April 20, 2022 kmelectric equipment and faults

You can chamfer a board in a variety of ways. The most common of them are two: using manual and automatic tools. The negative side of using hand tools (various planes) is considered to be a high degree of injury risk, as well as a catastrophically low pace of work. Of course, automatic and semi-automatic milling cutters are ideal for these purposes.

On the website https://www.zaoportal.ru/product/view/111 you can purchase a professional chamfering machine. The main reason why home craftsmen avoid purchasing such equipment is the apparent difficulty of operation. In fact, setting up and using it for its intended purpose does not cause any difficulties even for a novice user.

Tool structure

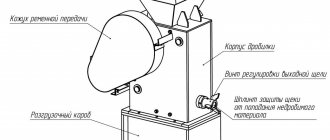

At first glance, the design of a power edging tool is similar to a manual router. A conventional electric spindle and sliding base make both tools very similar. However, these are different equipment, differing both in design, purpose and methods of performing work. An edging machine is usually smaller in size and designed to be held with one hand. Processing edges does not require deep cutting into the material, so the tool is equipped with a low-power electric motor. Another difference between a hand router and an edge router is the design of the base plate. The first tool features free vertical movement, allowing for varying milling depths. When processing edges, such a movement is not required. A cutter for working on the end almost always has a constant overhang. Therefore, the base plate of the edging machine is simple in design and is usually not equipped with additional mechanisms.

Manufacturers offer several targeted modifications of edging tools, with some differences in design. When working on drywall, it is recommended to use an edging router. It has the simplest base design and low engine power. The purpose of the machine also determined the small diameter of the cutters used. For work on installing door fittings, an edge-hinged router is positioned. This machine features a body with a bent handle, and resembles a classic drill. Milling cutters for processing PVC edges are included in a separate category. Their main feature is an additional handle, which is necessary when holding the equipment suspended.

Aligning the cutter at a given distance from the surface

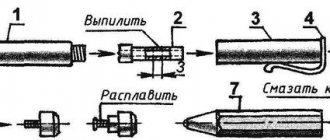

Initially, the cutter height adjustment head must be turned until it clicks. The depth regulator is pulled down 3 mm. Then it lowers onto the head. Thus, we obtain the “zero” position of the cutter.

Now, by rotating the height adjustment head, you can quickly and without much difficulty change the position of the cutter by 5, 10 mm.

The router guides should also be adjusted for correct chamfering. This is achieved quite simply - it is only important to tighten the nuts on the guides until the router slides along the surface being processed, as if on rails.

The following are recommendations for using a semi-automatic router:

Source

Application

Cutting, grinding, and drilling have become the main operations in the processing of wood, plastic and other soft materials. But achieving many tasks is impossible without milling work, which requires a special tool. The area of use of an edge router is clear from its name. With its help, work can be easily done along the edges of a flat workpiece. First of all, this is the implementation of chamfers and roundings. Using profile cutters you can obtain an edge of complex shape. An edging machine is indispensable when adjusting veneer to the size of the workpiece, for cutting grooves for installing hinges, locks and other fittings.

An edging tool can be used not only for edge processing, but also for milling work. To start cutting a groove or engraving, just install the appropriate cutter. If you do not require high productivity from this tool, then it can easily replace a vertical milling machine in a small workshop.

Wooden floors

When laying floors with wooden boards, you need to take into account many nuances. This includes the quality of the material, the degree of drying, and the conditions under which the surface will be used. While the first two questions can be easily determined in advance, the operating conditions of the floor cannot always be reliably predicted. In this case, a chamfer is used. What this is is explained above. It will not only make the floor look neater and more beautiful, but will also help to avoid visible gaps between the boards, which are sure to appear over time.

When working with solid wood, the question may arise: “How to make a chamfer?” Moreover, a woodworking machine is not entirely suitable for this. First of all, the material is sanded clean (this will be impossible to do later). For chamfering, use an edge cutter on a bearing. This allows you to achieve ideal quality of the processed surface even with slight curvature of the boards.

Popular models

Manufacturers offer a large number of wood edge routers to choose from in various configurations. Large brands are represented by such companies as Makita, DeWalt, Bosh. The most common Makita edging machines, the 37xx series, are high-quality tools positioned for occasional use. The 440 or 550 W motor with a rotation speed of 35,000 rpm allows processing with cutting depths of up to 40 mm. Among the shortcomings, it should be noted the all-plastic construction of the body and sole parts, as well as the only collet with a diameter of 6 mm. The DeWalt catalog contains similar Trimmer models DWE6005. Its special feature was the presence of a spindle speed controller. The Bosh product line is limited to the professional model GKF600. The advantages of this model include a 600 W electric motor, a metal base and 6 and 8 mm collets. Domestic manufacturers did not stand aside either. For example, Interskol offers the FM30/430 edge-loop router. The low engine power is compensated by a comfortable handle. Such a tool will easily find its place in the home workshop.

Cutting pipes is a weak point when installing pipelines

According to GOST 16037-80 (Welded joints of steel pipelines), a certain technology must be followed during welding. The chamfer shape is selected based on the diameter and wall thickness of the pipe and welding equipment. For example, when the pipe wall thickness is 4 mm and above, a V-shaped cutting of edges with a bevel angle of 30-35° is used.

To understand how the shortcomings of various pipe cutting methods manifest themselves, let’s put ourselves in the place of an installer and reproduce the entire process of repairing and laying a pipeline.

Of all the above actions, workers spend the most time preparing the edge of the pipe - chamfering.

Quite often, pipe ends are processed at the pipeline laying site, and not in workshops or workshops, and unsuitable tools are used for this, for example, hand-held power tools. This is a very labor-intensive, dirty and noisy method, in which the cleanliness and chamfer angle leave much to be desired.

Let's look at the tools that help deal with this problem.

Choosing an edge router

Unlike many other tools, an important criterion when choosing an edge router will be ease of use. Given the specific nature of operations performed with one hand, characteristics such as weight and ergonomics come to the fore. Engine parameters play a secondary role. A powerful, but not convenient router will negatively affect the result.

It is recommended to choose a professional model if the tool will be used constantly. For irregular use, the simplest models are quite suitable. For home use, an edge-loop router would be a good option.

Among the additional equipment, you should pay attention to the stops and clamps used in specific types of work. In some cases, a rotating sole for milling at an angle will be in demand.

The equipment for the edge router is represented only by a variety of cutters. You should choose models with a shank with a diameter of 6 mm. Other options cannot be installed in most routers.

What it is

A chamfer is the beveled, rolled edges of a parquet board. They highlight the seam between adjacent boards, emphasize it, giving the surface a voluminous appearance.

Note! The chamfers give the three-layer parquet board the appearance of a more expensive material - solid parquet. This tendency to style cheap materials as expensive ones is in demand, because the building materials market, as we know, is formed by buyers.

There are several types of chamfers based on shape and depth:

- Microchamfer (depth 0.5 - 1 millimeter);

- V – shaped, about 2 mm deep;

- Deep (from 3 mm) rolled, with rounding;

- Deep (from 3 mm) V – shaped;

- Deep planed.

The chamfer can be two- or four-sided. In the first case, it is removed only on the side edges of the board, in the second - from all four sides.

Useful: the double-sided chamfer highlights the longitudinal seams. They, in turn, visually lengthen the floor of the room, making it look like a corridor. If wooden parquet is being installed in an already elongated room, the obvious instruction is to prefer a flooring with seams highlighted on all four sides.

This flooring will make the room more elongated in length.

Pros and cons

Let's compare two types of parquet boards based on their main consumer characteristics.

| Characteristic | With chamfer | Board without chamfer |

| Price | 2 – 7 thousand rubles | 2 – 7 thousand rubles |

| Seam visibility | Always | When the linear dimensions of wood change due to humidity fluctuations |

| Contamination of seams | Always | When expanding |

It would seem that an objective comparison is not in favor of the board, which has so rapidly supplanted competing solutions. Marked seams are noticeable and, contrary to the claims of numerous sellers, accumulate dirt. Perhaps we are missing something?

Advantages

The main advantage of chamfered material in the eyes of buyers is, of course, its more attractive, solid appearance.

However, the list of advantages is not limited to them.

How to choose?

When choosing a cutter, you first need to decide on the type of cutting base, the shape of the blade, the presence of a bearing and other design features.

That is why it is important to understand in advance what types of work a tool is needed for, what the scope of work is, and how hard the material will be processed. Be sure to ask the seller for a certificate of compliance with GOST requirements, since these days the market is flooded with cheap fakes from Southeast Asian countries

They are characterized by low processing quality and a short period of use. If you are denied documents, make your purchase elsewhere. The supply on the market these days is so great that finding a sample that meets your requirements will not be difficult.

In general, the choice is usually made according to the following scheme:

- for rough grinding - face and end mills;

- for finishing planar processing - cylindrical;

- for forming grooves – disk, end;

- for processing corners and edges - angular, curly;

- for selecting keyed recesses - keyed;

- for cutting through grooves – T-shaped, curly.

Why do you need a milling machine?

What can be done with a router? This question often interests people who first learned about a wood processing machine. Milling equipment makes it possible to cope with a wide range of tasks. Machines will be needed not only by owners of large enterprises, but also by those who like to work with wood in their free time.

Milling cutters are widely used in:

- furniture and door production (cutting material, trimming, drilling holes, making grooves for edges, engraving);

- making plinths, balusters (applying various patterns on wood, making complex ornaments);

- production of bas-reliefs, high reliefs (removing the top layer from wooden blanks, thanks to the immersion of the cutter to different depths, a pattern is formed that will protrude above the main surface);

- souvenir production (figurines and wooden structures, engraving of images).

DeWALT DWE 6005

The model is entirely made of polycarbonate, and the cost is comparable to Bosch (RUB 14,000). A proprietary DeWALT adjustment system is provided, where the cutter itself is placed on the base, and it rises and falls along a spiral groove. In this type of work, the location of the power cord is not thought out, which can get into the most inconvenient place.

Users often choose this model for a number of advantages:

- low noise level - up to 77 dB;

- quite powerful motor of 600 W;

- productivity – 34 thousand rpm;

- comfortable grip.

However, the high cost and small cutting depth (up to 2.2 cm) often becomes the reason for purchasing a more modern model.