of the main chamber;

- remove faults in the fuel pump diaphragm.

The procedure for checking and adjusting the correct operation of the engine

The standard ignition system of a carburetor engine consists of:

- magneto;

- spark plugs;

- an electrical cable connecting them to each other;

- motor shutdown buttons.

Ignition circuit for the Ural chainsaw

A magneto is a type of alternator that supplies electricity to the spark plugs. Adjusting the carburetor on a chainsaw by adjusting the idle speed. First, you need to remove the carburetor on the chainsaw, and how to adjust the level of the intake carburetor. It consists of a stationary winding of an inductance coil and a permanent magnet mounted on a flywheel that rotates with the crankshaft of a gasoline engine.

For contact magnetos, the first terminal of the high-voltage winding is connected to the spark plug, and the second is connected to the ground through a mechanical switch. How to adjust the carburetor on a chainsaw, fuel consumption,. At a certain moment, a special design element separates the contacts, which leads to a sharp increase in voltage in the network and a spark in the interelectrode space of the spark plug.

To prevent overheating and oxidation of the breaker contacts, a capacitor is connected to the electrical circuit.

The most vulnerable element of a carburetor engine is the spark plug. How to adjust the carburetor on a Husqvarna chainsaw. It also allows us to judge the probable causes of malfunction of individual components of a gasoline engine. The following procedure is recommended.

- Remove the spark plug and inspect it. A dry spark plug with a slight brown tint to the electrodes can be considered serviceable.

A magneto is a type of alternator that supplies electricity to the spark plugs. It consists of a stationary winding of an inductance coil and a permanent magnet mounted on a flywheel that rotates with the crankshaft of a gasoline engine. The moving magnetic field creates an electromotive force in the low-voltage winding, which is converted by the transformer into a voltage with a potential sufficient to produce a spark.

For contact magnetos, the first terminal of the high-voltage winding is connected to the spark plug, and the second is connected to the ground through a mechanical switch. At a certain moment, a special design element separates the contacts, which leads to a sharp increase in voltage in the network and a spark in the interelectrode space of the spark plug.

Read:

The ignition circuit of a chainsaw with a contactless magneto is based on the operation of a control coil, which plays the role of a voltage regulator. The electronic unit also includes a diode, a capacitor and a thyristor that passes current with a voltage of a certain value. When it opens, the capacitor is intensively discharged, forming a current in the turns of the primary winding, which is induced into a high-voltage voltage, causing a breakdown on the spark plug installed in the cylinder. The electrical network operates in pulse mode in time with the rotation of the crankshaft and the translational movement of the cylinders.

The chainsaw does not start or does not start well. Reason and how to fix it.

Why the chainsaw won’t start. Reason. How to fix it.

The most vulnerable element of a carburetor engine is the spark plug. It also allows us to judge the probable causes of malfunction of individual components of a gasoline engine. The following procedure is recommended.

Read:

Carbon deposits on the spark plug

Chainsaw ignition coil

When installing a new electrical module on the engine, the magneto clearance should be adjusted. The optimal distance between the flywheel and the ignition coil is 0.2-0.4 mm for most chainsaws.

Currently reading: Do-it-yourself cultivator attachment for lawn mowers

Gap between magneto and flywheel

To be sure, it is recommended to carefully study the documentation for the purchased model and follow the manufacturer’s requirements.

With such a small gap, it will not be possible to use the available measuring tool for direct measurement. In practice, for the Husqvarna saw, a template is used in the form of a spacer, cut from a thin and flexible sheet material of the required thickness. It is clamped in the space between the flywheel and the coil when installing it, and then pulled out.

To avoid the need to adjust the ignition, operate the tool carefully, avoiding impacts. In particular, this applies to chainsaws with electronic chips in the ignition system, as they are very sensitive to mechanical damage.

Read:

- magneto;

- spark plugs;

- an electrical cable connecting them to each other;

- motor shutdown buttons.

Here are some common cases:

- The chain saw does not start;

- If so, it works intermittently;

- Insufficient power to operate properly.

Here are some common cases:

- The chainsaw does not start;

- If it starts, it works intermittently;

- Insufficient power to operate properly.

The carburetor serves to prepare a combustible mixture of gasoline and air in a proportion determined by the operator.

The proper functioning of the device depends on proper configuration and adjustment.

And for this you need to know the principles of operation of the Husqvarna chainsaw carburetor.

Its design consists of the following elements:

- housing with clamping bolts and a set of gaskets;

- fuel pump - a device that pumps a gasoline-oil mixture into the carburetor;

- diaphragm - designed to limit the flow of combustible mixture into the engine;

- float chamber - fuel is collected in it, the level is adjusted by a float, and as necessary, the mixture is supplied to the main chamber for mixing with air;

- main chamber - air passes through it, and fuel is injected there; the amount of mixture supplied to the engine is regulated by a throttle valve located here;

- diffuser - a narrowing section of the air supply tube at the point of fuel injection;

- needle valve - a device that regulates the fuel supply;

- jet - screws that regulate the flow of mixture at high and low speeds, as well as the idle screw.

Also in the carburetor design, in addition to the throttle, there is a damper located at the inlet of the air filter. It artificially reduces the air supply, making the mixture richer for easier starting of a cold engine.

The injector valve is responsible for injecting fuel into the main chamber, and it also prevents air from entering. When setting up the carburetor on a Husqvarna chainsaw, special attention should be paid to this valve, since its condition has a direct impact on the operation of the engine. If stored for a long time, the nozzle may stick. This will restrict the flow of fuel and prevent the engine from starting.

Also, due to prolonged use or due to a manufacturing defect, the valve may allow air into the main chamber. In this case, only replacing it will fix the problem.

The carburetor operates as follows: the air flow entering the diffuser is mixed with the injected fuel, and the resulting mixture is supplied to the engine. The amount of mixture is controlled by the throttle valve. The more mixture, the higher the engine speed.

In the event that the chainsaw does not develop speed or, on the contrary, operates at too high speeds, the carburetor can be adjusted without removing it.

But if the chainsaw does not start, the speed hangs at the same level or it works unstably. Adjusting the chainsaw carburetor will not change the situation. It must be removed for cleaning or replacing parts. You must proceed in the following order:

- After unscrewing the retaining fasteners, remove the upper casing of the saw.

- We remove the gasket and part of the air filter by unscrewing the bolts or snapping off the fasteners.

- There is a fuel hose on the right side of the carburetor. We remove it together with the air damper control rod.

- Remove the carburetor from the mounts holding it.

Disassembling the carburetor is carried out in accordance with the instructions supplied with the kit. When disassembling, take special care to place the parts on a previously prepared cloth. Due to its small dimensions, there is a risk of losing components during disassembly and washing.

All parts obtained in this way are washed in a special liquid, dried and wiped with a lint-free cloth.

Currently reading: The chainsaw leads to the side - All about the vegetable garden

Channels, tubes and jets are purged with compressed air, if possible, after having previously washed them in an ultrasonic bath.

After setting up, you need to start the chainsaw. Check stability at idle speed. In this case, the chain should not move. When you press the accelerator, the chainsaw should accelerate steadily and stop without delay.

At minimum and maximum speed levels, the Husqvarna 350 should operate stably, without any extraneous noise. There should be no sudden loss of power or shutdown during operation.

When adjustment is necessary

The need to adjust the carburetor of a chainsaw rarely arises. More often there are problems with the supply of fuel, air or wear of parts. But sometimes adjustment is still required:

- a running engine stalls after a few seconds, or does not start - the reason for this is that the mixture is too rich;

- excessive exhaust, high speeds, increased consumption - in this case, on the contrary, the mixture is too lean, i.e. there is not enough air;

- the speed remains at the same level after the operator reduces or increases it - the cause may be a stuck needle valve.

Factors leading to such changes may include the following:

- Strong vibration damages the protective cover, and the adjusting jets are unscrewed, changing the setting. In this case, it is possible to adjust the carburetor on the chainsaw.

- Wear of piston system elements. Adjusting the carburetor in such a situation may provide temporary relief. Replacement of worn components is recommended.

- Poor quality fuel, a faulty filter, or long-term storage can cause blockages. In this situation, the carburetor must be removed, washed with a special liquid or clean gasoline, reassembled and adjusted again.

It is best to start adjusting the operation of the saw by checking the jets, fuel and air supply. After this, proceed to dismantling the carburetor, and then to checking the piston system.

Features of the Husqvarna chainsaw

Despite the fact that ideal chainsaws have not been created and it is unlikely that anyone will succeed, this Swedish company strives to improve the design and increase the power of its models. The entire line of Husqvarna saws is characterized by pleasant improvements that significantly facilitate the work of its owner.

General view of the husqvarna chainsaw

These positive options include:

- use of the fuel “suction” button (primer) for the convenience of starting the internal combustion engine;

- automatic carburetor adjustment by Auto Tune system;

- chain tension mechanism located on the side;

- environmentally friendly and powerful X-Torg engine;

- vibration reduction system;

- a mechanism for forced lubrication of the chain through a hole in the driven sprocket;

- centrifugal air purification Air Injection, allowing you to change the filter less frequently;

- universal key for maintenance and repair.

Possible faults

If the saw won't start, the first thing to check is the spark, which is producing the spark that ignites the fuel in the cylinder. Start by removing the high voltage wire that the spark plug is connected to. Then remove the spark plug from the cylinder cover and check its condition. When used correctly, the candle should be dry and shallow on fine ceramics:

- If the spark plug is wet, problems with the carburetor occur. It is necessary to adjust and set the fuel level in it;

- The carbon on the spark plug walls is dark or black, indicating a problem with the piston group.

If you have not found an obvious cause of the malfunction here, the spark plug is dry, the light sediment continues to come from the opposite side. Since this is the end point of ignition of the working mixture. Now check if the spark plug ignites. This is the ignition system unit.

If the saw does not start, the first thing you need to check is the spark plug, which gives a spark, which ignites the fuel in the cylinder. Start by removing the high voltage wire that the spark plug is connected to. Then unscrew the spark plug itself from the cylinder cover and inspect its condition. When working properly, the candle should be dry and have small deposits on the ceramic of a light color:

- If the spark plug is wet, it means there are problems with the carburetor. It is necessary to adjust and set the fuel level in it;

- Soot on the walls of the spark plug is dark or black in color, indicating a malfunction in the piston group.

If you have not found any visible causes of the malfunction here, the spark plug is dry, the carbon deposits are light, continue to work backwards. Since this is the final point of ignition of the working mixture. Now check if the spark is getting to the spark plug. This is the ignition system unit.

Checking whether there is a spark will not be any particular problem; to do this, just take the high-voltage cable to which the spark plug is connected, bring it to the cylinder block, leaving a small gap between them, so that you can notice the spark slipping between them. Then we pull the starter cord and see if there is a spark and what color it is.

Now let's try to set the correct gap between the moving and fixed contacts. Ideally, it should be 0.2 mm. You can check it with a dipstick since it is not a deficiency.

This was a description of the malfunctions of the older generation of chainsaws. The new generation includes modern chainsaws Goodluck, Shtil and Husqvarna.

Modern systems

Modern systems are equipped with chips that regulate all of the above problems. A method for independently setting the ignition timing depending on engine speed and power transmitted to the cutting element. At the same time, fuel is saved significantly without sacrificing power. It also makes starting the saw much easier, regardless of weather conditions.

Currently reading: Which chainsaw is better and from which brand? Best Rating

In addition to everything read, a video is offered here for a complete overview of the material presented.

Ignition

The main one in this group of problems is the engine.

Ignition is one of the main elements affecting the trouble-free operation of the tool. Therefore, we will consider this block first.

Gone are the days when the ignition was controlled by a breaker with cams and moving contacts that supplied a spark to the spark plug.

It was not a very reliable system due to the many elements that affected the operation of the engine. If there were no visible faults, the chainsaw could simply stop starting. And we could observe a picture of constant tugging on the winding cord. Today, manufacturers have switched to contactless ignition systems.

They have fewer moving parts and no contacts that need to be reset periodically, which often fail. The coil used on a modern chainsaw will last until the end of your tool’s service life. The chainsaw has become much more reliable and easier to maintain.

How to understand that everything is done correctly

For this purpose, the design of the device provides 3 adjusting jets. The idle air adjustment screw (T) is located at the top of the carburetor. Below there is a pair of jets for adjusting the fuel supply at minimum (L) and maximum (H) speeds, left and right, respectively.

The procedure for adjusting the carburetor on a Husqvarna chainsaw is as follows:

- Warm up for 5 minutes.

- By turning screw L, we bring the engine to the highest speed in an unloaded state and return it back a quarter turn.

- Hold the gas button with one hand for 15 seconds. At this time, turn the jet H to the right until it stops and reaches maximum speed. Then we turn it back one and a half turns or until the “squealing” of the engine disappears.

- After releasing the gas, turn the idle speed screw (T) clockwise until the chain begins to move. After this, we rotate it in the opposite direction until the chain stops moving.

During the adjustment process, a situation may arise in which the chainsaw stalls. This could be due to the jets being too tight or the mixture being too rich or too lean.

If this happens, you need to tighten the minimum and maximum speed jets all the way. Then turn them back one and a half turns and try to start the saw.

If cleaning and adjusting the carburetor does not correct the existing problem, you need to check the spark plug and adjust the engine. You should act in the following order:

- The spark plug is unscrewed and a visual inspection is carried out. If it is dry with a slight brown soot, it can be considered in good condition.

- If traces of gasoline are found on the spark plug, the carburetor should be re-adjusted. This happens because it supplies excess fuel to the internal combustion engine, flooding it.

- If the spark plug looks normal, check the operation of the electrical equipment. First of all, the cable that supplies current to the spark plug. Its end is brought a short distance to the radiator grille of the cylinder and the starter is turned with a cord. There should be a spark. If it is not there, the cable is checked with a tester and replaced if necessary.

- If the cable is in good condition, test the ignition coil. If the inspection does not reveal singed or broken wires, the coil is run through a tester, comparing the data with the accompanying documentation. If deviations are detected, the block must be replaced with a similar one.

After replacing the coil unit, the gap in the magneto should be adjusted. The gap between the ignition coil and the flywheel should be from 0.2 to 0.4 mm. To set the gap, you need a set of feeler gauges or you can use foil of a suitable thickness. The probe is clamped between the coil and the flywheel at the time of installation, and then pulled out.