Hoists, like hoists, are indispensable in cases where frequent movement of heavy loads is necessary. The use of lifting equipment significantly increases productivity, ensures the safety of cargo, and ensures the safety of workers. Therefore, this equipment is constantly in demand at construction sites, service and automotive workshops, production and storage facilities, etc.

In the manufacture of the main parts and elements of hoists and hoists, high carbon steel is used. To increase service life, anti-corrosion protection is provided. A steel rope or chain is used as a lifting element. To secure loads, additional devices are used - slings. Depending on the type of load, its shape and type of sling, they have a different number of branches. To secure the load, the following types of hooks are used: open, s-shaped or self-locking.

Hoists and hoists have structural and functional differences, which determines their scope of application and provides certain advantages when performing one type of work or another. A specialist working with lifting equipment must undergo special training, know and be able to apply basic slinging methods.

What is a hoist and how does it work?

A hoist is a special compact device that is used to move loads. The maximum weight of cargo moved at one time reaches twelve tons, and the maximum height is twenty-four meters. They are in demand in various areas: warehouses, industry, construction, etc.

The design includes:

- fixation system to the support;

- lifting chain/cable;

- main drive mechanism;

- a hook or other device for grasping cargo.

By type, hoist drives can be manual or electric. They are classified into:

Wormworms . They are attached to an object using a hook, which is used to grab the load. The name comes from the type of main mechanism. The hoist works by transmitting torque from the “worm” to the gear. There is no way to spin the wheel if the “worm” does not rotate. A chain with a hook and a load is screwed onto the wheel, which rotates from the “worm”. The wheel is permanently connected to the drive, which prevents spontaneous lowering of the load.

Lever . They have a universal purpose, are compact, and weigh little. They are convenient to use in conditions of limited space, since they are fixed directly above the work site. They are quick and easy to install and have a small lever amplitude. The worker is located on the side of the hoist and sets the load in motion by operating the lever.

Electrical . They are the most popular due to the fact that the electric drive provides a high speed of lifting the load. Capable of lifting loads to a significant threshold height. Depending on the engine power, they are connected to a standard or industrial power supply of 220 V and 380 V, respectively.

In turn, electric hoists are classified depending on the type of fastening into the following types:

- stationary mini hoists;

- combined mini hoists.

In the first case, lifting equipment is fixed directly above the work site. In the second, the hoist is connected to a special carriage or electric trolley, due to which the functionality is expanded - it is capable of moving cargo along a specially equipped path from the monorail.

In some cases, the stationary trolley and the hoist have different control panels, which is not always convenient. In combined models, one remote control is often sufficient for control, since a special connecting plug is provided.

Manual hoists

Manual hoists are operated using a hand drive. This makes them energy-independent and allows them to reduce overall dimensions and weight. But the most significant arguments in their favor were their affordable price and ease of use. It is advisable to purchase them if there is a periodic need to lift small volumes of cargo weighing from 0.5 to 10 tons. But some models are capable of lifting objects weighing up to 20, 30, 50 and even 100 tons. The lifting height can reach 25 meters.

When choosing the load capacity of a device, you must also consider how many people are needed to operate it. Products that lift loads weighing up to 10 tons are designed for 1 person. But to lift heavier objects, joint actions of 2-3 people are needed. This is not always convenient for domestic use.

Manufacturers offer various types of manual hoists :

- lever - they are controlled using a lever. It has an ergonomic shape, which makes the hoist easier to operate. Thanks to the optimal gear ratio, even a small force applied to the lever is enough to lift objects weighing from several tens of kilograms to 9 tons.

The chain guide integrated into the housing ensures smoother pulling of the chain through the traction sprocket. The driven chain moves easily and grips the load.

The load capacity of lever mechanisms is lower than that of gear structures, and the lifting height is also limited. The person must be close to the hoist’s suspension point, so it is convenient to use it to lift loads to a height of no more than 1.5-2 meters or install equipment. But this design is more resistant to wear and damage. It is easy to install almost anywhere, convenient to use in limited space - in mines, wells, when repairing cars, etc. Neither severe frosts nor precipitation affect its performance characteristics.

- chain gear - equipped with transmission gears, traction and load chain. The traction chain transmits force to the gears. The object being lifted is attached to the end of the load chain.

Chain gear hoists have a higher load capacity compared to lever hoists. They are recommended to be used if it is necessary to lift objects to a height of more than 2 meters.

Telpher device

A hoist is a lifting equipment that is used for lifting and further moving heavy loads of various types in a horizontal plane. If the basic configuration of an electric hoist includes a carriage, then this type of equipment is called a telpher. As a rule, they have a powerful electric motor and are connected to an electrical network with a voltage of 380 V.

These units are widely used in various fields of industry and construction. It is difficult to imagine the work of a car service center, warehouse and other enterprises without a hoist. When developing models, special attention is paid to safety. A distinctive feature is not only the presence of its own movement system: it has larger dimensions and higher technical characteristics.

Electric hoists

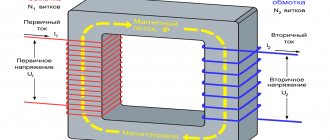

Electric hoists are equipped with a motor that converts electrical energy into mechanical work. The torque from the engine is transmitted to the gearbox, where the number of revolutions is reduced, and they are supplied to the lifting drum drive. During its rotation, the traction element is set in motion, and the load rises to the required height.

In workshops, warehouses, when performing construction and installation work, loading and unloading operations, various types of electric hoists :

- Rope - optimally suited for overhead cranes and monorails. They are capable of working at maximum load for a long time.

- Chain - designed for jib cranes, and are also often used as auxiliary devices. The mobility of the links allows the use of various slinging methods. There is no risk of damaging the chain when lifting objects with sharp edges. They are distinguished by more compact dimensions and lighter weight, low noise levels, and resistance to dynamic loads.

Electrical ones are also divided into stationary and mobile.

A mobile electric hoist is an electric hoist with an electric movement mechanism (carriage). The carriage is located on a metal I-beam - a monorail. The telpher allows not only to lift and lower loads, but also to move them in a horizontal plane.

Depending on the budget and need, movement mechanisms are divided into manual and electric. The manual movement mechanism uses a drive chain as a traction element. Hoists are also produced that are intended for operation in conditions of increased danger of explosions and fires, contact with aggressive environments, and sea water. This is an expensive, but highly productive and reliable production equipment that allows you to automate and make production processes safer in many industries. They are also in demand in ports and loading terminals of railway and road transport.

To order hoists, get additional information about their technical and operational characteristics, selection features, call +375 17 510 23 65; +375 33 617 23 55 and +375 29 617 23 64.

Features and differences of hoists and telphers

The main difference between a hoist and a hoist is that the latter has additional functionality: the basic design requires a hoist with a powerful electric motor and a special carriage. Thanks to this, this type of equipment is able to lift a load and simultaneously move it in a horizontal plane.

Hoists are used to handle very heavy loads, which cannot be done with hoists, especially if they are manually driven.

Thus:

- hoists are recommended for use when working with loads of small size and weight, as well as in cramped conditions;

- hoists are suitable for working with heavy loads where electric traction is required, as well as large-sized ones.

Pneumatic hoists

When working with explosive objects and substances, the use of electrical appliances is undesirable. There is also often a need for large-scale work that requires lifting loads in places where access to the electrical network is difficult or impossible.

Pneumatic hoists can be a profitable alternative to manual hoists. They are driven by the force of compressed air, which comes from air lines or compressor units. To make the mechanism even safer, remote control is provided from a remote control connected to the hoist with a flexible hose. It is also possible to control its operation by opening and closing the corresponding valves to which cords or circuits are connected.

The mechanisms of pneumatic hoists are protected from exposure to steam, smoke, conductive dust, and are resistant to temperature changes. But in terms of cost, durability and load capacity, they are inferior to electric models, so they are used mainly in the absence of electricity or an increased risk of fires and explosions.

Other lifting equipment with similar functions

To move especially heavy loads - lift them and subsequently deliver them to their destination, in addition to hoists and hoists, more complex lifting mechanisms are used. These are suspended or support-type crane beams, which are widely used in the construction and warehouse industries, as well as when working with containers, when transporting timber, etc.

The hoist is the main lifting mechanism, so the key characteristics of the crane are the lifting capacity and lifting height. The working space of the crane beam is considered to be the span (the length of the monorail track). It is also important that the faucet is installed indoors or outdoors at a temperature range from -20 to +40 °C.

Telphers

Telphers are a type of hoists that are mounted on special carriages. Electric hoists can be used not only as an independent lifting device, but also as part of gantry, bridge and jib cranes. The design of the hoist is as simple as possible, and is based on a block mechanism, which consists of a drum, an electric motor with a cone rotor, a brake, a hook and a load-handling element.

Electric hoists are classified into single-speed and two-speed mechanisms. The hoist is controlled by the operator from the floor, using a remote control on a flexible cable or from the cabin.

Telphers can be chain or rope. Chain ones are used for jib cranes, rope ones are used for overhead cranes and monorails.

Differences between the hoist and other lifting devices

The main difference between a hoist and hoists and other lifting devices is its high productivity and the ability to work for a long time in intensive mode. It is connected to an industrial electrical network of 380 V (optional - 220 V). At the same time, it has a long service life and safe wired remote control.

Telpher and hoist

Hoists are considered one of the closest solutions to hoists in solving complex problems. They are manufactured with three types of drives: electric, mechanical and manual. The most convenient and productive is the electric hoist. This is a compact lifting device with an electric motor, a system of suspensions and load securing. The hoist has a load capacity of up to 12 tons, while the hoist is capable of handling loads weighing up to 50 tons.

Crane beam and hoist

Often, when performing complex tasks, it becomes necessary to make a choice between a overhead crane or a hoist. Each type of equipment has a number of advantages that allow them to be used to solve certain problems.

A beam crane is a bridge lifting device that has a moving system. Its ends rest on specially equipped tracks (so-called crane tracks).

This is the difference from a standard hoist. Crane beams come in two types: support or suspended. The supporting ones have a supporting beam and are located below the plane of the supporting structures. In the second option, the elements are arranged in reverse.

The main advantage of the crane beam is the presence of four degrees of freedom. Thanks to this, the possibilities for manipulating loads are significantly expanded: lifting or transporting them in different directions.

Marking of hoists

All hoists are designated by brands, each of which contains important information about the technical characteristics of the hoist. In the designation of a hoist, as a rule, there are 5 mandatory marks indicating the main characteristics of the hoist in the standard version, as well as 6 additional ones. Having studied the simple principle of labeling when placing an order, you will not need additional clarifications on functionality and characteristics. In some cases, this will save money, since even with the standard version it is possible to exclude a number of options.

Where and how are hoists used?

Hoists are constantly in demand in areas such as heavy industry, construction, warehouses, manufacturing, etc. They are used for lifting and moving heavy loads. It is prohibited to use it for lifting people or working with hot and liquid metal; toxic explosive and flammable substances, as well as in explosive and fire hazardous areas (with the exception of special explosion-proof modifications).

Electric hoists are used as independent equipment, or as part of more complex lifting mechanisms for lifting loads with various types of cranes (bridge, cantilever, etc.).

With their help, very heavy and complex-shaped loads are quickly and safely lifted: units, mechanisms, machine tools, etc. Unlike manual and electric hoists, the hoist provides high speed of handling loads, greatly increasing the efficiency and productivity of labor.

Disadvantages of telphers

But there are also disadvantages, this is natural. In particular, like any industrial equipment, hoists, compared to their manual counterparts, have too much weight and dimensions, which makes it difficult to work in cramped and confined spaces. Electric hoists are also characterized by high energy consumption. Unfortunately, the installation of automatic analogues remains complex and therefore time-consuming. Manual hoists are much easier to install. For them, it is enough just to be suspended on any beam, as long as it is reliable. With their own weight of fifty kilograms, they are capable of lifting a weight many times greater than their own - up to 9 tons. Naturally, the more the load weighs, the slower the lifting is. Telphers require much more attention to their installation than their manual counterparts. And they cost much more. However, since their operating efficiency is quite significant, as well as their service life, they more than pay for themselves.

Where are hoists used?

Along with other lifting machines and mechanisms, the hoist is used in a wide range of very diverse jobs. Having proven themselves well in construction and installation work, they are also widely in demand for repair work, as well as when operating in warehouses. They are widely used in industry, and most often in electrical versions. The drive in the hoist can be either electric or manual. Electrically driven hoists are also called hoists.