Slotting machines (Fig. 1) are designed for mechanical processing of metals by cutting using special cutters. This group of machines is highly specialized due to the limited operations that can be performed on standard equipment.

Figure 1. Slotting machine.

Figure 1. Slotting machine.

Design and principle of operation

The slotting machine consists of the following structural elements:

- a movable block with clamps for the workpiece;

- frames;

- electric motor;

- chisels.

The electric motor of the machine is pendulum. It provides vertical reciprocating movement of the bit.

A slotting machine should not be confused with a milling machine. The latter can also cut grooves. But he does this according to a different principle - the cutting elements rotate, and do not move from top to bottom and back.

The workpiece is placed in a block with clamps, the chisel is placed at the beginning of the future groove. The unit is started. The chisel is lowered and strikes the wood, gouging out a groove. When the hole is completely cut, the block with the workpiece is moved. The bit begins processing the next area. The workpiece is moved until the groove is completely hollowed out.

Where is it used?

Slotting machines are used for carpentry work. They are most suitable for processing wood when creating furniture products. After all, with the help of the unit you can quickly create an even rectangular groove for assembling an object.

Rating of the best models

Let's look at several current models of slotting machines available on the Russian market.

JET JBM-5 708580M

Compact model designed for processing small volumes of wood. Ideal for those for whom furniture making is a hobby and not a professional activity. One of the cheapest options.

You need to understand that due to its compact size, the unit is not suitable for processing voluminous parts, and due to its low power, it does not penetrate the groove too deeply and interacts poorly with hard types of wood.

Therefore, the model is the best option for those who make small-sized wood products (for example, small crafts or souvenirs).

The unit is small in size. It does not have its own full-fledged frame with a base. But at the bottom of the device there is a clamp that allows you to secure it to a carpenter's table.

There is also no moving block for the workpiece. You will have to move it by hand. Hold it too - since there is no block for the workpiece, there are no clamps that fix it.

For more precise movements of the chisel, a U-shaped guide is attached to the frame holding the electric motor.

The average cost of the model in Russian retail stores is 25,000 – 26,000 rubles. It is unlikely that you will be able to find a slotting machine at a lower price.

| Options | |

| Power, W) | 700 |

| Speed (revolutions per minute) | 1450 |

| Penetration depth (mm) | 120 |

| Dimensions (mm) | 370x350x800 |

| Weight (kg) | 20 |

JET JBM-4 10000084M

A more “advanced” model from the same manufacturer. It also attaches to the carpenter's table. However, the unit has its own base, a movable holder for the workpiece.

Thanks to this, making grooves in wood is much more accurate. This model can already be called “semi-professional” - it is suitable for the full assembly of furniture, although not in production, but in domestic conditions.

The cost of the unit is higher than its simpler counterpart and amounts to 35,000 rubles.

| Options | |

| Power, W) | 550 |

| Speed (revolutions per minute) | 1420 |

| Penetration depth (mm) | 110 |

| Dimensions (mm) | 275x440x640 |

| Weight (kg) | 39 |

Corvette 92

The unit is of domestic production. It has everything necessary for professional woodworking, making it ideal for small furniture production.

The lower part of the device is a metal cabinet in which you can place a chisel or tool. The base of the frame is attached to it with four bolts. Thanks to this, the unit is quite stable. If necessary, the frame can be mounted on another base (for example, on a carpenter's table).

The workpiece area is quite large (40x15 cm) and has its own clamps. This allows you to fasten even a large part, securing it securely.

A massive block with a motor can move along the workpiece. Its location is changed using two rotating knobs. There is also a lever that can move the bit not only from right to left, but also forward and backward. This allows you to hollow out grooves of almost any geometry.

The workpiece platform can also be moved from place to place if desired. Another rotating handle is responsible for its movement.

Thanks to the maximum chiselling depth of 76 mm, it is able to process even fairly large workpieces.

The machine costs from 55,000 to 60,000 rubles. This is not a very high price, so the unit can also be purchased for use on a personal plot.

| Options | |

| Power, W) | 1500 |

| Speed (revolutions per minute) | 1450 |

| Penetration depth (mm) | 155 |

| Dimensions (mm) | 650x550x2030 |

| Weight (kg) | 220 |

720HD

Professional unit. Designed for processing large-scale workpieces. It has good performance, so it can be used in furniture production.

The block with the workpiece moves in any direction horizontally. The frame with engine and bit has hydraulic shock absorption. This allows you to move it very smoothly and thereby achieve high precision chiselling.

The model costs about 150,000 rubles.

| Options | |

| Power, W) | 750 |

| Speed (revolutions per minute) | 1400 |

| Penetration depth (mm) | 76 |

| Dimensions (mm) | 560x480x830 (without cabinet base) |

| Weight (kg) | 108 |

STALEX B5013

Professional level slotting machine. Ideal for medium-scale furniture production. It has great power and the ability to process large workpieces. Thanks to this, it has high performance and is practically universal.

The unit has an electric motor with a chisel at the end, which can only move in a vertical plane. But the workpiece board can also move horizontally. And not only left and right, but also back and forth.

You can change its location very quickly - just make a few turns of the rotating knobs that are responsible for it. The bit is lowered and raised using a spring-loaded lever.

The device has a powerful steel base, which makes it as stable as possible. If desired, the unit can be fixed to the floor. For this purpose, there are holes in the base for bolt fastening.

The cost of the machine ranges from 180,000 to 200,000 rubles.

| Options | |

| Power, W) | 1100 |

| Speed (revolutions per minute) | 1650 |

| Penetration depth (mm) | 125 |

| Dimensions (mm) | 1090x1120x790 |

| Weight (kg) | 330 |

Technical characteristics of the 7A420 slotting machine

| Parameter name | 7A420 | 7402 |

| Basic machine parameters | ||

| Machine accuracy class | N | N |

| Maximum stroke of the cutter, mm | 20..200 | 20..200 |

| Limits of double strokes per minute (number of speeds) | 40..163 (4) | 32..202 (6) |

| Table diameter, mm | 500 | 500 |

| Distance from the table plane to the cutter guides, mm | 320 | 320 |

| Distance from the cutter to the frame (reach), mm | 480 | 450 |

| Adjustment adjustment of the cutter stroke, mm | 264 | 265 |

| Maximum cutting force, kN (kgf) | 15,0 (1500) | 15,0 (1500) |

| Maximum longitudinal table movements, mm | 500 | 500 |

| Maximum table transverse movements, mm | 400 | 400 |

| The largest movements of the table are circular, degrees | 360° | 360° |

| Price for dividing the longitudinal movement dial, mm | 0,05 | 0,05 |

| Transverse movement dial division price, mm | 0,05 | 0,05 |

| Price for dividing the circular movement dial, min | 2′ | 2′ |

| Longitudinal movement per flywheel revolution, mm | 6 | 6 |

| Transverse movement per flywheel revolution, mm | 6 | 6 |

| Circular movement per flywheel revolution, deg | 4° | 4° |

| Feed limits for one double stroke, longitudinal, mm (number of steps) | 0,1..1,2 (12) | 0,1..1,2 (12) |

| Transverse feed limits for one double stroke, (number of steps) mm | 0,1..1,2 (12) | 0,1..1,2 (12) |

| Feed limits for one double stroke circular, (number of steps) deg | 0,064..0,81 (12) | 0,066..0,799 (12) |

| Speed of rapid table movement longitudinal, mm/min | 1,8 | |

| Speed of rapid table movement transverse, mm/min | 1,8 | |

| Speed of rapid table movement circular, deg/sec | 3,4 | |

| Maximum angle of inclination of the cutter, degrees | 5° from the bed | 5° from the bed |

| Maximum angle of rotation of the tool holder head, degrees | ±90° | ±90° |

| The largest section of the cutter (height x width), mm | 32 x 20 | 32 x 20 |

| Electrical equipment. Drive unit | ||

| Number of electric motors on the machine | 2 | 2 |

| Main motion drive electric motor, kW (rpm) | 2,8 | 1,8; 3,0; 3,6 (710, 1460, 2920) |

| Electric motor for rapid table movement, kW (rpm) | 1,1 (1400) | 1,1 (1400) |

| Total power of all electric motors, kW | 4,7 | |

| Dimensions and weight of the machine | ||

| Machine dimensions (length width height), mm | 2300 x 1270 x 2175 | 1900 x 1270 x 2175 |

| Machine weight, kg | 2000 | 2000 |

- Slotting machine 7A420. Manual, 1968

- Kopylov R.B. Working on planing and slotting machines, 1975

- Petrukha P.G. Cutting of structural materials, cutting tools and machines, 1974

- Yakovtsev A.D. Working on planing and slotting machines, 1966

Bibliography:

Related Links. Additional Information

- Hydraulic drive of the 7M430 slotting machine. Typical faults

- Repair of hydraulic systems of metal-cutting machines

- Designations of hydraulic circuits of metal-cutting machines

- Classification of metal-cutting machines

- Selecting the right metalworking machine

- Testing and checking metal-cutting machines for accuracy

- Directory of factories producing metal-cutting machines

- Manufacturers of metal-cutting machines

- Directory of slotting machines

- Articles on the topic

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

How to do it yourself

As can be seen from the short review above, the cheapest slotting machine costs from 25,000 rubles, which is a lot. What to do if there is no opportunity or desire to give that kind of money? You can make the unit yourself. Let's talk about what is needed for this.

Materials and skills

First of all, we need a “donor” from which we can take an electric motor. It is important that it performs not rotational, but reciprocating movements.

Of course, you can make a pendulum. But this is difficult and not everyone can do it. Therefore, we will take the path of least resistance and take a ready-made solution. The power unit from a jigsaw is ideal for its role. After all, the file moves vertically.

Expert opinion

Levin Dmitry Konstantinovich

For work, it is better to take a jigsaw with adjustable saw stroke. If it is not there and the movements of the cutting part are too frequent, the slotting machine may damage the workpiece.

You will also need:

- iron clamps (we will use them to secure the power unit);

- steel pipes (will hold the workpiece);

- metal profile (we will make guides from it);

- carpenter's table (we use it as a base).

Skills required include the ability to use welding. Without it, alas, you won’t be able to assemble a slotting machine yourself.

Work process

Here's what you need to do to create an aggregate:

- Draw a drawing . At least a simple one. It will help you navigate the work process.

- Secure the power unit . Everything is simple here: using clamps made from strips of sheet iron, we attach the jigsaw (you can directly in the body) to the carpenter’s table. In this case, the mount for the file should face the opposite side of the table.

- Changing the holder . We remove the file holder from the jigsaw, and in its place, using a clamp or welding, attach another one for the chisel.

- We attach the profile to the carpentry table . We screw the transverse strips onto the bolts, and two longitudinal ones onto them.

- We are preparing a frame holder . We make it so that it moves freely along the longitudinal guides on the carpentry table. Don't forget about the clamps. They should be both where the frame “rides” along the guides and where it holds the workpiece. We fasten the clamps for the workpiece on a separate frame, and we mount it on the main one through vertical stands with wine, which allows us to move the wood closer and further away from the cutting part.

As a result, we get an analogue of a factory machine, but with one difference: the engine is mounted horizontally.

What are the savings?

The costs of assembling such a unit will be as follows:

- inexpensive Chinese jigsaw - about 2,500 rubles;

- metal profile – 1,500 – 2,000 rubles;

- wood for assembling a carpentry table - about 1,500 rubles.

Even taking into account the costs of electricity, clamps and bolts, the total cost will be no more than 10,000 rubles. This is more than half the price of the factory model.

Which wood slotting machine would you choose?

PurchasedHomemade

Analogs

The difficulty of self-assembling a slotting machine is that the jigsaw engine:

- travel speed is too high;

- too little power.

As a result, it does not always work satisfactorily. What to do? Assemble a milling machine instead of a slotting machine. The algorithm of actions and materials will be the same. The only difference is that instead of a jigsaw we use an electric drill with a milling attachment.

The main difference between a milling machine is that it does not produce a rectangular groove, but a hole with slightly rounded edges. However, in most cases it will do for household purposes.

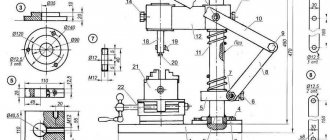

Location of controls for the 7A420 slotting machine

Location of controls for slotting machine 7a420

Specification of controls for slotting machine 7A420

- Flywheel for manual movement of the cutter

- Levers for turning the clutch on and off

- Button for enabling accelerated table movement

- Start button

- Stop button

- Square for setting the stroke length of the cutter

- Handle for setting the number of double strokes of the cutter

- Cutter clamp handle

- Square for changing the angle of the cutter

- Handwheel for manual longitudinal feed of the table

- Handwheel for manual circular table feed

- Handwheel for manual table cross feed

- Handle for turning on the table circular feed

- Cutter tilt adjustment nut

- Local lighting button

- Table feed switching drum

- Table feed cut-off drum

- Table fixing handle

- Table feed reversal handle

- Button for rapid oil supply to the cutter guides