Modern corrugated sheeting is a universal building material that is in quite high demand. It is also used as a base for covering and reinforcing building structures, as roofing, wall cladding and for many other purposes. The corrugated metal sheet looks neat, has a simple and reliable profile, can be painted in almost any color and is brilliantly easy to install.

And, if you pay attention to this particular material, you need to choose the type that is suitable for the desired task. And for this it is important to know what sizes of corrugated sheets are needed, to what extent they are strong and with what profile height. And, depending on these three important parameters, corrugated sheeting is divided into specific types and types, which we will tell you about now.

What are profiled sheets?

The largest range of technical metal sheets today is presented in the form of profiled and flat sheets.

We can say that this is one of the best materials for low-rise construction, which is great for covering the roof and for building fences, creating floors and cladding walls:

Thin sheet metal with aluminum or zinc coating is used as the basis for modern profiled sheets, and the manufacturing process takes place using two different technologies - TU 14-11-247-88 (ats) and TU 14-11-236-88.

Disadvantages of corrugated sheets and ways to minimize them

Despite the solid list of positive qualities, corrugated roofing sheeting also has disadvantages that are revealed during operation. Understanding the weaknesses of the material makes it possible to reduce their influence at the roof installation stage. The disadvantages of the profiled sheet include the following features:

- Low sound insulation . The insignificant thickness of the metal sheet leads to the appearance of a drum effect - amplification of sound during rain. Some people like to fall asleep to the sound of falling drops, while others slowly begin to get annoyed by the monotonous noise. In order not to experience discomfort during every, even slight rain (and in some areas there is a lot of them), they use a proven method - reinforcing the roofing pie with an additional layer of sound insulation. The role of the insulating layer is most often performed by mineral wool with a parallel insulation effect.

Advantages of corrugated sheets over other materials

Profiled decking (corrugated sheets, corrugated sheets) are sheet corrugated profiles with corrugations of various shapes repeating along the width of the sheet. They are produced by cold bending of thin cold-rolled sheet.

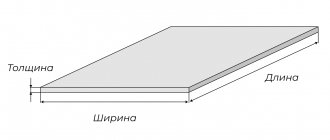

It is not for nothing that such a coating is called a multifunctional building material. It's all about the presence of different types, which differ in terms of application, profile shape and metal thickness. The thickness of the metal in the profiled sheet varies from 0.35 to 0.9 mm, and the width - from 600 mm to 1150. In the factory, the height of the waves is made from 20 to 130 mm, as indicated by the special markings on the packaging. The length of the sheet is often that which is preferred by a particular manufacturer or specially ordered by the buyer.

This type of roofing is valued for the following qualities:

- Ease. The weight of a square meter of corrugated board is from 3.9 kg to 24.1 kg. Thanks to this, it is possible to significantly reduce the volume of load-bearing structures, and there is no need for serious support.

- Anti-corrosion protection and the possibility of decorative coating. The best products from leading manufacturers have a service life of 45 years.

- Possibility of repeated use, which cannot be said about a soft roof.

- Large selection of fasteners and their colors.

- Machinability. Corrugated sheeting is cut and drilled using conventional construction tools.

By the way, corrugated sheeting is often compared with metal tiles as a material that is similar in the manufacturing process and operation. The same base, the same cold press, just a different look. In fact, there is a huge difference between them! It's all about the so-called “dead zones” of metal tiles, which makes them difficult to cut. For example, if you do not order cutting of the coating in the factory in advance for a specific project, then large cost overruns cannot be avoided. In addition, it is quite difficult to join individual pieces of metal tiles together in order to achieve an even and tight seam, but with corrugated sheeting everything is much simpler.

And finally, such a roofing covering has excellent mechanical strength and flexural rigidity along the corrugations. And this is not an empty phrase: such technological qualities make it possible to build safe and durable structures. Therefore, let’s summarize and name the three main qualities of corrugated sheeting: durability, fire safety and environmental friendliness.

And ordinary people value this material for private construction for its price, efficiency, simplicity and ease of installation. Let's see through the eyes of a practitioner: the sheets are light, convenient, cut with ordinary metal scissors, and easy to store and transport. Any home craftsman can handle installing corrugated sheets; you just need to read the useful tips on our website. In addition, during the process of repairing a corrugated sheet covering, it is easy to replace its individual fragments and even reuse old ones for a new roof.

Here is an educational video on this topic:

Video description

What problems may arise when purchasing and installing long-length corrugated sheets, watch the video:

Width

With the same wave height, painted and galvanized corrugated sheets will also have equal width dimensions. They change when the profile changes: the higher the wave, the smaller the width. This is explained by the fact that for the production of any profile a flat sheet of standard width is used (most often 1250 mm). Therefore, the more pronounced the relief, the more material is spent on its creation, and the more noticeably the width decreases.

There are no standards here; for different manufacturers this parameter may differ slightly with the same brand of products.

When calculating the required amount of material, it is necessary to distinguish between the total width of the sheet and the useful (working) width.

- If a metal profile is mounted without overlap, for example, in the frame of a sectional enclosing structure, the total width is taken into account.

- When installing cladding or roofing, the area of each sheet is calculated by the useful width without taking into account the width of the wave that goes under the overlap.

It is important! On roofs with a slight slope, it is recommended to overlap in 2 waves. In this case, you need to determine the useful width yourself.

The total and usable width is indicated in the documentation Source dom198.ru

On average, the total width of wall corrugated sheeting is 1050-1150 mm, while for a load-bearing sheet with a high profile it can be only 750-800 mm.

Permissible deviations

Deviations from dimensions may concern not only the thickness of the products, but also the length, width, and height of the profile. In our country, they are regulated by GOST 19904-90 and depend on the declared parameters: the greater the length or width, the higher the tolerance.

The characteristics and dimensions of imported profiled sheets depend greatly on the manufacturer and the equipment he uses. If the products of Western European companies have extremely accurate dimensions, then for Chinese ones the difference between the declared and actual sizes can be several millimeters.

Additional coating and corrosion protection

Modern corrugated sheets are produced by cold rolling from high-quality galvanized steel. Zinc is necessary here, because it protects well from the effects of the external environment, but in addition it must be protected with polymer coatings. Modern coatings provide not only an attractive appearance, but also significantly improve its mechanical properties, protect it from atmospheric influences and impart durability.

Basically, this is either galvanization, which provides excellent protection against corrosion, or aluminum-galvanization, when the sheet is coated with a mixture of zinc and aluminum. This is a more economical coating option, but also less durable. The fact is that cheap aluminum reduces the protective properties of corrugated sheets. That is why such sheets are additionally covered with another decorative layer, for example, polyester.

And the most budget-friendly corrugated sheeting, which is often found on the domestic market, is produced without any color coating at all. Not only does it have an unpresentable appearance, but the quality of the material is low. But to create a ceiling for large areas, aesthetics are not needed, but low cost is a priority. Galvanization with the addition of silicon is not much different from this option, but still better.

They make corrugated sheets with a special polymer coating. After all, without a coating, a galvanized sheet quickly wears out, and it constantly needs to be cleaned of dirt and rust. Therefore, this is not an option for a roof, and it is better to give preference to profiles with an outer layer of pural and similar coatings.

The color of the coating itself is important not only as an aesthetic aspect, but also for designers. For example, an industrial building must be maintained in the chosen corporate style. And colored polymer coating also has the following types:

- Glossy polyester that looks great and protects against corrosion. It is often used for corrugated sheeting for exterior walls and facades. Polyester is enough to resist corrosion and not necessarily to be resistant to mechanical damage, of which there is little. Therefore, such profiled sheets are often ordered for industrial buildings, which usually have more than one floor. But if you choose corrugated sheeting to decorate your own home, think about the fact that the wind will carry branches and other debris, and therefore scratches are more likely here and it is not worth saving.

- Pural is a more expensive coating. It is made on the basis of polyurethane and polyamide. Provides high reliability and excellent resistance to ultraviolet radiation and low temperatures. For roofing corrugated sheeting, you can’t find anything better.

- Plastisol is the most durable of all types of coating, 200 microns thick. It is based on polyvinyl chloride, and in the factory, relief embossing with a notch is applied to such a coating, for particularly difficult climatic conditions.

Less commonly found on corrugated sheets are coatings such as acrylic, polyvinyl chloride PVC and PVDF , which also have their own advantages:

When it comes to roofing, the thickness of the zinc coating and the method of its application are critical. If this is not enough, any scratches on the roof will lead to rapid corrosion. The type of rolled product is also important, which affects the durability of the future roof:

How to determine quality

First of all, an external inspection. The quality of application of paint, polymer or galvanization is the first indicator. There should be no sagging, drips or bald spots. GOST allows for abrasions and small scratches that do not damage the integrity of the protective layer. That is, if the scratch does not reach the metal, this is normal. This happens all the time during transportation. The main thing is that the coating is intact.

One of the indirect indicators of the quality of corrugated sheets is its weight. Reference values are indicated in GOST (available in the table). If the weight varies significantly downwards, this means that a thinner sheet or less dense (and cheaper) metal was used.

Direct evidence of the manufacturer’s reliability is the thickness of the sheet. If the declared thickness matches the actual one, this is a good sign. How to measure the thickness of a profiled sheet? Using an electronic caliper. Not such an expensive tool, but easier to use. If you have a regular one, you can take measurements using it. But keep in mind that the actual thickness - with a layer of paint or polymer - should be at least a little (several micrometers) greater than declared. This difference will be shown by an electronic device. A mechanical one will not cope with such a task.

Stiffness requirements and corrugation shape

Modern corrugated sheeting is sold in different sheet sizes and profile shapes. It is not difficult to select corrugated sheeting specifically for the roof; take into account a simple principle: the higher the corrugation, the stronger the roofing will be.

But, if you approach the matter with all responsibility, first calculate the loads of the future roof and only then look at how well the selected metal thickness and profiling height correspond to these parameters.

So, today corrugated sheeting is produced with this form of corrugation:

- Wavy , which has a cross section in the form of a sinusoid. The wavy form is the earliest, appearing at the end of the 19th century. This corrugated roof has a particularly aesthetic appearance, which is so valued by designers. The waves themselves are sinusoids or more complex conjugate circles.

- Trapezoidal , which provides the corrugated sheet with maximum rigidity and load-bearing capacity. This form of rolled metal sheet appeared in the 20s of the 20th century. The trapezoidal profile turned out to be more durable in practice, with high load-bearing capacity and ease of installation. And until today this is the most popular form of corrugated sheeting, which is produced with corrugation heights from 2 to 208 mm.

- Cassette , with a cross-section and corrugated shape in the form of the letter “P”, which is excellent for strengthening wall structures. Corrugated sheets with this shape appeared relatively recently and are intended specifically for use in wall structures.

Look how visually different these types are:

The height of the profile of the corrugated sheet is also different: it is 12, 14, 18, 20, 30, 35 and even 65 mm. On the packaging of the corrugated sheet the height of its profile is indicated. The main requirement for this parameter is that the sheets be rigid and high enough. And the higher the profile, the harder the corrugated sheet itself will be, which is the secret. But a low profile, up to 12 mm, is more often used for outbuildings.

You will be interested to know that corrugated sheeting has a certain relationship between the dimensions of the sheet, profile and corrugation height. For example, sheets with a height of 30-55 mm have a thickness ranging from 0.25 to 0.5 mm, and sheets with a height of 12-20 mm have a thickness of 0.5 mm.

And finally, corrugated sheeting is also distinguished by the presence of grooves. For example, when you lay sheets overlapping, and they have a capillary groove, it should be under the sheet - this is an additional element that will help remove moisture from the roof.

Content

First, let's answer the question why corrugated sheeting is so popular among other roofing materials. All because of such valuable qualities:

- Durability.

- Price.

- Light weight.

- Versatility of use - both as a roofing covering and as a basis for insulating a flat roof.

- Easy installation.

- Rigid and fixed joint with roof sheathing.

- Resistance to atmospheric and mechanical influences.

- Rich color range.

Modern corrugated sheets cover both industrial and industrial buildings of enormous area, as well as residential buildings with a wide variety of roof types - flat, semicircular, stepped and complex shapes.

Corrugated sheets are made of steel, with or without coating. For additional strength, profiled sheets are cold bent to form a specific profile. And depending on how the ribs were made, what height, frequency and shape they are, it depends on whether this or that type of corrugated sheet is suitable for you.

Types of corrugated sheeting: wall, load-bearing or roofing

Modern corrugated sheeting is in demand in construction and architecture, and is especially valued in prefabricated technologies. It is used not only for arranging roofs, but also for finishing walls, facades and much more, and such corrugated sheets are thinner than what is necessary specifically for roofing.

This is why it is so important to understand its types:

If we take a closer look at the scope of use of corrugated sheeting, it is made for the following areas:

- Wall corrugated sheeting is used for cladding walls and cladding various fences. Typically, its profiling height is no more than 20 mm.

- Roofing corrugated sheeting is designed to cover the roof, from simple to complex shapes. The standard corrugation height is 20-45 millimeters.

- Load-bearing corrugated sheeting with a height of 45-160 mm is produced specifically for creating floors for warehouse and industrial facilities.

So that buyers do not get confused, wall corrugated sheeting is designated by the letter “C”, roofing “CH” or a separate abbreviation bearing “H”, and there is also a separate type of corrugated sheeting with a trapezoidal shape, which is denoted by the letter “T”.

The number that will appear next to the main letter indicates the height of the profile, although some manufacturers may additionally indicate the thickness of the metal, the type of coating and their brand:

Let's look at each type separately.

Wall corrugated sheeting: lightness and rigidity

Today, the letter “C” is used to mark all profiles with a wavy and trapezoidal shape with a height from 8 to 44 mm. Such profiles are used for wall railings, sandwich panels, partitions and fences. The main function of the C-profile is protective and decorative.

C8 – wall decorative corrugated sheeting. It has a profile height of 8 mm, which is considered the most suitable cladding relief, and all thanks to its short repeat period. And the rigidity of the sheet is achieved not by the shape of the profile, but by the small bending radius of the sheet and the increased slope of the side shelves. European analogues are T6 and T8 .

C10 is already included in the list of profiled sheets, which are included in GOST 24045-94. For the manufacture of this type, not standard blanks with a width of 1000 and 1100 mm are used, but unusual ones with a parameter of 1250 mm. Thanks to this, sheets are obtained with a thickness of 0.35 to 0.8 mm. It is C10 that is most often used for constructing fences that imitate wood texture and other ideas of modern designers. Also, C10 is the main material for sandwich panels.

C13 – thin galvanized steel sheet for roofs and walls. This corrugated sheet is widely used in fencing, cladding, prefabricated panels and structures. Moreover, the fence, thanks to its increased rigidity, can already be built higher than 2.5 m. The working installation width of such sheets is 1100 mm. And in this case, colored polymer painting on both sides is already allowed. European analogues are C15, T14 and RAN-15 .

C17 is a more durable corrugated sheet for fences and roofs, which is additionally used for internal and external cladding of metal buildings and fencing areas from fire and lightning. This profiled sheet also differs from previous options by the presence of a groove for water drainage, which accidentally leaks into the joint of adjacent sheets. Installation width C17 – 1090 mm. European analogues of profiled sheets C17, 18 and 20 are T18 and T20, RAN-20, MP20 .

This roofing looks great on slopes of simple shape, but has some limitations: the minimum angle of inclination should be 14 degrees, with the exception of some types of corrugated sheeting, where both 8 and 9 degrees are acceptable. There is also a special corrugated sheet for almost flat roofs with a slope of 3-4 degrees.

C18 – more or less high-quality corrugated sheeting with small stiffening ribs. They eliminate the main drawback that metal roofing usually suffers from - the flapping of the flat sheet with every gust of wind. For this reason, this type of metal profile was endowed with excellent joining ability and tight sealing of narrow corrugations. There is also a groove for moisture drainage. Installation width – 1150 mm. Analogue - Finnish profile RAN-19R and Orion .

Another type of C18 is C18 (wave). As you may have guessed, this profile has a wavy shape. This gives it a large bending radius and, at the same time, too little rigidity. Because of this, the maximum installation area does not exceed 1100 mm. Analogs: B18-1000, A18-1000, MP 18 and RAN-18R .

C20 is a slightly stronger option than the previous one. Analogs: T20 and RAN-20 .

C21 is a wall profile that complies with GOST 24045-94. It has a regular, honeycomb-like trapezoidal structure. It gives the product versatility in use and quality in joining. Installation width – up to 1000 mm.

NS35 is one of the most popular metal profiles for walls, fences and roofs of outbuildings. The stiffening ribs here have a depth of 7 mm. Thanks to this, such a profiled sheet is suitable for arranging permanent formwork and covering with lathing up to 1.5 m.

NS44 for coatings, walls, and fences. It is made from a sheet with a width of 1400 mm and a strength that corresponds to profiled sheet H114 with a width of 750 mm. This covering is laid at a sheathing pitch of up to 2.5 m.

Another option is NS44 TU , as an imitation analogue of NS44-1000 , where for external similarity there are also stiffeners on wide and narrow shelves. But here the workpiece is smaller in width, due to which the profile periods are reduced from five to four, the angle of inclination of the side shelves is also reduced, and the dimensions are reduced for wide and narrow ones.

C44 is manufactured according to GOST 24045-94. There are no additional stiffening ribs, and the raised lines look neat and simple. The installation width is 1000 mm, and such corrugated sheets are used for walls, roofing and wall cladding. Such sheets can be laid on the lathing in increments of 2 m.

Load-bearing wall profile: boundary values

A separate type of corrugated sheeting is marked “NS”. To some extent, it is too good for ordinary wall decoration and too weak to make ceilings from them. But there are many areas where exactly these are needed: high solid fences, wall fences and even some roofs.

H750 – load-bearing corrugated sheet. Due to the fact that it is included in GOST 24045-94, it is successfully used even by inexperienced designers. The only drawback of this type is the lack of the 1100 mm roll blank required for it.

H900 is a more durable sheet metal profile, which factories today produce according to their own specifications. It is allowed to be laid at a sheathing pitch that does not exceed 3 meters.

Load-bearing corrugated sheeting: strength and thickness

For the construction of interfloor ceilings, corrugated sheets with a height of 57 mm or more are used. If the spans are more than 3 meters, then choose corrugation from 57 to 75 mm, if more - then from 75 mm and a corrugated sheet thickness of 0.7-0.8 mm. Such corrugated sheeting is produced with additional stiffening ribs for higher load-bearing capacity.

Load-bearing corrugated sheeting is used for interfloor ceilings, reinforcing permanent formwork, supporting structures and, of course, roofing. In addition, such sheets are also used as an element of the supporting structure of the frame of a house or building:

H60 - bent sheet corrugated sheet for load-bearing structures under soft roofs, permanent formwork and metal roofing. The basis is a galvanized sheet 1250 mm wide, with a rolled grade of at least 220. It is also installed on supports no wider than 3 m. GOST - 24045-94. Its analogue, made from a structural blank, is today used as a replacement for the H57-750, which is considered less reliable.

H75 is the most popular corrugated sheeting, which is actively used in steel structures for all climatic zones. It can even be laid on lathing, which is installed in increments of up to 4.5 m! And H75 from rolled steel grade 220-350 according to GOST 52246-2004.

H114 is a metal profile that is used as a ceiling. With a width of 600 mm, H114 has the highest load-bearing capacity among other steel decks. It is made from steel 0.7-1.0 m thick and 1250 mm wide. Also suitable for permanent formwork.

Its subtype H114 750 with a workpiece width of 1400 mm significantly limits the possibilities of using such corrugated sheeting and increases the width of the overlap in one sheet, much more than H114-600 . H114 also has the highest trapezoidal corrugation, the parameters of which are determined by the GOST 24045-94 standard. Thanks to this, such sheets are already laid with a support spacing of up to 6 m. An analogue of H114 is RAN-113 .

H153 is a load-bearing profiled sheet of European quality, otherwise called “Europrofile”. For him, the permissible lathing pitch is up to 9 meters! That is why it is used both for roofing and for arranging interfloor ceilings, and when maximum load-bearing capacity is needed, but without a serious increase in the weight of the entire structure. Analogs: T150.1 and RAN-153 , which is available only in white.

H158 is the highest and most durable Euro profile produced in Russia. It is produced according to European standards. The analogue for H158 750 is T.160.1.

By the way, load-bearing corrugated sheeting has two subtypes: load-bearing and self-supporting. The load-bearing type is needed in the construction of swimming pools and other private construction, while the self-supporting type is used in large industrial facilities.

Types of corrugated sheets depending on the scope of application

Roofing corrugated sheets

This type of material is used to construct lightweight, airtight and durable roofs. Its main distinguishing feature is sufficient rigidity and the ability to withstand heavy loads. Attractive design and beautiful colors make this profiled sheet quite suitable for facing work, constructing decorative (but at the same time reliable) fences and other fences that will not be damaged by bad weather. As an example, we can name the following types of corrugated roofing: NS44, NS35.

Advantages of roofing profiled sheets:

- low weight per square meter;

- low cost;

- long service life, high reliability;

- speed and ease of installation;

- beautiful external design.

This material is used when necessary:

- Build a new roof that can withstand heavy loads;

- repair the old roof;

- clad the façade of the house;

- build a fence or fence;

- erect a decorative structure.

Load-bearing corrugated sheet

This material is used when elements of buildings and structures that are subject to significant loads are installed. Load-bearing external walls, strong roofs, strong floors - this is the area of use of this profiled sheet. It is easy to recognize the load-bearing profiled sheet - its profile is quite high, and there are special grooves on the corrugation. Examples of brands: H57, H60, H75 and H114.

Advantages of a load-bearing profiled sheet:

- It is possible to produce sheets of any size upon request;

- affordable price;

- long service life (it can range from 40 to 60 years);

- installation is simple and convenient, takes place in a short time.

This material is used when necessary:

- Build load-bearing elements of the house (for example, external walls);

- reliably repair the roof, the load on which is high;

- install a new roof, assuming that a lot of snow will accumulate on it, and wind and rain loads will also be noticeable;

- decorate the facade of the building, as well as its walls or ceilings;

- build a strong fence.

Wall corrugated sheeting

It is used not only for the construction of walls (external and internal). It is also good to make fences surrounding private houses from such profiled sheets. It is inexpensive and thoroughly protects against corrosion, which is why it is very popular among professional builders. As a rule, it has a rectangular or trapezoidal profile, it can be simply galvanized, or have a polymer coating. Examples of brands: C8, C10, C18, C21, C44. It should be noted that the most popular types of corrugated sheeting for walls and fences are C8 and C21.

Advantages of wall profiled sheets:

- Walls made of it are much lighter than those made of reinforced concrete;

- Drilling holes and cutting this material is very easy, so installation is simple;

- low cost.

This material is used when necessary:

- Carrying out cladding or facing works;

- carrying out facade works;

- installation of load-bearing elements;

- performing roofing work (construction of a new roof or repair of an old one);

- production of decorative metal structures.

Aluminum profiles

Nowadays suspended ceilings are used for finishing residential and office premises. They are distinguished by a wide variety of models, ease of installation and a very attractive price. Baguettes for this kind of ceiling structures are made mainly from aluminum, since this material is resistant to high pressure, which is formed due to the tension of the PVC film.

Profiles for tiles are also created from aluminum; such products play a decorative role in finishing. Aluminum baguettes for suspended ceilings are presented in several modifications:

- Wall moldings - canvases are attached at a considerable distance from the floor slabs (from five centimeters);

- Ceiling baguettes - canvases are fixed on load-bearing slabs, if insufficiently strong material was used when finishing the walls (unable to withstand high tension);

- Universal baguettes - can be fixed to the ceiling or walls;

- Structural baguettes - with the help of this product, multi-level stretch ceilings or single steps and ledges are created;

- Connecting baguettes - used to fasten individual panels to each other.

Types of metal profiles

Today, there is a wide selection of metal profiles on the market; they can be used to produce structures of various sizes and configurations. Below is a table of main sizes:

| Name | Size | Metal thickness |

| U-shaped | 50x22x20 mm, 65x22x20 mm, 80x22x20 mm, 100x22x20 mm | 1.2 mm |

| L-shaped | 40x40 mm, 50x50 mm, 44x60 mm | 1.2 mm |

| Z-shaped | 40x22x20 mm, 30x22x20 mm, 50x22x20 mm | 1.2 mm, 1.5 mm |

| T-shaped | 65x30 mm, 80x30 mm | 1.2 mm |

The metal has high technological properties, which allows it to be used without restrictions in the construction of a wide variety of structures (even under the negative influence of environmental factors).

Which metal profile is more in demand?

Accessories

As experts note, creating a steel frame is simply impossible without the use of special components. These include:

- Internal corner connectors;

- Longitudinal connectors;

- Cross connectors.

To secure the metal profile for drywall, use self-tapping screws or screws with anchors. Thus, the most reliable fixation of the connection is achieved.

As for siding, it is worth noting that attaching siding to a metal profile is the most durable cladding option, especially when compared with a similar structure on a wooden sheathing.

Roof profiles

The rafter system involves the use of steel elements to reduce the negative impact of mechanical and force loads, as well as to increase safety and service life. Within this system, profiles with a square cross-section are often used.

Profiles for load-bearing structures are divided into hot-rolled and bent. Metal profiles for roofs are made of high-strength steel with a protective anti-corrosion coating.

Advantages of metal rafters

The main advantages include:

- Environmental cleanliness and fire safety;

- Not subject to deformation due to temperature changes;

- High strength and low weight material.

Distinctive features of metal profile roofs

Before construction of the roof begins, sufficient strength should be determined. To ensure the most reliable fixation, the metal tiles are fixed to the sheathing to a metal profile (in most cases, galvanized steel profiles are used for this).

The cost of metal rafters is significantly higher than similar wooden ones. Mixed rafters of metal and wood can also be made.

Important: condensation on a metal structure can lead to excessive moisture and, as a result, rotting of the wooden part.

The rafters are fastened to the building frame using anchor bolts, after which the head profile and metal tiles are laid across.