and the production of prefabricated structures, installation of equipment and household appliances, various fasteners are used to connect individual parts of mechanisms. At first glance, they are similar, they have a metal threaded leg and head. But, each group of fasteners has features that determine their purpose. Therefore, we will consider in detail how a screw differs from a screw and a bolt, and what a specific type of hardware is used for. This will allow you to avoid mistakes when purchasing materials and perform installation or assembly work in accordance with the technology.

Using these products, unlike welding, it is possible to make a structure that, if necessary, can be quickly disassembled for repair and maintenance. Their production is regulated by state standards or DIN, the material is brass, stainless steel with anti-corrosion coating.

What is a screw, screw, self-tapping screw, bolt, washer and nut, what does it look like, what is it intended for?

A washer is a fastener that is auxiliary and is placed under the head of the nut. The main purpose of such a product is to increase the pressure area and also prevent the destruction of other fasteners. In addition, the washer prevents the fastener from loosening and makes it more resistant to various types of mechanical stress.

Washer

A screw is a fastening element, which is a type of screw, differs from it in that it has a thick rod, external thread, and a pointed tip. This makes it easier and easier to enter a hard surface. Namely, in wood or concrete. Most often, special holes are made for screws, which are filled with relatively soft material. Usually this is a tree.

Screw

A screw is also a fastener, a type of which is a self-tapping screw or screw. The main feature of the fastener is that it is a rod with an external thread and a head large enough for screwing. Most often, special holes are made on the head so that the screws can be tightened with a screwdriver. Or they make special notches to screw in the products using a special key.

Screw

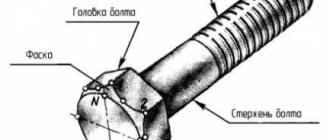

A bolt is a fastener that is a cylinder with a fairly high hexagonal head. Most often it works together with a nut in pairs, and is used to connect some parts.

Bolt

A nut is a fastener that has a thread inside it and is used in conjunction with a screw or bolt. Typically, nuts are made in a hexagonal shape so that they can be secured with a wrench.

screw

What is the difference between a bolt and a screw: comparison, photo

A screw and a bolt look very similar to each other, and many can confuse them. But they are used in completely different industries. The fact is that there is a peculiarity in the design, because of this, a bolt is mainly used to fasten parts using a nut. That is, there will be a bolt on one side and some part in the middle. On the other side there will be a nut that will hold it all together.

Bolt and nut

A screw differs from a bolt in that it is not used together with a nut, but is most often used separately. That is, in the part itself there is a thread into which the screw is screwed. This way the connection is made, that is, additional nuts for the screw are not used.

Anti-vandal screw

What are the differences between them?

1. Method of fastening parts: a bolt passes through the parts completely, as a rule, it is fastened with a nut (less often with a threaded hole in the part), and a screw is screwed into one of the parts that has a thread;

2. Method of entering parts: the screw fixes the parts by turning inward, but the bolt does not do this, it remains static;

3. Tools for screwing: the bolt is secured with a wrench, and the screw can also be screwed in with a screwdriver (if there is a slot);

4. The presence of a head: for a bolt - always, for a screw - most often, but not always;

5. Deepening of the head: for a screw it deepens when screwed into the fastener, for a bolt it remains outside;

6. Thread: for a screw - along the entire length of the rod, for a bolt - can reach up to half;

7. Dimensions: the range of sizes of screws is wider (they can be small) than that of bolts (there are no small ones);

8. Strength characteristics: when calculating screw connections, only tensile load is taken into account, i.e. for screw rupture along the axis, and when calculating bolted ones - both for tension and shear.

What is the difference between a screw and a bolt and a screw: comparison, photo

A screw differs from a screw and bolt in that it has a thinner thread and a pointed tip. Used without nut and washer. Most often, its surface is self-tapping, that is, when a certain force is applied, the self-tapping screw can be screwed into a wooden surface, without cutting a preliminary thread. Screws and bolts are not used for these purposes because they do not have a pointed tip and do not have a self-tapping characteristic.

Plumbing screw Bolt

Screws

Installation

To install ring screws, first of all, it is worth calculating their quantity, which directly depends on the amount of work, the quality characteristics of the materials being fastened, and the size of the products. Calculation of the exact number of hardware can only be done individually.

You can attach the self-tapping hook to the surface with your own hands or using tools. In this case, you can use a screwdriver or a metal rod. To attach a screw to a wooden surface, you will need to drill a hole and then start screwing the hardware inside. If you need to insert the product into concrete or brick, you will initially need to insert a spacer plastic dowel into the hole.

The principle of fixing a screw with a ring is practically no different from the procedure with other screws. The algorithm shows the need to perform the following actions:

- drilling a hole - the working surface is often brick, concrete or stone walls;

- cleaning the surface from existing debris and dust;

- installation of a plastic dowel;

- screwing in the screw.

To select the correct hole diameter, you can take into account the following recommendations:

- if the hardware will be fixed into a hard surface, then the characteristics of the hole must coincide with the dowel dimensions;

- if a ring screw is attached to a soft plane, then the diameter of the hole should be approximately 50-70 percent of the diameter of the product.

Fastening a screw may fail and there are several reasons for this:

- heterogeneity of the structure of the material in which the hardware was mounted:

- the presence of voids in the plaster;

- the immediate proximity of the drilled hole to a corner, wall, or brick joint.

After dismantling and unscrewing the hardware from the hole, the latter must be closed with a specially designed plug.

The following video talks about life hacks for attaching ring screws.

What is the difference between a screw and a self-tapping screw: comparison, photo

The self-tapping screw itself is a type of screw, but differs in some ways. The fact is that the technology for making self-tapping screws is somewhat more complicated. Since harder, more durable materials are used for manufacturing, which can destroy the surface with a certain force. For example, a self-tapping screw can be screwed in without making a separate hole, just apply some effort. Screwed in from a certain force. This way the screw will fit tightly into the surface of the wood or other material. In order to insert a screw, you must first make a hole on the surface.

Screw

That is, the screw itself cannot be screwed in without making an additional hole. Since the material is quite fragile and the edge is not so strong. They are not so sharp, so screwing without an additional hole is quite difficult. In addition, the screw is not as tall and has a smaller thread pitch. In this case, the tip of the self-tapping screw is sharper than that of a screw.

Self-tapping screws

How to choose?

Of course, the most important thing is to decide on the purpose of using the screw: what and where the hardware will be used, whether it will be affected by natural conditions (rain, snow). In addition, it is worth checking the quality of the necessary screws.

- Hardware must be identical in color - this is direct evidence that they are processed equally well and will serve absolutely the same.

- There should also be no difference in size - visually everything is the same length and thickness. The same applies to the thread pitch: the turns are clear and with the same cutting interval.

- If there are special drills at the end, there should be no burrs there. The edge must be sharp and not broken, otherwise such a part automatically becomes unusable.

- The recess in the form of which the slot is made must be clear, deep and symmetrical.

- High-quality self-tapping screws, as a rule, are marked with a special marking on the packaging - this is a capital Latin letter. Fasteners with such markings are produced in large factories and undergo additional testing and are certified. By choosing high-quality products, you won’t have to worry that the fasteners will break off at the most inopportune time.

What is the difference between a nut and a bolt: comparison, photo

A nut differs from a bolt in that they are two fasteners that are used in pairs. That is, the nut has an internal thread, and the bolt has an external thread. Accordingly, the nut is screwed onto the bolt. In this way, the structural elements are connected.

Bolt nut

What is the difference between a nut and a washer: comparison, photo

The nut is also significantly different from the washer. The fact is that the nut has a thread inside. A washer is a component that is typically used to seal the joint between a bolt and a nut. That is, it is inserted immediately before screwing on the nut. This helps improve the connection. This minimizes the possibility of unscrewing, unscrewing the nut and removing it from the surface of the bolt. There are different types of washers, both flat and shaped. They are also called growers. Additional pressure improves the adhesion of the bolt and nut and makes the connection of the parts more reliable.

Nut Washer

As you can see, there are many fasteners and parts that are used to connect components, mechanisms and structures. They have a large number of differences and are used in each specific case.

How to choose?

Before purchasing a screw, it is recommended to take into account several parameters:

- the expected load that will be placed on the product during operation;

- type of mounting block;

- the dimensions of the future screw, which you can calculate yourself;

- spacing between threads, determined through additional calculations.

On average, screws with sizes from 12 to 220 mm and a diameter of up to 6 mm are considered in demand. The remaining fasteners should be classified in a specialized class. Medium-pitch screws called “herringbone” deserve special attention. If you purchase them, you will need to additionally purchase special dowels.

If we are talking about purchasing dowels for a concrete base, then it is better to give preference to models with a cylindrical or countersunk head. If necessary, you can consider the design of such elements in advance and study their features.

The difference between a screw and a self-tapping screw is described in the following video.