One of the types of overhead crane is a beam crane. It has become widespread due to its versatility of use. The beam crane is used at production and construction sites, in warehouses, and is indispensable when installing or dismantling various structures.

The device is intended for use in rooms of appropriate size, as well as under awnings or in the open air. The overhead crane is designed to withstand adverse weather conditions and can operate in a temperature range from -40°C to +40°C. Designed to safely carry loads in vertical and horizontal directions. Features simple controls. Made from durable metal alloys that are not afraid of high loads.

General device

A beam crane differs from an overhead crane in that it has only one main beam part. It consists of:

- lifting device;

- span beam - the trajectory of its movement;

- end beams.

The work cycle consists of several operations:

- lifting the load to a given height;

- its horizontal movement to the place of installation work or laying;

- unloading materials;

- returning to the starting position.

This design is convenient:

- compactness - it can be used in small spaces;

- ease of installation;

- ease of maintenance;

- sufficient load capacity;

- affordable price.

Beam crane design

Beam cranes: classification and characteristics

A beam crane is a bridge-type crane equipment used to carry out a variety of lifting, transport and loading and unloading operations on crane trestles, in warehouses and in industrial workshops of manufacturing enterprises.

In addition, similar equipment is used in unloading river and sea vessels, construction of industrial and civil buildings.

Beam cranes are distinguished by their versatility and relatively compact size, which is why they are widely used for work in places that are difficult to reach for other types of cranes and in narrow spans.

Types of equipment

Today, the crane beam market offers two types of such equipment, which have minor differences:

- support crane beam;

- suspended crane beam.

In the first type of model, special rails are used to move the end beams along the crane runway, along which their running wheels move. The support crane can be controlled manually or electrically. They are typically used for warehouse handling or industrial workshops.

Construction of a support crane beam

In a suspended structure, crane tracks do not require additional supports; they are installed in the ceiling, which saves installation time. Suspended crane beams are moved using a control panel. They are convenient for servicing large materials and industrial equipment. Their main advantage is the expanded work space. In addition, with the same load capacity, they are much lighter.

Installation of a suspended crane beam

For large working areas, a successful design solution was the use of suspended two-span crane beams. They differ from standard ones only in the length of the bridge. By increasing its length, the service area is significantly expanded. To reduce the excess load on the bridge and prevent its deformation, another I-beam track is mounted to the floors as an additional supporting element.

Support crane beam

Crane beams are classified into suspended and supporting. The support crane-beam includes a span (bearing) beam and an electric hoist (telpher) moving along it, a control panel and a number of auxiliary devices (various grips for lifting loads, a load limiter, etc.) At both ends of the span beam there are special “end” beams used to move the hoist along crane tracks. A beam crane of this class is driven by an electric or manual drive.

The crane can be controlled either directly from the cabin or from outside, using a specialized push-button station. The main area of its use is low-intensity loading and unloading operations in warehouses and industrial workshops.

Crane devices with telescopic boom

When unloading covered cars at railway stations, it is most convenient to use beam cranes with a telescopic boom. They consist of:

- from a crane bridge;

- telescopic beam;

- support rollers;

- devices for extending the telescopic boom;

- hook, which is mounted on hinges capable of rotating in all planes.

Very compact jib cranes

To ensure that the extension of the boom does not disturb its support base, the drive with rollers is mounted on an intermediate beam. It is known that telescopic forklifts with inclined crane beams are indispensable in warehouses, railway stations, and ports. Telescopic crane beams, capable of changing the angle of inclination in the range of 0-30 degrees, have become especially popular.

Telescopic loaders are presented on the market in three modifications. They can simultaneously combine three beam cranes. Telescopic forklifts are equipped with a comfortable cabin and a safety system. Some models are capable of lifting loads to a height of up to 18 m. Telescopic loaders are multifunctional; they can be equipped with various attachments - buckets, loading platforms.

Advantages of overhead cranes

- Having a relatively low weight, they minimize the load on the supporting elements, so they can be used effectively even on small objects.

- With their installation, there is no need to employ or separately hire a crane operator.

- Featuring a simple design, they are reliable, have a long service life, and therefore their purchase pays for itself many times over, especially since they cost much less than overhead cranes.

- They are completely safe to work with, since all operations are carried out from the floor and not at height.

Thanks to the extensive classification, today it is not difficult to choose a beam crane model that is most suitable for solving your problems.

Mobile crane racks

Instead of ceiling trusses, special overpasses can be installed for suspended modifications. Such structures are more often used in open areas. Mobile crane racks are made of metal structures and mounted on the concrete surface of the working site.

The columns are interconnected and do not require attachment to fixed structures or walls. The size of the overpass is calculated depending on the technical specifications and the required load capacity. The mobile structure consists of:

- several types of beams, among them - load-bearing, span I-beams and others;

- running carriage;

- lifting telpher;

- remote control.

Beam crane: characteristics, device, purpose

Man constantly strives to facilitate any process, especially production. During work where you need to move various loads, you cannot do without mechanisms and devices. Now is the time for the latest lifting devices, among which the most famous and in demand equipment is the beam crane. The equipment is widely used in the construction industry, when unloading various warehouses, servicing piece goods, containers, and timber cargo. It is used both in large factories and in private enterprises, which saves time and production costs.

The beam crane is one of the types of modern lifting equipment used for lifting and transporting cargo of any tonnage. The principle of its operation is as follows: using fastening systems, a load is attached to the lifting mechanism. The fastening element can be hooks, cargo electromagnets, grabs, trolleys and other systems. When the load is securely secured, it is raised to the required height using an operating lifting mechanism. The key parameters of any crane are its lifting capacity and hoist lifting height. After lifting, the load is moved to the required distance in a horizontal plane along the rail tracks. The crane's working space is the crane's span, which is another fundamental characteristic. When the load is located above the unloading point, it is lowered and the fastenings are disconnected. Today, most cranes are quite unpretentious to environmental conditions and in normal operation operate at temperatures of -20 - +40°C.

Types of drives

The crane design uses two types of drives.

Manual overhead crane - device diagram

Manual is cheaper and easier to operate. It is usually installed when lifting small masses and dimensions, and provides a low speed of movement of the hoist compared to an electric one.

The manual mechanism is used less and less; it gives low productivity, as it is driven by the worker’s muscle power. It operates using a shaft connected to running wheels and is more often used in small repair shops or artisanal workshops and warehouses. Manually driven beam cranes have the following characteristics: lifting capacity – up to 10 tons; span – 20 t.

Undoubtedly, the electric drive has higher performance characteristics; it also has the greatest application. The movement of cargo in it is ensured by an electric motor, a gearbox and a transmission shaft, which transmits rotation via gears to the wheels of the cargo trolley. The electric drive is designed for high performance:

- significant carrying capacity;

- intensive use of crane equipment;

- high labor productivity.

At the same time, the electric drive significantly increases the weight of the lifting mechanism and the entire structure as a whole.

The electric motor can be controlled:

- from the operator's cabin located at the level of the crane beam;

- using a wired remote control;

- via radio control is the most convenient option.

Electrically driven overhead cranes

Beam crane: application, advantages, classification

This overhead machine is used more than widely today for carrying out lifting operations. The crane beam is in demand equipment for open and closed sites: it is used both in workshops, workshops, warehouses, and on overpasses, civil and industrial construction sites, ship docks, cargo transshipment points, and so on.

Versatility, protection from the influence of environmental factors, compactness, and comparative ease of installation and dismantling determine the wide range of applications of this overhead lifting machine.

The crane beam is always controlled from the floor line using a remote control - by an operator who has permission to carry out such work. Operational safety is thus maximized. This equipment has proven in practice to be in demand for low- and medium-intensity cargo operations.

Other options

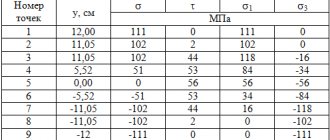

At the same time, other important characteristics of the beam are taken into account, among which the following can be distinguished.

The span size or area of the crane's working area is its possible range of 3-28.5 m. For single-span cranes it is 3-15 m, for double-span cranes it is from 7.5 to 12 m.

Crane beam - installation diagram and characteristics

Lifting height . For suspended modifications, this figure reaches from 6 to 36 m, for a support version – from 6 to 18 m, but a model with a lifting height of up to 36 m can be custom-made.

Electrical voltage . To operate the devices, a three-phase current with a voltage of 380 V and a frequency of 50 hertz is supplied using a flexible cable.

Speed of cargo movement. For supporting devices - 24-60 m/min, for suspended devices - no more than 30 m/min.

Temperature conditions . Most modern models can operate in the temperature range from -20 to +40 degrees, and low-temperature modifications can operate even in 40-degree frosts.

The main differences between an overhead crane and a beam crane

Many believe that these are two names for the same device. Both cranes really belong to the same category - bridge-type equipment, but they have differences in configuration, characteristics and design. A beam crane is a simplified overhead crane with a lightweight design, greater mobility and ease of operation. The bridge is equipped with a large number of additional equipment, including crane tracks (rails). The technically permissible lifting capacity of the crane can reach up to 320 tons.

For nearly 40 years, overhead and overhead cranes have been making work in production easier. In the 1980s, the USSR produced from 6 to 7 thousand units of overhead cranes. Devices of this type are still in great demand.

Metal faucet components

The supporting structures of the crane - span and end beams - have the highest metal consumption, which affects its weight. The main beam is usually rectangular in shape, welded from steel parts or lattice trusses to increase load resistance.

Features of the crane beam configuration

To ensure strength, diaphragms with stiffeners are inserted inside the beam. The main beam and end beams are connected by welding or using bolts. The second method eliminates the possibility of deformation and guarantees quick and accurate installation of the crane.

The weight of the outer, auxiliary wall of the bridge is reduced due to cutouts in the metal sheets, without reducing its load-bearing characteristics. The main beam may experience bending deformations from constantly moving loads. To prevent its deformation, the beams are given a construction lift in advance, that is, when cutting the steel sheets, they are slightly bent upward.

The end beams, which have a rectangular shape, have limiters. If the crane is used in an open area, additional anti-theft devices are installed to protect against wind.

Principle of operation

The design of the crane beam is a combination of the following elements:

- End beams (2 pcs.) Designed for movement of the crane along guides.

- Span beam. Is a guide for movement.

- Lift. A mechanism that lifts loads.

The workflow algorithm comes down to four steps:

- Grab and lift.

- Movement along the span beam in two directions (horizontally and vertically). The device is driven by a drive, which is controlled using a remote control.

- Unloading cargo or material.

- Return the tap to its original position. Repeat the work cycle.

Necessary conditions for installing a crane

Before you begin installing the crane beam, you should make sure that the building can withstand the loads that arise during operation. The assembly process is carried out in several stages:

- delivery of all mechanisms to the assembly site;

- installation of the unit on crane tracks;

- lifting and installation of the bridge;

- final installation steps.

Before installing the crane, the following preliminary work should be done:

Design of the crane runway of the support crane beam

- complete the installation of metal structures for at least 5-6 spans;

- install and check crane tracks;

- make sure there is a railway track on the site;

- calculate the length of the installation area - it should be twice as long as the bridge.

After receiving the certificate of completion of the preparatory work, installation of the installation can begin.

Affordable prices, ease of assembly, and good performance indicators have ensured that the beam crane is highly popular among customers. They often act as the only possible option for carrying out lifting work in hard-to-reach places.

Beam crane: principle of operation, types of structures, main characteristics

Published 03/13/2018 · Updated 05/06/2018

A beam crane is a type of lifting crane equipment. The device is designed to perform unloading and loading operations, lifting oversized and heavy loads. The equipment is used in industrial and production premises, as well as during construction. The crane has found particular application in river (sea) ports - for loading and unloading ships. Maneuverability and relatively small installation parameters are advantages that allow the work process to be carried out in hard-to-reach and narrow places.

The state's economy largely depends on the development of industry. The efficiency and capacity of the industrial sector directly affects the solvency of the region. For a properly functioning complex, the presence of mechanisms and equipment is required. Cranes play one of the leading roles in the range of industrial equipment. The beam crane occupies an important niche in the arsenal of equipment. This article will talk about what a beam crane consists of and what the principle of its operation is. And also: types of installations, device characteristics and main differences from overhead cranes.

The production of beam cranes at our plant is organized in accordance with current safety requirements. We offer the production of crane beams on special order to adapt to the conditions and specifics of your production. The company's products are certified and completely ready for installation and operation.

Our website contains detailed information, documentation, drawings and photos of any type of beam cranes we produce. We provide consulting assistance in selecting a crane and selecting additional equipment and characteristics taking into account operating conditions.

Hoist control

The hoist is also controlled using special buttons. In order to direct it to the left, you need to close the corresponding contact. The current will flow through it through the limit switch located at the extreme left point of the hoist.

When the limit position is reached, the target feeding the starter will open and movement will stop. How to determine this moment? When the hoist collides with the rubber buffer. This mechanism protects the electric motor from overload and also protects the wheels from rapid wear, preventing them from rotating aimlessly while in one place.

The right direction works in a similar way.

Description of action

The operating diagram of an electric crane beam is as simple as possible. Reversible magnetic starters installed in the mechanism control the start and operation of the engine itself. Auxiliary elements are also soft buttons that help the operator carry out the assigned task. They are connected to the drive by a high-tech flexible cable.

The crane moves in four directions:

- back and forth, moving along the rails;

- up and down, delivering the goods.

To control these actions, special windings and contacts are used. They are also connected to a flexible cable. The corresponding signals are sent to the contacts, and the crane performs the specified action independently, without human control. If an excessive load is placed on the network, which it potentially cannot withstand, a protective mechanism is triggered. A special switch automatically opens the circuit and no power is supplied, thereby stopping the operation of the equipment.

The limiting unit of the electrical circuit monitors the correctness and orderly movement of the lifting mechanism. It is triggered in cases where, for example, the set height is violated. Or the weight of the load being lifted does not correspond to the technical characteristics of the crane beam.

The distribution node is responsible for distributing energy throughout the device. It strictly controls the supply of current to parts and elements of the system.

A generalized basic design of an electric crane beam circuit is described here. But, depending on the purpose of the device being designed, the features of its operation and use, it is laid down at the project stage and may have some differences.

Installation

Only specialists should install the crane beams, as installation requires compliance with safety precautions. A lot of time is spent on installing a beam crane, since the structure consists of a large number of parts. Before starting work, specialists assess the premises, its design features, and the location of the crane itself. Next, deadlines are set, as well as the need to use additional auxiliary tools.

Installation of the crane beam can be carried out using different methods. First, you can install the crane tracks and only then assemble the crane parts element by element. Or assemble the crane beam on a special site and transport it to the desired location.