| № | Name | Rating | Nomination |

| The best domestic cold welding adhesives | |||

| 1 | "Second" 403-203 | 4.45 | The most versatile cold welding |

| 2 | ASTROhim heat-resistant Total Bond AC-9315 | 4.41 | Better thermal stability of the connection |

| 3 | "DIAMAZ" METAL | 4.39 | Best price. The most popular cold welding |

| 4 | NANOPROTECH NPGSU 0006 | 4.26 | |

| 5 | "CONTACT" | 4.21 | Eliminates emergency leaks without drying out |

| The best imported cold welding adhesives | |||

| 1 | Poxipol 10 minutes transparent | 4.75 | The strongest glue |

| 2 | TANGIT EPOXY-LOCK | 4.58 | The best combination of price and quality |

| 3 | Point H-44 | 4.35 | The most accurate application |

| 4 | IMG MG-425 | 4.19 | |

| 5 | Linocol Bostik | 4.07 | Best curing speed |

Universal glue in a matter of minutes eliminates not only leaks in the heating system or water pipe. It is used for fixing linoleum and baseboards, ceramic tiles and mirrors, and any other objects. Cold welding is in great demand among car enthusiasts and emergency repair specialists. On the road, such glue will be useful for restoring the integrity of loaded suspension elements - you can independently drive to the repair site. Stopping a radiator leak or eliminating a muffler burnout in a matter of minutes without disassembling components is not a problem for cold welding.

Which brand of cold welding should I choose?

The market offers a large selection of cold welding adhesives of domestic and foreign production. Traditionally, high quality repair work is ensured by compounds from Linocol

,

Poxipol

, "

CONTACT

",

IMG

.

Almaz

and

TANGIT

(Henkel Corporation brand)

welds are popular among buyers metal-working NANOPROTECH

is also attractive, but can be difficult to obtain.

Adhesives for PVC materials “ Point

” and “

Secunda

” have good adhesion, and domestic

ASTROCHEM

is distinguished by high heat resistance. The presented brands have long established the central niche of the cold welding market and are deservedly considered one of the best solutions depending on the tasks at hand.

The secret behind the popularity of cold welding

This is a universal tool for repair work in the home and industrial sphere. Advantages of using special glue:

- ease of use;

- resistance of the resulting compound to corrosion and aggressive environments;

- compliance with environmental safety standards;

- saving gas and electricity costs;

- surface hardening within 3 hours;

- no waste after completion of work;

- pliability to sand treatment.

In order to carry out cold welding, no additional equipment or professional training is required.

Choosing a universal glue: what to look for?

When choosing cold welding, in addition to the brand and price, the following parameters are important:

Type of bonded surface.

There are universal adhesives for metal, linoleum and rubber, plastic and concrete. Moreover, the composition allows you to combine materials in any combination, combining into one whole, for example, concrete and wood, rubber and plastic, steel and glass.

Vibration resistance.

Cold metal welding withstands vibration loads, is resistant to aggressive environments and temperature changes. Successfully restores the tightness of radiators, tanks and fuel lines, oil pans and other elements.

Tear resistance.

Restoration of components operating under physical load using universal glue allows the connection to withstand forces of up to 200 N*m. Such welding is indispensable for emergency repair of a car suspension, as it will allow you to independently eliminate the malfunction (broken lever, rod, etc.) and get to a service center or garage without the help of a tow truck.

Heat resistance.

A special type of cold welding that can withstand heating up to 150-250˚C. It is successfully used to restore car mufflers, highways and heating system equipment.

Moisture resistance.

Adhesives of this group are impervious to moisture, and in some cases can be applied even to a wet surface, maintaining high adhesion to it.

Hardening time.

Since cold welding is often used for emergency repairs, setting time is important. The smaller it is, the better.

Criterias of choice

When choosing a specific brand of cold welding, you need to be guided by the scope of application.

Temperature

Many universal compounds have good tensile strength, about 300-400 newtons (for comparison, this is the power of an electromagnetic lock on a standard entrance door), for example, cold welding “Titan” from the Russian one.

It is suitable for gluing metal, wood, some types of plastics, even ceramics and glass in various combinations. Has a metal filler.

Relatively resistant to aggressive environments, although it is not “automotive” welding. BUT its heat resistance index is relatively low. The manufacturer claims that the performance characteristics of the welded joint will be maintained only up to +130 °C.

An example of heat-resistant cold welding for metal is the domestically produced Almaz composition for metals, produced in the form of a cylindrical bar of plastic mass, which must be kneaded with your fingers before use.

On average, the temperature that most universal compounds can withstand reaches a maximum of 260 °.

Sealants

When choosing cold welding, you need to focus primarily on its purpose.

It is impossible to create a truly universal composition that works well both as an adhesive and as a sealant, moreover, for substances with different chemical compositions and physical properties. Types of cold welding, declared by the manufacturer as means for repairing plumbing fixtures, are always waterproof and contain a metal filler.

Some types can even set under water. But they are primarily sealants; requirements for high tensile strength are not imposed on them, so you should not expect increased strength from them when gluing two steel sheets. Such welding is often produced in liquid or semi-liquid form to make it more convenient to apply to pipe joints.

Compositions for cars

Automotive welding, as a rule, is resistant to temperature changes, vibration, and the effects of various oxidizing agents and solvents, but does not set under water.

The tensile strength of the connection is quite high, about 200 Newtons. The composition has average performance in terms of tightness, but the plasticine-shaped release form expands the scope of application.

From such welding you can fashion a copy of the missing bolt and cut the thread with a regular nut before the mass hardens. The connection on such fasteners can last, depending on the load, from several hours to several days. This is enough to get to a place where qualified repairs can be carried out.

Very often, such welding is used to seal broken pipelines, radiators, gas tanks, mufflers, and other similar situations.

Fill value

Most universal compounds are primarily adhesives. When choosing, you need to be guided by the material that needs to be glued. If it is metal, it is better to take a mass with a metal filler, otherwise you will not get good adhesion.

Strictly speaking, this type of glue is called “welding” only because, thanks to the metal powder in the composition, the seam after drying becomes similar to a welded one.

If you have a choice, it is better to buy cold welding with a filler made of the same metal that will be glued - steel for steel (the grade is no longer important), cast iron for cast iron, aluminum for aluminum. In this case, the metal atoms will be able to diffuse with each other, and the connection will be much stronger.

Top 5. "CONTACT"

Rating (2021): 4.21

11 reviews taken into account from resources: Otzovik, YandexMarket

Eliminates emergency leaks without drying Thanks to its high adhesive ability, the universal cold welding “Contact” can quickly eliminate a leak in a pipe, oil pan or gas tank without first drying the damaged area.

- Characteristics

Average price: 239 rub.

- Country Russia

- Weight: 50 g

- Curing time: 180 min.

- Temperature resistance: -40…+150˚C

- Number of components: 2

The universal adhesive has proven itself excellent in restoration and gluing of various metals, glass, ceramics, plastic, and wood. Easily takes a given shape and sets quickly. For cold welding, stopping a leak in a water pipe or gas tank is not a problem. At the same time, the glue performs its task by working with a wet surface. Due to its high adhesion, “Contact” perfectly seals the most inaccessible places. The plasticity of the compound prepared for work decreases sharply after 3-5 minutes, so you need to work with it quickly. Treating the base during application (cleaning and degreasing) increases the reliability of the connection, however, during emergency repairs this is not always convenient.

Advantages and disadvantages

- Hardens quickly

- High adhesion

- Solvent resistance

- Foundation preparation required

Advantages

Liquid welding material is advantageous because... does not require experience or special technical skills. The use of cold welding takes place without electric current or heat, therefore it is safe. When the surfaces being bonded interact, no toxic smoke is generated, there is no bright light, and no special protective equipment is required for operation. The highly plastic adhesive substance is very mobile, you can take it with you and use it at any time. In this case, preparation is minimal.

The composition is characterized by high corrosion and temperature resistance, electrical conductivity, and non-toxicity. The process of joining surfaces is fast, the material dries in the first minutes, proceeds without deformation, due to which the appearance is preserved and impurities do not get into the seam.

Top 4. NANOPROTECH NPGSU 0006

Rating (2021): 4.26

- Characteristics

Average price: 147 rub.

- Country Russia

- Weight: 55 g

- Curing time: 25 min.

- Temperature resistance: -60…+150˚C

- Number of components: 1

The versatility of NANOPROTECH cold welding allows you to join metal, wood, plastic and stone into a single whole. The plasticine-like consistency of the glue (after kneading) takes on a given shape and can be used in the restoration of any elements, including those working under load. The compound perfectly tolerates temperature changes, exposure to moisture and solvents. After hardening, it can be processed (grinding, drilling, painting, etc.). Buyers are pleased with the price, but the glue is poorly represented in retail, which makes it difficult to quickly purchase.

Advantages and disadvantages

- Plastic

- Suitable for loaded elements

- Processable

- Can be difficult to buy

See also:

- 10 best adhesives for PVC boats

Rating of the best adhesives for metal

| Nomination | place | Name of product | price |

| Rating of the best adhesives for metal | 1 | Weicon VA 110 (NSF certified) (60 g) | 3 630 ₽ |

| 2 | Strong steel stick renewal composite 114 g | 3 256 ₽ | |

| 3 | Two-component structural adhesive Weicon RK-1500 (60 g) | 1 978 ₽ | |

| 4 | Epoxy adhesive EpoximaxX 1.2 kg | 1 990 ₽ | |

| 5 | Special glue Poxipol “Cold welding” (gray) | 779 ₽ | |

| 6 | Universal super glue super Bison Super Glue Gel, 3 g | 138 ₽ |

Weicon VA 110 (NSF certified) (60 g)

Why it: Eco-friendly, healthy composition.

The universal cyanoacrylate Wiecom VA 110 has passed NSF certification, which confirms its safety in use and zero emissions of substances harmful to health. It can be used to glue parts and elements that even come into contact with water or food, including metal ones.

Top 3. "DIAMAZ" METAL

Rating (2021): 4.39

39 reviews from resources taken into account: Reviewer

Best price Universal adhesive “Diamond” has the most affordable price among cold welding products.

The most popular cold welding Low price and high performance characteristics of the joints make ALMAZ cold welding the most popular in the domestic market.

- Characteristics

Average price: 90 rub.

- Country Russia

- Weight: 20 g

- Curing time: 30 min.

- Temperature resistance: +5…+150˚C

- Number of components: 2

The top participant in our rating, ALMAZ METAL, has gained great popularity among consumers due to its high efficiency and ease of use. The two-component adhesive composition based on epoxy resin demonstrates the best adhesive characteristics in relation to ferrous and non-ferrous metals. The presented cold welding reliably holds parts together, eliminates a small leak in a radiator or water supply system, and restores the integrity of the item. Among the advantages is the ability to work with a wet surface. Not everyone likes the pre-glue preparation stage - the top layer is very sticky and gets your hands dirty.

Advantages and disadvantages

- Moisture resistance

- Durable seam

- Black color

- Component mixing process

See also:

- 5 best welding machines for polypropylene pipes

What happens?

Cold welding, created on the basis of epoxy resin, is a worthy competitor to the usual method. It comes to the rescue in cases where it is not possible to use the usual one due to various reasons. The only thing to keep in mind is the inferior strength of the seam.

The composition affects the quality of the connection and state of aggregation.

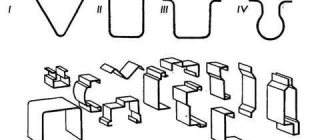

According to the method of connection they are divided:

The choice of glue is determined by the composition and specification. The range covers almost all spheres of human life. Depending on the intended purpose, there are:

Top 2. ASTROhim heat-resistant Total Bond AC-9315

Rating (2021): 4.41

Better thermal stability of the connection Cold welding ASTROhim Total Bond can withstand heating up to +250˚C. This is the best rating indicator.

- Characteristics

Average price: 120 rub.

- Country Russia

- Weight: 55 g

- Curing time: 180 min.

- Temperature resistance: -60…+250˚C

- Number of components: 2

For hermetically sealed gluing and restoration of parts made of ceramics and various types of metals, two-component Total Bond adhesive is suitable. High resistance to maximum temperatures in the range of -60...+250˚C allows the use of this composition in automotive applications. Cold welding is also effective in assemblies operating under load. After preparing the compound, the plasticity of the adhesive mass allows you to recreate even a threaded connection. The disadvantage is the need to fix the applied layer for several hours, but the strength gained over time evokes sincere respect among the owners.

Advantages and disadvantages

- Affordable price

- Excellent heat resistance

- Connection strength

- Requires fixation before hardening

See also:

- 15 best liquid nails

Component Shape

Cold welding differs in the degree of thickness: paste-like and liquid compositions are produced.

- Paste-like is a one-component substance, ready for use. In appearance it resembles children's plasticine.

- Liquid welding for metal is produced in special containers. It is a two-component adhesive that must be mixed before use.

Two-component solutions have the advantage of a long shelf life , while one-component glue must be used after opening the package.

Top 1. "Second" 403-203

Rating (2021): 4.45

97 reviews from resources taken into account: Yandex.Market, Ozone

The most universal cold welding Secunda glue is the most universal in the rating. With its help you can connect the largest number of materials in any combination - from linoleum and metals to glass and wood.

- Characteristics

Average price: 305 rub.

- Country: Russia (manufactured in China)

- Weight: 75 g

- Curing time: 6 hours

- Temperature resistance: 0…+60˚C

- Number of components: 1

Construction adhesive "Secunda" 403-203 does an excellent job of joining PVC materials of different densities. Users note an invisible and ultra-strong seam when working with water pipes, plexiglass, linoleum, etc. Using this cold welding, you can fill chips and cracks in plastic, wood, glass, metal and stone. Resistance to moisture allows the product to be used for gluing parts in contact with water. The composition gains maximum strength after complete drying for 6 hours. If the instructions for use are not followed, the surface of the linoleum may be corroded.

Advantages and disadvantages

- Glues well

- Large volume

- No needle to apply

- Requires careful use

- Takes a long time to set

See also:

- 10 Best Shoe Adhesives

to the beginning of the rating

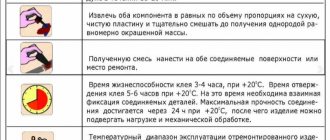

Recommendations for use

Despite the fact that the process of using cold welding is quite simple, you should still know some of the features of its use.

Drying period

It is different for each type and even for each brand, but it usually dries completely within 24 hours. However, there is also such a concept as “pre-drying” - it means that the substance has already created the final form, is no longer susceptible to deformation, but has not yet achieved a stable connection with the processed object. In this position, the applied seam is still vulnerable, so you should not subject the treated object to unnecessary stress. “Pre-drying” usually occurs in the first 5-20 minutes after application, so this period is quite enough for the user to form the seam itself. Some brands of cold welding reach final drying in half a day, but professionals recommend starting to use the glued object only after 24 hours.

Precautionary measures

At first glance, cold welding itself may seem like a harmless composition, but certain safety measures must be observed when working with it:

- It is preferable to work in protective glasses and gloves - do not allow the composition to come into contact with exposed skin or eyes. In the event of a traumatic situation, you need to rinse the damaged area of the body with clean water and immediately consult a doctor;

- The adhesive mass should be stored out of the reach of children and pets;

- Cold welding particles should not be allowed to come into contact with food.

Typical errors during operation

These primarily include:

- Inattention to the expiration date - an expired expiration date will cause poor-quality sutures;

- Surface preparation contrary to the recommendations of the welding manufacturer - the welding seam may simply fall off;

- Unsealed storage of the adhesive composition - the composition will simply harden and will not be suitable for use (for plastic compositions it is possible to heat them in warm water, but this will reduce the quality of the seam);

- Use of the composition for other purposes – use of the composition for welding materials for which it is not intended;

- The use of the composition without taking into account the conditions of future operation - if we are talking about the operation of a repaired object under conditions of elevated temperature background, then the welding applied to it must be heat-resistant;

- Failure to comply with proportions when mixing liquid compositions - incorrect adherence to proportions can lead to an almost complete lack of adhesion (adhesion) for these compositions.

Top 5. Linocol Bostik

Rating (2021): 4.07

Best hardening speed Cold welding for PVC Linocol Bostik hardens within a minute after application - this is the best indicator in the rating.

- Characteristics

Average price: 290 rub.

- Country: France

- Weight: 60 g

- Curing time: 1 min.

- Temperature resistance: +5…+35˚C

- Number of components: 1

One-component cold welding for rubber and polyvinyl chloride products (pipes, linoleum, etc.) reacts with the surface being treated and transforms the joint into a homogeneous area within one minute. Polymerization of the seam eliminates the passage of moisture - this is one of the best compounds for sealing and connecting PVC pipelines. A convenient needle attachment for careful application is very useful - if glue gets on the decorative surface of the linoleum, it will not be possible to remove it. After a quarter of an hour, the treated area is ready for work. Among the shortcomings, the owners indicate only a pungent odor (disappears after hardening) and the high cost of Linokol.

Advantages and disadvantages

- Best setting speed

- Moisture resistance

- Strong odor before drying

How to work?

- The application site is thoroughly cleaned and degreased. The surface will become rough after using coarse sandpaper.

- To prevent the composition from sticking to your hands, it is recommended to moisten them with water.

- Before starting work, carefully study the instructions. Pay special attention to the temperature conditions and drying time of the glue.

- Squeeze the substance into a prepared container in a 1:1 ratio. Mix until the mixture is homogeneous in color and viscosity.

- Cover both surfaces to be treated with glue and press. Remove excess with a cloth soaked in acetone.

- The part should be at rest for 5 to 60 minutes (primary drying time).

- The product will dry completely in 12 - 24 hours.

An example of the use of cold welding is in the video:

Top 4. IMG MG-425

Rating (2021): 4.19

- Characteristics

Average price: 220 rub.

- Country: USA

- Weight: 50 g

- Curing time: 10 min.

- Temperature resistance: -50…+149˚C

- Number of components: 2

IMG MG-425 adhesive is the best choice for a wide range of applications. Due to its resistance to high temperatures and aggressive chemical compounds, the presented composition is used for car repairs. It is successfully used as a cold weld to restore a gas tank, radiator, muffler, etc. In the process of gluing various parts, the epoxy base demonstrates optimal setting speed and strength of the seam, which can withstand mechanical loads. Some users believe that due to the strong smell, welding IMG MG-425 is not suitable for work inside residential premises.

Advantages and disadvantages

- Non-corrosive

- Fast cure

- Doesn't change volume

- Strong smell

Where is this technology applicable?

Essentially, this product is glue. It is very strong, suitable for repairing cast iron pipes or water pipes. In many situations, cold welding is even used to repair a machine, for example, if there are any breakdowns or cracks in the engine area . In addition, it is suitable for working not only with metals, but also with plastics, glass, ceramics and wood. Also, users on the network indicated that with the help of this welding it is possible to further increase the missing parts of the product.

Of course, welding metal will actually be much more reliable than gluing it together.

But cold welding pays off in emergency situations. Many motorists share on forums their experience of repairing minor car breakdowns. Someone sealed the holes in the fuel tank, someone had to repair the radiator tank using cold welding .

There are plenty of other similar reviews. This glue may not completely solve problems with metal breakdowns, but it will help in cases where a welding machine is not at hand. If you need to repair a hole in a hard-to-reach place, it will be easier to use cold welding.

I repaired the fuel tank underneath. It takes a long time to remove it from the car, steam it, and then solder it, and it’s very inconvenient. He climbed in and looked - and there was a very thin hole, as if it had been pierced with a needle, the stream was like from a syringe. Friends said that cold welding would not hold up. I didn’t listen and smeared it right over the running gasoline. After that I drove quietly until I parted with the car and sold it.

RAF [Muravlenko.] forum.drom.ru

Top 3. Point H-44

Rating (2021): 4.35

25 reviews taken into account from resources: Wildberries, Ozone

The most accurate application Cold welding Point H-44 has a special needle for application, resulting in a small but no less strong seam when joining butts.

- Characteristics

Average price: 285 rub.

- Country: Poland

- Weight: 100 g

- Curing time: 24 min.

- Temperature resistance: -30…+80˚C

- Number of components: 1

When carrying out interior renovation work, users often choose Point H-44 cold welding. The presented glue helps to organize a high-quality and neat joint when laying linoleum yourself. For maximum efficiency and precision of application, the package includes a hard plastic needle tip. The transparent seam is durable, resistant to moisture and chemical compounds. Most of the reviews about this product are positive; dissatisfaction often occurs when the glue is used for other purposes. They also note that the nozzle is not thin enough.

Advantages and disadvantages

- For rigid PVC

- Elastic seam

- Ease of use

- Needle diameter

Other types of glue

Let's talk in more detail about special products designed for gluing other materials.

For different plastics

Most often it has a household purpose; it is excellent for repairing basins and buckets, cracks in plastic windows, balcony and interior doors, as well as interior cladding parts and outdoor furniture.

For linoleum

It is also suitable for rubber. It is very popular in construction and renovation because it solves the issue of laying flooring. This material is more durable than standard double-sided adhesive tape.

Top 2. TANGIT EPOXY-LOCK

Rating (2021): 4.58

The best combination of price and quality German cold welding TANGIT EPOXY-LOCK is characterized by high frost resistance, adhesion, and resistance to aggressive environments. The glue is relatively inexpensive, demonstrating the best price-to-product capabilities ratio.

- Characteristics

Average price: 250 rub.

- Country: Germany

- Weight: 48 g

- Curing time: 70 min.

- Temperature resistance: -40…+110˚C

- Number of components: 2

Once the TANGIT EPOXY-LOCK two-component cold seal mixture is prepared for application, the user only has 3 minutes. High adhesion makes it easy to manually repair leaks in water pipes and heaters without blocking the lines. Universal glue is quite environmentally friendly, as it does not contain solvents. Users like that after hardening, the composition holds the glued parts (wood, plastic, metal, concrete, etc.) at -40˚C, and is impervious to water, solvents, oils and gasoline. The disadvantage is that it will not work with materials such as polypropylene and Teflon.

Advantages and disadvantages

- Can work on wet surfaces

- Sets quickly

- Frost-resistant

- Doesn't stick to polypropylene

See also:

- 12 best wood glues

Classification

Cold welding is classified according to two main characteristics. The first is the state of aggregation in which it is before use. There are two forms of release - in the form of a block of plasticine-like mass or in the form of two bottles or tubes (always included) with a liquid or semi-liquid component.

One of the tubes contains glue, and the second contains filler. Before use, you must measure the required amount of each substance and mix according to the instructions.

A block of plastic mass can also be two-component, but more often a one-component product is produced in the form of a frozen paste. From a practical point of view, the form of release is not as important as the area of application.

Depending on the area of use, different compositions can be ranked as follows.

Universal cold welding is suitable for a variety of materials, including metals, wood, plastic, ceramics.

For temporary repairs of metal products, it is better to purchase specialized glue. It consists of metal powder made from steel, cast iron, aluminum or other metals. They have the best adhesion to their “profile” metal.

Cold welding for car repairs also includes metal powder. In addition, it contains a polymer mass and special additives that provide resistance to aggressive environments (acids and solvents), as well as increased mechanical strength and resistance to vibration.

For plumbing repairs, it is better to choose waterproof types of cold welding. They are usually two-component and will withstand long-term water resistance. Some manufacturers produce compounds that can be applied to a wet surface, for example, to a pipe directly over a leak.