Home » Building a house » Do it yourself

Alexander Korovaev 10/16/2019

2941 Views 1 comment

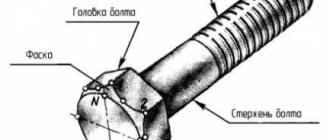

Most modern connections of various mechanisms are assembled using threaded fastenings - bolts, nuts, screws, etc. The threaded connection is quite simple and reliable, one might say it has stood the test of time.

With the right approach to the choice of material and its manufacturing technology (for example, the use of hardening in production), threaded connections on bolts and nuts can provide a reliable connection for decades.

How to unscrew a broken bolt using a drill with a left-hand spiral

In two stages:

- First you need to take a regular nozzle and center it.

- Then arm yourself with the one that rotates counterclockwise (let it be a little larger in diameter) and, using it, gradually remove the body.

You should be careful and control the direction of movement - then the edges of the working rod will catch the remaining hardware, pushing them upward, but without destroying the thread. If any damage occurs, it will be so minor that you can easily fix it with a tap. This method is effective when the fastening joint is not yet very rusty or stuck.

Features and advantages of cylinder head studs

Almost every car is equipped with studs, and not serial bolts, to secure the cylinder head. The steel used for their manufacture can significantly increase the level of tightness of the engine head gasket. This ensures a reliable gasket seal and eliminates the possibility of oil and coolant leaks.

If used for a long time due to metal aging, this cylinder head part requires replacement. Possible damage when removing the head. The work is quite painstaking and requires a lot of effort.

All work must be carried out in stages and some recommendations must be followed.

Unscrewing a broken bolt using another

This method is suitable if the diameter of the residues is relatively large.

Because you will have to drill a smaller threaded hole in the body, into which you will then install a fastener with a left notch and begin to tighten it, going deeper and deeper - it will push out the previously destroyed part. The only downside is that a drill is required to complete the task, but it is not always at hand, and you will have to spend one new hardware. Therefore, it makes sense to consider solutions that are easier to implement and universal in everyday life, and put this aside in reserve for the case when there is no other option.

Application of lubricants

When drilling holes in hardened metal, it is imperative to use a lubricant. It partially cools the work area, preventing the equipment from quickly breaking down. As a lubricant, you can use regular machine oil or special mastics for drilling. Proper lubrication treatment is as follows:

- The drilling area on hardened metal is marked with a core. Apply a small amount of lubricant to this point. If it is liquid, then squeeze out a drop of oil so that it does not spread.

- The cutting area of the tool is dipped into the lubricant and placed at the previously marked point.

- When drilling hardened metal, monitor the amount of lubricant and add it as it is used up.

- Monitor the heating status of the instrument, preventing it from overheating. Intensive smoke emission from burning lubricant indicates the need to stop work and cool the equipment and metal.

How to pull it out, drill it out and how to unscrew a broken bolt from a thread: the best methods

The choice of a specific method depends on the situation, but in practice, the fastening element we are considering most often turns out to be simply licked off (due to poor quality of workmanship). You can remove it without damaging the thread: to do this, just carefully sharpen the head so that its shape matches the size of the key. Well, if you want to minimize risks, you should additionally saturate the joint with lubricant - it will reduce the resistance to pulling.

Now let's pay attention to what to arm yourself with in the event of some kind of damage - due to rust, excessive pressure or for other reasons.

Flat head screwdriver and hammer

This is how to unscrew a broken bolt when the break occurs above the thread surface and the edge of the resulting surface is uneven. Here you need:

- Clean the contact area, examine it carefully and find the largest protrusion.

- Place the tool at the selected point, placing it at an angle; It is quite acceptable to deepen the uneven area with a core so that you can rest even more reliably.

- Try to turn the hardware using light blows; If it doesn’t work, increase the force of influence a little at a time until it works.

Of course, this method should be implemented with extreme caution so as not to accidentally damage adjacent elements or make the hole too deep.

Unscrew with a chisel

Another option for unscrewing is to drill out a broken bolt and remove the broken piece from a hole in a hard-to-reach place. It is carried out using the same technology as the previous one: they cleared the place, found a point of emphasis, and began to turn. Moreover, the remainder should be unscrewed quite easily and quickly, because the contact area of the tool in this case is larger than in the past.

Excellent for removing hardware with the top flying off.

Core and hammer

A suitable choice when the head has been torn off or if a defect is discovered at the very beginning of the thread, and there is no screwdriver at hand. Look, the tip of the marking tool is sharp and therefore excellent for deforming the cut. A few light blows, and the surface is no longer flat; you can grab onto it with pliers and pull out the stuck body.

Weld the nut by welding

Let's imagine that the head of a bolt is broken: how to unscrew the remaining part?

An original but effective solution is to attach something to it that you can pull on. A hollow fastener with a similar thread is an ideal option, but how to fix it? Using heat treatment with plastic deformation! To solve this, in addition to the element already mentioned, you need to take more wire cutters, and also connect a welding machine and:

- Take the nut with a holder and lean it against the fragment with a slight offset.

- Connect the body to the part using an arc.

Now it will not be difficult to remove the failed hardware and replace it.

Also, as an alternative, you can weld the pin - at an angle, and small. It will perfectly serve as a lever that can be pulled to remove the body.

When deciding how to remove and unscrew the remains of a bolt if it has broken off, many people prefer welding - because it has at least 3 advantages:

- You can start unscrewing almost without delay, since the same nut heats up strongly and quickly; and this does not harm the body of the part, because it continues to remain cold. Also, due to thermal expansion, decoking of the stuck contact is observed.

- Using this method, it will not be difficult to remove even fragments of hardened hardware made of high-strength steel, drilling which is very time-consuming, difficult and impractical.

- A strong seam is created between the body and the lever (consumable), which allows you to pull out the worn element with pliers even with force.

Welding is also a convenient answer to the question of how to remove a broken bolt from a thread, because it allows you to unscrew any remaining hardware - protruding from the body, running flush, and even deeply recessed. In the first and second cases, you can attach a washer with a nut or a lever and pull, in the third - insert a metal tube and build it up - there are options, and each of them is quite simple to implement.

Unscrew the pin using an extractor

This is a specialized tool, and it is effective where available tools fail.

Previously, it was wedge-shaped (a cone with special edges) or rod-shaped, and both of these options were driven into holes. Its screw model, with a cut spiral, has also gained popularity. Today it is a whole set of devices, which includes bushings, drills and metal strips. So, you have a kink in the bolt, how to unscrew it using this device:

- Fill the contact area with lubricant or, if the connection is old and stuck, with a rust solvent.

- Make a hole (the same diameter as the damaged fastener), using one of the supplied tubes as a guide.

- Drive the rod to the wedging depth.

- Remove the tool element along with the remains of the body using a wrench.

After this, you just need to place the worn hardware on a hard surface and lightly hit it several times to loosen the contact force and remove it from the working part of the tool.

The method of how to unscrew a crimp with an extractor may differ slightly depending on where exactly the fastener managed to break off:

- Above/below the engine housing (or other functional unit) - you need to install a guide, drill a hole, hammer a rod into it, and remove the damaged element.

- Flush with the surface - you should also use a punch for centering; and when you mark the point for the location of the sleeve, all that remains is to repeat the above operations.

Universal sets are good because they can be used to remove not only hardware, but also screws and even thin studs. They are quite affordable in price, and when purchasing, it is better to give preference to extractors made of hardened or chrome vanadium steel - they are stronger.

How to properly drill out a broken bolt body in a hard-to-reach place

This is one of the most labor-intensive ways to remove a broken bolt from a thread, and it is worth using it in practice only when there are no other options. And not only because it takes time, it is important to maintain the accuracy of the work. The slightest mistake and the internal coils of the case will be damaged. In addition, to implement the method you will need a whole set of tools:

- Metal drill with a set of attachments.

- Screwdrivers with different blades.

- Triangular file

- Reliable pliers or, better yet, a wrench.

- Tap.

- Several needle files of various shapes and sizes.

WD-40 will also be useful: we remind you that it is worth pouring it into the work area 15 minutes before performing operations, it will dissolve some of the rust.

So, the bolt has broken off, how to unscrew the broken part from the thread using drilling:

- Put on the thinnest attachment, turn on the drill and make a recess exactly in the center of the hardware; try not to go aside, this is fraught with subsequent difficulties.

- Change drills, gradually increasing their cross-section, until the hole occupies 1/3 of the diameter of the body.

- Drive the file in, carefully but firmly, because if it does not hold well, you will not be able to remove the damaged element.

- Take pliers or a gas wrench, clamp the trihedron with them and begin to make circular movements, trying to pull out the fasteners.

It should work, but how to unscrew and remove the broken part, how to unscrew a broken bolt if it does not give in even after all these steps? It is necessary to widen the hole so that another hardware fits into it, but smaller and with the opposite thread (usually the left one). In this case, the second one will act as a cap after it is screwed into the first one.

If this doesn’t work, just continue to increase the diameter and length of the recess until the pressure on the remaining fastening element weakens, then they will begin to wobble and it will not be difficult to remove them using a suitable tap.

We remind you that this is a solution for extreme cases; in general, there are simpler, faster, more convenient options.

Complex option

If you can't unscrew it using these methods, we'll drill it. The main thing is that the broken bolt is not hardened. There are several methods to try before attempting to drill out a broken bolt. The most basic thing is to take a drill with reverse and a drill bit. Sometimes this trick can be done with a regular metal screw with a drill at the end. We press on the broken part, try to unscrew it with small turns, accuracy is needed here - you need to twist it “tightly”. If these methods fail, we move on to serious action. When the diameter of the pin is small, you need to determine how to remove the fragment - there is not enough space for two options.

Method one. Using a small diameter drill, we make two holes in the fragment. Against each other. We drill shallowly - about 5 - 10 mm, preferably away from the center. Then we take a lock ring remover, narrow-nose pliers, or simply insert two nails, clamp them with pliers and try to unscrew them.

Bolt Removal Technology

Method two. You need a special tool - an extractor. It is sold in tool stores. It is something like a cone drill, has a reverse thread, very hard hardened metal. First, we select a drill according to its diameter. Carefully mark the center of the stud with a core; we need it to drill the hole. It is not necessary to go deep - just drill a little deeper than the length of the extractor. Then we wrap the extractor and try to unscrew the broken piece.

Read also: Thick silicone grease for plastic gears

When none of the methods help, the most difficult option remains - drilling. To do this you need several sharp drills of different diameters and a strong hand. The most important thing is to catch the center of the fragment. We mark the center as accurately as possible with a core; the accuracy of drilling depends on this. Then, using the smallest drill, we drill through the broken one.

It is important to drill exactly along the rest, parallel to the wall, so that the alignment of the holes on both sides is maintained. Then we take the next diameter of the drill and so on until we reach the wall of the hole. If you slightly miss the center of the hole, it happens. The main thing is to stop in time, leaving the thread intact. We take a chisel, screwdriver or nail, and crush the rest of the wall of the fragment inward. Then we simply pull the resulting lump out.

If you find an error, please select a piece of text and press Ctrl+Enter.

A situation where a bolt breaks during tightening and the broken piece remains in the part is not uncommon. But not many people know that there are quite a few effective ways to drill out a broken bolt.

A situation where a bolt breaks during tightening and the broken piece remains in the part is not uncommon. But not many people know that there are quite a few effective ways to drill out a broken bolt. The main thing is not to panic, but to carefully read this information material to the end.

How to remove a bolt if it is broken and nothing helps or the thread is already badly damaged

In such a difficult situation, you should drill a hole so that its width is sufficient for cutting new turns. Although the hardware may be hardened and difficult to give in. Then it must be subjected to heat - heated red-hot - and then left to cool. It is strictly forbidden to forcibly cool it with water - too sharp a temperature rise will only lead to the appearance of cracks.

The operation of slowly changing the temperature regime must be carried out several times. Due to this, the metal will be tempered and slightly softened, and the damaged element will become easier to drill out. But if the body of the part (unit, functional unit) is made of aluminum, special care should be taken to ensure that the surface in the heating zone does not warp.

Replacing the stud

It is better to carry out planned replacement of studs and repair of the head at the same time. For a simple replacement, before unscrewing it, it should be moistened with brake fluid or a brake fluid. It should be unscrewed using a special stud puller or a gas wrench. Unscrewing, especially at the beginning, should be done smoothly, without jerking.

If the force is not enough, you can use an extension cord. It is important to feel the effort here and not miss the moment when the pin begins to twist and break. At the first sign, it is better to reapply brake fluid and let it sit. Move on to the next detail. The pin is unscrewed, move on to the next one. After unscrewing all the studs, we return to the soured part.

We are trying to unscrew it. It may work out, but often such a part breaks off. If it works, install the head with the gasket in place and begin tightening the nuts according to the diagram, observing the tightening torque:

- First, we tighten each nut, going in a circle with a special wrench with a dynamometer;

- Then we go through it several times after a short break to seal the gasket;

- We do the final tightening of the nuts. The cylinder head tightening torque is different for different engine models; it is better to find out this value from the repair manual.

Drill the screw

Select a drill bit that is slightly smaller in diameter than the screw head. Place it in the center of the screw head and drill slowly to create a hole 1 to 3mm deep. Remove the drill from the screwdriver and install the cue ball. Often the hole will help the screwdriver go deep enough into the screw, which will improve the grip between the cue ball and the screw.

Common Mistakes

Despite the fact that automakers clearly indicate the procedure and nuances of tightening the cylinder head, many car enthusiasts make mistakes when assembling the engine. The most common of them are:

- Pouring oil into the mounting holes to lubricate the threads (the liquid is incompressible, so poured oil will not allow the head to be properly tightened);

- Over-tightening (exceeding tightening forces leads to damage to the cylinder head and the fasteners themselves);

- The use of damaged or inappropriate keys (the edges of the bolt heads may be torn off, after which it will be problematic to tighten or unscrew them normally);

- Use of unsuitable bolts as replacements (fasteners from different engines may differ in length, thread spacing, head height and diameter);

POPULAR WITH READERS: Cylinder misfires, causes, diagnostics, repair

To avoid problems in the future, you should use only fasteners designed for a specific engine and fully comply with the work conditions.