In recent years, electric chain saws have occupied one of the main positions in the market of gas- and electric tools. They are lighter than their gasoline counterparts and are quieter. An electric motor, unlike a gasoline internal combustion engine, does not require such careful maintenance, so an electric tool is much easier to operate. However, the most important part of an electric saw – the cutting chain – requires constant maintenance.

For this purpose, special lubricants have been developed.

Electric saw oil must be constantly present in the friction zone.

In modern devices, lubrication is performed automatically from a special reservoir. In older ones, it is done manually, by periodically immersing it in oil, brushing or spraying.

For any model of electric saw, lubricating fluid is the main consumable. The service life of the tool depends on its quality. Therefore, the issue of choosing a lubricant should be approached with special attention.

Theory: The role of lubrication in the saw chain

Chain lubrication oil fulfills its main purpose - it lubricates the chain guide links, the guides in the bar and the driven sprocket. The lubricant should be fed slowly, ideally in a controlled manner, through the channel provided for this purpose into the busbar groove. Next, the chain oil is captured by the guide links and distributed over the entire surface of the grooves, delivered to the teeth of the driven sprocket, reducing the influence of friction forces between the moving elements and the guide surfaces.

Oils for lubricating the chain of an electric saw are no different from those used in mechanisms with a gasoline power plant. The only difference is that not all models with an electric drive are equipped with a built-in saw tool lubrication system. The lubricant in such modifications is delivered to the tire with a syringe, a brush, or by dipping the saw element into an oil bath.

Some of the models of branded saw units Shtil or Makita, which have an electric drive, are equipped with oil pumps with the ability to adjust the supply of lubricant. Increasing or decreasing the amount of lubricant can be done in two ways: by changing the diameter of the channel for its passage or by changing the stroke of the oil pump plunger, for example, in professional Stihl saws. The screw for changing the feed is usually located in the lower or side part of the housing, close to the point where the tire is attached. It is more reliable to adjust the plunger stroke in a specialized workshop.

Most electric chain saws do not provide such adjustment by design and oil is supplied in the amount specified by the manufacturer. The oil pump, if present, has a direct connection with the engine: the engine is running and oil is supplied to the chain. Stopping the rotation of the motor automatically stops the supply of lubricant. The oil supply in such saws can be changed in one way - by using lubricants with invariant viscosity.

Not enough oil

Lack of lubrication naturally leads to local overheating of the rubbing surfaces. The consequences of overheating and dry friction can lead to very sad consequences:

- tire deformation;

- premature wear of the guide bus groove;

- jamming and wear of the driven sprocket;

- jamming or broken circuit.

All this can not only damage the power saw, but also lead to injury.

Excess oil

Excessive supply of lubricant does not lead to critical disturbances in the chain-bar pair. If you do not pay attention to the increased consumption of lubricant and the contamination of the saw body with oil-soaked sawdust, then you can follow the rule “pour the oil...”. Meter-scale emissions of oil splashes from the chain at high and medium engine speeds are another inevitable consequence of excessive supply of lubricant to the chain saw.

The role of oil in the operation of a chainsaw

In order to understand the role lubricants play, it is necessary to have a general idea of how the device operates. Although in a store, when purchasing, they usually say a few words about what it is and how it works, and which neck to pour what into, it would be useful to update simple information on this issue.

Engine oil

Without exception, all chainsaws, like their fellow lawn mowers and cultivators, are equipped with two-stroke engines. With small sizes they develop high power density. Due to the completion of the working cycle in two strokes, the speed of such engines also exceeds that of automobile engines. On the other hand, there is a heavy load on components and parts, air cooling, which also requires a safety margin in the design. The wear of elements can be reduced only by using high-quality lubricants.

A feature of two-stroke engines is the absence of an oil pan and a pump that would deliver liquid lubricant to all rubbing and interacting parts. The advantage of this scheme is its design simplicity, fewer units in the engine. On the other hand, the question arises of how to deliver lubricant to critical places, of which the most demanding are the cylinder and piston.

The solution was to add oil to the fuel. Gasoline is not poured into the saw tank in its pure form, but with the addition of lubricant in a certain proportion. Before entering the combustion chamber, this mixture washes the necessary components, and then exits the exhaust manifold in the form of exhaust gases.

Chain oil

A chain for a chainsaw is no less important than the engine.

For full and long-term operation, it also requires lubrication. Without it, the metal will very quickly begin to overheat, and then cease to perform its functions altogether. In addition, the oil supplied to the chain facilitates its movement when pulled through solid wood. By reducing resistance, you can achieve not only long chain life, but also reduce the load on the engine and reduce fuel consumption. At the same time, chain oil has fundamentally different characteristics from that which is mixed with gasoline.

Recommendations from electric chain saw manufacturers

What types of lubricants do manufacturers recommend using? Branded chain tools from the brands Stihl, Ryobi, Makita, Husqvarna are recommended by their manufacturers to be lubricated with special chain oils. The same position is shared by specialists from Oregon, the main manufacturer of accessories and components for chain saws. It is clear that special chain oils mean lubricants from the brands Stihl, Ryobi, and everywhere else.

At the level of intuition and common sense, it is natural to assume that the best oil for a grade N saw is an N grade lubricant. This is in fact true. With the exception of one very significant moment, the name of which is price. All lubricants recommended by manufacturers have undoubted advantages:

- high adhesive ability;

- biodegradability;

- the presence of additives that counteract wear and scuffing.

The main competitor to all the listed advantages is only the one mentioned above. Branded oil for electric saws costs between 300–700 rubles per liter. And that's not all that matters. Biodegradable oils tend to polymerize naturally. This means that the lubricant must be drained from the reservoir after finishing work with the tool. The oil supply system should be flushed to remove any remaining lubricant. Otherwise, there is a risk of clogging the supply system with polymerization products.

Practical recommendations

It’s hard to believe that a user who has allowed himself to purchase a power saw, for example, from Stihl or Makita, will use grinding or other exotic options, widely presented on thematic resources, to lubricate the chain. Just like pouring sunflower or corn oil into an oil tank, boil graphite lubricant with diesel fuel.

Less knowledgeable users should not rely solely on the definition of “oil” when choosing a lubricant for a saw chain. Although there are those who like to present industrial, transformer and other brands of oils with specific properties as universal lubricants.

Practical experience in operating chain saws with an electric drive shows that oils of the M8 and M10 brands, tested for decades, have quite decent lubricating, consumable and, ultimately, economic indicators. To lubricate the chain of an electric saw, you can use all brands of oils that, according to their inherent characteristics, are designed specifically for lubricating rubbing surfaces.

With experience comes an understanding of what viscosity of oil to use for work in the cold season or summer; cut soft and wet wood or dry and hard wood.

Source: masloforum.ru

What kind of oil should be poured into an electric saw?

For most owners of electric saws, it is no big secret that the oil used to lubricate the electric saw chain is one of the main consumables. However, not everyone pays due attention to the quality of the lubricant. And it is completely in vain, since the life of its further operation will depend on how well this product lubricates the working surface of the chain. Therefore, before pouring oil into an electric saw, you need to pay attention to its technical characteristics.

Why is it necessary to lubricate the chain on an electric saw?

Electric saw oil is used as a chain lubricant to neutralize frictional forces and reduce heat generation. As a result, fast and uninterrupted operation of the cutting blade is achieved. Sometimes it happens that at some stages of cutting it is necessary to make additional efforts to obtain the required cut, and this directly indicates an insufficient amount of lubricant or its not very good quality. In this case, it is recommended to immediately check the oil level in the reservoir or simply lubricate the chain to complete the current work.

Most new models of electric chain saws have a built-in automatic oil supply system to the surface of the cutting element, and manual lubrication is only necessary for older equipment.

How to properly lubricate a power saw chain?

Modern electric chain saws are equipped with a system for automated supply of lubricant to friction units. In this case, you don’t need to invent anything - you just need to pour oil into a special reservoir and let the tool work for a few seconds without load, “idle”. During this time, the lubricant will be evenly distributed along the entire length of the chain.

Older models of electric saws do not have such a system. Their chain is lubricated by periodically dipping it into a container of oil. You can use brushes or a grease gun for lubrication.

Chain oils in aerosol packaging are especially convenient for this purpose.

We especially note that to ensure safety, lubricating electric saws should only be done when the power supply is completely turned off.

Main components of the lubrication system

Typically, oil enters the chain lubrication system of an electric saw from a special tank, where it is periodically added. From there it is pushed out by a powerful oil pump, doing this at certain time intervals sufficient to expend the previous injection. The main task of the oil mechanism is to prevent the occurrence of such situations when the lubrication on the chain becomes insufficient, and as a result, severe overheating of the cutting part may occur due to sharply increased friction forces. As a result, the chain may become dull and fail. Therefore, the oil must be constantly monitored. Typically, the lubrication system of an electric saw consists of the following components:

- oil tank for chain lubrication;

- special oil filter;

- oil line, which is a small rubber hose that serves to supply oil from the tank;

- an oil pump that pumps lubricant from the tank to the cutting mechanism;

- a special gear with the help of which force is transmitted to the pump from the electric saw motor.

A tire could also be added to this list, since it has special holes for oil supply.

Features of chain oil

If the engine arsenal must have such properties as purity and low ash content, then chain oil must have completely different basic characteristics. It does not burn, so it is not required to be carbon-free after use.

The design of the saw set includes a bar with a driving and driven sprocket and a chain. Lubricating the blade facilitates its movement along the tire channel, the passage of the drive links along the sprockets, reducing wear on the rubbing pairs. Since the oil is applied to the surface of the chain in special holes or grooves, it must adhere well to the blade, since when the sprockets rotate, the centrifugal force will cause it to fly apart.

At maximum speeds such spread is inevitable. There is even an experiment to check the lubrication on the chain:

Apply full throttle, holding the tire over the fresh cut. Drops of oil that appear will indicate that there is enough lubrication.

Based on this, we can outline two most important characteristics of “chain” oils:

- Good adhesive ability . This means that the oil should stay as tightly as possible in the grooves and holes of the chain. At medium speeds it doesn't even leave the surface. Such indicators are related to viscosity - it is quite high for lubricants. At the same time, excessive thickness also harms the chain - the oil does not have time to envelop the chain in the required amount.

- Highly environmentally friendly . Chain oil ends up in nature almost unchanged, like from a bottle: it drips onto the ground, remains on wood, bushes, and grass. Once on the snow, in the spring it flows into a reservoir. Its impact may seem insignificant, but there are thousands of chainsaws operating all over the world. Large companies are very concerned about environmental issues. Therefore, they try to make their oils safe for the environment. Many of them are made from plant-based ingredients and disintegrate in a few days. Therefore, high-quality products have a limited shelf life.

Operating principle of the chain lubrication system

As already mentioned, the main link in the lubrication system is the pump. It works like this. When the engine speed increases, the gear, which is located on the main shaft, begins the pump operation process through a transmission. At this moment, the pressure in the oil supply system increases, and it begins to move towards the tire. This movement ends where the saw housing comes into contact with the tire, in the very place where the longitudinal groove is located, to which the oil channel itself is directed when mounting the tire. This groove is required to supply lubricant to the tire at any tension level of the chain mechanism, i.e. Regardless of the position of the bar during operation of the electric saw, the groove will ensure the supply of lubricant to it. The next feed link is the chain itself. Its links have their own separate groove or hole through which the material is distributed along the length of the chain.

Consequences of lack or excess of lubrication on the chain

For each mechanism whose operating mode is associated with lubricant based on machine oil, certain parameters must be observed. This primarily concerns the amount of oil required for its normal operation. The following problems may occur if there is not enough oil:

- circuit overheating;

- premature dulling of cutting teeth;

- chain jamming or breaking;

- additional time spent on cutting;

- increased sprocket wear;

- tire failure.

For an electric chain saw, it is recommended to fill the oil tank in the following proportion: one full filling of oil per full filling of the gas tank, i.e. 1:1. In some models, for example, Bosh, the lubrication system operates in a fully automatic mode and, if there is too much or little oil on the chain, the saw itself begins to regulate its supply. However, if a malfunction occurs and oil literally begins to pour from the chain mechanism, then its excess can lead to the following undesirable consequences:

- increased oil consumption;

- excessive contamination of the instrument body;

- wide emission of oil splashes from the chain.

As you can see, an excess of lubricant does not lead to critical consequences, but its overconsumption will definitely hit your pocket. Considering that the cost of high-quality lubricating oil is quite high, it is better to use it carefully.

General recommendations for choosing lubricant for electric saws

When choosing oil for lubricating an electric saw, each user asks the question, which option is more profitable and acceptable - special oil for chain mechanisms or regular machine oil? If you listen to the experts, then, of course, the first option is preferable, since the chain lubricating oil was specially designed taking into account the technical characteristics of the electric saw.

Technical characteristics mean a certain temperature regime and friction of the working parts of the lubrication mechanism.

Although regular motor oil is cheaper than special motor oil, it must be taken into account that it serves completely different purposes and cannot guarantee moderate wear of working parts . So you can gain a little in price now, but then you will have to overpay for the repair of prematurely worn out mechanisms.

Many experts recommend using a special brand of oil with the letter N to lubricate the electric saw. It is a little more expensive, but guarantees long-term and trouble-free operation of the chain. Its main advantages include:

- excellent biodegradability;

- increased adhesive capabilities;

- the presence in the composition of special additives that protect against premature wear.

By following these recommendations, you can significantly increase the service life of the chain mechanism of your electric saw. However, the final choice of lubricant always remains with the user.

Consequences of using low-quality oil

Serious manufacturers of chainsaws indicate directly in the instructions for their products which oil to use with the device. Naturally, the company of the related products will be the same. This is not only a marketing ploy, but also a practical recommendation. Companies that have been producing saws for many years have sufficient production capacity and produce really good oils.

For many household chainsaw models, such advice is not available. The user equips the gas tank at his own discretion. And here it is also better to choose a quality product, tested by thousands of owners of gasoline units. Even an inexpensive saw with the correct operating modes and proper selection of consumables can last for more than one year. And vice versa: an unnamed oil of unknown composition can “kill” even a good Stihl or Husqvarna piston group.

If the exhaust system of the saw becomes clogged with particles of burning and soot, then the engine power will inevitably drop. Purge of the combustion chamber can no longer be carried out so intensively, most of the exhaust gases remain in the cylinder, and the fuel pump does not have enough strength to pump the required amount of mixture.

Incomplete combustion of the oil component in gasoline leads to the deposition of soot and carbon deposits in the cylinder and on the bottom of the piston. Poor fluidity indicators lead to heating of the cylinder-piston group, during which scuffing can form on the surface of the working parts. After several cycles of such work, it may be necessary to replace the piston.

Review of brands from various manufacturers

Today there are many tempting offers on the market from a variety of manufacturers of specialty oils that can operate in high temperature conditions and still provide excellent gear lubrication performance. The most popular of them are presented in the following list.

- Forest Plus has high adhesive characteristics and can be used at ambient temperatures down to - 15°C. Subject to certain conditions, the shelf life of the oil is 3 years. Sold in 1-liter and five-liter packaging. Cost 1 l. – 330 rubles, 5 l. – 1140 rubles.

- Bio Plus products are made on a plant basis. When released into the soil, it quickly decomposes. The oil can be used at temperatures down to - 15°C. Packaging – 1 and 5 liter containers. Cost 1 l. — 360 rubles.

- Synth Plus is made on a synthetic base. Withstands increased loads and can be used at particularly low temperatures down to – 25°C. Packaging – 1 and 4 liter containers. Cost 1 l. – 790 rubles, 4l. – 2970 rubles.

- CHAMPION adhesive oil is designed to operate over a wide temperature range. Sold in 3 and 10 liter containers, which is very convenient for use in forestry. Cost 3l. – 490 rubles, 10 l. – 2200 rubles.

- The HUSQVARNA Vegoil product is one of the most economical solutions for the lubrication mechanism of an electric saw. According to the manufacturer, the consumption of this material is 40% less than others. Cost 1 l. – 390 rubles.

Using special oil to lubricate the chain mechanism of the electric saw will ensure its uninterrupted operation for a long time. This will allow work to be carried out quickly, efficiently and with a high level of safety, which will ultimately lead to significant savings on repairs and maintenance of the entire tool.

Source: tehnika.expert

Review of famous brands of chainsaw engine oil

So, you shouldn’t pour anything into the chainsaw. For those who have not made a choice, there is always a time-tested assortment from different manufacturers that is familiar to the masses.

Stihl HP

Mineral composition with a high degree of purification. Color - dark red. Due to its organic origin, it has a limited shelf life - 4 years in unopened packaging. Be careful when purchasing: expired products may contain sediment. Several packaging volumes are available to the user: from 100 ml to 10 l. There are canisters with and without dispenser. Sometimes you can find a very small 20 ml bottle on sale. This volume is convenient for one-time use of the saw. The average price per liter is about 500 - 600 rubles.

Stihl HP Super

It belongs to the category of semi-synthetics, superior to regular HP in all respects, including price. It has a dark green color. It has low ash content. No carbon deposits on the piston and cylinder walls, as well as less smoky exhaust.

Stihl HP Ultra

This is already pure synthetics. It is the most advanced and expensive in the Shtil line. Also green, just a little lighter than Super. Suitable for motors of powerful professional tools. It is distinguished not only by maximum cleanliness, which benefits the engine and nature, but also by excellent frost resistance. Does not change its density and solubility in harsh conditions where logging is carried out. Available in 0.1, 1 and 5 liter containers. The cost of a liter is 1400 - 1500 rubles.

The German manufacturer is unlikely to clash with Greta Thunberg over its premium oil: HP Ultra disintegrates in open air within 21 days.

Husqvarna HP 2

The Swedish manufacturer does not spoil us with such variety as its German competitor. The branded oil available for purchase is a laconic dark package of 1 liter. Occasionally you can find 5 liter canisters. The color is green, the base is mineral, but with additives, so it would be logical to classify this product as semi-synthetic. The company is significantly silent about secret additives that not only minimize the amount of soot, but also help compensate for the low quality of fuel. The cost of a liter is about 600 - 650 rubles. The Swedes position their product as universal, suitable for both the household segment and professional equipment.

Oregon 90720S

The American brand, which produces chains and tires, could not stay away from the production of motor oil. True, these lubricants are not made in the States itself. The tricky wording “country of manufacture” is Russia or the USA. Being cheaper than the previous ones, this semi-synthetic product still holds its mark, demonstrating good purity and low ash content. Color - dark red, container - 1 and 5 liters, cost - about 450 - 500 rubles per liter.

Huter 2T

Universal oil for motorcycles, positioned as semi-synthetic, as it contains additives. Made in Russia, bottled in 1 liter containers. It is positioned as all-season, although at frost below 20 degrees it thickens noticeably. It is inexpensive (about 200 rubles) and is definitely a better option than nameless bottles with half-worn labels.

Oleo-Mac Prosint 2T

High-quality semi-synthetics in bright packaging. The cost of a liter on the market is from 500 to 600 rubles - not so little. But unlike cheaper analogues, it has API TC approval. It is not necessary to understand this; it is enough just to know that such oil has passed the appropriate certification and test system.

Hammer Flex 501-004

Another cheap semi-synthetic (250-300 rubles), which has received a certificate of conformity and the trust of users. The temperature limit for use is honestly indicated on the bottle: - 15 degrees. Most users who leave positive reviews do not put too much strain on the tool - there are more expensive oils for professional use.

What kind of chainsaw engine oil do you use?

MineralSynthetics

Lubricating compounds for electric saw chains - which option is better to choose?

Don't think that electric saws don't require oil. On the contrary, high-quality lubricant is almost the most important and necessary substance. A good product allows you to use a power saw for a longer period and provides protection from negative impacts.

I have an electric saw at home and my main task is to protect the tool during storage. I think many are looking for options to provide protection for the electric saw chain during the conservation period. In this review, I will talk about which lubricants are most suitable for applying to an electric saw chain and whether motor oil can be used for this purpose.

Types of lubricants for electric saws

The modern lubricant market offers several options for such products. The compositions differ in the base - synthetics, mineral water or semi-synthetics. In recent years, lubricants developed based on plant components have begun to gain popularity. Each option has strengths and weaknesses:

- Synthetic lubricants. If we consider lubricants in terms of stability, synthetics will take the lead. The substances can ensure the operation of electric saws even in very cold times (down to -40 degrees Celsius). Among the disadvantages, the high cost of the product can be noted.

- Mineral lubricants. Products from this group are quite popular because they cost several times less than synthetics. On the other hand, the technical parameters are inferior to synthetic lubricants. Mineral-based oils cannot withstand temperatures as low as -25 degrees Celsius. The lubricant hardens and has a detrimental effect on individual parts of the saw. The substance is not suitable for the winter period.

- Semi-synthetic lubricants. An intermediate link between synthetics and mineral water. They cope well with their functions. They have an affordable price. The properties do not reach the level of synthetics.

Today, choosing the appropriate composition for lubricating an electric saw is not difficult. When choosing, you should focus on the operating conditions of the saw and the composition of the lubricant.

Types of oils for electric saw chains

Special oils for chains of electric and chainsaws are presented on the modern market in the main groups - these are mineral-based products, fully synthetic and semi-synthetic. The latter contains both synthetic and mineral components. Another group of chain oils for electric saws consists of special materials based on plant raw materials.

Each group of oils has certain advantages and disadvantages.

From the point of view of stability and the ability to work in the most severe conditions, synthetic oils are undoubtedly the leaders. They ensure operation of electric saws even in frosts down to -40 degrees. The main disadvantage of such products is their high cost.

Mineral oils are much cheaper, but their level of performance properties is also lower. Most of them, at subzero temperatures as low as -25 degrees, stop entering the friction zone and performing lubricating functions.

Semi-synthetic oils for petrol and electric saws, both in terms of characteristics and cost, occupy an intermediate position between mineral water and synthetics.

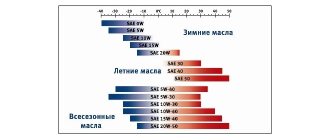

Based on temperature properties, oil for lubricating chains of electric saws is also divided into three groups:

- Summer oils work well at high temperatures, but become extremely thick as early as -15 °C

- Winter - retain their viscosity properties at -20 °C and below

- All-season suitable for use both in winter and during the warm season

To obtain specified performance characteristics, various additive packages are introduced into the formulation of such products. It is especially important for electric saws that the lubricant is not discarded from the friction units under the influence of centrifugal forces when the saw rotates. Therefore, adhesive additives play a vital role in chain oil.

Popular brand lubricants

Many manufacturers produce lubricants for saws. Among the current offers there are little-known and not very popular ones. If you need a lubricant for your electric saw chain, then you should pay attention to the most popular formulations:

| Name of lubricant | general description |

| Forest plus | Oil is in demand. The composition has excellent adhesion. The product can be used at temperatures down to -15 degrees. Retains its properties for up to three years. |

| BioPlus | Made on a plant basis. When it penetrates the soil, it begins to decompose. Can be used at temperatures from -15 degrees. |

| Sunth Plus | Made from synthetic materials. Easily bears heavy loads. Suitable for use at temperatures down to -25 degrees. |

| Champion | A unique product suitable for use at very low temperatures. Sold in containers of 3 and 10 liters. It is characterized by low cost. |

| Husqvarna | Popular composition. It is characterized by low cost. Gives good results. |

You can easily select the appropriate product from the lubricants presented. It is important to consider at what temperature the electric saw will be operated in the future.

Popular brands of oils for chainsaw chains

Stihl

The Germans traditionally offer several solutions:

- Forest Plus

Inexpensive for a branded product, but very effective. There will be no problems with it down to -15 degrees. Packaged in 1 and 5 liter containers. It retains its properties for three years, so when purchasing it, you need to consider how tightly you will use the saw.

- BioPlus

The name hints at the environmental friendliness of the lubricant. Plant origin makes the product completely safe for forests and water bodies. Biodegradable lubricants are at the peak of popularity in Europe, although in Russia they are still reluctant to shell out money for them.

- Synth Plus

Professional oil for real tough lumberjacks from countries with harsh climates. Although such forests are cut down mainly in Russia and Finland. The formula of the components allows it to work at -25, and the high price makes its use in household saws pointless.

Husqvarna

The Swedes have not remained aloof from “chain” lubricants. This segment offers two options:

- Bio Advanced

A universal solution, both for amateurs who value their efforts and tools, and among professionals for whom maximum speed and durability are vital. Biodegradation is a must.

- Vegoil

A more budget-friendly solution for the amateur sector. Positioned as an oil with reduced consumption. In practice, it is almost no different from competitors in terms of the speed of emptying the tank.

Other manufacturers

The oil is produced by many companies that also make chainsaws. Their products are less popular than Shtil or Husqvarna, but are also in demand among owners of gasoline units.

- Polar Lube

Mineral lubricant from the Italians Oleo-Mac.

- Champion

An adhesive lubricant that the manufacturer of the same name recommends for its power tools.

- Biotop

Following the global fashion for ecology, the Japanese company Makita decided to keep up.

If you have a saw that you don't want to lose, don't put car engine waste into the oil tank. Although this liquid still has lubricating properties, there is practically no adhesion. Everything around will be worked out. In addition, small particles of metal that accumulated in the waste while it was inside the 4-stroke internal combustion engine act on the chain, sprocket and tire like an abrasive.

For an expensive instrument, it is better to take high-quality consumables. For an inexpensive one, they are still of high quality, if the saw is not purchased for the purpose of a one-time job. Chain and engine oil is a way to both extend the life of a chainsaw and “kill” it faster.

Is regular motor oil suitable for lubrication?

This question is considered one of the most common. Motor oil is often at hand, but special lubricant for the electric saw chain is not always available. For this purpose, it is permissible to use motor and transmission compounds, but you must remember that mineral oils should be avoided. Mineral water is only suitable for specific models of saws, which is written in detail in the technical documentation.

It is strictly not recommended to lubricate saws with such compounds unless permitted by the manufacturer. This is not the main purpose of motor oils, which means you should not use the product so as not to harm the instrument.

You should not use vegetable oil either. The lubricating effect will be achieved for a short time, but it is important to remember that the product will dry out very quickly and the saw will again be left without protection. You shouldn't use working off. The quality of such a product is extremely low and it does not provide any protection for the saw.