Compression in STIHL MS180 and POULAN 2250 chainsaws.

Dear visitors to my blog! If you liked, and most importantly benefited from, watching my videos and photographic materials on repairing gas-powered tools, then I ask you to contribute whatever financial assistance you can to your e-wallets:

WebMoney – R397899742942

or

Z103294956413

The money will be used to pay for servers, hosting, domain name and website development. With respect to you, Evgeniy Kravchenko.

Today we will measure compression. For this purpose, we will need an electric drill with a reverse function and a maximum speed of about 2500-3000 rpm, a car compression gauge, a flexible shaft for transmitting rotation from the drill to the crankshaft of the chainsaw and, in fact, the experimental samples of the Stihl MS180 and Poulan 2250 chainsaws themselves.

It’s worth mentioning that the Stihl is an absolutely working saw (it was sent in for repairs to replace the starter cord), but the Poulan has a deliberately ruined piston.

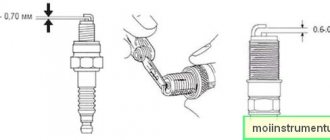

On both chainsaws, for measurement accuracy, the carburetors were dismantled (the inlet resistance should be as low as possible), the starter covers were removed (in order to be able to put the flexible shaft with a “13” head on the nuts securing the flywheels), the spark plugs were unscrewed and the shutdown keys were located in the "off" position

So . Our "gentleman's set"