All types of cutting machines with electric motors have a brush assembly. This is a bracket with carbon-graphite coins fixed on it, which are pressed against the collector rings. Through these elements, electric current flows to the rotor windings.

An electromagnetic field appears, due to which the angle grinder shaft begins to rotate. It turns the gears of the gearbox, and through them - the cutting or grinding wheels.

After using the grinder for a long time, sparks may begin to fly out of the brush assembly. This indicates that the carbon-graphite nickels are very worn out.

It is typical that the contact of their surfaces with the collector plane deteriorates. In this case, the power of the electric motor will drop significantly. You can feel this: if you press hard on the grinding wheel while cleaning parts, the electric motor of the angle grinder will stop rotating. If the wear of the brushes is critical, the grinder will not work.

Causes of abnormal sparking of an electric motor

Intense flashes on brushes can occur for a number of reasons:

- the service life of the sliding contacts is exhausted (the springs or the brushes themselves are worn out);

- dustiness of the walls and contacts on the commutator and rotor;

- fault in the rotor or stator winding.

To determine a specific malfunction, it is necessary to diagnose the electric motor. This will help eliminate the cause.

Repair operations

So, if an angle grinder sparks in the area of the brushes, how to eliminate this defect? You should start with the simplest solutions: carefully cleaning the contact surface of the commutator using “zero” sandpaper, removing graphite dust from the gaps using a pointed tool, replacing worn or abnormal brushes with new ones.

If, after 10-15 minutes of working on the grinder, the new brushes also burn, the reasons for this should be sought in the armature windings, although wear of the bearings, imbalance of the rotor or the geometry of its shaft are also possible. Entrust the repair of your angle grinder to the professionals of the Udachnaya Tekhnika Service center - you are guaranteed prompt diagnostics, quick repairs at an adequate price and high quality services!

Checking the contacts of the brush-collector unit

The reason for sparking of serviceable parts of the block may be poor contact due to insufficient contact with the collector lamellas. During operation of the vacuum cleaner, roughness forms on the surfaces of the engine's switching parts, which prevent the necessary contact. Grinding with fine sandpaper – “zero” – will help eliminate bumps, grooves and scratches on the commutator.

Advice! If the brushes spark excessively, then they should be pressed more tightly to the commutator using springs. In this case, the free movement of the block elements must not be disrupted.

The essence of the problem

Sparking brushes prevent the power tool from operating at full capacity. Since they are the connecting link in the electrical circuit, disruption of their operation leads to interruptions in the current supply. This negatively affects the motor winding and reduces its operating life.

Sometimes the fault may lie in the brushes themselves. They quickly burn out due to cracks, chips, scratches, and overheating. Replacing the old brush set will solve the problem. If the reason for the sparking is not the brushes, then the new ones burn the same way.

Heavy sparking on USM brushes

I mentioned Robert Ivanovich Bosch), I had a high-power machine, which is hard to hold on the palms during normal starting

No need to waste more than 1.5 kW of soft start. If it's closed, change it. I tried Bulgarian Interskol. terrible, out of control. Just look at it head-on using dialing. Severe curvature on the brushes Ear. Good evening everyone. In order not to create an additional topic, you decided to ask here. The situation is this: we have a pole-to-pole 230 mm at 2300 W. Smoothly running something brain powder sometimes works exactly right, and sometimes this picture doesn't. you press the button, at first there is a sharp jerk, and then it starts, as if with a soft start. Guys, can this be cured? And if so, how. Basically, don't say that hell is some kind of problem because of this, but, you know, the situation is not very good. Postscript Bulgar worked for about three years in professional conditions: for a long time, a lot, and sometimes with heavy (but not prohibitive) workloads.

This message was edited by Devil666: July 12, 2014. 22:13

Prevention

The problem of sparking grinder brushes can be prevented by taking preventive measures:

Read also: Why you can't hold back your sneeze

- follow the operating rules;

- regularly change the lubricant in the gearbox and bearing sections, reducing mechanical and thermal loads (factory lubricant must be replaced before starting any work);

- promptly replace bearings while maintaining the structural integrity of the armature shaft;

- install a new set of brushes before the old ones start sparking.

If you notice that the brushes spark and burn, you should immediately check the tool or contact a specialist. The lack of timely diagnostics of angle grinders leads to the fact that the sparking brush block ultimately breaks the entire power tool.

You will learn how to replace faulty brushes in an angle grinder in the following video.

Grooving with sandpaper

The armature shaft is fixed in the chuck of some torque mechanism (lathe, drill). The rotation starts and the abrasive is applied to the commutator. Avoid forceful pressure and the use of coarse sandpaper. The minimum grain size is 1000 P.

Using a multimeter, detect the presence of a breakdown in the armature winding. Set resistance test mode. Place one probe on the lamella and the other on the contact of the corresponding winding route. The absence of an open circuit will be indicated by an audible signal. If there is no signal, this route is broken. You will need to replace the armature or rewind its winding.

Determine whether there is any runout in the bearings. If it is found, replace the bearings and measure with a micrometer the diameter of the edges of the armature shaft in the places where it adjoins the assemblies.

Strong sparking on angle grinder brushes

Having mentioned Robert Ivanovich Bosch), I had a high-power machine for a reason, which is difficult to hold in the palm of my hand during normal starting

Than just 1.5 kW soft start you don’t need to throw it away. The brushes on the grinder sparkle. If it's covered, replace it. We tried the grinder Interskol. It's scary, it breaks out of your hands. If you don't look at him in the forehead, he'll hit you with a disk. Strong sparking on the brushes of the angle grinder. Good evening everyone. In order not to create an extra topic, I decided to ask for advice here. The situation is this: we have an interskal of two hundred thirty mm at two thousand three hundred W. The soft start is kind of mind-boggling, but it works quite correctly, but this is the picture. You press the button, at the first moment there is a sharp jerk, and then it starts as if with a soft start. Guys, can this be cured? in case and sell, then how. By and large, keep silent about the fact that there are some hellish problems due to this, but, you know, the situation is not good. PS The grinder is about three years old, it was used in professional conditions: for a long time, for a long time, and sometimes with heavy (but not prohibitive) loads.

Post edited by Devil666: twelve July two thousand fourteen. 22:13

Strong sparking on the brushes of the angle grinder, guys, question: angle grinder one hundred and twenty-five arsenal threw out the speed controller, now how to connect the stator

Attached images

Devil666, Conder is outliving his own skill, very similar. the capacitor needs to be changed

Strong sparking on angle grinder brushes

From my experience. After replacing the brushes, running for a minute after LATR with increasing voltage (from minimum to about one hundred and fifty volts), everything seemed to be normal. After a minute (I think the brushes got used to it at least a little), I began to increase the voltage higher. After 170-180 volts, a circular fire began. And with low voltage (with slow rotation), the rotation was smooth and uniform. Something doesn't fit. When I loosened the springs of the brushes a little, the fire disappeared.

How to understand that you need to change the brushes

Many people change brushes only after they notice strong sparking from the tool, as well as the appearance of a burning smell. Many craftsmen are not stopped even by these signs, and they continue to use the tool until it stops turning on. When is it necessary to change carbon brushes so as not to damage the structure of the power tool? There are the following signs for this:

- Strong sparking - if signs of strong sparking appear, then it is necessary to disassemble the tool and inspect the consumables. Sparking is the first sign that consumables need to be replaced.

- The appearance of a burning smell - if the smell of soot is heard when using the tool, it is recommended to disassemble the grinder and replace the graphite brushes

- When the wear of the main part is over 30% -40%. However, it is almost impossible to determine their initial length, unless you measure it before installing the elements

- When signs such as jerking or “growling” of the power tool appear

Devices are also subject to replacement if they have uneven wear and do not correspond to quality.

This is interesting! It is not recommended to buy copper-plated brushes for a home grinder, as they will quickly damage the armature commutator due to the high copper content in the composition. Copper-plated elements can be used on grinders that have a special coating on the collector plates.

https://youtube.com/watch?v=Wt0n_ECSwvE%3F

How to open a SIM card slot in a phone

Developers of phones, or rather smartphones, never cease to amaze with meaningless innovations.

However, you have the right to disagree with my opinion, but I, for example, absolutely did not like, for example, the hybrid slot.

This code allows you to insert either a SIM card or a micro SD flash drive into it. Maybe earlier, when there were no two slots at all, such a decision would have been received with a bang by everyone.

Only today no one likes to constantly change cards, but many have to, especially those who call to foreign countries.

The second “misunderstanding” is the key slot. Not only is it hard to find, it also requires a key or something similar.

I don’t know why they didn’t like the traditional slot on a regular latch - I pressed it once, the slot opened, pressed it a second time, the slot closed tightly.

If your smartphone can only install one SIM card, then there is a good way to install two - more details here.

Simple and convenient, but if this happens, I’ll show you how to open the slot on Samsung, Xiaomi Redmi 3, iPhone, Meiza, Asus, Huawei, Lenovo, and so on.

How to properly open a SIM card slot with a key

For those in the know, this may be obvious, but there are many people who may miss these pinholes as they are not very well integrated into the design.

Step 1: Find a small hole on the device body.

Step 2: Find the SIM card insertion tool inside the box of your phone. If you lose it, you can use something like a paperclip.

Step 3: Insert the tool into the hole, press firmly and the slot should pop out.

Step 4: Remove the SIM card from the tray or carefully place the SIM card or flash drive into it.

Step 5: Insert the tray back into the phone and press it to close.

NOTE: You can use a paper clip, but be careful and never use a sharp object like a pin. This will damage the tray. Also, do not use wooden sticks - they may get stuck in the hole.

How to properly open the SIM card slot in a Samsung / Lenovo / Xiaomi Redmi 3 / Meizu 2M / Asus / Huawei and others

In order to open the SIM card “pocket” you need to find it. This is not difficult - carefully inspect the body and find a small hole (like for a needle).

Of course, I’m only writing about pull-out trays, because they’re still ordinary ones, most often under the radiator.

When you find it, insert the key or straightened paperclip into the hole next to the pocket.

A key is a small metal tool that you sometimes receive with a new phone, but you can open the SIM card slot without a key.

How to properly open a SIM card tray without a key

If you are a lady or have a girlfriend, then almost any earring can open the tray.

Why do the brushes on the grinder SPARK and BURN. Repair or replacement of angle grinders

Why do the brushes on a grinder SPARKLE and BURN so quickly? Let’s look at the reasons and methods of elimination. Strong sparking often indicates imminent tool failure. It is necessary to promptly understand the reasons for the appearance of increased spark formation and take measures to eliminate it. Causes of electric motor brushes sparking Brush wear. If these elements are severely worn, the electric motor does not develop speed at full power, and may also not turn on (continuously or periodically). In this case, when the electrical appliance is turned on, you can press the brush against the armature with a screwdriver with an insulated handle. If an increase in engine speed is observed, then the problem has been correctly identified. Most likely, replacing worn parts with new ones will correct the situation. Sometimes the brush holder springs also need to be replaced.

Where can I buy

It is important to replace the worn part with the same new one, made by the same manufacturer from the same material, and having all the necessary properties. There is no need to go shopping with the brush removed in your hands and select a very similar product, it may well turn out to be only similar

There is no need to go shopping with the brush removed in your hands and pick up a very similar product, it may well turn out to be only similar.

You can find the manufacturer’s catalog online, select a modification of your angle grinder, and determine the number (code) of the required part. Then go on an Internet search for the supplier company. Then persuade her to send you not a box, but only one pair of original brushes.

Choose.

Sections: Grinders

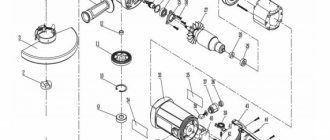

Angle grinder device

To understand the operation of the mechanism and why breakdowns are possible, you need to have an idea, at least schematically, of the main components of the tool.

Regardless of the model, manufacturer and technical characteristics, any angle grinder has the following details:

- The moving part of an electric motor is called an armature, or, what would be technically correct, a rotor. As a rule, this element is combined with a working shaft that transmits torque.

- Contacts of the collector, which is a switching board, through which the voltage is removed from the current collectors.

- Brushes pressed against it provide electrical contact. When pressed lightly, they begin to spark strongly.

- The internal stationary winding is the stator. The rotation of the armature in it is achieved due to electromagnetic induction.

- Mechanical reduction gearbox for speed regulation.

- Other components: housing, usually plastic, handles, start button, power cable.

As a working tool, an angle grinder is subjected to high loads and increased continuous operation time. Despite the maximum tightness, dust, small fragments of processed materials, and scale periodically get inside the housing. This negatively affects both the mechanical parts and the electrical part.

As a result, the conductive parts become contaminated and the collector lamellas gradually burn out due to overheating. In turn, this leads to destruction of the current collecting brushes, which will be signaled by increased sparking.

Care and proper operation of the grinder

To make the grinder work for a long time, follow the rules:

- Monitor the integrity of the insulation of the wire and plug. Don't remove your protection.

Lubricate and clean the entire tool.

After turning off the grinder, wait until the circle stops rotating, then place it on the ground. When the engine stops, the tool, through the ventilation holes, sucks in, along with the air flow, particles of earth and other hard fractions that hit the motor windings. As a result, a break or short circuit occurs.

Try not to use an angle grinder outside in the winter. While you are running, the engine gets hot. The air is icy. As a result, condensation forms. Moisture is harmful to the engine. Always use the circles recommended by the tool manufacturer. If the angle grinder is 180 mm, do not put more than 200 mm there. The larger the circle, the lower the revolutions should be. You will have to remove the protection, and the speed will be exceeded. Vibrations and vibrations will increase. As a result, the circle will break into pieces. This is not only fraught with serious injuries. The gearbox bearing breaks and the gears wear out.

Post Views: 10

How to replace brushes on an angle grinder

Very often, the manufacturer of angle grinders completes their products with a spare pair of brushes (graphite contacts that allow the transmission of electric current to the rotating rotor).

Is this part really wearing out so intensively that it’s the only thing that needs to be added? If the tool is used occasionally, the brushes will outlive the owner. But if you use the grinder every day, then, indeed, their wear will be significant. And the day will come when a several-centimeter graphite rod will be worn down to a thin plate. It is impossible to allow extreme wear of the brushes, so as not to damage the rotor contacts. The condition of the rods must be checked periodically, after tens of hours of operation.

The most basic way, without disassembling the case

Some manufacturers approached the possibility of replacing brushes very rationally. There are screw plugs in the machine body. And the entire test or “repair” process takes two minutes (for both graphite contacts):

- Unscrew the plug with a screwdriver.

- Use a thin screwdriver to pry off the pressure cap and remove the brush.

- If the brush has lost 70–80% of its length compared to the new one, then it should be replaced. Otherwise, the old graphite contact must be placed on the same side as it was before removal in order to eliminate the grinding process. After all, brushes wear unevenly due to the fact that they come into contact with a rotating cylindrical surface.

- Screw the plug until it stops. Attention! The cork can also be screwed upside down. Therefore, you need to make sure that there is a groove for a screwdriver on top. Otherwise, difficulties will arise the next time you unscrew it.

- Repeat all steps with the brush located on the back side of the grinder body.

This is the easiest way to replace brushes on an angle grinder and does not involve disassembling the body. Therefore, when purchasing a new tool, this nuance can be taken into account.

Reasons why brushes spark

Very often you can notice how the brushes on an angle grinder sparkle. Signs of sparking are detected through the ventilation holes in the body of the power tool. Craftsmen are interested in why the brushes on an angle grinder spark, even after they have been directly replaced. There are many reasons for this, and to understand this, you need to have an understanding of the structure of a power tool. If you know how the angle grinder works inside, then understanding why the brushes spark strongly will not be difficult.

The reasons for strong sparking of brushes on grinders are the following factors:

- Faulty armature winding. If a violation of the insulation of the armature winding occurs, then this ultimately contributes to the development of an interturn short circuit, as well as a short circuit to the core. In addition, a winding break may occur, which will ultimately cause an increase in load. A characteristic sign of a faulty armature winding is a decrease in speed, an increase in noise and a drop in power

- The brushes do not press well to the commutator. A spring is responsible for pressing the main part, which, over time, loses its original springing properties.

- The rotor winding has broken off from the copper plate of the commutator - this phenomenon is extremely rare, however, if the power tool is overloaded, it may well occur

- The centering of the electric motor armature is disrupted, which ultimately contributes to strong sparking of the brush on the angle grinder

- The shape of the collector is broken. The collector, consisting of copper lamellas, has a cylindrical shape, which can be broken when the rotor is rewinding. At the slightest deformation of the commutator shape, sparking of the brushes will occur

- Violation of insulation between the collector lamellas. Each collector plate is insulated from each other, and if the micanite insulating layer is damaged, sparking occurs. The insulation between the plates may also be compromised due to the settling of the graphite layer in the grooves

- When the armature bearings are worn. If the bearings are faulty, then a beating of the rotating armature occurs, and as a result, signs of sparking appear

- Curvature of the rotor shaft. It is difficult to bend it, but if this happens, the engine begins to work under load. To prevent the tool from malfunctioning, it is recommended to replace the rotor

- If the ends of the armature windings are soldered incorrectly to the copper plates of the collector. Such errors are not allowed at the factory, but they can be made by the wrapper who rewinds the armature of the power tool.

- Inappropriate composition of graphite brushes. The parts in question are made from coal and graphite, adding different types of impurities. This is done for a reason, but in order to use brushes depending on the voltage and shaft rotation speed. Graphite can be soft or hard. The lower the supply voltage, the softer the grade of graphite selected. For high-voltage power tools, it is necessary to take hard brushes that do not contain copper.

- Deformation of the lamellas due to their heating. If the angle grinder experiences excessive loads, deformation of one or more lamellas of the collector may occur. The plates rise relative to the others, resulting in the contact being broken. This malfunction causes strong sparking of the brushes when operating the power tool.

- Poor contact at the brush connection point. If the terminal is loosely connected to the device, the result of this contact failure may manifest itself in the form of excessive sparking

- Presence of carbon deposits on copper plates - periodically or regularly it is recommended to clean the surface of copper lamellas from carbon deposits. Carbon deposits usually appear due to wear of the brushes, so if blackening is detected on the surface of the commutator, it should be wiped with alcohol

Often, after changing the brushes on an angle grinder, craftsmen observe the phenomenon of excessive sparking. Based on the factors described above, you can identify the cause and eliminate it before the tool fails. The elements in question are inexpensive, but due to their incorrect selection and use, the power tool may break. To find out what malfunction is causing strong sparking, you will need to disassemble the power tool and inspect it, as well as ring the rotor winding.

Create an account

Register for an account. It's simple!

Problem solving options

In most cases, the reason why the brushes burn may be a short circuit in the stator or rotor. Very often angle grinders come across craftsmen for whom an angle grinder is a grinder, a tool for cutting metal, and a saw. When cutting metal, the rotor stops not so often, but when using disks for cutting wood, the cutting tool often jams.

In this case, the voltage in the wiring will rise, and a short circuit and sudden wear of the graphite may occur. When parts are subsequently replaced, the same wear may be observed, accompanied by “all-round fire,” that is, excessive sparking. In such cases, new brushes sometimes burn out in 5-10 seconds.

In addition, a burnt winding can be rewound by experienced specialists in workshops, but if the specialist makes a mistake during the work, or the winding is connected incorrectly, the result can be disastrous.

Such faults can be checked with special devices that are often used in workshops. For example, carry out inductance measurements or determine the short circuit of turns with a special device. If a short circuit has occurred, this can be determined visually or by measuring the resistance. The resistance on all turns should be the same or with a slight difference. Burnt armature lamellas can also tell you why the brushes on an angle grinder are burning and the reason: uniform burning is most likely the reason in the stator, and if it is uneven, then in the rotor.

The interwinding breakage of the armature can be checked using an ohmmeter: take measurements between adjacent lamellas and diametrically opposite ones - the difference in resistance should be no more than 5%. Motor with a power of 0.6−0.7 kW: the resistance of the stator winding can be 40−6 Ohms, and in the armature between adjacent lamellas 1−1.5 Ohms.

What are they made from?

Brushes for grinders and other power tools are made from different materials, but the main ones are coal and graphite. This material has a low coefficient of friction and also has increased abrasion resistance. To improve contact, various impurities are added to the composition of graphite or carbon during the manufacture of brushes. Depending on the impurities used, the following types of brushes are distinguished:

- Coal

- Copper plated

- Carbon-graphite

- Graphite

- Copper-coal

- Copper-graphite

The composition of the main part affects not only the service life or wear, but also such a parameter as signs of sparking. The amount of brush sparking depends on the composition from which they are made. When purchasing them, you need to pay attention to the composition, and not purchase equipment of unknown origin and dubious quality.

This is interesting! The design of the brushes contains a ceramic tip, which performs one of the important tasks. When the graphite layer is abraded to the limit, the tip begins to contact the copper lamellas of the commutator. Ceramics do not conduct electricity, so when the brushes wear out, the grinder will work intermittently or will not turn on at all until the devices are replaced.

The concept of the brush mechanism

Since contamination of the grinder is inevitable, you need to know more about the design of this part. For various malfunctions, the largest percentage is detected in this node. In addition, even in a serviceable tool, unforced wear of the brushes is inevitable, although this happens very rarely.

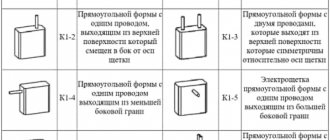

Selection of electric brushes

This element is a hexagonal geometric figure with identical parallel edges. To ensure electrical contact, a copper lead is pressed into it.

The sizes and shapes of brushes vary, as does the material used to make them. The initial device was simple: copper wire and a conductive brush. But due to great wear and tear, this design had to be modernized.

Modern current collecting elements are produced by compressing carbon materials with increasing temperature and pressure.

If, when working with an angle grinder, as well as a drill, the tool functions jerkily, with a characteristic burning smell, then the root cause lies in the wear of this small part. It is not recommended to neglect their replacement, as this will inevitably lead to failure of the device. In this case, you need to stop work, find out the reason why the brushes on the electric motor are burning, and begin repairs.

Types of devices for collecting current

Underestimating the importance of the good condition of this part leads to serious consequences. Timely measures to prevent them will extend the service life of the tool.

First you need to understand the types of current collectors:

- The production of graphite brushes for an angle grinder occurs by mixing the base substance with a binder composition. As a result of pressing carbon materials under pressure and further firing, a product with additional strength and wear resistance is obtained. Then the graphitization process begins, which consists of heating to a temperature of 2500-2600 degrees in special furnaces. This is the most common type of such products, although it is quite expensive, but its service life partly compensates for it.

- To produce carbon brushes for grinders, the same graphite or carbon black is used, only additional hardening is excluded from the cycle. This significantly reduces both the cost of the product and its durability.

- The raw materials for the manufacture of metal-graphite brushes, as the name suggests, include metal in addition to the main element. Usually this is copper powder, but the addition of tin, lead or silver is not excluded. The content of the metal component can reach up to 80 percent. Applications for such parts are primarily in industrial generators and electric motors. For household needs, these products are too expensive.

Before purchasing a replacement set of brushes, you need to find out their type and dimensions in the technical data sheet of the tool.

Causes of wear of current collecting elements

The grinder, like most power tools, was originally designed to operate from a DC power source. Then, by connecting the rotor and stator windings in series, it became possible to be powered by alternating current without limiting the speed, as happens with brushless motors. Therefore, increased requirements are placed on the unit with the current-receiving mechanism. And if the brushes on an angle grinder burn, the reason may be as follows:

- Malfunction of the rotor winding: turn short circuit, broken coils. A characteristic sign of this is a decrease in the number of revolutions and a loud hum.

- An equivalent reason is poor contact between the lamellas and the winding.

- The springs of the brush holder mechanism have weakened.

- Armature runout due to destruction of bearings.

- Reservoir development.

- The paths between the lamellas are clogged with graphite dust or they have shorted out. They can be cleaned with a metal saw blade.

- Deformation of the rotor shaft.

- As a result of rewinding the armature, the current-carrying coils are mixed up.

- The wrong brand of brushes was selected.

- Natural wear of the current collector.

Not every one of these reasons causes brushes to wear out quickly, but none of them can be ruled out.

Replacement methods

Once it has been established why the brushes on the angle grinder are burning and the cause of this malfunction has been eliminated, you can begin to replace them. There are two options for the process itself:

- The easiest way to carry out this activity is on those models of household electric tools where there is free access to the brush compartment without disassembling the case. In this case, this can be done quickly: just open the cover, remove the worn part and insert a new one of a suitable type.

- However, this method is not always available. In other cases, you will have to disassemble the device. The first step is to remove the cutting disc from the grinder and disconnect it from the power supply. Then, in accordance with the instructions, disassemble the tool. Usually it is enough to carefully remove a few screws and split the case in half. Then you need to disconnect the copper contact of the old part and remove it from the mounting socket. When installing a new spare part, you need to firmly connect the leash into place and check that the brush is securely pressed to the commutator by the spring mechanism. It is especially necessary to make sure that the type of component being replaced corresponds to what is used in this angle grinder. If the discrepancy is only in size, the problem can be solved using a needle file, small file or sandpaper.

Replacing angle grinder brushes

In most models of grinders, electric brushes are located inside the handle (see photo). This arrangement is due to savings in the production of the body, as well as more comfortable operation of the tool due to its compactness. On some other models, for the convenience of quickly replacing brushes, the screws are located directly on the body. In any case, it is more advisable when replacing brushes to also clean and lubricate the entire tool, and for this it must be disassembled.

Regardless of the location of the electric brush, first you need to disconnect it from the electric circuit of the angle grinder. The tips are removed, a visual inspection of the holder structure is made, and the brushes are pulled out, as shown in the photo. If chips, abrasions or other signs of wear are found, they are replaced with new ones.

Usually, a spare belt is given along with the grinder upon purchase. a set that includes brushes. They can also be purchased at any specialty store. It can be difficult to find suitable ones for some models of grinders, so brushes are purchased a little larger than the required size and carefully filed. If the tips are different, the leash from the old brush is attached to the new one.

For Interskol angle grinder models, in order to remove the brushes, you need to remove the back cover of the stator housing. Then the screws from the holder are unscrewed.

Wear of elements is determined by their residual length. The length of working carbon brushes cannot be less than 5 mm. For a more detailed study of the technology of changing brushes, you can watch the video.

Access to the electric brushes on Bosch angle grinders is achieved by opening the handle of the stator housing, which is held on by a screw. The length of working carbon-type electric brushes must be at least 8 mm. By the way, carbon electric brushes for Bosch are distinguished by the presence of a device that stops the operation of the tool when the brushes reach their minimum operating length.

In the Makita angle grinder, the screw is unscrewed and the back cover of the case is removed. The Makita 9565 model uses carbon brushes with auto-off.

Selection of electric brushes

Brushes differ in size, shape, and material of manufacture. Previously, they were produced in the form of a structure consisting of copper wire and a conductive brush. But due to very rapid wear and tear, it was decided to modernize this design. Currently, electric brushes are produced by pressing carbon material at high temperatures.

These replaceable elements of the mechanism should not be underestimated, because the service life of the engine depends on the correct operation of the brushes, because by replacing the brushes in time, you can protect the angle grinder from destruction of the armature commutator plate.

- Graphite brushes. During production, graphite is bonded to a special composition, to which carbon black can be added. Next, molding occurs under pressure, and then firing. The difference in the production of such brushes is due to the fact that the material is given additional strength and wear resistance. They are made from carbon materials (graphite, carbon black) and binders. After the standard molding procedure, graphitization follows, which involves firing at a temperature of 2500-2600°C in specialized furnaces. Such electric brushes are the most common for using grinders. Despite the relatively increased price category, the advantages of the properties outweigh the high cost;

- Carbon brushes. The main material for the production of these brushes does not differ from graphite. The difference between the production technology is the absence of heat treatment, which reduces production costs. Hence the low price tag in stores. But the wear resistance of such brushes is insignificant.

- Metal-graphite brushes. The composition of raw materials for making brushes includes not only graphite powder, but also metal. Mostly copper powder is added, but lead, tin or silver may also be added. At the same time, the metal base of the powder contains about 80%. Such brushes are used in generators and electric motors, because They are characterized by high wear resistance and reliability. But they are very rarely used in household electrical appliances. The price category is high.

Before buying electric brushes, it is better to look in the instructions or technical notes. in the grinder's passport, which brushes the manufacturer recommends. You can also consult service centers about choosing the right brushes.

SIM card ejector

Get your SIM out without any problems

A needle clip for opening the SIM card slot.

Once - and you're done

It happens that you need to open the SIM tray when your smartphone is frozen or to move the card to another phone. But this is not so easy to do. The rod from the handle will not fit into the hole. And if you poke it with a needle, you can damage the mechanism and scratch the case.

You will need a special tool - a paper clip . It has the right length and thickness so that you can open the slot in one motion .

Always at hand

It’s convenient to have several fasteners . Leave one at home, put the other in your wallet, and the third in the car. And such a simple procedure as removing a SIM card will never cause you problems or irritation.

| Manufacturer | Novatek Science and Technology Company Limited., Room 609, Yeshu Village, Shangsha, Shenzhen, China (China) |

| Supplier in the Republic of Belarus | Forever-mobil LLC (portative.by) |

| Guarantee | 30 days |

Delivery by courier in Minsk

The courier will be polite and neat. He will call you 20 minutes before arrival. He will have change.

- We accept orders for delivery from 9:00 to 18:00 daily.

- We deliver orders from 14:00 to 21:00 on weekdays.

We deliver orders

over 50 rubles

for free . If the order amount is less, delivery costs 5 rubles.- We deliver to all districts of Minsk

, except for the Sosny, Sokol and Minsk-2 microdistricts. - You can pay for your order in cash to the courier, by card or ERIP.

Pickup from stores

We will reserve goods for you in any of our stores

- Pickup is possible from stores where the product is in stock. You can pick it up on the day you order.

- Before arriving , place your order on the website

so that we can set aside the goods. - There is parking in front of all stores. On Komarovka we pay for parking for customers.

- The stores have terminals for plastic cards.

Delivery by mail throughout Belarus

When we send the parcel, we will send the postal code via SMS.

- We send parcels every day, except Saturday and Sunday. Delivery takes 3–4 days.

We deliver orders over 50 rubles for free If the order amount is less, delivery costs 5 rubles.- Orders placed before 18:00 are dispatched the next morning.

- You can pay by cash on delivery at the post office, by card on the website or through ERIP.

Express mail - delivery in one day. Sending costs 8 rubles.

We guarantee:

- You will receive exactly the product you ordered. In the same set as indicated in the description.

- You will pay the amount you see on the website.

- Your order will be delivered at the time you specified.

Payment in Belarusian rubles upon receipt of the order.

- You can pay in cash in stores or upon delivery by courier.

We accept plastic cards from all banks in Belarus and the world, including Belcard.

- The easiest way is to pay by card when ordering on the website. It's fast and safe - the payment is made through the Assist system and Belarusbank.

- There is a terminal for card payments in stores

- The courier can accept payment by card via a mobile terminal

Pay as you would with a regular bank card.

Bonus card Halva Plus

. With every purchase you get 2% back

Bonus card KEYcard

. With every purchase you get 3% back

Pay as you would with a regular bank card.

Halva MIX and MAX installment cards

Installment period is 2 months.

Installment card Purchase card.

The installment period is 4 months.

FUN installment card

. Installment period is 3 months.

Installment card Turtle

. The installment period is 10 months.

Priorbank credit card

*. The installment period is 6 months. *Only in stores or courier.

You can pay at cash desks, ATMs, information kiosks and at the post office.

- An invoice for payment is generated when placing an order on the website.

- Select the “Online stores” category. Then the letter “P” and the Portative.by store

- Enter your order number and pay

Convenient payment method for delivery by mail throughout Belarus.

You pay for your order upon receipt at your post office.

Why do the brushes on an angle grinder burn? – Metals, equipment, instructions

“Bulgarian9” itself has nothing to do with it. This phenomenon applies to all commutator-type engines. Motors of the so-called serial type are installed on hand-held power tools. This is when the stator windings are not connected in series. This is because initially the myth was that the type of electric motors was created for direct current.

However, the use of a sequential circuit allows it to be connected to an alternating current circuit. The speed of such a motor is not limited by the frequency of the current, as is the case in brushless electric machines. Due to the increased speed, a number of requirements are imposed on the commutator assembly, which are aimed at reducing sparking under the brushes, without thereby reducing engine heating.

- The armature winding is faulty. Interturn short circuit, breakage of no more than one winding section. A characteristic sign is a drop in speed and increased noise.

- Loss of contact of the winding with the collector plates. Equivalent to the winding break mentioned in paragraph 1.

- Poor brush pressure. Sometimes, due to prolonged operation, the springs that press the brushes to the commutator lose their elastic properties, because heated up not to be “annealed9″.

- The balancing of the electric motor armature is disrupted.

- The cylindrical surface of the collector is damaged. For example, it was removed for some purpose, during rewinding, not when it was put back on the shaft, or turned on a lathe.

- The micanite insulation between the collector lamellas is broken. Breakdown between the lamellas, in other words, settling of graphite in the grooves of the track.

- Bearing wear does not result in increased armature runout.

- Changing the geometry of the armature shaft. For example, it was slightly bent when disassembling the electric motor.

- Violation of the so-called “electro-neutral9”. If the brushes are in the wrong position relative to the stator poles. Various engines have this adjustment. It is not available in handheld power tools. But it happens that when rewinding the armature, the winder incorrectly selects the lamellas onto which it leads the ends of the winding. Under such circumstances, oil will also be disrupted.

- The wrong brand of graphite brushes was supplied. The grade of graphite is selected based on the supply voltage and the expected speed. Relatively speaking, the lower the voltage, the softer the graphite. In low-voltage machines, brushes with high copper content are used to reduce losses. In high-voltage, on the contrary, there is no copper. The graphite used for high-speed motors is harder.

- Additional reason . For example, due to overheating during prolonged operation, you will experience a change in the physical properties of the glass melt from which the collector is made. It happens that one, as it is also called, several lamellas, gradually begin to rise. The wear of the brushes increases, but this common rumor is also accompanied by a strong spark.

Something like this. Choose from this list that doesn't just suit your situation.

READ Disc For Grinder Cutting Wood

Why in Bulgarian

Do the brushes burn out quickly (I installed new ones and they burned out in three minutes)?

Let me argue a little with the previous answers. That's it, under no circumstances should you install copper-graphite brushes. They are denser and do not cause mechanical damage to the anchor. Which then leads to a possible short circuit of its winding, and this turns the contact surface into something similar to sandpaper, this again gives rapid wear for simple graphite brushes.

Copper-graphite brushes are mounted only when the contact surface of the armature has a special coating or is made of a special alloy.

There is another option for the reason for rapid wear of brushes - armature beating. Edelweiss is a matter of wear on the bearings of the electric motor bushings, depending on what is installed. However, this is a rarer case.

And as another possibility, it is worth mentioning the possible presence of a micro breakdown in the winding. Heating occurs in the electric motor just at the right time, this heating does not manifest itself as a micro breakdown, something like this happens. only very weak, the brushes begin to burn out quickly.

The best option would be to take the grinder to a workshop. There they would check it - if desired, they would grind the contact surface, ring the winding, replace the bearings or bushings.

If you can’t do this, then you can at least try to grind the anchor yourself. Disassemble the engine, clamp the armature into a drill at maximum speed and polish it.

You just need to use sandpaper of the smallest grit, micron.

Not here, practically do not put any effort on it, but only lightly touch it. And then carry out the second stage - initially rubbing the sandpaper against each other, thereby erasing the surface layer and such a situation will already be like polishing. And the final step is to polish it with a piece of cloth, also called felt, moistened with machine oil.

Don’t forget that the layer to be removed must be minimal - a micron or two, based on the existing damage.

Here you need to make a precise determination - are your brushes burnt out or worn out?

If they burnt out, then I have never seen anything like this before; when the motor shorts out, the brushes themselves do not burn, since they are made of a material that, by and large, has no right to burn out, unless it is subjected to a large current, alas, then it will be a bunch of sparks no short circuit at the bottom. Which, as far as I understand, did not happen for you.

Therefore, I assume that rapid wear has occurred. Then, of course, we’re not talking about brush wear, but wear on the motor commutator. I've encountered this many times. When, due to commutator wear, the brushes are not worn out first.

What's happening is that the collector itself is divided into parts, look at

To determine the wear of the collector, you will have to get to it without checking the coating.

So I’ll answer it myself, since I figured out what the reason , it turns out I added problems to myself! Like an office worker, when the brushes on the angle grinder wore out and the machine started to work jerkily, it was necessary to stop immediately. alas, for the reason that I had nothing to finish cutting with, I still cut it further.

The worn-out brushes hung on the limiters and did not create a huge arc in a circle, alas, the machine continued to spin the disk, it was not I who sawed, the arc ate out a groove on the armature commutator like electric welding, and when I installed new brushes they did not have a plane of pressure against the armature commutator, they did not burn out, they just idled very quickly work.

Having disassembled the grinder, I saw a gloomy situation, an attempt to polish the armature commutator at the turner did not end in success, I had to buy a new anchor, since it was impossible to replace only the commutator, and besides, honestly no one even wanted to take on this. The result was that the finished 40X40 profile resulted in the purchase of a new anchor, but that’s not the whole reason for this action.

What spare parts for angle grinders can be changed independently, and how to properly maintain power tools

A grinder at home is like a telephone connection. When the oil is in good working order, no one remembers about it. Once a breakdown occurs, it immediately becomes obvious that you can’t do without it for a day. Repairing this useful electrical appliance on your own is possible even for a novice craftsman.

First of all, let's look at the structure of the grinder.

An internal moving component of an engine. Usually it is integral with the working shaft, through which rotational energy is transmitted to the gearbox.

Contact elements pressed against the commutator plates.

The outer winding of the motor, inside which the armature is required to rotate. Located along the inner contour of the instrument body.

A mechanical component that reduces the speed on the working shaft while simultaneously increasing it.

Causes of severe sparking and how to eliminate them

Now let's move on to strong sparking. It occurs mainly for the following reasons:

- contamination of collector contacts with carbon deposits

- graphite dust getting between the collector contacts

- interturn short circuit in the armature winding

1) Soot contamination occurs as a result of engine overheating. The presence of carbon deposits leads to even more friction, which leads to even faster overheating and even more carbon deposits. Which very quickly leads to breakdown.

Excessive sparking here results from the fact that carbon deposits form additional resistance, which causes the spark to break when it breaks, becoming larger and more powerful.

In general, carbon deposits should be removed immediately.

This is done with zero grade sandpaper. That is, you need to remove the collector along with the armature and carefully clean it. Ideally, it is advisable to carry out the grinding on a lathe so as not to disturb the correctness of the circle. But, as a rule, this is not possible, so you can get by with manual stripping. The main thing is not to overdo it.

2) When using a drill, the brushes wear out, which causes the formation of graphite dust. It can easily accumulate between the collector contacts and lead to short circuits between them, since it is a conductor of electricity and has its own resistance. Because of this, the current is distributed unevenly, which leads to large sparks in some places.

In a working drill, wear occurs quite slowly, so graphite dust hardly accumulates. Accordingly, its accumulation signals that the brushes are in the wrong position during operation. This usually happens when they do not stand tightly in their groove, but, on the contrary, have some play.

This often happens when replacing brushes, when they are selected to be not quite suitable in size. Therefore, when replacing this point, you should pay close attention.

Repair of such a malfunction is carried out by removing dust with some pointed tool and replacing the brushes with more suitable ones.

3) In the event of an interturn short circuit in the armature, the current flows in a larger value to some contacts and a smaller value to others. Because of this, more current flows in some places than necessary, resulting in large sparks.

Identifying such a short circuit should be done when the two previous points did not give much effect. It is produced using a special device that creates an alternating magnetic field. When an armature is placed in this field, it begins to rattle, as induced currents appear in it.

Poor contact between brushes and commutator

The electric motor spends part of its operating time in overheating mode. Under such conditions, carbon deposits form on the collector. Poor contact leads to increased brush sparking and even more carbon deposits.

You need to use fine-grain sandpaper to clean the surface of the commutator. To increase the stripping effect, use a screwdriver. Clamp the engine rotor into the chuck and remove carbon deposits with sandpaper at low speeds. Afterwards you need to finally polish it on a felt wheel.

Types of faults

These replaceable and relatively inexpensive parts may also have faults:

- They are poorly polished and do not fit the entire surface of the collector.

- With broken edges.

- With deep scratches.

In this case, there will be increased sparking. To remove them, rub them with glass paper. During the lapping process, you must first use coarse-grained material, and then fine-grained material. The use of emery cloth is undesirable in this case, since emery dust, if it gets on the commutator, can short-circuit the commutator plates.

Collector breakdown and repair

Another reason why brushes on an electric motor burn is a faulty commutator. Brushes don’t just burn out, unless, of course, this is associated with a large increase in current. In this case, a short circuit may occur. If this does not happen, and the graphite brush for the grinder is bought one after another and washed, then you should pay attention to the coating of the commutator surface.

READ Grinder Wheel for Paint Removal

The surface of this part has a special coating, and after it wears out, the brushes wear off much faster. Also, when sparking, carbon may form on the surface, which will simply erase the graphite. Wear of the commutator and brushes may occur due to a faulty motor winding. In this case, any installed brushes will be “eaten”.

Very often, consumers try to restore brushes from large spare parts, since they cannot find original ones, so they try to pick them up from another motor, file them down, and adjust them to the size of the brush holder. The graphite rod is adjusted to the desired size, a hole is drilled for the copper conductive wire and then sealed with tin. However, such a procedure can result in wear of the commutator and, in the worst case, the entire armature winding.

If everything is checked and the operability of the windings is confirmed, but the brushes still wear out quickly, it’s worth returning to the commutator again. If the surface roughness is compromised, which is very common in DC motors, graphite parts wear out quickly. Solid particles inside the angle grinder body, which enter through the impeller or through the ventilation holes, can scratch the surface. Also, when the instrument is idle for a long time, moisture accumulates and an oxide layer appears.

Such causes of damage can be easily eliminated by grinding the collector or simply wiping it with a rag. Sanding can be done at home to remove scratches and strong oxide. To do this you will need a drill, grinding material and a vice. The armature shaft is clamped in the drill chuck, and the bearing housing is clamped in a vice. As the commutator rotates, grinding material is supplied to it and grinding is performed. In this case, you need to handle both the bearing and the commutator carefully, as you can damage both.

With prolonged use of the tool, unevenness such as scale may form. To fix the problem, you will need to machine the manifold on a lathe. This possibility is determined by the copper plating of the collector itself. However, even if the process is successful, the collector will last less than the new anchor.

If the commutator wears out a lot, micanite may protrude between the plates, or the edges of the plates become sharp and cut off the graphite material. In this case, you can clean the grooves between the plates and clean their edges with a scraper. Protruding micanite is removed using a fine file. At the end, you need to clean everything with a hair brush and preferably blow it with air. Brush wear can also occur due to commutator runout when the plates are worn out and have different heights. Such a malfunction can also be solved by grooving and further grinding.