The longevity and performance of a two-stroke engine is directly dependent on cleanliness. The first circumstance is that carbon deposits formed on the piston are a soft abrasive, which contributes to increased wear of the CPG (Cylinder-Piston Group). Wear of the CPG leads to a drop in compression, power and increased fuel consumption.

Worn parts on two-stroke engines have to be replaced, and this procedure is expensive. In addition, time is spent on its implementation. The second circumstance is that deposits in the exhaust tract reduce engine performance and its effective power. This is especially noticeable on equipment equipped with a power valve, on karts and cubic cross-country motorcycles.

The amount of carbon deposits is mainly influenced by the composition and amount of two-stroke oil. Mineral and ester agents produce the maximum amount of carbon deposits, and their use reduces the performance of a two-stroke engine. They are also the most “smoky” oils, which directly affects the environment. Technically, the smokiness of such a product is expressed as “ash content,” that is, the dry residue after combustion. Must be indicated in the technical documentation for the oil.

Features of two-stroke engines

Two and four stroke designs are internal combustion power plants. A 2-stroke drive carries out a full cycle of operation of the piston in the cylinder during one complete rotation of the crankshaft around its axis. During this period, the piston travels completely from bottom to top and back. This distinguishes the two-stroke design from its four-stroke counterpart, in which this process takes place in two turns of the crankshaft. Two-stroke units are not equipped with clean air intake and carbon monoxide exhaust valves. Fuel injection, smoke purging, and injection of clean air occur due to the pressure and vacuum created by the piston during operation.

The two-stroke engine combines the cleaning and filling procedure of the cylinder. This does not happen in separate strokes, but is performed over a short period of time, as the piston approaches its lower position. During its movement, it opens the exhaust and purge channels. Additional equipment for this purpose is a purge pump.

A two-stroke engine has a liter power greater than a 4-stroke engine, approximately 1.7-1.9 times. This value is obtained because with the same number of revolutions and cylinders, the working stroke of the pistons is twice as fast.

A negative feature of a two-stroke unit is the ability to overheat. This is a consequence of the release of a large amount of heat during operation. To dissipate heat, characteristic fins are made on the engine block. The air flow acts on the fins that cool the engine. Additionally, forced cooling can be used.

What does an internal combustion engine consist of?

You need to start with what an internal combustion engine consists of:

– the cylinder head is a kind of vessel for the combustion chamber of the working mixture, gas distribution valves with a drive, spark plugs and injectors;

-cylinders are hollow parts with a cylindrical inner surface; pistons move in the cylinders;

– pistons are moving parts that tightly cover the cylinders in cross section and move along their axis;

– piston rings are open rings that are tightly seated in grooves on the outer surfaces of the pistons; they seal the combustion chamber, improve heat transfer through the cylinder walls and regulate lubricant flow;

– piston pins serve to articulate the piston with the connecting rod, each of them is an axis relative to which the connecting rod makes an oscillatory movement.;

– connecting rods are a link of a flat mechanism, connected to other moving links through rotational kinematic pairs and performing a complex flat movement;

– the crankshaft is a shaft consisting of several cranks;

– flywheel – a massive rotating wheel used as a storage device (inertial battery) of kinetic energy;

– a camshaft with cams is the main part of the gas distribution mechanism (GRM), which serves to synchronize the intake or exhaust and engine operating strokes;

–valves are mechanisms with which you can, at will, open or close openings for various purposes;

-spark plugs serve to ignite the combustible mixture; they are a set of electrodes between which a spark occurs.

But for the internal combustion engine to fully operate, several more systems are needed:

– the internal combustion engine power system consists of a fuel tank, fuel filters, fuel lines, a fuel pump, an air filter, an exhaust system and a carburetor (if the engine is not fuel-injected);

– the exhaust gas system of an internal combustion engine consists of an exhaust valve, an exhaust channel, a muffler exhaust pipe, an additional muffler (resonator), a main muffler, and connecting clamps;

– the internal combustion engine ignition system consists of a power source for the ignition system (battery and generator), an ignition switch, an energy storage control device, an energy storage device (for example, an ignition coil), an ignition distribution system, high-voltage wires and spark plugs;

– the internal combustion engine cooling system consists of specially designed double walls of the cylinder block and heads (the space between them is filled with coolant), a radiator, an expansion tank, a pump, a thermostat and pipelines;

-the lubrication system consists of a sump, an oil pump, an oil filter, pipes, channels and holes for oil supply.

Design and principle of operation

A two-cycle drive is installed in places where small dimensions and low weight are important. The design of the unit includes: a crankcase with channels, a cylinder block, a crankshaft, pistons. The unit operates in two strokes: compression and stroke.

When compression occurs, the piston begins to move from its lowest to its highest position (top and bottom dead centers). As it moves, it blocks the purge and exhaust holes, forming a sealed chamber. At the moment the holes close and the piston moves upward, gasoline is supplied to the cylinder. The gasoline-air mixture is compressed to its maximum when the piston reaches its highest point. A discharged space is formed under the piston, in the crank chamber. It facilitates the flow of fuel from the carburetor through the inlet channel.

Methods for purging cylinders

It is obvious that the purging process, a mechanism that qualifies as complex. Properly performed purging directly affects power and efficiency indicators. To improve performance, designers are constantly trying to improve and bring the process to perfection.

How to blow out a cylinder:

- “Circuit” blowing. This type of blowing is simple and therefore widespread. The disadvantage is that the application is associated with excessive fuel consumption. Types of contour blowing: return-loop, deflector, high-altitude.

- “U-shaped” purging. The “U-shaped” principle is to be used only on engines with two cylinders. When carrying out, one cylinder participates in the process of gas intake, the second releases waste. The effect of purging is felt in fuel efficiency; the process is accompanied by uneven heating of the steam responsible for the exhaust.

- “Valve-slit” purge. It differs in that it requires a gas distribution mechanism to control the valves. The valve is used both to provide fuel and to remove exhaust vapors. Purge involves the removal of waste through a valve in the cylinder head and the flow of fuel through the holes. The advantage is that purge increases fuel efficiency and minimizes the toxicity of emitted vapors. Disadvantage, complexity of design and violation of regimes associated with an increase in the operating temperature of the unit.

- “Direct flow” blowing. Used in power plants with the number of pistons equal to two. In this case, the cylinder is located in a horizontal position. The pistons move towards each other. While moving, each piston releases and closes the valve: one piston admits a portion of fuel, the second removes a portion of waste from the cylinder. The combustion chamber is formed when the pistons approach each other. The effect of this purge option is maximum: it removes burnt gases and saves fuel. Minus, a complex mechanism of cranks and connecting rods is required, engine temperature indicators require the use of coolers and resistant materials for the manufacture of parts.

Two-stroke engine 5 TDF with direct-flow purge

Lubrication system

Oil for lubrication of 2-stroke engines for various operating mechanisms can be supplied in two ways. It can be poured into the fuel tank along with the fuel or use an individual fuel system.

When oil is poured into the fuel tank, it is mixed with fuel. The gasoline-oil mixture from the tank enters the carburetor through the fuel pipeline and is injected into the cylinder. As a result of this, a gasoline-oil cloud is created in the cylinder, which lubricates the internal parts of the engine and removes a significant part of the heat.

The oil-fuel mixture ratio should be within 1:35. This value is considered optimal, but sometimes the characteristics of the oil, operating conditions and engine features are taken into account. In this case, the proportion of the oil-fuel mixture can change up or down, but no more than 15 points, from 1:20 to 1:50. It is necessary to add oil liquid to the fuel tank in a mixed state in accordance with the proportion. Oil combustion occurs together with gasoline in the engine cylinders.

On more modern mechanisms, lubrication can be supplied from an individual oil system. Such a system includes:

- Oil tank.

- Tube system.

- Plunger pump.

- Oil filter (can be installed separately or located in the oil tank).

Lubrication in the oil system is supplied in small doses, depending on the volume of gasoline and air supplied.

What oil to dilute gasoline for a motorcycle

Two-stroke engines do not provide for separate filling of lubricant into the engine crankcase.

Strict requirements are imposed on the oil that burns together with the fuel:

- the lubricating fluid must provide effective lubrication of all parts;

- The oil should burn easily and not form carbon deposits after burning.

When deciding on the type of oil, you should follow the recommendations of the equipment manufacturer specified in the operating manual. Preference should be given to branded oils produced by well-known manufacturers. The preferred oil class is API-TB. It is also possible to use oil marked API-TC.

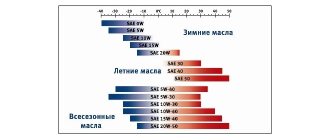

The type of lubricant is selected depending on climatic conditions:

- in the warm season, gasoline can be diluted with mineral oil;

- in the winter months you should give preference to synthetic oils;

- For all-season use, branded semi-synthetics are suitable.

You should follow the recommendations of the equipment manufacturer when deciding on the type of oil.

To obtain detailed information about the temperature threshold for use, you should read the information on the oil packaging. Knowing the ratio of fuel and oil required for stable engine operation, as well as the volume of the gas tank, you can easily calculate how much oil is required for a certain period, taking into account the frequency of trips or use of gas-powered tools.

When buying oil for preparing the fuel mixture, you should pay attention to its purpose. This information is indicated on the packaging

Do not use tractor oil or boat lubricant to mix with gasoline to fuel a scooter or motorcycle. Please note that on the branded label of oil for two-stroke engines it must be designated 2T.

Standards and characteristics

Current standards provide for the use of two brands of oils. These brands are designated as 2T or TS-W3.

2T oil for lubrication of two-stroke engines is used on mechanisms with air-cooled engines. This could be a chain saw or chainsaw, a lawnmower, a motorcycle or a scooter.

TC-W3 oil is used for engines designed for water cooling. For example, the Mercury boat drive. If the boat has an air-cooled drive, then you can use 2T motor oil to lubricate outboard motors.

In areas with low atmospheric temperatures, a special lubricant with low viscosity is used for drives of units such as a snowmobile.

The table summarizes the characteristics of 2T and TC-W3 motor oils.

| Name | Unit | Index | |

| Brand 2T | BrandTS-W3 | ||

| Kinematic viscosity, t=100°С | mm2/s | 13.5-15.5 | 6.8-7.1 |

| Minimum viscosity index | 90 | 85 | |

| Maximum ignition t in an open crucible | °C | 210 | 110 |

| Minimum pour t | °C | 16 | 19 |

| Minimum Base Number | mg KOH/1g oil | 2.0 | 1.8 |

| Density at t=20°С, no more | g/cm3 | 0.9 | 0.86 |

| Sulfate ash content, no more | % | 0.16 | 0.11 |

Mineral or synthetic

2T motor oil is divided into types, depending on the method of its production. The type of oil liquid can be:

- Mineral. This type is not distinguished by high quality and positive characteristics. Obtained as a result of oil refining. As the temperature rises while the engine is running, it loses its thickness. The consequence is a loss of the ability to properly lubricate rubbing parts and destruction of the power unit. Has a low retail price.

- Synthetic. Manufactured in laboratory conditions. To improve the quality of the lubricant, the necessary fillers are added. Oil molecules have the same size, resulting in reduced friction of parts and engine heating. It has a somewhat high cost.

- Semi-synthetic. Mineral water and synthetic are mixed in prescribed proportions. It has the necessary technical characteristics and is affordable.

Without experience, you can select the oil by studying the markings on the container. It contains information about the oil and what it can be used for.