Finished products and parts are painted in different ways. Paintwork materials are applied with a brush, spray, or dipping technology is used.

The powder coating technique is recognized as economical. It is especially convenient to apply paint to small parts. To coat a polymer layer with dry dye under the influence of temperature, a thermal structure is needed - an oven for the polymerization of powdered CM. Having melted, the dye penetrates into the smallest pores of the product. The dyeing method is considered the leader in coating quality.

You can assemble a stove for powder painting with your own hands in a home workshop; the procedure is not complicated. Installation can be a good start for organizing your own business.

What is a paint booth

The spray-drying booth is often used for painting work on cars and trucks. A special feature of the chamber is the presence of a special ventilation system and temperature control.

So that when painting, no small particles can get onto the paint layer. And also during drying, the necessary temperature conditions are created for the process to proceed correctly.

The powder paint polymerization chamber is distinguished by a special system for influencing the layer so that the adhesion strength of the composition is high.

Thus, the painting chamber is the place where the required conditions are created for applying and drying the paint and varnish material. Depending on the type, the arrangement of the room will differ.

The powder paint polymerization chamber is distinguished by a special system for influencing the layer so that the adhesion strength of the composition is high.

Principles of staining technique

The part is cleaned and degreased before painting. In a bowl with a prepared detergent solution, with the addition of a solvent (white spirit or acetone), at a temperature of 40-60 degrees above zero, several parts are degreased at the same time. All contaminants are removed using shot blasting and sandblasting devices.

The type of polymerization design dictates how the part will be powder coated. Then it is processed in a thermal installation. The powder heats up, melts and the polymer covers all the small pores of the surface of the part. The coating with a high degree of adhesion goes through a sintering stage, which increases the strength of the layer and its adhesion to the base.

Advantages and functional features of the paint box

A car painting booth has a number of advantages over working in a regular garage. Due to the special arrangement, the possibility of dust and other contaminants getting onto the base after applying paint is eliminated, which is very important when covering the surface of a car.

There is also the possibility of creating a homemade camera. The process is not so complicated, if you do not violate the technology and take into account fire safety requirements, the result will be of a high level.

Due to the special arrangement, the possibility of dust and other contaminants getting onto the base after applying paint is eliminated.

Painting

Painting a part is quite simple; it is carried out only if all stages of preparation have been carried out perfectly. First you need to place the workpiece in the painting compartment, then connect the negative wire to it, which is included in the power source.

- To check whether the voltage on the part is sufficient, a converter is used.

- A bottle with a metal stopper must be brought to the part 20 cm from the surface; sparks should appear.

- This will signal that the voltage supplied to the part is sufficient.

After checking, you need to start painting; using a paint gun, paint is sprayed onto the workpiece. Due to the voltage, the particles will become electrified and stick to the surface, thus coloring the part. It is worth noting that a certain part of the paint and varnish material will still fall to the floor.

When the painting is completed, you need to put the part in the oven for further polymerization. There the part will be exposed to high temperatures, which will harden the paint layer.

This completes the process of painting the part; you need to wait until it cools down and can be used in the assembly.

Varieties

The equipped room can be done in different ways; the requirements for the arrangement depend on what they intend to paint. This could be a car, furniture, or other parts. For example, there is a chamber for powder painting. Therefore, you need to understand the types of cameras in order to choose the appropriate option.

The equipped room can be done in different ways; the requirements for the arrangement depend on what they intend to paint.

Powder

The powder coating chamber must be equipped with lighting, transport elements and a monitoring and control panel. Externally, this is a box made of dense metal, where polymerization of powder paint takes place, and can be lined with polymer materials.

The powder coating chamber must be equipped with lighting, transport elements and a monitoring and control panel.

For furniture

Furniture factories often use a special painting chamber, where wood undergoes all stages of coloring. This is how the material is prepared, painted and dried. There are different types of premises:

- Dry type;

- With water curtain;

- Excessive pressure.

Furniture factories often use a special painting chamber, where all stages of wood coloring take place.

For details

A powder coating or other type of painting chamber can be designed for a variety of parts that require optimal working conditions. To create the necessary parameters for sanitary work and increased productivity.

Powder coating or other types of painting chambers can be designed for a variety of parts.

With water curtain

A water curtain spray booth, like other spray booths, helps remove harmful solvents from the air that evaporate when paint is sprayed. This type provides three levels of air purification:

- Frontal water curtain;

- Internal air purification;

- Dry filtration.

A water curtain spray booth, like other spray booths, helps remove harmful solvents from the air that evaporate when paint is sprayed.

Painting and drying chamber

Such chambers are used for applying liquid paints and varnishes. To ensure even distribution of paint particles on the base, creating optimal and safe conditions for painters to work. It also prevents the release of harmful substances into the environment.

Such chambers are used for applying liquid paints and varnishes.

Made from polyethylene

Special polyethylene is used; it is distinguished by its ability to magnetize so that dust particles are retained on its surface. This way you can avoid them settling on the paint layer. The matte film is stretched onto the walls; usually its effect is sufficient to paint 10-12 cars.

Special polyethylene is used; it has the ability to magnetize so that dust particles are held on its surface.

Powder application process

After completing the preparatory work and before painting the calipers with powder paint, we proceed directly to applying the composition. To do this, the product is placed in a chamber, which has several priorities before painting directly in the garage:

- traps powder particles and prevents them from spreading throughout the garage;

- ensures the disposal of waste that has not yet settled on the surface to be painted;

- provides good filtration.

You can paint calipers or discs directly on the car without dismantling them. This is a simple operation, but when performing it there is a risk of paint getting onto adjacent parts that do not need to be painted. The quality of the result is affected by weather conditions and wind direction.

The dyeing technology consists of the following steps:

- Painting at home begins with preparing the dye. To achieve the desired shade, take powders of several colors and mix.

- We prepare a respirator, gloves and goggles to protect against the effects of the composition.

- After the first layer has been sprayed, leave it to dry. The first layer is never perfect. The thickness of the powder paint layer is not too large, so a single application is not enough.

- The number of layers can vary, from 4 to 10. Apply until the thickness of the powder paint coating is ideal.

- The polymer coating is applied using a sprayer, which is positioned during the process at a distance of 25–30 cm from the surface to be painted.

What is needed to create a paint booth

A DIY paint booth requires the preparation of tools and materials. Knowing what is needed will help you create an estimate for the work. This way you can understand whether it’s worth pursuing the process or limiting yourself to renting a camera. List of required materials:

- A room with dense walls and floors;

- Ventilation;

- Filter system;

- Thermal generator;

- Wall covering material;

- Reinforcement grid to cover the floors.

A DIY paint booth requires the preparation of tools and materials.

Making your own oven

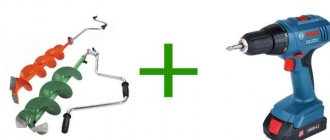

To create such a stove yourself, you will need the following list of materials:

- Profile pipes

- Fireproof thermal insulation (basalt slab is ideal)

- Sheet metal for cladding (ordered on any online resource or in a hardware store in the required quantity and size)

- Tangential fan and heating elements

Build process

- Initially, it is necessary to create a frame for the future furnace from profile pipes, then insulation is laid into it.

- The walls are sheathed on the inside using sheet metal; gypsum fiber should be used for sheathing on the outside.

- To create convection, a tangential fan is used, a wide inlet is created for it, and, accordingly, a narrow outlet is created to create draft.

- The fan is inserted into the chamber, its task is to suck in air from above, and then direct it through the heating elements, then the air will flow along the bottom and disperse throughout the chamber. The heating elements must be installed along the walls located opposite each other and connected, having previously been distributed into phases.

- Further, after installation, the heating elements are closed, only the fan is left open, the main part should be outside the chamber, this will avoid melting of the winding.

- At the final stage, an electrical panel is installed to which the camera will be connected. It is recommended to entrust this step to a specialist to avoid incorrect installation.

Thus, the equipment will be no worse than purchased. During the heating period of the chamber, the furnace power will be 12 kW, during operation only 6 kW. This device can use more than just electricity as an energy carrier.

Gas and diesel fuel are allowed, but the design changes slightly; it is necessary to install a gas meter, just as when working with diesel fuel, the installation of additional equipment will be required.

Requirements for a spray booth

There are certain requirements that should be taken into account to create a quality room for painting:

- High-quality ventilation and air purification are created;

- Adjustment of temperature indicators so that differences do not exceed 3 degrees during drying;

- Good lighting to see all the flaws;

- Compliance with safety rules.

It is important to make the room airtight; any breeze can greatly affect the temperature, which leads to the formation of defects.

It is important to make the room airtight.

Powder painting equipment: selection and self-production

Many of the necessary tools and devices can be made with your own hands. This will save a lot of money, but will require a lot of effort and time. To obtain optimal results, it is recommended to purchase some equipment.

Spray

The sprayer is one of the most important tools; the quality of the spraying determines how the coating will turn out. Therefore, it is better to refuse to create a device yourself and give preference to ready-made options. The principle of painting is that paint particles, passing through the gun, acquire a certain charge.

The device comes in two main types:

- Electrostatic. The particles in it are charged from external influences. It can be used to paint with any type of powder composition.

- Tribostatic. This option is simpler; the particles acquire a charge due to rapid departure from the nozzle and friction with each other. This spraying method requires compliance with certain conditions; the quality of the coating is affected by humidity. It is also necessary to correctly calculate the length of the connected hose, which depends on the power of the compressor.

- An interesting option is the Start pistol, especially with serial number 50. This variety is universal and combines both paint application technologies. For this purpose, the device is equipped with an additional tube for tribostatic spraying.

- Leader is more accessible. It allows you to do work at home. It features low paint consumption.

- For professional processes and large-scale production, Tesla equipment would be an excellent solution. The cost of such an installation is significantly higher than previous options, but provides a comfortable level of work.

Painting chamber

You can make a spray booth yourself; this does not require complex materials. But many masters believe that this area can be abandoned. Indeed, if the event is held once, then it is enough to prepare a comfortable and clean place, which is covered with thick plastic film. But for constant work, such a device will be useful.

Camera creation algorithm:

- The frame of the required size is welded, a metal profile is used for this. If painting will be carried out in a special room, then if there is free space, the camera is made stationary. The box created should be quite spacious.

- The profile is sheathed on the outside with iron sheets, and thermal insulation is placed on the inside. It is necessary to achieve extreme tightness, which will save most of the unused powder.

- For better paint collection, it is recommended to make the floor lattice.

- Separately, forced ventilation is provided.

You can simplify the task by placing the painting area along one of the walls of the room. Adjacent surfaces are sheathed with sheets of iron, the hanging point is located at some distance from the wall, and a container is placed under it for partial collection of the composition. The space is covered with a thick curtain.

The oven is one of the most important elements when performing powder painting. It is necessary to melt the composition particles applied to the surface of the part. An important condition is the choice of the optimal temperature. The essence of the polymerization process is that it is not the surface that needs to be heated, but the entire product that is being processed.

Making a furnace

Making such a device is not the easiest procedure. The detailed process algorithm includes several stages.

Preparing the necessary material

To create a furnace you will need:

- welding machine;

- Bulgarian;

- drill with attachments for metal;

- scissors.

- 100 mm thick basalt wool slabs;

- metal profile measuring 5*2 cm;

- galvanized steel sheets;

- tangential fan;

- heating elements (for a chamber with a width and depth of 100 cm and a height of 200 cm, 12 pieces will be required);

- temperature sensors and control unit.

Exhaust and ventilation system in the painting booth

The chamber helps to start the required air flow in the room, clean it of contaminants, and eliminate harmful substances present in the paint. Obtain the required temperatures for drying.

The chamber helps to start the required air flow in the room, clean it of contaminants, and eliminate harmful substances present in the paint.

Application of powder dyes

The powder is applied by spraying it with a special gun, so the paint particles have a positive charge, the base has a negative charge, this is how the materials adhere, and after fixing the result, it is carried out in a polymerization chamber.

Application of the composition includes the processing of metal, ceramic, glass, MDF, and stone bases. This property makes it possible to use it in the following areas:

- In the mechanical engineering sector;

- For the production of household and office equipment;

- For sports equipment;

- For furniture production;

- For products used in everyday life;

- In construction;

- When creating decorative elements.

The powder is applied by spraying it using a special gun.

Mode of application of cleaning and ventilation systems

Air masses are purified through three filters: coarse cleaning, where dust and heavy particles are removed; cleaning, the filter is located behind the heating element; fine cleaning, which is located behind the air duct.

It is necessary to install the filtration system so that filter replacement is easy.

It is necessary to install the filtration system so that filter replacement is easy.

Classification of furnace equipment

Thermal furnaces, combined into groups according to several common characteristics, are classified:

- dead-end and walk-through;

- single-pass and multi-pass;

- horizontal and vertical.

For full operation you need electricity, hydrocarbons (fuel oil, diesel fuel, natural gas). Several heating methods are used: convective, thermoradiation, induction. The convection oven model is more common. The structure heats up due to the movement of warm air masses. Infrared radiation is used as a heating source in thermoradiation models. The substrate heats up very quickly.

Heating system

Working temperature standards must be observed in order to obtain a high-quality result without putting the painter at risk of health problems. The following points can be noted regarding the heating system:

- Conventional heating and electric heating elements will be sufficient for the winter period;

- A heat gun will help warm up the room and ceiling areas;

- A heat generator is only needed for large jobs, otherwise the expense is not justified.

Working temperature standards must be observed in order to obtain a high-quality result and not expose the painter to the risk of health problems.

Interior decoration and arrangement

For interior decoration, it is advisable to use non-combustible materials in order to comply with safety standards. This is how a metal profile is often chosen. Also, non-combustible materials are selected for thermal insulation work.

For ease of work, an area is allocated for storing the necessary equipment and materials.

For interior decoration, it is advisable to use non-combustible materials in order to comply with safety standards.

What you need for work

The powder painting method involves the use of suitable equipment and devices, as well as dividing the process into sections.

For quality work you will need:

- Cleaning area. All parts undergo mandatory training. At this stage, the old layer is removed and degreasing is carried out. The process can use manual or specialized tools. If you plan to carry out constant cleaning, then sandblasting equipment is the best solution.

A convenient location of all areas should be provided; much attention is paid to the suspension system. Using a hanging trolley can make the task easier. Placing equipment even in a minimal amount will require a fairly spacious room, although some areas can be combined if desired.

Water curtain chambers

Such equipment is presented in several variations on the construction market. The choice is made taking into account the objects that will be painted in them. So there can be chambers without side walls and floor, with an active water floor and walls, etc. It is important to decide in advance what work will be performed in the chamber.

It is important to decide in advance what work will be performed in the chamber.

Advantages of using a stove

This oven will help you save money , because painting with it costs much less.

Any materials remaining on the body will be returned at a later date. This happens thanks to filters. After this, the remaining materials are cleaned. This economical approach to material makes it possible to prevent its loss. The maximum loss that can occur is two percent. Conventional dyeing has a loss of about fifty percent. Note that the difference is significant. Let's move on to the manufacturing process.

Consumables

To paint a vehicle, you will need to purchase other consumables. It is necessary to study their features in advance.

To paint a vehicle, you will need to purchase other consumables.

Cardboard pleated filter

Necessary to catch varnish, paint and other substances in the paint mist. This way the waste is collected without affecting the speed of air masses.

Necessary to catch varnish, paint and other substances in the paint mist.

Floor filter in rolls

Fiberglass material that absorbs small particles of fog; in terms of thickness, the best option would be a 7-centimeter option. Convenient to use, fire resistant.

Fiberglass material that absorbs small particles of fog; in terms of thickness, the best option would be a 7-centimeter option.

Fiberglass filters in cardboard frame

They are suitable for dry chambers and are installed in the 2nd level of filtration. They are distinguished by a good degree of air purification and durability of use.

They are suitable for dry chambers and are installed in the 2nd level of filtration.

Coconut fiber filters for water cabins

Suitable for high humidity, usually installed for the third degree of air purification. They can be washed several times for reusable use.

Suitable for high humidity, usually installed for the third degree of air purification.

Ceiling filter (for supply ventilation)

Required for the third stage of cleaning the intake air flow. They decide which type to choose based on the requirements for air purity. The filter also helps to equalize air masses.

Required for the third stage of cleaning the intake air flow.

Adhesive coating for dust protection

Necessary for removing dust particles during drying, painting and sanding the surface. It is distributed with a roller over the base; when the effectiveness decreases, a new layer is made.

Necessary for removing dust particles during drying, painting and sanding the surface.

Water Cabin Paint Remover

If you introduce the product into a water cabin, solid particles of material will bind, which will help remove paint waste without draining the water from the cabin. This ensures that the strong odor from the paint is eliminated.

If you introduce the product into a water cabin, solid particles of material will bind, which will help remove paint waste without draining the water from the cabin.

A powder paint booth or other paint booth helps provide the necessary conditions for high-quality painting, as well as safe work. In order to save money, you can make such a room yourself.

Features of the powder coating chamber device

Any powder coating booth usually consists of two main systems. This is high-quality air filtration, as well as powder recovery. Before the dyeing process, the powder must undergo a certain magnetization, which gives it a certain pole of the magnetic field. Here the second pole is the vehicle body. During the painting process, the powder adheres to the metal in a uniform and dense layer.

After the paint is applied, the layer is baked. For this purpose, the body will need to be heated literally to 160-180 degrees. When carrying out this process, the powder melts a little, but it should remain in this temperature mode for at least 10 minutes, preferably 20.

If such painting is carried out in a production environment, then it is used to paint not only the body, but also bumpers, wheel rims, headlight reflectors and plastic parts. Nowadays, special powder paint with a matte or leather-like effect is widely used.

As for the household dyeing method, the use of simpler materials and methods is quite sufficient. You need to follow the above tips and your powder paint booth will be ready.