Original German autobuffers Power Guard

Mirror-video recorder FUGICAR FC8

Sun blinds Trokot with magnets!!!

Compressor oil is a special type of fuel and lubricant, specially designed for use in moving components and assemblies of compressor equipment. There are several types of compressor oils, each having its own area of application and differing in operational and technical characteristics.

see also

Comments 83

By the way, here I began to clarify in more detail the topic of compressor oils... Indeed, if the compressor is kept warm and operates warm, pour decent compressor mineral water. Or Total Dacnis 100 or Shell Carena S P2 for example and don’t bother. But if, like me, the compressor is located in an unheated room, and is needed not only in the summer, you should think about a more decent oil. Because Paraffin-based mineral water freezes at -9. I initially set my sights on the two-ester synthetic Shell Carena S P4, but there is no small packaging, only 20 liters and 208. Well, the price tag for a small one, I found the lowest in Exist for 21,500... But that’s what I’m talking about. The factory workers didn’t lie about the compressor oil - the number 100 is mainly important, this is the viscosity at 40 degrees. After running in, I drained the compressor of Teboil HPD 5W40 with a viscosity of 86 and filled it with regular Mobil synthetic gasoline with a viscosity of 60. And what was rolled on Fubaga, the valves on the “Monster B” clearly rang. Naturally, I immediately drained it and, until the circumstances were clarified, I filled it with Total Dacnis 100 mineral water. I began to understand the issue and found out that compressor synthetics in the mass have a different base, rather than motor oil. Namely, it consists of dibasic acids. And so it turned out that the purely physical properties of this base are ideal for a piston compressor. But, there is also compressor mineral water with a viscosity from 90 to 100. So there is room for maneuver. And in the absence of compressor two-ester synthetics, I will risk filling the engine with Liqui Molly Diesel Synthoil 5w40; it has a viscosity of 90. There is also an “official” PAO synthetic for compressors, for example, Total, brand NEVASTANE SH, so the diester base as such is not a stumbling block.

Instead of B6800, I bought (assembled) ASO Bezhetsk S416M “Monster B”, there is a separate entry about it in the BZ. But that's not the point. The same original KS-19 slop was poured into it, which is what the factory prescribed. To remove them from there without a trace, I needed 10 liters of gasoline. I’m writing to the plant asking what you can say about diesel synthetics. They answered - “STRICTLY PROHIBITED”, I ask why? They answer - “The compressor KS and VDL 100 have a flash point of 220 degrees” I answer - “Teboil HPD 5w40, for example, 236 degrees” They - “Well then, the dynamic viscosity should be at least 100 on cold oil... otherwise it will flow down to the next start of the wall the cylinders will be without oil” Well, without comment, I stopped the dialogue at this point. I advise everyone to draw their own conclusions

I fill the same brand name 5-40 as in the motor(s). Toyota, Elf, etc. The first Fubag B2800 compressor worked for 8 years, is alive and well replaced by a more powerful B5200, to understand the load - I have everything “in the air” Drills, ratchets, impact, sandblasting, painting. I've been pouring oil for almost a year now. B5200 is not enough. Ordered B6800.

I also asked myself this question at one time, I also racked my brain on what to fill, I read a lot of information about advice and about oils, I came to the conclusion that the compressor is the same engine without igniting the combustible mixture, which means the operating temperature is lower than that of the engine and why the hell am I I’ll pour special oil into it, that’s it. Secondly, the compressor faded into the background, since it was purchased more powerful, I took it and filled it with semi-synthetic. A year of work, normal flight, no symptoms that the oil had any worse effect on its performance.

Foreign standards, but not alien

The existing range of compressor oils is wide. Its increase is due to the growing demand for compressed air, the development of compressor designs, and tightening requirements for their performance, reliability and energy efficiency.

Compressor oils of various viscosity classes are offered by the main players in the Russian oil industry (compressor oil LUKOIL, ROSNEFT).

As foreign trade liberalized, foreign-made products appeared on the domestic market, manufactured taking into account the latest advances in oil refining technologies (SHELL compressor oil, MOBIL compressor oil).

It is not surprising that today in Russia brands of compressor oil have become widespread, the production of which is regulated by European standards (DIN 51506-2017, ISO 6743-3A).

In DIN 51506-2017, compressor oils are classified into groups depending on the final temperature of the compressed air:

- VB, VB-L – up to 140°C;

- VC, VC-L – up to 160°C;

- VD, VD-L – up to 220°C.

They differ in their aging resistance (VDL compressor oil is especially resistant). “V” means compressor oil, “L” indicates the presence of additives.

Manufacturers, in order for their products to be easily recognizable on the market, give them their own names (SHELL CORENA compressor oil, MOBIL RARUS compressor oil, LUKOIL STABIO compressor oil). If the name contains (or implies, ─ as indicated by the reference to DIN 51506-2017) a combination of the letters VD, VDL (VD-L), VB, VBL (VB-L), VC, VCL (VC-L), present in Brand numbers in most cases indicate the kinematic viscosity of the oil at 40 OC. It is equal to the ISO viscosity grade with relatively small deviations (± 10%).

Examples: compressor oil 32, compressor oil 46, compressor oil 100 (for example, compressor oil VDL 100 or compressor oil VG 100), compressor oil 150.

The brand of compressor oil may contain a direct reference to its ISO viscosity ─ compressor oil ISO 100. Or a more specific example ─ Mannol Compressor Oil ISO 100.

Mannol Compressor Oil

Compressor oils Mannol Compressor Oil ─ one of the products of the company Sudheimer Car Technik-Vertriebs GmbH ─ is represented in Russia by the company BITECH (https://bi-teh.ru/). The German manufacturer produces a wide range of products, including lubricants and oils ─ industrial, motor, and transmission. Including compressor oil brands:

- Mannol Compressor Oil ISO 46;

- Mannol Compressor Oil ISO 100;

- Mannol Compressor Oil ISO 150.

Mineral compressor oil Mannol Compressor Oil based on paraffin oils is used to lubricate piston, screw, and centrifugal air compressors, and Mannol Compressor Oil ISO 46 is also used for pneumatic tools. Its effectiveness is enhanced by the presence of ashless additives.

Mannol Compressor Oil has vital properties for compressors:

- thermal stability;

- oxidation stability;

- anti-corrosion properties;

- low volatility;

- leaves minimal deposits.

All of them help to guarantee stable, reliable operation of the equipment.

Buying compressor oil Mannol Compressor Oil means making the right choice for the correct operation of compressors.

Compressor oil manufactured in northern Germany is distinguished by high quality and compliance with the requirements set by consumers for this type of product.

A few lines below about the requirements, but now we list the main functions of compressor oil.

Compressor oil functions:

- lubrication;

lubrication of rubbing surfaces reduces abrasive wear of parts, reduces energy losses caused by friction, ensures the cleanliness of rubbing surfaces, helps prevent scuffing, jamming and other defects fraught with serious breakdowns and rapid wear;

- cooling;

removal of excess heat is a necessary condition for the functioning of the compressor;

- corrosion protection;

- sealing gaps;

Having several orders of magnitude less fluidity than air, oil fills gaps, promoting better sealing of cavities.

The piston compressor lubrication system includes a pump, oil filter, thermostat, and oil cooler. Compressor oil for reciprocating compressors lubricates pistons, valves, bearings and crank mechanism. It forms a stable liquid layer between the rubbing surfaces (cylinder liner and piston ring).

Compressor oil for screw compressors lubricates shaft bearings, screws and gears (or just gears), helps reduce the temperature in the compression chamber, and seals the gaps between rotors.

Why pour oil into the compressor?

At first glance, it may seem that the pistons in the compressor can operate without oil. There are modern materials that have a minimum coefficient of friction (Teflon, fluoroplastic, etc.).

For example, piston-type automotive compressors do not use separate lubricant. However, there is a huge difference in the volume of air pumped. Let us remember the elementary laws of physics: when gases are compressed, a large amount of thermal energy is released.

Simply put, the piston group gets very hot during operation: the higher the pressure in the receiver, the stronger the heating. It is for this reason that the compressor cylinders are equipped with air cooling fins.

- Oil has good thermal conductivity (albeit less than ordinary water), so washing the piston group to some extent helps remove heat.

- No matter how low the coefficient of friction of the piston rings, heating still occurs. If you leave the compressor without lubrication, the metal may become hot, it will “lead”, and the geometry will be disrupted.

- In addition to the pistons and cylinders themselves, the piston group consists of many elements: connecting rods, crankshaft, and possibly a gearbox. These elements require lubrication, and according to the classical method (as in an internal combustion engine). That is, the compressor has a crankcase in which lubricant splashes.

To understand the principle of operation of a piston compressor, consider its structure:

The crankshaft (1) rotates freely using bearings (2) . The need to lubricate these components is not even discussed: without it, work is impossible. The connecting rod (3) and piston pin (4) do not have rolling bearings. Just like in an internal combustion engine, liners are installed. If these friction pairs are not lubricated, the compressor will seize within a few minutes.

To prevent air compressor oil from leaking out of the housing, a seal (8) . What about the piston (5) ? If the rings are not sealed, fumes from the lubricant will enter the working chamber (6) . And then through the valves (7) the contaminated air will enter the working line.

With such a lubrication system, the cylinder walls are sufficiently washed with oil to ensure normal sliding and additional cooling. To clean the air from possible vapors, filters are installed.

It is usually a porous material that retains any liquids. To obtain breathing air (for example, when filling scuba tanks), more advanced cleaning systems are used.

There is another design of the piston group, which is used in compressors with guaranteed purity of the pumped air. Only the crank mechanism is lubricated; a slider is installed between the piston and the crankcase, guaranteeing complete dryness in the working chamber.

True, such systems cannot provide high performance: loads are contraindicated.

Functionality of compressor lubrication

To achieve stable operation of the device, it is necessary to find out exactly what kind of oil to pour into the piston air compressor. This fluid must perform various functions that ensure stable operation of the device during normal maintenance. Failure to perform any function will reduce the performance of the device and may even cause it to fail. The most important properties of a piston compressor fluid are:

- Protection of parts from increased wear.

- Excellent heat dissipation.

- Reducing engine knock.

- Sealing of the working compression chamber.

Is it possible to fill the compressor with motor oil?

Traditional oils are not suitable for several reasons:

- Compressor oil has higher environmental standards. Air can enter the operator's respiratory tract, even if he is a mechanic using pneumatic tools.

- The composition must ensure fire safety. That is, lubricant vapors, if mixed with air, should not pose a risk of ignition. And in such temperature conditions the risk is very high.

- The viscosity characteristics are fundamentally different.

- The compressor can run longer than the car engine (other terms for replacing used oil).

An amateur's experience or what will happen if you pour engine oil into a compressor - video

In addition, uniform standards have been established for oils that can be poured into the compressor. Each manufacturer (of equipment) sets its own requirements, but the approach remains the same.

- Minimum coke number. This means that during thermal decomposition of the lubricant (if it occurs), the amount of solid precipitation should tend to zero.

- Requires high thermal conductivity not available with traditional motor oil.

- When temperature and pressure increase (normal conditions for an air piston compressor), the physico-chemical properties should not change. This is especially true for the parameters of dripping, melting, solidification and flash. Although for this type of oil it is more correct to use the term “discharge temperature”.

Myth #3: An industrial compressor can be used in a continuous production cycle.

Even an industrial compressor is not designed for continuous use. Even more durable screw-type devices will not withstand such a load.

The classification of piston compressors into industrial, semi-professional and household is based not on their ability to withstand certain loads, but on design features. Industrial compressors differ from household and semi-professional compressors by a belt drive and can only be oil-powered, while lower-class devices can also be oil-free with a direct drive. This is what allows industrial compressors to be used more intensively, but this does not mean that they can work around the clock.

Characteristics that determine which oil can be poured into the compressor

It is the discharge temperature that is one of the main parameters (relating to the safety of the compressor).

- category 1 – gentle operating conditions, up to 160°C;

- category 2 – standard operating conditions, up to 180°C;

- category 3 – heavy duty for continuous operation of compressor stations, up to 200°C;

- category 4 – harsh working conditions, including in aggressive environments, over 200°C.

- Oil is supplied under pressure using nozzles. This is an entire system that has a separate capacity (replenishment and replacement are carried out directly during operation). Viscosity is selected in strict accordance with operating conditions, including ambient temperature.

- Discharge using an internal gear pump also requires low viscosity, but is not dependent on the degree of oil heating.

- Natural splashing from the crankcase oil bath does not require special characteristics; standard values for transformer oils are sufficient.

As an example, an illustration of the parameters of Lukoil KS-19 motor oil.

Basic requirements for the characteristics of compressor oil

Due to the fact that compressor lubricants must be separated from the gases pumped into the cylinders, volatility is an important parameter. This characteristic is measured when the liquid is heated to operating temperature, which occurs after 10-15 minutes of operation of the unit. Characteristics of Ravenol compressor oil - video

- When creating oils, manufacturers are forced to compromise. On the one hand, a minimum viscosity is required, on the other hand, oil that is too thin is prone to evaporation. Therefore, binders must be added to the composition.

- Another requirement that compressor manufacturers make is a low oxidation coefficient. With prolonged use, the oil may burn. Soot and soot are formed, which gets on the cylinder walls and leads to the formation of scratches and scoring.

- The degree of wear resistance characterizes the ability to maintain specified characteristics until the oil is changed. If the parameters gradually decrease, it is impossible to ensure stable operation of the compressor.

- After short-term heating to a critical temperature, the basic indicators should return to their original state.

- Additives must be added to prevent foaming. The crank mechanism works like a mixer. The oil will simply whip up in the crankcase without creating a strong working film.

The complex of properties of compressor oil, from any manufacturer, must ensure:

- reliable start-up of equipment regardless of external temperature;

- if possible, reduce energy costs for operating units;

- at high loads on the piston group, there should be no prerequisites for jamming of the rubbing pairs;

- prevention of emulsion formation: with a sharp change in pressure in the piston group, condensate forms, which must be bound by demulsifiers.

Instructions for use

In order for compressor oil to provide effective protection of the mechanism, you must follow the main rules for its use:

- To select the correct class and type of oil, you must carefully read the technical instructions before filling. Manufacturers of compressor equipment always indicate the recommended lubricant in the specification;

- When filling, half of the required volume of lubricant is poured directly into the compressor mechanism, and the second half into the oil tank (receiver). In this case, the oil will be evenly distributed throughout the entire volume of the mechanism, ensuring the most complete filling of the gaps between the rubbing parts;

- When starting a compressor with freshly filled oil, there is a high probability of water hammer occurring, which can damage internal components and parts of the equipment. To avoid this problem, it is necessary to rotate the shaft manually several times to evenly distribute the lubricant;

- After filling, do not immediately turn on the compressor. It is necessary to wait about an hour, allowing the compressor oil to settle and fill all internal gaps;

- The oil must be changed in accordance with the manufacturer's technical recommendations, after a certain number of operating hours. If the operating hours during operation of the compressor are not calculated, then the optimal option would be the oil change range - twice a year.

Correct use of oils will increase the service life of compressor equipment, reducing wear of its units and components.

It is prohibited to mix different types of oil when filling, and when changing oil, the oil system of the mechanism must be flushed.

How to replace compressor oil?

If you adhere to the technical requirements, replacement is not provided. That is, there is no alternative among other types of lubricants. However, based on experience in using low-power compressors, it is possible to fill in engine oil for diesel engines with a viscosity of SAE 15W40.

This may not be profitable from an economic point of view: branded compressor oil is cheaper. And given the availability of these materials, there is no point in experimenting with the equipment.

I have one friend who is not friendly with technology at all. At the same time, he has to work with the units constantly. Either he and his wife will go to the dacha, or something needs to be done around the house. One day we got to talking, and I was surprised to learn that he had an air piston compressor, but my friend didn’t even know that it needed some kind of oil.

So, my friends. Air piston compressor oil is essential. Without this composition, the equipment will not work fully, it will quickly break down and you will only have to throw it away. I will tell you about choosing the right oil for a compressor in this review.

Application and purpose of equipment

Equipment producing compressed air today comes in many versions. This is primarily due to the undying popularity of such devices, since they can be used both in everyday life and in various fields of industry. And oil for different types of piston air compressors prolongs the operation of such a device, as a result, wear of the main parts does not occur so quickly.

Watch the video, the scope of application of the compressor:

Compressor equipment is known for its ability to produce low-level performance, however, the process of producing compressed air occurs at fairly high pressures. The combination of these two factors allows the use of oil-free and oil piston compressors in appropriate conditions when the use of other types of devices is impractical.

Is it necessary to add oil to a piston compressor?

Not everyone knows that you need to pour oil into a piston-type air compressor. Does the equipment require maintenance at all? To understand this issue, you first need to understand how the device works. The operation of the device is based on the reverse principle of the internal combustion engine.

In a piston compressor, the shaft rotates using an external drive. The pistons begin to move in the cylinders, and pressure arises. It was precisely for the appearance of pressure that such a mechanism was designed.

The pistons may seem to move just fine without oil lubrication. There are many modern materials that provide a minimum coefficient of friction, but such parts are not stable enough under heavy loads. The volume of pumped air is of great importance.

For example, piston-type automotive compressors do not require the use of special lubricant. It is important to note that during operation the piston group becomes seriously hot. The higher the pressure in the receiver, the higher the temperature. To reduce performance, the mechanism is equipped with special cooling systems

Myth No. 4: How much compressed air a compressor consumes is equal to its performance.

This statement is completely false. Performance does not depend on the volume of air consumed, but on temperature conditions and ambient pressure, that is, on suction conditions.

The characteristic of a piston compressor is its suction performance (theoretical), which actually corresponds to the volume of air that the device can consume in a certain unit of time. However, in reality this value will be significantly less - real performance is approximately 1/5 lower than theoretical.

Read also: Machine for the production of gloves China price

Is it possible to fill the compressor with motor oil?

This is absolutely impossible to do. There are several reasons for this ban. The fact is that traditional motor lubricants are not suitable for compressors according to the following parameters:

- Compressor oil has high environmental characteristics, which most motor oils do not have. This requirement is due to the fact that the product may enter the respiratory tract of users.

- The product must not ignite when mixed with air. Since the equipment is operated at high temperatures, this risk is very high.

- The viscosity indicators of oils for compressors differ significantly from the characteristics of motor oils.

- Compressors last much longer than a car engine. The lead time for replacement is much longer.

From all that has been said, it turns out that it is absolutely not worth pouring motor oil into the compressor. Even if acquaintances and friends advise you of this option, do not give in to provocations.

Top 5 best oils

The most common in the domestic environment are piston compressors (for example, the Russian brand Intertool). Of the many lubricants for them, the top five in the 2022 ranking will be presented.

- Mobil Rarus429 is suitable for many types of compressors. The oil provides a high level of purification and produces a minimum of coke particles.

- Ariane K-12 ─ mineral liquid lubricant for the piston group of both medium and high pressure devices. Its viscosity index is 18-22, thickening temperature is 15 degrees.

- Ariane K-28 ─ mineral composition based on petroleum with sulfur. Its viscosity is 26-30, thickening temperature is 10 degrees. No additives.

- BP EnersynGCS-180 ─ synthetic group of oils for piston gas apparatus. It is characterized by increased temperature stability.

- Ariane KS-19 is a mineral product based on paraffin oil. Its viscosity is 18-22, thickening temperature is 15 degrees.

General standards for compressor oils

There are generally accepted standards for oil products that are poured into the compressor. Each equipment manufacturer has the right to establish additional requirements, but in general, the approach remains the same. These requirements include:

- minimum coke number. The characteristic indicates that the decomposition of the lubricant at high temperatures will not lead to the formation of solid deposits;

- high thermal conductivity. Such characteristics are not available for conventional motor oil;

- physicochemical characteristics should not change under the influence of pressure and high temperature. Here you can specify the melting, flashing, and freezing temperatures. For compressor oils, the term “discharge temperature” applies.

Any product that claims to be a compressor lubricant must meet standards, otherwise it will not perform its function and protect the unit.

Special formulations

What kind of oil should I pour into the compressor? A piston air compressor has special requirements. The lubricant must be in close contact with the highly heated compressed gas. Thus, the product must be safe even when heated to temperatures of 170°, 180°C and more. It should include only high-quality additives that eliminate the risk of carbon deposits on moving parts. Also, the substance must have high resistance to temperature oxidation, otherwise the likelihood of compressor failure increases.

Due to long-term use, its density increases as the liquid evaporates and contamination increases. Because of this, a fire is possible, so the oil in the air compressor must be changed regularly.

Technical characteristics of compressor oils

All lubricants of this kind are divided into categories. This allows customers to choose a composition that will be ideal for specific operating conditions. There are the following categories:

- “1” - gentle working conditions, up to 160 degrees Celsius;

- “2” - standard operation, up to 180 degrees;

- “3” - heavy operating mode, continuous operation, up to 200 degrees;

- “4” - harsh working conditions in an aggressive environment. Temperature indicators – from 200 degrees Celsius.

Volatility is of particular importance. The indicator is measured when the liquid is heated to operating temperature. The necessary conditions arise after 10-15 minutes of operation of the unit.

Procedure A. Compatible Base Oils

- Start the compressor and allow it to run at normal operating temperature for at least 1 hour.

- Stop the compressor, turn off the power, relieve pressure, take an oil sample.

- Drain the compressor oil from the main reservoir, cooler, separator tank and lower piping system.

- Replace filters.

- Fill the main reservoir with Texaco compressor oil to the correct level.

- Repeat steps 1-5.

- Start the compressor and allow it to operate normally /Take an oil sample.

Submit the sample to Starlube technicians to evaluate the effectiveness of flushing/replacement. Repeat steps 1-5 if necessary.

How to select oil for a compressor?

Manufacturers are trying to produce lubricants that meet the requirements. As a result of testing, the product receives a quality certificate and approval for use. The instructions for the equipment can help in choosing the appropriate composition. The document often states which lubricant will be optimal for the unit.

Sometimes people wonder whether it is possible to replace the oil with a different composition. There are no such options. Other types of lubricants can significantly harm equipment and even damage it.

Oil review - brief description of oils from different manufacturers with prices

Compressor oil is a rather specific material, designed specifically for narrow-profile use. Manufacturers strongly recommend using only high-quality, certified product to achieve the best performance of their products. Among the high-quality and inexpensive oils, the following names can be distinguished:

Unlike the ones above, the following oils are more common and can be purchased online from the comfort of your home.

Mineral or synthetic

Opinions are divided on what kind of oil to pour into the compressor: some praise mineral oil, while others say synthetic oil is better. Mineral is cheaper and is usually used when the compressor is used infrequently. In this case, there is a temperature limit - no more than 90 °C. Higher temperatures may cause ignition or detonation. The oil service life is short - 2-4 thousand hours, depending on the brand and manufacturer.

Synthetic oil has different properties:

- High viscosity allows its use for any screw compressors.

- Heating to 180−200 °C does not disrupt the structure of the substance and does not lead to detonation. Therefore, it is considered universal.

- It performed well when working in low temperatures: it can be used outdoors in winter.

- Service life is up to 8000 hours, which is 2-4 times longer than mineral.

Synthetic oil is more expensive than mineral oil, and they prefer to buy it when the compressor is used frequently and actively.

Selection by characteristics

Read the labeling carefully. The main thing is to have heat resistance and high thermal-oxidative stability. Moving parts become hot during high temperature operation and the use of a low-quality product may cause a fire. These characteristics must be indicated on the container.

In the case of screw models, it is especially important to create tight gaps, so the use of oil with a viscosity of less than 7 mm²/s is unacceptable. In this case, the operating temperature is not so important, but it is still not recommended to use brands in which this indicator is 90 °C. Otherwise, the oil will have to be changed much more often than indicated in the passport in order to increase the service life of the compressor.

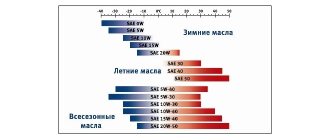

When studying the markings, pay attention to the designations. As a rule, the options are standard: SAE 20, SAE 40, SAE 60, etc. You can also find the following markings: SAE 20W, SAE 30W. Here the letter W indicates that the oil can be used in the cold season. At temperatures of -20 °C or -30 °C, the viscosity will ensure high-quality pumping.

Which type of feedstock is better - minerals or synthetics?

Mineral lubricants are always cheaper, and they usually have a wider variety of additives. Such oils are not very resistant to external factors - humidity, temperature. They are mainly made from paraffinic oil containing sulfur using a selective purification method.

Recommendations for choosing oil have recently leaned towards synthetic lubricants. They perform their lubricating and cooling purposes much better, since they are less dependent on external conditions. Some brands can be 4-5 times more expensive than mineral ones. But they satisfy the most stringent requirements, since they contain oxidation inhibitors, have excellent thermal stability and the ability to eliminate corrosion of parts.

Types of modern compressor units

Piston air compressors are divided according to the method of placing the cylinders. There are such devices:

- Vertical. The pistons are placed vertically.

- Horizontal. The cylinders can be installed on one side of the crankshaft or on both.

- Angular. The cylinders are located both horizontally and vertically. In addition, they can be placed at a certain angle, for example, in the form of the symbols “V”, “W”.

Compressor units are also divided into oil-free and oil-based. For type 1 devices, engine oil is not required. Such units are used when it is necessary to obtain a gaseous medium without any foreign particles.

Depending on how many compression stages there are in the compressor, it can be classified as a one-, two-, or multi-stage device.

The temperature of the compressed air increases due to carbon deposits that accumulate in large quantities on various parts. This is the main disadvantage of oil units.

Level monitoring and oil change schedule

Each compressor is equipped with a round inspection window. There are control marks on it. Many models have a maximum division and a minimum. Look, if the level is at the minimum level, or below, it’s time to drain and change. But often on such a window there is only one mark - the possible maximum. Then you need to measure with a feeler gauge. The dipstick often has critically low level marks. If they are not there, then take a rough guide - less than 1/3 of the crankcase also needs to be changed.

Basically, experienced professionals can hear from the sound of the compressor that it is already in need of an oil change. With new oil, the unit runs smoother and quieter.

You can rely on the advice and hearing of the craftsmen, but it is better to have a clear replacement schedule - once every 100 hours of operation. If the computer works 1-2 hours a day, then it turns out that replacement is needed once every 2-3 months, which is not so difficult.

Some experts recommend replacing it more frequently - up to once every 50 hours. Then there will be no problems with oil. There is also some good advice - when you drain the oil, look at its color. If the substance is light and clean, the work is normal. If the oil is dark and cloudy, the work wears out, there is constant overload and overheating. Then the oil needs to be changed more often, perhaps once every 50 hours of operation.