Mechanical processing of metal is a technologically complex process. This is a necessary part of working with parts that will subsequently be used in various fields. The most common is metal milling. The workpiece is processed with a special tool - a milling cutter. It is a drill sharpened at a certain angle, or a circular saw of a non-standard shape. A multi-tooth device, moving at high speed due to the operation of the machine, removes a layer of metal of the required thickness on the workpiece. Milling is a popular method of processing parts.

What is milling

In principle, hand-carved wood can be conditionally classified as milling. But there is a clear difference - only those types of processing that are carried out using a rotating cutter on manual or stationary machines are called milling.

If we exclude other simple woodworking techniques - sawing, hewing, planing, drilling, then there are two main directions in woodworking.

- turning - carving a rotating part to give the desired shape to the diameter of the part;

- milling – the formation of linear (not radial), longitudinal shapes.

The scope of application of milled parts is limitless. Such details can be found in many complex modern products. The operation is quite labor-intensive, but sometimes there is nothing to replace it with. Casting or stamping will not give accurate dimensions, or these methods cannot produce such complex formats. The only way left is milling.

Main technological stages

All milling work begins with determining the dimensions of the future part or product.

When milling with hand tools, mainly in woodworking, most often they work without drawings or even sketches. It is enough to imagine and understand the desired result and decide on the dimensions. The photo below shows the simplest wood milling, edge rounding:

In industrial production, drawings of the future product are necessarily used. Therefore, the milling machine operator must be able not only to operate the machine, but also to read drawings. A fairly high qualification of the machine operator is also required.

When working on modern CNC machines, electronic versions of drawings and appropriate software are required. Here the manual skills of the machine operator fade into the background. And the most important thing is competence in modern computer systems. Although manual work skills are also required - you need to install the cutter, place the workpiece, and control the processing process.

After determining the dimensions for any type of milling, a suitable cutter is selected and installed. The workpiece is placed on the work table and the actual processing takes place.

Types, structure and design features

Tabletop milling machines have several varieties, which differ in design features and functionality. Tabletop machines are compact, easy to operate, low noise, and affordable.

Compact models consist of the same basic components as industrial equipment: bed, spindle, guides and work table. Fastening elements, a control system, and wires are installed on the frame.

Console

Console machines have a similar principle of operation with vertical milling equipment. The spindle in them moves along vertical guides.

Portal

In this case, movement occurs along three axes. The portal machine is mounted on a special guide, which is mounted transversely to the table.

Types of milling on machines

There are three main types of milling.

- Terminal . It takes its name from the end mill used with the cutting end (end). It is used for making rectangular grooves, curved holes and windows, pockets and niches for various purposes.

- End _ This is the processing of large surfaces with cylindrical cutters with straight, fairly large cutting edges. The edges, side and horizontal surfaces and ends of workpieces are processed, which is why the operation is called end milling.

- Shaped . The most difficult type of processing. It can be used to manufacture products of any configuration. This could be the spiral teeth of a worm gear, a shaped sample of a wooden baseboard or railing. Milling cutters of various profiles are used, including prefabricated modular ones.

In metalworking, sometimes milling refers to cutting metal using a cutter. But such an operation can be performed in a large number of different ways, both in metal and woodworking, so the operation is conditionally classified as milling.

Industrial portal milling machine manufactured in 1978.

Popular models of narrow specialization

Milling cutters designed to perform a narrow range of tasks and have a limited set of functions to optimize a certain type of material processing.

Makita MT M3700

Characteristics:

- type – edge;

- speed – 35 thousand rpm;

- power – 530 W;

- cutter stroke depth – 42 mm;

- collet size – 6 mm;

- cable – 2 m;

- weight – 1.4 kg;

- cost – 5349 rub.

A tool with easy milling depth adjustment, good performance and low cost. Equipped with a comfortable rubber-coated handle, it can perform up to 35 thousand rpm.

Advantages:

- price;

- build quality;

- light weight;

- ergonomics.

Flaws:

- no spindle lock;

- low power.

BOSCH GKF 550 Professional

Characteristics:

- type – edge;

- power – 550 W;

- collets included – 6 mm;

- speed – 33 thousand rpm;

- weight – 1.4 kg;

- price – 5290 rub.

A unit with stable support for milling depth. The 550 W motor helps you cope with many types of finishing and carpentry work. The ergonomic body ensures ease of use. Optimized ventilation reduces device heating.

Advantages:

- ease of use;

- ease.

Flaws:

- no cutters included;

- there is no protection against accidental activation.

Makita 3709

Characteristics:

- type – edge;

- speed – 30 thousand rpm;

- power – 530 W;

- cutter stroke – 40 mm;

- collets in the set – 6 mm;

- cord – 2.5 m;

- weight – 1.5 kg;

- cost – 5931 rub.

Edge router for forming grooves and holes of various shapes in composite, wood, plasterboard, and ceramic products. High speed of rotation makes it possible to interact with compacted materials. The transparent plastic platform allows you to clearly see the element being processed.

Advantages:

- convenient depth regulator;

- good equipment with limiters and stops;

- high power and speed.

Flaws:

- there is no stopper on the shaft;

- there is no depth limiter;

- no soft start.

CNC

The machine tool industry today offers hundreds of options for a wide variety of CNC machines for processing any materials. From the smallest for small home workshops, to the most powerful for industrial production.

The main series of such machines:

- lungs;

- professional;

- industrial;

- special.

Light ones (among them the lightest) cost from 150 thousand rubles.

Professional is an intermediate option between light and industrial options. These include wood milling and engraving machines costing from 200 thousand rubles. up to 600 thousand rubles.

Industrial - for continuous production, cost more than 1 million rubles.

Special ones are most often designed individually for specific tasks and details. These include machines for milling stones, as well as small, ultra-precise ones for jewelry.

Advantages and disadvantages

Advantages:

- The ability to process a workpiece from different sides from one installation.

- Additional spindle head.

- The presence of the function of separate and simultaneous processing of a part with both spindles.

- A larger number of technological operations performed on one machine.

Flaws:

- The presence of a movable console, trunk and head rotation device reduces the spatial rigidity of the machine. To compensate for this shortcoming, the longitudinal dimensions of the guides have been increased in the machine designs, devices for fixing the moving components of the machine have been provided, and their strength has been increased.

- The high cost of universal machines compared to simpler units.

3D milling

Modern 3-6 axis 3D CNC machines have brought this method of processing various materials to a fundamentally new level. Today there are no parts that such machines cannot make. They even make sculptures with their help.

The most important points are the correct selection of cutters for different materials and the appropriate software. There is both free software on the market, including open source software for possible modification, and paid packages created specifically for the manufacture of specific parts and tasks.

Basic software standards: CAM System and CAD system

As an option, programs are offered for free testing for a month.

The capabilities of such a machine in woodworking can be seen in the following video:

Equipment

The main equipment, of course, is the milling machine itself or a hand router.

The main components are cutters for various purposes and profiles. However, there are no technological lines or small production facilities consisting of only one machine.

Before the workpiece is processed, it is most often prepared on other equipment.

- format cutting machines;

- miter or hand-held circular saws;

- gas cutting or laser cutting of metal.

Sometimes it is necessary to prepare the workpiece in terms of thickness. Then it is adjusted to the desired size using the following equipment:

- wood - trimming on circular saws or band saws, planing on a jointer or planer;

- metal – cutting to thickness in different ways, preliminary rough milling.

Stationary machines

In addition to the modern CNC machines described above, of which there are many, there are also simpler options.

These are the simplest wood milling machines, consisting of a table, a motor, a cutter landing shaft and a guide for manual feeding of the workpiece. There is also an option with installing a manual router into the table upside down.

More complex ones are industrial milling machines for wood and metalworking. They can have automatic feeding of workpieces, regulation of the position of the cutter, positioning of workpieces, etc. Quite a lot of these old machines, manufactured before the 21st century, are still in working order. Although there are fewer and fewer of them left.

Hand milling machines

This type of tool is sometimes called a "milling machine." This is so because a hand router is a completely self-sufficient tool. It has everything that a stationary machine has:

- own electric motor;

- rotating spindle with mount for different cutters;

- working platform with adjustable cutter immersion depth.

This tool is intended for manual work, so there is no point in comparing it with large industrial machines. The manual router copes with its tasks to the fullest extent. Moreover, it has its own number of advantages over stationary options:

- mobility , ability to work anywhere;

- the ability to process large-sized workpieces that do not fit on the desktop of stationary machines;

- great versatility . Unlike special machines, a manual milling machine can perform all basic operations for milling soft materials;

- affordability . The cost of a manual milling machine is tens, sometimes hundreds of times less than the cost of stationary machines;

- compactness . This router does not require large areas to operate and store. When they are not using it, it is simply removed to the side, freeing up space.

Modern manufacturers offer the widest selection of such tools of different power, from 350 W to 2500 W.

In addition to universal ones, there are also special-purpose models - lamella, edge, filler.

Safety precautions

Although all modern machines are necessarily equipped with protection, divided into a number of elements, compliance with basic labor protection instructions is still mandatory. The protective parts themselves must certainly be placed in the correct positions. Their serviceability is checked in any case before starting work and after any long break. Do not work in poor visibility or during any sudden deterioration in health.

A milling machine is serious equipment, and you shouldn’t allow just anyone into it. You must be of legal age and be willing to obtain a 2nd level in electrical safety (this is the minimum). A first aid kit and a fire extinguisher must be available at the workplace. You need to master each machine model very carefully from scratch. If we are talking not about home conditions, but about an enterprise, then additional instruction is certainly required.

Wood shavings must be removed regularly. Its excessive accumulation threatens a fire. The milling machine must be grounded, as well as all the wires feeding it. You can work with workpieces only after checking their fastening. Cutting parts with chips and deformations, with cracks and burrs must be replaced.

Milling cutters

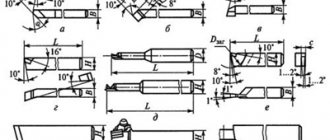

This small detail makes a huge difference. The machine only serves its work, and it is the milling cutter that directly processes the material. Therefore, the quality of processing depends largely on the cutter. With hundreds of varieties of milling machines and different cutters available, thousands of varieties are used. The main difference is in three respects:

- Mounting method. Shell cutters have a hole in the middle and are mounted on the spindle (shaft) of the machine. The photo shows a shear cutter for woodworking with replaceable knives:

- Milling cutters with shanks are clamped in collets. In the photo, a set of such cutters for a hand router:

- Profile . Simple, straight and profile cutters of various configurations are used. Nozzles with straight cutting edges are used to make the same straight recesses. Profiles form a sample on the workpiece that repeats the profile of the cutter itself.

The exception is 3D CNC machines. They cut complex profiles and reliefs with a simple thin end mill. Profiles on the part are formed due to the mobility of the cutter itself in three coordinates.

On 4-6 axis machines, cutters not only move vertically and horizontally, but can also tilt.

Task

Generally speaking, sandwiches and salads are made “in a hurry”; a romantic dinner can be whipped up in a hurry, but not a machine. However, I included this phrase in the title of the article. Why? I'll try to explain.

“In a hurry” this means technologically for home production. Those. the machine must be designed so that it can be manufactured using a minimum set of the most common metalworking tools. Literally, if you have in your arsenal a jigsaw with a metal file, a drilling machine, tap dies and a file, then this should be enough. At worst, a simple hacksaw and a drill will do.

Some people will say: “Well, you’ve gone too far, comrade!” This doesn’t happen,” and he will be right. That really doesn't happen. Because if milling work can be eliminated completely, then we cannot do without basic turning work, which means there should be very little of this work, everything else should be done by hand, in the kitchen.

When setting yourself such a task, you need to understand well that your plans can only be achieved if you widely use purchased components and standard aluminum profiles. Guides - the cornerstones of a portal engraving and milling machine - will also have to be purchased, and they are expensive. So, “quickly” does not mean cheap!

One final thought. “In a hurry” is associated with the concepts of simple and fast. If you can agree with the definition of “simple,” then it’s unlikely to work quickly. The production of even simple parts can take an indefinite period, but as they say, “patience and labor will grind everything down.”

Let's summarize:

- For milling balsa, plywood, wood, plastics and thin (up to 2 mm) aluminum alloys.

- On linear ball guides and timing belts.

- The working field is at least 1000x300x90.

- Positioning resolution is no worse than 0.1 mm.

- Positioning speed no less than 2 m/min.

Milling materials

The cutter material must be stronger than the material being processed. If this is not a problem for soft materials, then in metalworking special heavy-duty alloys are used to make cutters. Some machines are equipped with a system for lubrication of the machined surface and the cutter with an oil-water emulsion. It lubricates the cutting area, removes small chips and cools the cutter.

Tree

This is a soft material. It is processed both by hand milling machines and by powerful industrial machines.

A hand router can be used to do almost all types of milling work, but in small quantities.

On industrial machines, moldings are made in-line - lining, floorboards with a groove/tenon connection, baseboards, corners, round products in two passes with a semicircular cutter, etc.

Despite the softness of the material, cutters are made of hard alloys so that they retain their sharpness for a long time and are less abraded by friction. As a rule, these are “high-speed cutters”, alloys such as R6M5, R6MZ and R12 (HSS in Western markings) - steel containing tungsten, molybdenum and vanadium in different proportions.

Plywood

Plywood sheets are large-sized material of small thickness. Sometimes it is necessary to mill edges, cut out non-through and through ornaments, curved or straight lines. Hand-held routers are better suited for working with large sheets. It is better to move a small tool relative to the sheet than to move a bulky sheet relative to a stationary router.

For plywood, universal cutters are used (hardwood, plywood, MDF, etc.). The hard adhesive resins in plywood can dull the cutter faster than when working with wood. Therefore, it is better to use high-quality cutters made of harder alloys.

Furniture board

Furniture board is wood, wooden beams glued together. Processed in the same way as wood. If the sheet is large, it is better to use a hand router, as is the case with large sheets of plywood.

MDF, OSB, laminated chipboard (LDSP) and plain chipboard

These are materials containing wood similar in structure. They are based on crushed wood, sawdust or shavings, compressed and glued under pressure at a certain temperature with adhesive resins. The difference is in the size of the wood particles and the manufacturing method. They are milled in the same way as plywood. Either universal or special cutters for such materials are used.

It is extremely undesirable to allow the cutter to overheat to prevent burning of adhesive resins, wood and the release of acrid smoke. Overheating of the cutter is possible when the cutter moves too quickly, the speed is too high, or the cutting edge of the cutter is dull.

Features of working with a drill

When using a drill instead of a router, you must take into account the features of working with this tool

Important to remember:

- The rotation speed of the drill is lower than that of the router, so cutting will be slower.

- The electric drill motor overheats during prolonged use. It is necessary to take breaks to cool the instrument.

- The gearbox shaft bearings are designed for longitudinal loads and can fail during transverse milling. Do not apply large forces in the transverse direction. This increases the processing time.

- The electric drill chuck may not withstand lateral loads, which leads to damage to the part.