People who deal with welding not at work, but at dachas, in private homes, etc., know how important the quality of the welding electrode is. Of course, with the advent of inverters, welding has become better and easier, but practice shows that a lot depends on the electrode: the amount of slag, the quality of the seam, the quick ignition of the consumable.

Today there are no problems with purchasing these elements - the market offers a huge assortment.

Various models from different manufacturers. Professionals prefer branded products, whose cost is higher than that of ordinary ones.

Good, for example, are the products of the Swedish company ESAB , which produces high-quality electrodes of the same name. The Swedish products are truly excellent rods, although the price is appropriate. Due to the latter circumstance, not every home craftsman will afford to buy an electrode of this brand.

Similar in technical terms. According to the characteristics, consumables today are produced by the Ukrainian "Plasmo Tek" - these are "Monolit RC" electrodes corresponding to the ESAB KO 46.00 brand. Their quality is lower, and the rods are also worse in certain positions related to the welding process, but the affordable price makes the products attractive.

Electrodes Monolith RC

Electrode brand Monolit RC E46 is intended for manual welding in domestic and industrial conditions. Used for critical structures made of low-carbon steels using alternating and direct current. Electrodes can be used for installation welding. Work is carried out from all spatial positions.

Figure 1 — Electrodes Monolith

Monolith electrodes marked RC have a rutile cellulose coating. For the RC brand, the deposition coefficient is 9.5 g/Ah, and the consumption parameter is 1.75 kg. You can weld walls 3–20 mm thick with butt, corner and overlap joints. Consumables of this type can be used with household inverters and professional equipment.

When welding in the lower position, craftsmen advise holding the rod at an angle of 20–40°. Weld vertical seams with a short arc with the electrode tilted relative to the vertical at 40–70°, so that the slag will not flow in front of the arc.

Distinctive characteristics

In Monolit RC electrodes, it was possible to reduce the volume of harmful emissions by 28%. They can operate at the lowest currents from a household network. They are simple and easy to carry out welding work, so they are recommended for novice welders.

Positive characteristics:

- always stable and even arc;

- the seam turns out beautiful, with a uniform filling;

- easy ignition at the beginning and during operation;

- low metal spatter rate;

- the resulting slag is separated without much effort;

- when welding in hard-to-reach places, it is possible to bend the rod without compromising the quality of the seam;

- connecting non-critical parts does not require careful preparation;

- Traces of grease, oil, oxides, rust and other contaminants are allowed on the edges.

In conditions of high humidity, before welding, the rods are dried for half an hour at t = 110 °C.

Analogues are ESAB OK 46.00, Overcord, AV-31.

Specifications

The main technical characteristics are welding polarity and type of current. Monolith rods can be used with both direct and alternating current . The polarity can be direct or reverse. With reverse polarity, “-” is applied to the part, and “+” is applied to the electrode. The minus and plus poles are indicated on the welding inverter; they are connected to the part and the rod by wires.

It is important that when welding with electrodes, you can weld in different positions. Using Monolith this can be done without any problems. But the Ø5mm rod cannot be used from top to bottom. An experienced welder will understand what we are talking about. It is important to be able to weld metal structures and workpieces in different positions. It is better to weld from top to bottom with a “Monolith” with a short arc, that is, with a minimum distance between the weld pool and the end of the rod. To ensure maximum quality of the vertical seam, the welding rod must be held at 40−70°. In the lower position, the angle should be 20−40°.

Monolith Professional

Electrodes Monolit Professional E50 are used for manual arc welding of products made of ordinary quality and low-alloy steel. They allow you to work under unfavorable conditions due to the formation of a gas bubble, which neutralizes moisture and creates the environment necessary for welding.

Figure 2 — Electrodes Monolith Professional

Therefore, they are successfully used for restoring water mains under pressure up to 1 atm and welding tanks, in shipbuilding, and for parts for general engineering purposes. The seam provides high mechanical characteristics.

Available in diameters of 2.5, 3, 4 and 5 mm. There are two standard sizes in length: 350 and 450 mm. They can be used to make corner and butt welds, as well as lap joints. The limitation on the thickness of the metal being connected is 1–20 mm.

Analogs are ESAB OK 43.32, Overcord S, Fincord, Lincoin Electric MGM-50K.

Specifications

The deposition coefficient is 8–9 g/Ah. For surfacing 1 kg of metal, 1.7 kg of consumables will be required. Rods with a cross-section of 2–4 mm allow you to work in all positions except vertical in the direction from top to bottom. To do this, take rods with a diameter of 5 mm.

| Electrode diameter, mm | 2,5 | 3 | 4 | 5 |

| Welding current, A | 50–100 | 60–120 | 120–190 | 240 |

For welding work, direct current of direct and reverse polarity is required. You can also use alternating current at an open circuit voltage of 50 V. Subject to storage conditions, they do not require calcination. Damp electrodes need to be dried at 110 °C for an hour.

Welding electrodes Monolith Basic (Uoni-13/55)

Electrodes Monolit BASIC (UONI-13/55) are needed for connecting critical structures and pipes in places where increased resistance to the formation of hot cracks in joints is required, and the seams must meet high parameters of ductility and impact strength. They are used in shipbuilding, bridge construction and in the manufacture of high pressure vessels.

Figure 3 — Welding electrodes Monolith Basic (Uoni-13/55)

They have a basic coating with the addition of iron powder, which increases the efficiency of use by 20%. In application, they are characterized by a higher deposition rate - 10.5–11.5 g/Ah and reduced consumption - 1.58 kg. The finished seam has high strength and metallurgical purity, where the hydrogen admixture is minimal. Metal transfer occurs in a fine-droplet manner, which allows you to lay an even seam without slag getting into the weld pool.

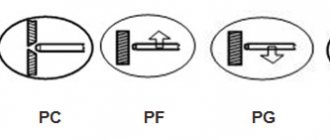

What kind of coverage is needed?

There are four main types of coating, each of which has its own distinctive properties.

1. Acid coating is mainly composed of iron, manganese, silicon and other chemical elements. Electrodes with this type of coating are marked with the letter “A”. Advantages of acid-coated consumables: high resistance to the appearance of air channels in the welded joint; the ability to process rusty products and parts with scale. The main disadvantage is the risk of hot cracks appearing in the weld metal.

2. Electrical conductors with cellulose coating are designated by the letter “C”. A special feature is the high content of organic substances (mass fraction can reach 50%): cellulose, organic resins, ferropalms, etc. When burned in an arc, this type of coating releases a large amount of protective gases and a small amount of slag. This guarantees the convenience of welding work in a vertical position. Disadvantages : high hydrogen content when working with steel can negatively affect the characteristics of the deposited metal; significant amount of splashes.

3. Rutile electrodes are marked with the letter “P”. The basis of the coating is rutile, as well as some silicon and oxygen content. This type is characterized by quiet melting, a small amount of spatter, easy slag separation, and the seam has a fine pattern. An important feature is the ease of re-ignition of the arc. Welding work should be carried out in conditions of normal humidity and after calcination of the materials, otherwise the quality of the connection deteriorates and signs of oxidation appear.

4. The main coating of the electrodes is designated by the letter “B” and consists of magnesium and calcium carbonates. Conductors with this type of coating are designed to operate on direct current, as well as for connecting critical structures and pipelines. The deposited metal has an increased level of ductility and is not prone to oxidation. The main advantage is that the low saturation of this type of coating with hydrogen eliminates the deterioration of the characteristics of steel and other metals. The main disadvantage is the formation of a large amount of slag.

Monolith OZL-6

Monolit OZL-6 electrodes are intended for welding austenitic stainless steels (08Х18Н10, 03Х18Н11), heat-resistant stainless steel (AISI 309, AISI 309S and 20X23H13, 08X23H13).

Scope of application: tanks and containers for liquid and bulk substances, equipment for the food and pharmaceutical industries, in the chemical or mining industries.

The OZL-6 grade is characterized by good weld quality, resistance to cracking and intercrystalline corrosion. During welding, the metal hardly spatters, and the slag layer quickly separates.

Advantages

Monolit has a number of advantages over other brands of electrodes that are often used during the welding process at home. The products were appreciated by both professional welders and amateurs.

This is what we are talking about:

Thanks to its characteristics, “Monolith” allows even a beginner in welding to easily perform welding. The rod does not stick, it welds easily, and there is practically no metal spatter, and the seam is of high quality. Monolith RC electrodes are universal. Can be used at home or in industrial production, and are suitable for any type of welding.

Monolith Special TsL-11

Special TsL-11 electrodes provide welding of critical products made of chromium-nickel and corrosion-resistant steels (12Х18Н10Т, 12Х18Н9Т, 08Х18Н12Т) used in aggressive conditions. The welding conditions are characterized by stability and high quality of the seam. Subsequent mechanical processing of welded parts is allowed.

They are used in the production of equipment for aggressive environments and high temperatures in the food and chemical industries. The weld is characterized by resistance to corrosion and intercrystalline cracks. Sandvik wire and coating with a low content of gases and harmful impurities are used as a base.

Specifications

The deposition rate of this brand is 11 g/Ah. It will take 1.7 kg of rods to fuse 1 kg of metal. Productivity parameter – 1.5 kg/hour. For calcination within an hour after moistening, a temperature of 200 °C is required. For electrodes Ø3 mm, the current is set to 50–90 A, for Ø4 mm – 110–150 A.

Preparation of edges before welding involves thorough cleaning of all types of contaminants. It is recommended to cook with a short arc and narrow rolls, excluding transverse vibrations. TsL-11 electrodes with a cross section of up to 4 mm operate with direct current of reverse polarity. Welding work is performed in all positions of the electrode, except vertical.

Other characteristics

Inexperienced welders often set the wrong current strength on the inverter in accordance with the diameter of the electrode used. Such flaws always have a negative impact on the quality of the weld and the connection itself. Therefore, it is extremely important to correlate the indicators correctly.

Experts say that the consumption of rods of the described brand is insignificant. The diameter of the product is 3 mm. Relative elongation at 22%. Sensitivity to contamination is low. High deposition rate. Rods of this brand can be used for working with pipelines.

“Monolith RC” is sold in 1 kg packs, and the average price is 340 rubles.

Reviews from welders

According to reviews from welders, Monolith electrodes are the best choice for those who are just trying to weld. They consistently catch the arc and produce an excellent seam. It is noted that they absorb less moisture than products from other manufacturers. Reducing toxicity is an important factor when working indoors. You won't have to breathe harmful gases.

Monolith electrodes are pliable in the welder’s hand. They light up immediately: just swipe across the metal and get a spark. With full coverage and the required modes, there is no sticking. With strong pressure, the materials of the two parts fuse, which makes the seam strong.

Novice welders complain that the arc is interrupted, after which it is difficult to restore it. But it’s not the electrodes that are to blame here, but the lack of experience and too high a current. Welding professionals and self-taught people note that Monolith products are a reasonable price-quality ratio. We will be glad to hear the opinion of our readers, as well as discuss it in the comments to this article.

general information

SZSE is a manufacturer of welding equipment. It is located on the territory of the Republic of Belarus, in the city of Svetlogorsk. For more than ten years, this plant has been producing parts for welders.

These years have experimentally proven that the materials produced here are reliable.

The Svetlogorsk plant produces electrodes under several brand names. Among them are the trademarks Monolit, Arsenal and, of course, Continent electrodes.

For a long time, under the Continent brand, the MP-3 electrode model, suitable for household welding, has been produced. The rods of this model have a rutile coating.

It ensures ease of ignition and stability of the arc during operation. This characteristic is important for novice craftsmen who do not have the experience to properly ignite an arc.

SZSE produces consumable and non-consumable electrode models. However, that's not all. There is a lot more in the assortment in Svetlogorsk.