Today, profile flooring is a popular material in construction. Therefore, quite often questions arise about the possibility of cutting sheets yourself, what is the best way to cut corrugated sheets and about ways to prevent corrosion of their edges.

In this article, we will analyze the advantages and disadvantages of using tools for cutting profiled sheets known to craftsmen.

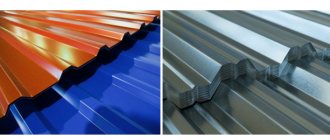

Corrugated sheets are steel sheets coated with zinc and a protective colored layer of polymer, which is easily bent and resistant to deformation, protecting the steel from destruction and maintaining color fastness.

In appearance, it resembles slate, and has alternating trapezoidal, rectangular bulges and depressions of different widths and depths. The metal for the production of corrugated sheets has a thickness of up to 1 mm, which is the peculiarity of cutting parts of the required size.

There are several options for cutting corrugated sheets: manually, using power tools, or using machine tools.

Return to content

Features of cutting sheets

The corrugated sheet is based on thin sheet steel with a thickness of 0.3-1.2 mm. To prevent the material from rusting and serve for a long time, it is coated on both sides with a thin layer of an alloy containing zinc. For the decorative component, there are layers of special primer and powder paint, which also extend the service life of the canvases.

During installation work, the corrugated sheet is cut. As a result, the protective layers are destroyed. Therefore, the most gentle tool is selected for cutting, and the edges are treated with anti-corrosion agents.

Edge protection against corrosion

There are special paints in cans that are applied by spraying onto the work surface. They are supplied for sale in the same colors as corrugated sheets. Another option is anti-corrosion mastic. In any case, you need to read the instructions to find out whether and what kind of primer should be applied to the damaged edge before finishing.

An example of special paints for protecting rolled metal products Source armadius.com.ua

Edge protection against corrosion

Regardless of which tool you select, the cut site will be damaged. Additional protection of the edges of corrugated sheets from corrosion will extend their service life.

In general, the drilling and cutting areas are resistant to corrosion, even if the protective coating is completely absent. Zinc molecules near the cut create a barrier that prevents oxidation of the sheet.

But this does not apply to cutting metal with a grinder or a manual circular saw.

Open metal is most susceptible to the influence of harmful external and chemical factors, and therefore quickly succumbs to destruction (rusts). To extend the service life, anti-corrosion and moisture-resistant preparations are manually applied to the edges of the cut, and then covered with factory paint, which should be included, or with a can of paint selected by color.

Taking into account the information provided, everyone will be able to decide for themselves what is the best way to cut the profile flooring. It is important to remember that the speed of work, the durability of the material and its aesthetic appearance depend on the choice of the right tool.

Return to content

Selecting a cutting tool

The main three criteria for choosing the optimal tool for cutting corrugated sheets are the permissibility of working with thin sheet metal, gentle and accurate cutting, and ease of performing the task. These parameters correspond to scissors, hacksaws, their electric analogues and equipment with replaceable discs. Let's take a closer look at the features of working with each option.

Scissors

Hand-held metal shears for cutting corrugated sheets are more convenient to use when cutting a small number of workpieces and forming curved edges. Craftsmen recommend choosing spline samples from this category. Here, the cutting part of the tool is represented by a rectangular plate (also known as the supporting part) and a movable sharpened head that fits into the groove of the plate. The thickness of sheet metal for cutting can reach 2.5 mm.

Using conventional metal scissors Source yandex.net

Another solution is nibblers or notching shears for corrugated sheets in the form of an attachment for a drill or screwdriver. There is a mechanism here that converts the rotation of the cartridge into reciprocating movements of the cutting elements of the device. They can cut both steel blanks and plastic with polycarbonate. The edges are equally neat regardless of the curvature of the intended line.

Example of using a screwdriver attachment Source leguidedelamaison.com

See also: Catalog of companies that specialize in finishing materials and related work

The third option for scissors for cutting corrugated sheets is a power tool. Externally, the technique is similar to an angle grinder. The working part is designed in a similar way to the drill attachment described above. There is also a static part and a moving part. Only there are models that, during cutting, act on the metal from one or both sides (like nibblers or hand scissors, respectively). In the case of the former, there is one drawback - the edges of the prepared sheet are slightly bent.

Option for electric metal shears Source amazon.com

Hacksaw blade

Despite the labor intensity, craftsmen often prefer a hand hacksaw for metal to other tools than can be used to cut profiled sheets. This is justified by accurate and accurate results, the absence of restrictions on the thickness of the blade, and safety compared to electrical analogues. Disadvantages include the difficulty of forming curved edges.

An example of a hand hacksaw for metal Source artem-tools.ru

Alternative powered or battery powered tools for cutting corrugated sheets include a jigsaw or reciprocating saw. Only in the case of the former, the height of the wave on the workpieces should be limited to 20-25 mm in order to prevent the formation of a torn edge. The latter are equipped with a comparatively smaller base plate, so there is no dependence on the topography of the sheet. But in each case, the speed of the saw must be adjusted downward so that the paint along the cut line does not burn.

Electric jigsaw Source ozone.ru

Hand-held power tool for cutting corrugated sheets

The most popular, practical and quick to use are power tools. A grinder, jigsaw, electric scissors and a hand-held circular saw can be used for cutting Chishmin corrugated sheets.

Modern construction is almost impossible without the use of concrete. To obtain high-quality concrete, you need to choose the right concrete mixer.

Here you will learn how to choose the right drill for construction work.

The link - https://vse-postroim-sami.ru/equipment/power-tools/2176_kak-vybrat-shurupovert/ - provides detailed information on choosing a screwdriver. This article discusses the types and main characteristics of screwdrivers.

Is it possible to cut corrugated sheets with a grinder?

A manual angle grinder, popularly called an angle grinder, is a widely used tool for cutting various metals, and corrugated sheets are no exception.

Many manufacturers of corrugated sheets do not recommend using a grinder, since the high temperature effect on the polymer layer has a negative effect. Despite this, some craftsmen and sellers of profiled sheets use it as the lightest and most practical cutting tool.

So is it possible to cut corrugated sheets with a grinder? And how to cut corrugated sheets with a grinder with minimal damage to the coating?

Attention! The main rule that must be followed when cutting corrugated sheets correctly is that the diameter of the cutting wheel matches the height of the relief of the sheet being cut.

When cutting corrugated sheets with deep relief with a small grinder, it will be difficult to immediately cut the sheet in the lower corners. It will have to be turned over to the other side. It is better to opt for an angle grinder with the largest wheel diameter and disc thickness from one millimeter to 1.6 mm, with teeth made of carbide materials.

It is important that the corrugated sheet does not touch the ground or the surface of the table where the cut is being made. Dust may arise or the desktop may easily become damaged. Using a grinder to cut sheets in the experienced hands of a craftsman allows you to cut out parts of the required geometric shape.

Using an abrasive wheel during work damages the protective coating of the corrugated sheet. The fact is that at the edges of the cut, the abrasive wheel greatly heats the metal. This leads to burnout of the zinc, polymer coating and other layers. In addition, sparks falling on the profile sheet can burn through the protective coating. This reduces the service life of corrugated sheets.

Alternatively, the abrasive disc can be replaced with an aluminum cutting disc. It’s better to use a special disc for cutting corrugated sheets. The edges of such a cut will be straight and neat.

Jigsaw

If the corrugated sheet matches the tool correctly, a jigsaw is a completely suitable option. It is better to use a professional-grade jigsaw, since a household-grade tool is low-power and sheets thicker than 75 mm are almost impossible to cut. The optimal sheet wave depth for a household jigsaw is about 20 mm. It does not burn the protective layer, but it tears the metal.

A professional-class jigsaw capable of cutting C8 profiled sheets, the properties of which are to the taste of buyers.

There are some disadvantages of this tool for cutting corrugated sheets. The sheet to be cut must be installed vertically; therefore, it is necessary to support the already cut strips, for which several assistants will be needed. Saws often break during operation.

Attention! The opinion of experienced craftsmen is that a jigsaw is not the most suitable option for cutting corrugated sheets.

Electric shears - scissors for cutting corrugated sheets

If there is no need for smooth edges, then electric shears are the best tool for cutting corrugated sheets. They cut metal quickly, in one millimeter layer. In addition, you don’t need to put in a lot of effort; the metal is cut automatically.

Slotted electric shears are most suitable for cutting corrugated sheets. It is considered a universal tool, capable of making neat cuts, without bending or deformation during shaped cutting.

Nibblers cut the material along two parallel straight lines, without the need to bend the profiled sheet. These shears for cutting corrugated sheets cope well with sharp turns. For greater convenience, the handle rotates perpendicular to the cutting line. In addition, you can drill a hole in the middle of the profiled sheet and use nibblers to cut in the desired direction.

Upon completion of the work, the edges of the cuts are smooth, without burrs and do not bend.

Hand circular saw

A hand-held circular saw is used to cut corrugated sheets using a disk with carbide teeth. Using a circular saw, cuts are made along a curve with the required radius of curvature.

The downside of this tool is that the protective layer burns out due to powerful revolutions. There may also be jagged edges.

How to properly cut corrugated sheets using a circular saw?

For smoother cut edges you will need a plywood jig. A groove is cut out in the center of the plywood, a kind of landmark.

Cut marks are made on both sides of the corrugated sheet, then the plywood jig is laid down and pressed tightly and cutting is carried out. The metal does not melt, but falls into small sawdust, which is very convenient. A circular saw is more practical for cutting large sizes of corrugated sheets.

So, what is the best way to cut corrugated sheets?

Attention! Having summed up the pros and cons of each power tool for cutting corrugated sheets, we come to the conclusion that the best and most practical are an angle grinder using a special disk for cutting corrugated sheets, a manual circular saw, and slotted electric shears. A jigsaw is more suitable for cutting short sheets.

Return to content

Recommendations from the experts

When working with thin sheet metal, you need to use construction gloves. They can significantly reduce the likelihood of injury from a sharp edge on the cutting line, from burrs and other defects on it. Another important point concerns tools with replaceable disks. They must be equipped with protective covers to prevent sparks from getting into the eyes and face in general. They also reduce the area of distribution of hot metal chips.

As a rule, cutting of corrugated sheets is carried out in a straight line. To make the process of creating a straight edge easier, you can use another sheet as a guide. Simply place it on top of the workpiece. It can also be used at the same time to protect the bottom sheet from damage from sparks.

Another point concerns the flexibility of rolled metal. If you use ordinary metal scissors to cut corrugated sheets, then reliable fixation of the workpiece is not required. In other cases, this must be done.

An example of a working platform using wooden blocks Source stroitelstvo.expert

Otherwise, vibrations and mobility of the blade will contribute to the performance of work in uncomfortable conditions. As a result, the quality of the formed edge will suffer.

How to cut corrugated sheets with a jigsaw?

If you just can’t decide how to cut corrugated sheets, then we advise you to choose a jigsaw unless, of course, you have already purchased other tools. As a rule, this is the best choice for those who decide to independently install roofing in their country house or build a fence from corrugated sheet metal. It is desirable that it has a laser guide.

This tool is the most versatile tool that can be used to cut corrugated sheets without spending serious effort and having special skills. In addition, it can be used for carpentry work and for cutting down a few dry branches in the garden.

In addition, the jigsaw is very easy to maintain and use. The speed of work is high, the likelihood of injury is minimal, if the file breaks, it can be easily replaced, and even a beginner can handle cutting. All these qualities make the jigsaw an almost ideal tool for this task.

Jigsaw for cutting corrugated sheets

Now let's focus directly on the technology of its use:

- Before cutting corrugated board with a jigsaw, draw a cut line. You can use a regular marker for this.

- Secure the sheet so that it is at least 10 centimeters from the surface and does not move when cutting. You can use regular sawhorses for this.

- Now you can start cutting directly. Don't rely on your eye - use a laser pointer to ensure that the cut line is straight and exactly matches your tasks.

- Try to press the jigsaw tightly against the sheet where possible. This will reduce the risk of the blade breaking.

- Despite the fact that this tool for cutting corrugated sheets is quite safe and has many mechanisms that protect a person from injury, be extremely careful. Hold the sheet by the edge rather than resting your hand on it. And especially do not keep your hand on the cutting line, even if the tool is still at a decent distance.

If you follow all these rules, you can easily cope with cutting corrugated sheets yourself. Moreover, you will do this quickly and without serious harm to the coating of the sheet.

Top ↑

Briefly about the main thing

Corrugated sheeting is a sheet material made of thin sheet steel, so a metal processing tool is used to cut it.

Hand tools for cutting corrugated sheets can be a hacksaw blade or scissors.

As an alternative to hacksaws, a jigsaw or reciprocating saw can be used.

Instead of metal scissors, there is a choice of attachments for a drill or screwdriver and electric shears.

Another option for an electric tool is an angle grinder or a hand-held circular saw.

It is technically considered incorrect to use cutting discs, since the rapidly rotating circle heats and burns the paint along the edge, and flying hot sparks damage the decorative and protective coating along the entire plane of the workpiece.

Ratings 0

Tips and tricks

When working with corrugated sheets, there is a risk of serious injury from cutting yourself on sharp edges. Therefore, experts recommend starting metal processing only with appropriate clothing:

- Protective gloves will protect your hands from cuts.

- When working with power tools, you should always wear safety glasses to protect your eyes from small metal shavings.

- Construction headphones will protect your ears from the loud noise generated by power tools.

- To protect the body from damage, it is necessary to wear overalls.

- Closed shoes will also help avoid injury.

Another useful safety tip when working with the tool: it is forbidden to use an angle grinder without a protective casing. The fact is that the cutting parts rotate at a very high speed, so special care must be taken when working. These are basic tips and recommendations that experts do not recommend forgetting about.

Other tools for profile sheet cutting

Today, other tools are used for cutting corrugated sheets.

The list of such products should include attachments for an angle grinder.

Complete with it, the grinder is a productive die-cutting machine capable of working in different positions. She doesn’t care whether she cuts flat metal or with a complex relief pattern, which is inherent in a profile sheet. The qualifications of the employee are important.

The spatial position of the grinder must be constantly changed. The cutting part of the nozzle must be in a perpendicular position to the material being cut.

A longitudinal electric saw with a special disk quickly cuts the metal profile, leaving behind an even cut.

The “Cricket” attachment for a drill is a know-how in the processing of sheet metal.

The tool is safe to use. Productive nozzle.

Cutting corrugated sheets with a grinder

The grinder is a universal construction tool.

With an abrasive disc attached to it, it is easy to cut off metal pipes, channels, and other products. It cuts corrugated sheets perfectly, but heats it to a temperature at which it loses its anti-corrosion coating.

In order not to weaken the profiled sheets before corrosive chemical reactions, after cutting, additional processing of the sections is carried out. They are modified with “cold” tools:

To cut profiled sheets with a grinder, use the thinnest cutting disc that is produced by industry.

Working with thin cutting discs, a small part of the profiled sheet is heated. It is advisable to cut this area to a length of 3 millimeters. The cut end of the sheet is coated with a special varnish, which the selling organization offers to buy, along with corrugated sheeting.

An anti-corrosion compound identical to the factory sample is used.

Guarantees the integrity of the material in any climatic region of the country.

A very progressive method that involves cutting corrugated sheets not on the rafter system, but on the ground.

If you trim directly on the roof, the hot abrasive particles will damage the water barrier and damage the thermal insulation.