Is vulcanization possible at home? The question is by no means rhetorical, but one of the most discussed on forums among car and bicycle enthusiasts. Self-repair of rubber products - from a tire to a children's toy - will save time and money, and will give vent to the creativity and ingenuity of a true car enthusiast.

If we talk about “cold” vulcanization, then the materials for this simplest and quickest repair are a must-have in your travel first aid kit.

The essence of the hot vulcanization method is the hardening of the rubber mass under the influence of heat. Knowing what should happen in the end, and having a fair amount of patience, you can repair any camera at home and quite reliably - car, bicycle, football. You will need simple equipment (more on this later) and a piece of raw rubber (patch), previously soaked in gasoline.

“Home” vulcanization technology

A piece of raw rubber (from auto tube rubber) should be slightly smaller than the size of the patch. The tire at the point of damage is sanded (with a reserve) - this will improve the adhesion of the materials, and then cleaned with gasoline. The edges of the patch must be rounded (cutting off the end of the patch at an angle of 45 degrees), then also treated with sandpaper and degreased with gasoline (B-70 or Galosh). Then you should cover the damaged area with a paw, place it under a press and heat until hardened.

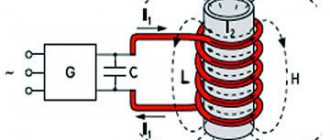

The most popular component of a home “vulcanizer” is the old one (a good Soviet one is the best option), using an electric stove with an open ceramic spiral. The main task facing the master is to create a reliable clamp connection in a home vulcanizing press.

Advice from the “experienced”

- Before applying the prepared patch to the cut site, lubricate it with glue. It is easy to prepare at home by dissolving raw rubber in gasoline.

- Get ready to gradually master this process. A very important point is maintaining the temperature regime. When the optimal temperature is exceeded, a characteristic smell of burnt rubber appears - your patch is “sintered”. If the patch does not merge with the cut, it means the vulcanization temperature was insufficient or the process was completed early.

- If the iron's thermostat works (this happens), you need to set the temperature to 140 degrees (or the designation for silk). This temperature regime prevents overheating of the patch and the product itself.

- To prevent the rubber from sticking to the metal during the vulcanization process, it is enough to lay a piece of paper.

- If water comes into contact with the vulcanizer and it boils, it’s time to turn it off. After waiting a little more, the vulcanizer can be removed, allowing the rubber to cool. Sugar is also used: if grains of granulated sugar begin to caramelize upon contact with the surface of the vulcanizer, the vulcanizer must be turned off.

- The product to be repaired is placed on a hot vulcanizer plate (heated iron) with the damaged area downward and kept for the technologically required time (10-15 minutes). After one or two ruined tires, everything will become clear and home vulcanization can be safely put on stream.

For cuts with a complex configuration, it makes sense to make a more complex mold from two sheets of steel 6-10 mm thick. The plates are tightened with screws using holes drilled in the corners.

When doing self-repair, there is a high probability of damage to the cord thread, which can lead to protrusion (herniation) of the rubber during operation. In addition, the wheel will be unbalanced; eliminating the imbalance at home is hardly possible. When the car is moving, such a wheel will make life very difficult for the driver.

Only a completely intact wheel can provide a 100% guarantee of safe driving. Therefore, it’s worth saving up and buying new tires.

Types of rubber

Rubber is one of the few materials that has different hardness. Depending on the percentage of sulfur, it is:

- soft – contains up to 3% sulfur;

- semi-solid – from 4 to 30% sulfur;

- hard – more than 30%.

Rubber is a natural material, and as a rule, products made from natural ingredients are of the highest quality and most durable. Therefore, components for bicycle and car wheels are made of soft rubber, which is based on rubber.

Characteristics of types of material

Non-vulcanized special-purpose mixtures include electrical materials that are resistant to heat, oil and gasoline. They contain different types of rubber. Depending on the type of raw material, operational parameters may differ. The best oil- and gasoline-resistant mixture is obtained from chloroprene rubber. Such compositions can be vulcanized without the use of sulfur. The mixtures themselves are very elastic and ozone-resistant. Raw materials with nitrile butadiene or polysulfide rubber are not of such good quality.

In addition, oil- and gasoline-resistant materials are divided into:

- universal. They are used for rings, the lower limit of fragility is -50 degrees. It is quite possible to replace other types of raw materials with such raw rubber;

- increased hardness. Used in production for the manufacture of rubber products for various purposes;

- medium elasticity. Also used for the production of rubber goods;

- soft. Used in the manufacture of seals for working with aggressive liquids (oil, fuel).

Crude general purpose rubber is made from non-polar rubbers (SKS or NK).

When the base is natural raw materials, it is vulcanized with sulfur. The mass with non-polar types of rubbers is of high quality. Such materials are elastic and durable, resistant to deformation. Of the class of synthetic rubbers, the most commonly used type of raw material is styrene-butadiene. It is worth noting that mixtures with this composition are of low quality. However, this indicator directly depends on the amount of styrene in the composition: the more of this substance, the stronger the material. General purpose mixtures come in high and medium density. The first ones are used to work with shock-absorbing parts. Rubber of the second category is used for sealing rubber products.

It is worth mentioning separately about mixtures that are intended for repairs or work with retreaded tires:

- for pouring into damage funnels. They look like a long cord with a diameter of 8 to 10 mm, used in extruders;

- lateral. This rubber is in demand for repairing the shoulder area of tires;

- primers – for the tread, tire frame;

- vulcanized compositions in the form of processed tapes. Used for repairing truck and large tires;

- unvulcanized compounds that have not been processed. Such raw rubber is taken when welding treads on tires in presses.

Electrical vulcanization of rubber

In general, vulcanization can be cold or hot. The electrical vulcanization process is a hot method. An electric stove with a ceramic heater is used as a heater at home; a hair dryer or a regular iron is also suitable. The optimal temperature for this method is 145C o. To determine the temperature, you can also use available means, for example, if a sheet of paper begins to char, it means that the temperature has reached the required values.

Electrical vulcanization of rubber

There are also special clamps with a heating element. Such devices can operate from a 220V household network, from a car battery, through a cigarette lighter socket, or from their own battery. It all depends on the performance of each device. These clamps are easy to use; you need to attach a rubber patch to the camera, clamp it and plug it into the network.

Sulfur vulcanization of rubber

After rubber vulcanization

This operation consists of a chemical reaction in which sulfur atoms are added to the rubber. When added up to 5%, it produces raw materials for the manufacture of tubes and tires. In the case of gluing two elements, sulfur helps connect the rubber molecules, forming a so-called bridge. This procedure refers to the hot method, but it is unlikely that it will be possible to do it on a hike or on the highway.

Hot vulcanization

Rubber, as a raw material, has the property of being welded into a single composition at a temperature of 150 °C. As a result of this process, the rubber becomes rubber and cannot return to its original position. Thanks to its capabilities, rubber can fix any punctures and cuts in the tube and tire.

It is necessary to vulcanize rubber using a hot method, only using a press. The depth and area of the cut will tell you how long to weld. Typically, it takes 4 minutes of cooking to repair a 1mm cut. Accordingly, if the cut is 4mm, then it needs to be vulcanized for 16 minutes. In this case, the equipment must be warmed up and configured.

By performing hot vulcanization at temperatures above 150C o, you can ruin the rubber and achieve nothing, since the material will deteriorate and lose its characteristics.

Using clamps or a press allows you to properly patch the damage. After finishing the work, you should make sure that there are no voids or air bubbles in the seam. If there are any, you need to clean the puncture site from fresh rubber and repeat the whole process again.

In order to hot seal a camera at home, you must do the following. From raw rubber, you need to cut a piece slightly smaller than the patch itself. The tube or tire is cleaned slightly wider at the damaged area, to a rough state, and then degreased with gasoline. When preparing the patch, you need to cut the chamfer at an angle of 45°, also sand and degrease. Then we cover the puncture site with a patch, clamp it in a vice and heat it to the desired temperature.

If you dissolve raw rubber in gasoline, you can get a special glue for rubber, the use of which improves the quality of the seam. Particular attention should be paid to temperature conditions. Vulcanization is carried out at a temperature of 140 - 150 ° C; if there is a smell of burnt rubber, it means the patch has overheated, and if it has not merged with the overall product, then it may not have reached the required temperature. To prevent rubber from sticking to metal, you need to place paper between them.

Raw Rubber Components

To obtain raw rubber, the use of natural or artificial rubber is required. When heated to 50 degrees, the rubber becomes soft and pliable, and it is in this state that it is mixed with other components. These components provide rubber with the specified technical properties.

The composition of raw rubber includes the following groups of materials

- accelerators;

- softeners;

- antioxidants.

Each substance from these groups has a certain effect on the finished product. For example, zinc oxide is classified as an accelerator (catalyst). This substance ensures the rapid interaction of all ingredients, and accordingly the process of obtaining the finished product is accelerated.

Zinc Oxide for Raw Rubber

After the raw rubber mixture is obtained, the aging process begins. That is, it loses some of its properties, for example, elasticity. This process is called scorching. To slow down this process, special antioxidant substances are introduced into the raw rubber.

Construction soot

Construction chalk

Components such as chalk, soot and some others significantly increase the strength characteristics of finished products. The use of third-party components not only improves performance characteristics, but also reduces the cost of the finished product. The thing is that the presence of additional ingredients leads to a decrease in the volume of natural rubber. Plasticizers added to synthetic rubber increase the wear resistance of the rubber.

Cold vulcanization

Nowadays, using this method is not difficult, since you can purchase a repair kit in every auto or bicycle parts store. The contents of this set may vary, but each one contains patches and special glue.

Cold vulcanization of rubber

The repair procedure in this case is similar to the hot method. You also need to treat the damaged surface with an abrasive, remove rubber dust and degrease. After drying, apply glue to the camera and glue the patch. In this case, it is not the duration of the pressure that plays a role, but its strength. Therefore, it will not be enough to simply press down with a stone; more force is required.

Making a vulcanization device

Each vulcanizer has two main elements - a heating part and a clamping device. The basis of such rubber processing equipment can be used:

- iron;

- “bazaar” electric stove;

- piston from the engine.

In a device with an iron, the heating part is the surface that is used for ironing in everyday life. If we plan to use an electric stove, then the heating coil should be covered with a metal sheet, and when working, you need to place paper between the rubber and the metal. Such a device must be equipped with a thermostat to avoid overheating of the material.

The pressing part of the vulcanizer is easiest to make from a clamp. The simplest device to manufacture would be a device consisting of an iron and a clamp. Since they are both metal, joining them using arc welding is not difficult. The iron also has a thermostat.

A piston vulcanizer also uses a metal plate. A rubber bladder is placed on it. The piston, with its smooth part, which is in contact with the explosive mixture in the engine, presses down the patch using a homemade clamp. Paper is also placed between the piston and the patch. After that, gasoline is poured into the piston and ignited.

Such a device made from a piston is especially useful on the road, when there is no way to connect to the electrical network. However, such a device does not have a thermostat, and the temperature will have to be controlled manually.

Brief characteristics of the species

Raw rubber rolled mixtures are a product that has undergone a certain stage of processing. This material is usually sold in bags (30 kg) and has a shelf life of up to three months. The main characteristic feature is that the material is passed through rollers at the final stage of production.

Calendered raw rubber compounds are supplied in rolls. The thickness of the rolled layer can be 1; 1.5; 2 mm. The main purpose of this type of material is to repair tires. Rolls are available in different weights: 15; 20; 30 kg. In addition, there are three other types of raw rubber:

- unvulcanized for special purposes;

- general use;

- resistant to oil and gasoline.

It’s worth taking a closer look at each of them.

Pros and cons of vulcanization

The main advantage of the tire repair process is that it is cheaper to repair than to buy a new one. However, each situation is individual, so it is important to determine whether repairs will save the situation.

The cold method is quite easy to use, it will not take much time, and the costs will be minimal. The main disadvantage of this method is the unreliability of gluing. This procedure is temporary, and you should contact a service station as soon as possible.

Hot vulcanization reliably welds rubber, allows such work to be carried out at any temperature and has a low cost.

So, you can repair a tube or tire in different ways, but it is better to entrust this work to specialists, because it is for your own safety.

If you find an error, please select a piece of text and press Ctrl+Enter.

There are several ways to repair a puncture or cut in a bicycle tube, one of which is hot or cold vulcanization of the tires. This method can be confidently called reliable and durable; a wheel secured with raw rubber will serve like new and will not go flat at the most unexpected moment. You can easily carry out such repairs yourself, both at home and outdoors on a hike, if you have some necessary parts. The hot vulcanization method differs from the cold method only in how the patch applied to the wheel is fixed - with or without heating.

What is vulcanization? This is a chemical process due to which, with the expenditure of heat, the strength properties of rubber improve, it becomes elastic and hard. You can apply a patch to a puncture using a piece of an old tube or a ready-made patch from a repair kit, and to secure them you need raw rubber with your own hands, which is sold in rolls with a protective film. This is a very plastic material, it sticks to any surface, easily sticks together into a lump, etc. raw rubber instructions for use are indicated on the packaging.

- There are two types of vulcanization - cold and hot, let's look at both of them in more detail.

Production of raw rubber

Rubber is used as the basis for the production of this raw material; it can be either natural or artificial rubber. The following substances can be used as plasticizers:

sulfur;

gas soot;

sand (silicon dioxide);

and many others.

The main properties of this raw material are provided precisely by its components. Sulfur, which is part of the molecular structure, is responsible for its hardness. Soot and oils give the finished part elasticity. Other components improve wear resistance and strength. Almost all raw rubber is produced on the basis of GOST and TU, for example, TU 38-105-1082-86. But in practice, you can purchase everything you need to make raw rubber with your own hands.

Production of raw rubber

The finished product is delivered to the customer either in the form of sheets or tape wound into a roll.

After mixing the components, the resulting mixture is sent to rollers or calenders, and on this equipment rolls or sheets are formed. After passing through this machine, the rubber mixture takes the form of a sheet, the required width and height.

This raw material also exists in liquid form. In appearance, this substance resembles honey, with the difference that it is black in color.

After receiving a sheet formed from a pre-prepared mixture, it is covered with a polymer film. It's all about the stickiness of this raw material.

Raw rubber covered with polymer film

Instructions for the production of raw rubber provide modes that allow the production of high-quality raw materials at low costs.

This raw material can be used to seal holes in inner tubes, boats and other rubber goods. For this purpose, the cold vulcanization technique is used. As a result, the hole will be sealed, but not for long. To perform a complete repair, ensure that the raw rubber is hot vulcanized. In this case, the formation of long-sized molecules bound together by sulfur occurs. Repairs using hot rubber vulcanization technology are widely used at car service stations. The production of almost all types of rubber technical products occurs at a vulcanization temperature of raw rubber of 150 degrees Celsius.

Application of cold vulcanization

The material for such repairs appeared back in 1939 in the USA, almost immediately began to be successfully used and is popular among cyclists and motorists around the world to this day. With its help, you can easily and hassle-free repair any camera; the cold method is very easy to use at home. For the convenience of consumers, some manufacturers offer ready-made repair kits (cold wet rubber, instructions for use are indicated on the packaging), which include several patches of various sizes in the form of a patch, sandpaper, which is used to clean a puncture site or scratch on the rubber. , as well as a special quick-drying adhesive for cold vulcanization. It is this that reacts with the layer of raw rubber on the patch - it is applied in bright color around black. This causes a vulcanization process, making the rubber of the chamber easily glued together without heat (i.e. cold process). This method is best suited for repairing wheels on the go, when there are no more tools at hand. You won't find a single cyclist who hasn't been helped out by a kit like this at least once in his life. It does not take up much space in a bag or backpack, and its importance is difficult to overestimate, especially if you are alone on a trip without friends far from the city. The entire process of repairing a tire using cold vulcanization using a patch for the inner tube will take the cyclist no more than ten minutes, and the wheel will be like new.

Do-it-yourself hot vulcanization technology for tires

This technology is used a little longer than cold technology. At a time when there were not so many tire shops around, car and bicycle enthusiasts repaired their vehicles in the garage using exactly this method, which uses an electric or gasoline vulcanizer, which can be easily assembled with your own hands. The technology here is as follows: the master burns gasoline, which warms up the rubber using a piston. As soon as the temperature rises to 90 degrees, the raw rubber for vulcanization begins to strengthen; if you raise the temperature to 147 degrees, the process goes noticeably faster and with better quality. But it’s better not to raise it above 150, because... the material begins to deteriorate and loses its properties. After 160 degrees, raw rubber begins to char. The ideal warm-up time for hot vulcanization of raw rubber is about 8-10 minutes. A fragment of material is applied to the puncture site on the camera and compressed using a clamp so that during the chemical reaction bubbles do not form and air does not collect, forming dangerous voids.

In field conditions, it is much more difficult to carry out such an operation for cameras, but it is still possible: if there is a piece of raw rubber, you can heat it over a fire. You can determine the temperature of the flame by looking at a piece of sugar or a piece of paper: both begin to melt/char at a temperature of 145 degrees – exactly what is required for vulcanization. You can use a flat heavy stone, a wooden log or any other suitable object as a clamp.

The entire operation will take you about 20 minutes. Do not forget that the area where the inner tube patch is glued must be cleaned with sandpaper or at least wiped with gasoline to remove dirt from the tire.

Liquid rubber

As noted above, in addition to sheet and roll versions, the rubber mixture can be in liquid form. As a rule, it is based on two components - a hardener and a filler.

This product has found its application in construction; it is used in waterproofing. This material has excellent adhesion to most building materials, brick, concrete, etc. Laying insulation using spraying allows you to create a seamless (seamless) coating. In addition, this approach allows you to carefully process corners, funnels and other difficult-to-process areas.

The resulting waterproofing coating is cheaper than using traditional roofing materials. This occurs by reducing the required number of personnel and reducing the time spent on covering construction work. In addition, the components included in the liquid coating provide resistance not only to moisture or snow, but also immunity to ultraviolet radiation. In addition to the listed properties, it should be noted that this waterproofing is completely environmentally friendly.

Cement for vulcanization and its application

Another alternative option for repairing bicycle wheels while traveling is a can of cement vulcanizer. You can buy them, for example, at the car market - this material is very popular among car enthusiasts. The composition is sold in tin and aerosol cans under pressure from brands such as Abro, BL, Zefal, Top RAD and many others. In terms of their composition, they are not hazardous to health and are not toxic, because... they do not contain chloride and aromatic hydrocarbons, so they can be used freely both at home and outdoors without a protective mask. In order for tire cementation to occur, a temperature of 18 degrees Celsius is required. The composition is also used for hot vulcanization (150 degrees required). To repair, you need to remove the foreign object that caused the puncture from the rubber of the inner tube, fill the inner tube with a cement vulcanizer through the nipple, slightly inflate it with a pump and ride a bicycle for 2-3 kilometers to adjust the pressure in the wheels. This tire repair technology is simple and is also used everywhere. To consolidate the result, it is possible to use a patch of plaster followed by the hot vulcanization method - exactly the same as described in the instructions above. The technology is suitable for any tire cuts. In this case, the patch for repairing the tubes is applied before filling the tire with cement.

Making a device from an iron

You can make a vulcanizer for repairing tires with your own hands from an iron.

You can do this as follows:

- Take 2 steel plates with a thickness of 8 mm and dimensions of 40 × 60 mm. They will be used as a press.

- All edges are chamfered so that the sharp edge does not cut the rubber.

- In one plate, 4 holes are drilled in the corners and an M12 thread is cut. In the second - in the same 4 places, holes with a diameter of 13 mm.

- Both halves are held together with bolts.

You can use the machine in this order:

- The damaged area of the camera is being processed.

- A patch is cut out of raw rubber, soaked in gasoline and applied to the hole.

- The camera with the patch applied to it is inserted into the mold and clamped with bolts.

- An iron is located below, and a mold is installed on it. It is important that they touch at the bottom.

- The iron heats up for 10-15 minutes.

When vulcanizing, you need to ensure that the rubber parts do not touch the heated iron.