Giving a hexagonal shape

At this stage, it will be more convenient to work if the metal is heated.

(I did not maintain a constant temperature and was unable to bend the entire part in one piece). Clamp the strip in a vice at the level of the previously made recess.

Use a hammer to bend the section protruding from the top of the vice.

Check if the angle fits by trying it on the corresponding nut.

Repeat for each segment.

As my strip cooled, the metal became more difficult to work with. This led to a breakdown over the third segment. In my case, this worked to my advantage, because when I started bending the fourth section, it turned out that its length was not enough and I needed to grind off a little metal so that the nut would fit properly. (I think adding a millimeter to each cut will help avoid running out of length on the inside edge of the key).

So I got a part consisting of two parts, each with three sides. (It may be easier to work with this than with a solid piece curved into a ring, as I originally planned to do).

Check that the workpiece fits properly onto the nut. But not too tight. (If necessary, you can grind off part of the inner surface of the edges)

Features of choice

Before choosing a tool in a store, you need to decide on the purpose of their use. If you need repairs of small parts, then you need to buy an appropriate set of keys

It is worth paying attention to the brand and composition of the metal alloy from which the tool is made. After all, you can often find cheap fakes on sale that will simply break off the nut and slip out of your hands.

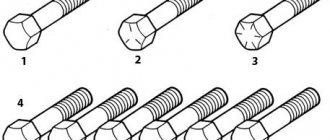

When choosing adjustable, gas and hex tools, you should also pay attention to where you are going to use them. The adjustable is numbered from 1 to 5, where the number indicates the size of the gripping volume

A gas wrench has the same difference, only reduced from 1 to 3. There should be no problems with a hex wrench; the main thing in it is the quality of the material from which the tool is made.

How to unscrew a broken screw

How to unscrew a rusty bolt

To do this, we will take several options.

1. The rudest, but in most cases helpful. Just press the screwdriver towards the screw and twist with sufficient force, so the friction will increase and therefore there is a good chance to slowly but surely unscrew the screw with the broken head

When performing repair work, sometimes the question arises: how to unscrew a bolt or screw with torn edges. This problem has several solutions, knowing which you can unwind almost any hardware. Even if you overdid it and tore off the head or broke the stud, there are ways and tools that allow you to unscrew the broken fasteners.

How to prevent edges from being torn off

To prevent such a problem as torn edges of a bolt or splines of a screw or screw from taking you by surprise, you must adhere to simple rules:

- You need to buy only high-quality fasteners that have high strength and reliability;

- When tightening and unscrewing screws or screws, do not allow the screwdriver to slip through the slots. This leads to their abrasion and it will be difficult to unscrew such fasteners;

- You should always monitor the condition of the instrument. If a screwdriver or key has licked edges, then it will be difficult to unscrew a screw, bolt or screw with their help.

It is much easier to prevent the edges of bolts, screws and screws from licking off than to then unscrew damaged fasteners.

Do not panic if a problem appears such as a licked bolt head or slots on the head of a screw or screw. There are many ways to solve it. It is necessary to adequately assess the situation and choose one of the available options.

How to unscrew a broken hex bolt

How to unscrew a screw with a broken cross

To unscrew a protruding hex or star bolt, you can use the following methods:

- Using a hacksaw or a grinder, make a neat and clearly vertical cut across the screw head. After these steps, you can unscrew it with a regular flat-head screwdriver.

- Using a Torx star: you need to drive it into the recess for the hex key in the hardware head. The size of the sprocket should be such that its splines do not fit into the hole. Then the hardware is unscrewed with a sharp jerk. It is not recommended to use a Torx with a hole in the center; the sprocket can break off.

- Before unscrewing the hexagon with torn edges, a drill with drills and extractors is used to drill a hole in its center. After this, the extractor is driven into it, then pulled out with pliers along with a hex screw.

- Using a drill with reverse rotation, a thin hole is drilled, then a hammer is inserted into it with left rotation and the fasteners are unscrewed. In this case, the rotation of the drill should be slow and the pressure should be strong.

Unscrew the broken bolt

In order to remove the broken bolt with an extractor, you will need to use a drill. You also need to take drills, dies for taps, and a strong core. In the broken “culprit” it is necessary to make a hole, the diameter of which should not exceed the diameter of the thread of the broken bolt.

The extractor has a reverse thread.

An extractor is screwed into the hole. When you screw the extractor, or rather its reverse thread, into the broken bolt, you remove it along with the latter.

If the bolt breaks off and it is possible to reach it, then you need to restore the geometry of what is left of it. Use a file or coarse sandpaper. Then you need to carefully paint the surface. Otherwise, the drill will always walk along the rest of the bolt and it will not be possible to make a hole strictly in the center. It is also necessary to maintain alignment. The hole should be drilled as close to the center of the bolt as possible.

It is necessary to start drilling with a small diameter drill and clearly position the hole in the center. The centered hole can be expanded very easily. The diameter of the extractor must be taken 1 mm larger than the diameter of the hole

It is important not to drill through the hole so that the extractor has something to grab onto.

The extractor must be screwed into the recess of the bolt surface. Then the extractor must be installed in the recess and struck with a hammer, trying to hammer into the hole like a nail. After this, it should remain in the recess.

It is necessary to clamp its head with a die and rotate it in the direction of unscrewing the bolt itself. You need to rotate the die slowly and as carefully as possible. By crashing into the bolt, the extractor tightens it as much as possible and transfers its torque to the broken “culprit”. In turn, the torque will unscrew the broken bolt.

Best Ways to Remove Licked Bolts and Nuts

“how to unscrew a bolt or nut with broken edges?”

There are plenty of options. But none of them can be called universal. Each of them fits certain circumstances and requires a competent approach. Below you can learn about the most effective methods for unscrewing licked parts.

Using a tourniquet

The method involves the use of a tourniquet. To do this, you can take a small piece of dense rubber from a medical tourniquet or bicycle inner tube.

It is important to choose a material that is as dense and rigid as possible. You need to select a screwdriver with a tip that fits the recess on the hardware head

The tourniquet is passed between the tip of the screwdriver and the head. They press hard and try to unscrew the hardware. Under certain conditions, the tight fastener unscrews.

Using an Impact Screwdriver

The method requires an impact screwdriver. First, pressing on the cap, they work with it. You won't be able to unscrew the entire screw with this tool, but you can move the tight mount. Next, take a simple screwdriver and unscrew it.

Removal using a special bit for bolts with ground crosses

This bit is specially designed for removing bolts with damaged grooves. The bat has sharp edges, with which it pierces the metal bolt, engages with its head and solves the problem. The attachment is attached to a screwdriver or screwdriver. You can buy it at any hardware store.

Unscrewing with an extractor

If possible, we use method No. 4, it is very convenient. An extractor is a tool specially designed for unscrewing licked or broken bolt heads, screws and other parts. The principle of use is almost the same as with a bat. First you need to select an extractor suitable for the recess. It is attached to a screwdriver and the stuck screw is removed with pressure.

Using a left-handed drill

It is possible to unscrew the bolt with a drill. It is necessary to purchase a tool in the store with a left-hand spiral. The process is the same as with conventional drilling, but using reverse rotation.

Using core

This option is good for loosening small bolts. The core is pressed to the edge of the head at an angle of approximately 45 degrees and lightly tapped with a hammer in the direction in which the bolt should be unscrewed. The core, due to its sharpness, adheres well to the part, so the chances of its removal are high.

Hammer and chisel

The hammer and chisel method is standard, but is only effective for large bolts. Taking the chisel, rest it on the head and unscrew the fastening with light blows. You need to move the head a little and then unscrew the part with pliers.

Unscrewing methods

To unscrew stuck bolts, you can use several techniques and methods. You can perform these manipulations yourself at home. Before using this or that method, it is necessary to thoroughly clean the connection site from all contaminants and, during a visual inspection of the mounting site, try to determine the type of damage to the bolt. Depending on the type of damage, you can resort to mechanical, chemical or physical methods of unscrewing it.

Mechanical

Mechanical methods include all methods that involve the use of great physical effort when trying to break a damaged connection. The mechanical method can only be used if the bolt is not cracked, chipped or bent.

The mechanical method involves several nuances.

Using box wrenches instead of regular wrenches. Since a regular open-end wrench is capable of influencing only 3 edges of the head when unscrewing, as a result of strong impact these edges can be erased and the key will slide off. The spanner grips all 6 corners of the bolt, which will help you apply more force to unscrew it.

Using the extended handle of the key as a lever. Lengthening the handle of the wrench will help put more pressure on the bolt, and prevent rust from getting in the way.

Application of short-term force effects on different points of the rusted connection part. You will need a hammer and a chisel, with the help of which you first need to knock out a notch on the bolt head, and then hit it with force in the direction of unscrewing. This effect is more powerful than when unscrewing it with a wrench, and it will be possible to unscrew a stuck bolt much faster.

The impact of a force of alternating direction on a bolt. To unscrew a bolt using this method, you must first tighten it and then try to unscrew it. This manipulation can be repeated several times, since alternating movement in different directions will help free the threads from rust.

Destruction of the rust layer using impacts. It is necessary to strike those areas of the bolt that are most affected by corrosion. The applied force will help remove the rust, but damaged connection parts after such exposure will have to be replaced with new ones.

Physical

These methods for unscrewing rusted bolts are based on the physical properties of the materials used in the manufacture of connecting parts. There are the most common and frequently used methods.

Heating of connecting pair parts. To heat the parts, use any source of heat or fire: gas burner, blowtorch, soldering iron, hair dryer.

If you heat up the entire connecting structure, then under the influence of high temperatures the rust will begin to break down and fall off the connecting elements.

Applying liquid to threads. When penetrating into the micro-holes between the nut and bolt, liquids such as gasoline, kerosene, white spirit, and turpentine can reduce the friction between the stuck surfaces, which will ensure easier unscrewing. The same property is possessed by products called “liquid key”, which can be purchased at any auto store.

Chemical

The action of chemical methods is based on dissolving a layer of old rust using acids. Acids have properties that help destroy the corrosion layer:

- salt;

- sulfuric;

- lemon;

- orthophosphoric.

To dissolve the layer of rust on the connecting pair, the joint must be treated with a few drops of the reagent so that they can penetrate the micro-holes on the bolt thread. If a large area is affected by corrosion, then, if possible, the bolt can be soaked in acid.

The time required for exposure to the acid must be at least 24 hours. After it has expired, first tap the connection with a hammer so that large pieces of rust fall off, and then try to unscrew the nut with a wrench.

Following the recommendations given, it will be much easier to unscrew a stuck connection. If none of the above methods failed to remove the stuck bolt, you can resort to cutting it off with a grinder or drilling it. But before applying these measures, it is necessary to weigh all their positive and negative sides.

If there is no suitable tool

Sometimes a problem occurs when a triangular screwdriver is not at hand. In such cases, there is no need to use brute force and break into the body of kitchen appliances. It is enough to replace the store-bought tool with one made by yourself. A suitable analogue is obtained from a hex key for furniture. It is included in the set of the wardrobe and any other self-assembled items.

Furniture suppliers deliberately make them from metals that are soft enough to save on processing costs. But you can still make a good tool for repairing household appliances. You just need to remove the excess part of the hexagon. For cutting, an abrasive wheel mounted on an engraver is preferable. It usually takes no more than ¼ hour and 1-2 adjustments to get a triangular screwdriver as good as the one included in the store kit.

Recommendations for selecting nuts

If you need to find a nut separately due to loss or damage to the complete one, then you should remember a few simple rules:

| The best selection option is based on the sample | Of course, if you have an old element, then purchasing a new one instead is much easier. It is enough to compare two products and make sure that they have similar parameters and are interchangeable. But you don’t always have a sample at hand, so you can take with you the faucet part that requires a fastening element |

| Explore quality | If there is no sample, then it is necessary to take measurements very carefully and carefully, and when choosing, select the option that is made better: there are no burrs on the thread, it is rolled evenly and accurately, there are no stains or cavities on the surface. Every little thing matters, since it can be used to judge how well the element is made |

| Consider the type of tap cover | Putting a bronze nut on a chrome-plated structure, or vice versa, is not the best solution, as it does not look very attractive. Of course, this point does not apply to cases where the fastening is hidden and simply will not be visible; in such a situation, any color will do |

Tips for Preventing Rust

Prevention is the best way to combat rust. Always tighten fasteners in accordance with the torque of similar threaded connections, use quality bolts, nuts and screws, and treat the part with lubricant before tightening. Even if the part is new, it is better to clean it again. All this will allow you to avoid the moment when you have to resort to shock methods.

All the methods described above are quite effective, so you can safely use any of them. They were tested by different masters and always gave a positive result. With these tips, you can easily overcome problems with stuck screws, bolts or nuts

And by taking preventive measures into account, you can avoid the problem from recurring.

How to burn through a rusty nut

An alternative to the previous method is to destroy large crystals of salts and oxides, reducing the friction force inside the thread. This can be done due to the thermal expansion of the metal of the nut and bolt. In the simplest case, another one, but of a larger diameter, is welded to the licked nut. Due to the heating of the thread and the presence of fresh edges, it becomes very easy to unscrew the thread.

Calcining the threaded connection helps in almost 100% of cases, but this is not always convenient to do for two reasons:

- There is no suitable equipment on site;

- Connected or adjacent parts are sensitive to heat.

A more sophisticated way is to wrap the nut with several turns of nichrome or fechral wire and apply voltage from a car battery to the ends. Such local heating will protect sensitive parts from exposure to flame and will help significantly weaken the threads.

The most typical failure situations

A bolt can break in different ways. The easiest case is when it breaks flush with the part. In this case, there will be no special problems in how to drill the bolt. But, nevertheless, it will be necessary to carry out some preparatory measures that will allow you to extract the remaining part without much difficulty. And they are as follows:

- The most important thing is to prepare yourself for the fact that you can only drill out a broken bolt without damaging the thread if you apply maximum patience and calm. Haste in this case is the main enemy

- First of all, you need to use a tool to quickly unscrew rusty bolted joints. There are a great many of them in the markets. But the overwhelming majority of such funds are absolutely useless. A self-respecting car enthusiast and mechanic should always have in stock a penetrating agent for loosening nuts and bolts, which contains substances that have the ability to penetrate any joint. Recommendations for choosing can be obtained from any well-known car service center. The most effective lubricants are those based on molybdenum disulfide and graphite.

- Next, you can try one of the simplest options on how to drill out a broken bolt without any problems. To do this, you need to use a thin drill and a low-speed drill to drill a slot for a screwdriver.

- You can purchase a gas torch for loosening bolts at any hardware store. If there is such a burner, then with its help it is necessary to slightly warm up the part itself in such a way that the remaining piece does not heat up. In this case, there should be a fire extinguisher nearby.

- Then try using a screwdriver with a wrench to slowly loosen the rest of the bolt. If the bolted connection is not old, then the piece should come off.

But not many people know how to drill a bolt correctly if it breaks inside the socket. Typically, such breakdowns occur when tightening the cylinder head studs of a car engine. In this case, some skills are needed when using a drill and tap.

Preparatory activities are the same as in the previous version. Then, before drilling out the broken bolt, you need to pour liquid into the hole for quick unscrewing and leave until completely penetrated into the joint for 2-3 hours.

Then, using a low-speed drill and a drill with a diameter half as big as the bolt, carefully drill a hole in the center, without tilting and at low speeds, to a depth of one-third of the total length of the fragment. Using a tap with a left-hand thread, cut a thread to the full depth of the hole

Then a high-strength bolt with the same thread is screwed in. Using a spanner wrench, lightly tapping and rotating the bolt, remove the remaining part of the bolt.

Replace the old fasteners with new ones: https://avselectro.ru/catalog/4976-bolty - excellent quality bolts from global manufacturers in a large assortment.

How to use a nut puller

Bolted connections that have remained rusty for ten years or more may become completely intractable. To separate parts, the nut was previously hacked or loosened using a chisel. Two notches on different faces are enough, but not on adjacent ones.

Today, a special tool is provided for these purposes. Pullers are similar to spanners, but on one of the faces there is a movable carbide cutter with a screw feed mechanism. Using the puller is very simple: having twisted the cutter tightly for reliable fixation, you need to put a crank on the tail of the screw and make another 2-3 full turns. The sharpening angle is specially selected so that the nut is deformed, and at the same time its internal diameter increases.

A couple of notches on different sides will be enough for the thread to start turning freely. However, you should be careful: the steel of the cutter is quite fragile, plus there is always the possibility of damaging the bolt thread, which in most cases is undesirable.

Torn edges of the head

How to unscrew a bolt with torn edges? This is a little easier than the previous case - after all, the bolt remains intact, it’s just that the key cannot be securely hooked onto the head.

In this case, instead of an open-end wrench, you can use a spanner wrench - it will prevent the head from being damaged even more. If the edges are severely torn off, so that even the head “turns”, you need to “file” new edges using a file - this is not as difficult as it seems.

Another way: weld a new nut to the head of a bolt with torn edges. And then unscrew the bolt, clinging the key to it. This method is reliable, but labor-intensive (welding is required) and is not always appropriate.

Unscrewing methods

There are three main methods for unscrewing a stuck nut:

- dissolving rust and dirt;

- heating the nut;

- mechanical damage to the nut.

Let's deal with each of them in turn.

How to dissolve rust

The essence of the technique is a chemical effect on rusty threads and, as a result, reducing the friction force when unscrewing. Vinegar, alcohol, iodine, kerosene or gasoline may be suitable for these purposes. But it is best to use a composition called WD-40, which is designed specifically for such purposes.

I will describe the methodology in detail:

- The nut is thoroughly moistened with the substance described above and allowed to stand for 15-20 minutes. Then they try to unscrew it. If this does not work, wrap it with a rag soaked in the composition used, or with a napkin. Again they wait for a while.

- Most likely, everything will work out, and success can be secured by hitting the nut with a hammer. Just don’t hit the bolt threads, otherwise you’ll make your task much more difficult. I recommend lengthening the wrench with a piece of pipe of a suitable diameter - the lever will be much stronger. It will be easier to move the nut out of place if you securely place the wrench on it and make a sharp jerk. Just don't pull clockwise!

- With a small thread diameter, it is very convenient to unscrew the nut by swinging, that is, working the wrench back and forth.

Heating process

Under the influence of high temperatures, metal tends to expand. As a result of such deformation, rust simply “looses its grip”, and the unscrewing process is greatly simplified. A hair dryer, a gas burner, a blowtorch - anything that produces a high heating temperature - can be used as a heating element. Don't be afraid - you are unlikely to be able to melt the metal from which the fasteners are made.

How exactly to proceed:

- Warm up the connection thoroughly, and then try to get the process off the ground using a spanner wrench.

- Sometimes it happens that the edges of the nut are licked off, then the wrench is useless. In such cases, a socket head is welded to it, the entire structure is heated, and then it is unscrewed using a wrench.

Mechanical impact

This method is resorted to if the previous two did not help or when there is no task to keep the connection intact. To work, you can use a hammer and chisel, a grinder or a hacksaw.

The essence of the technique is as follows:

- You can use a hacksaw or grinder to saw the nut along the axis of the bolt, and then removing it will not be difficult.

- There is another radical method - using a hammer and chisel. By driving it deeper, you can knock down the threads and increase the internal diameter of the nut. But this is completely, as they say, out of despair.

But the best way to combat souring of joints is to prevent it through timely application of lubricant. In this case, the service life of the fasteners will at least double.

Subscribe to our Social networks

Causes of licked bolts

Both masters and beginners face this situation. Slots or cuts are licked off due to the use of a worn-out tool, a low-quality fastening element, or incorrect use of a screwdriver or wrench. It happens that the edges are already damaged on the outside, or the hexagon is turned from the inside. Sometimes nothing is licked off, but it licks off when unscrewing. This happens because it was tightened tightly, and in order to unscrew the hardware, a lot of force is required. In addition to the tightening torque itself, the force must overcome the diffusion of materials, sticking and rusting of the bolt head. If the tool slips when trying to remove the fastener, the cause should be determined. It may be enough to change the key or screwdriver.

Types of screws

Let's start with the fact that a screw is a cylindrical rod with a special head onto which a screw groove is applied. Screws are produced according to a number of regulatory documents, including GOST 1144-80, GOST 1145-80, etc.

Screw

However, there are two main types of hardware:

- classic screws;

- self-tapping (also known as self-tapping screws).

Carving self-tapping screws for metal and wood For designation in this case, the diameter and length of the screw are used (for example, a product with a diameter of 5 mm and a length of 3.5 cm will be designated as 5x35 mm). In addition, hardware can be classified according to the shape of the slot and the features of the head itself:

- with a flat (countersunk) head;

- with the same, but smaller type;

- with press washer;

- with a hemispherical head.

Types of screw heads All of these varieties are produced with a Phillips, straight (flat) and Torx slot (the latter is also known as an “asterisk”), as well as with an internal hexagon and other less popular options. There are also self-tapping screws with hexagonal and octagonal heads (roofing), which are also made with different slots.

News

- The California Institute of Technology has created an upright robot that can fly 10/7/2021 23:47

- CANON's dual fisheye lens will shoot in VR mode with a 190-degree panorama 10/6/2021 11:53 pm

- Successful tests of energy transfer using laser were completed 10/5/2021 23:38

- How and what to equip a modern office 10/5/2021 10:28

- Why “Balda” is not just a game, but a useful brain trainer 10/5/2021 10:16

- Citroen Skate - autonomous cargo-passenger platform 10/4/2021 23:51

- Which floor coverings are considered the most popular 10/4/2021 11:51 pm

- Toyota C+walkT – electric scooter for moving around large enterprises 10/3/2021 23:12

- Arosno E-trace - an electric snowmobile for lovers of winter walks 10/2/2021 23:05

- Voice cloning using neural systems is a dubious working tool 10/1/2021 23:46

All news

Bolt with torn edges

Now we will figure out how to unscrew a bolt with torn edges. As a rule, the reasons for this problem lie in the following:

- The parts held by the bolt were misaligned in an unnatural way. This leads to pinching and damage.

- The bolt itself was very tight when tightening.

- The tool used to tighten it was the wrong size and improvised means were used (screwdrivers or chisels are often placed in larger keys when there are no suitable small ones).

Before unscrewing a broken bolt or nut, you need to do some preparation. This will allow you to spend less time and effort, and sometimes save expensive equipment.

Sequencing

- Coat the joint with liquid to aid unscrewing. Such a liquid can be the famous WD-40, brake fluid or kerosene. Take your time and let the liquid do its job. As practice shows, you can safely leave the part alone for thirty minutes, or even an hour.

- Take any available tool and lightly, not forcefully, tap the hardware from all accessible sides. Your goal, in this case, is not to launch the bolt like a golf ball, but just to slightly loosen it at the place where it is attached. While performing this activity, there is a danger of damaging the thread, so balance the strength and swing.

- If you have the opportunity and space, try heating the bolt. A gas burner is suitable for this. Make sure there are no flammable liquids or objects near the workplace. Also, before you start warming up, make sure that in case of an emergency you have somewhere to retreat. Do not heat the part with an open flame in enclosed spaces. It is better to open the gate or move the bolt to the air. Rust and grease scorched in this way will turn into ash and will no longer prevent the bolt from being unscrewed.

However, it often happens that it is the screw that jams that cannot be reached with a torch or tapping tool. In this difficult case, you should use a grinder or any available tool such as a chisel to make a deep cut on the preserved cap. This will become the hook that will allow you to pull out the entire bolt.

Now you can, clinging to this protrusion, try to unscrew the stubborn screw. Press the screwdriver into the recess, and while lightly hitting the handle of the hammer in the direction of unscrewing (not clockwise), slowly turn the bolt.

Method No. 1: dissolving rust

How to unscrew a rusty nut? We will not suffer with the tool, wasting our strength in vain. Let's go in search of a substance that will help dissolve rust and reduce friction. Of the most famous ones that have proven themselves well:

- Special product WD-40.

- Kerosene.

- Brake fluid.

- Petrol.

- Carburetor cleaner.

- Alcohol.

- Table vinegar.

- Iodine.

- “Coca-Cola” and other drinks containing inorganic phosphoric acid.

We are sure that at least one of the above is at your fingertips. Next, the algorithm of your actions is simple:

Wet the nut well with

Wait about half an hour. After this, try to carefully unscrew the part with a tool. If it doesn’t work out, apply the substance again and wait. The product will work better if you soak a rag or napkin in it and wrap it around the nut. You can then speed up the unscrewing by lightly tapping the part with a hammer. Another effective way is to try to twist the nut with a strong and sharp jerk after exposure to the solution. For a small nut, the “rocking” method will help - back and forth.

How to unscrew a broken screw

For this we will take several options.

1. The rudest, but in most cases helpful. Just press the screwdriver towards the screw and twist with sufficient force, so the friction will increase and therefore there is a good chance to slowly but surely unscrew the screw with the broken head

When performing repair work, sometimes the question arises: how to unscrew a bolt or screw with torn edges. This problem has several solutions, knowing which you can unwind almost any hardware. Even if you overdid it and tore off the head or broke the stud, there are ways and tools that allow you to unscrew the broken fasteners.

Heat with a soldering iron

This method also has the right to life. The easiest way to remove screws and self-tapping screws is from a plastic surface. To work, you will need a powerful soldering iron - at least 60 W. It will quickly heat up the surface. To unscrew, heat the screw head. In plastic, 4-5 seconds are enough, in wood - 15-20 seconds. Putting the soldering iron aside, press the screwdriver tightly and quickly try to tear it off:

- The heated screw melts the plastic around itself and unscrews without effort.

- A screw in contact with wood will char the wood and weaken the contact with the surface. The heated metal expands along with the wood. As it cools, it shrinks in size, stronger than wood.

- When heating a screw in metal, get ready for a longer process. Heat the head properly with a soldering iron and let it cool - when heated, the fastener will expand the hole, and when it cools, it will shrink. The friction is no longer as strong.

Don’t be upset if you couldn’t unscrew the fasteners right away. You can think of even more ways to safely remove it. Ingenuity and knowledge of the simplest physical laws will help with this.

Practical examples of loosening bolts

When it is necessary to clean the cooling and ventilation system of a personal computer, problems very often arise with unscrewing the mounting bolts. In this case, it is necessary to apply a small amount of glue to the bolt head, being careful not to get beyond its boundaries. When the glue dries. Once hardened, the glue will increase the area of the head and seal the edges of the bolt.

Now you can carefully begin to unscrew the necessary bolted connections

By strictly following the listed tips, you can easily deal with any problem regarding broken or worn bolt connections.

Note: The most stylish library is made of wood.

. Paper books are again gaining popularity, pushing aside electronic books. Like many centuries ago, the library is considered a place where you can retire. We can relax our souls with our favorite book and restore peace of mind. You can also create an office in the library.

Why do the edges on the fasteners break off?

Before we figure out how to unscrew a star screw with torn edges, we will highlight a number of reasons why the problem occurs. Most often, trouble is caused by using a low-quality tool. We are talking about using a screwdriver or screwdriver attachment with an insufficiently sharp tip. In this case, the tight contact of the tool with the notches of the fastener disappears. Therefore, so that in the future you do not have to be puzzled by the question of how to unscrew a screw with torn edges, before performing work you need to make sure that the tip of the screwdriver is completely immersed in the grooves.

Another reason is non-compliance with the fastener screwing technology. Trouble occurs when the performer does not apply enough pressure on the tool. Sometimes the problem is caused by placing the screwdriver blade at an angle to the screw head.

It is easy to guess that this can happen due to the poor quality of the materials from which the fasteners are made. Individual items may also have marking defects. So that you don’t have to look for a solution on how to unscrew a screw with broken edges, before purchasing fasteners you should inquire about its technical characteristics and carry out a visual inspection.

Recommendations

In order to no longer be tormented by the question of how to unscrew rusted nuts, when installing them, it is important to treat the threads with a special lubricant. You can use graphite, silicone or Teflon

Many craftsmen do not recommend using lithol or grease. Such products are more suitable for dynamic rather than static nuts and bolts. Choosing them will lead to the fact that such a lubricant will soon ossify and will interfere with the rapid unscrewing of parts.

Experts recommend working by heating the part. A change in temperature leads to expansion of the metal and, as a result, to the destruction of the corrosion layer and loss of strength of the thread connection. For heating, it is better to take a blowtorch. A hair dryer or lighter will also work.

You can unscrew the rusty part using a wax cup. To do this, you need to take a little wax or children's plasticine and mold the product in the form of a mini cup. The height of the sides of such a product must exceed the height of the nut. Sulfuric acid is poured into an improvised cup and some zinc is added. Due to the interaction of the components, a galvanic effect will occur, and the rust will begin to break down. After carrying out such an operation, unscrewing the nut will become much easier.

Using one of the listed options, you can easily unscrew a stuck nut. More attention should still be paid to prevention and the use of special means to prevent metal corrosion.

How to unscrew the nuts, see below.

How to unscrew a stuck bolt

Maintenance of a car or other equipment occurs in an aggressive environment. Moisture gets into the joints, which harms the metal, creating conditions for the formation of corrosion. As a result, the fastening units in the connections become stuck, and unscrewing the parts in such situations seems like an impossible task. Some craftsmen do not use tools and preparatory work, which leads to breakage of the bolt head or thread.

Unscrewing a stuck bolt

Each situation requires a separate approach; the type of damage to both the fastener and the threads should be assessed before performing the task. There are several basic ways to unscrew a stuck bolt.

Unscrew a rusty bolt or nut by tapping

One effective way is to tap the cap of the torn structure with a hammer.

Rusty stuck bolt

A hammer is used in tandem with a spanner wrench, on which force is applied to unscrew

The operation must be carried out with extreme caution, as it is possible to damage the edges of the cap, which will become an even bigger problem. Usually, rusted bolts are replaced with new ones; if this is not possible, dirt and traces of corrosion should be removed and the threads should be lubricated with a special lubricant.

Using solvents

There are many different categories of solvents available for sale. A variety of uses for elements such as white spirit, combustible fuel and even Coca-Cola. The most effective chemical for unscrewing torn elements is WD-40 and varieties. The liquid is used to treat the structure area; if the hole is through, it is necessary to fill the back part.

White spirit

To speed up the process, it is necessary to soak a rag in a chemical solution, treat the connection, and tap to remove the top layers of rust.

Thermal method

More severe corrosion deposits cannot always be treated chemically. Such compounds are heated with a gas burner to a red-hot state and cooled sharply with water. When exposed to heat, the metal expands, then sharply contracts, which allows deposits to escape through the threaded connection.

Removing a bolt using a gas torch

Using a torch is not always rational, as it can damage the paintwork and nearby components

Caution should be exercised when working near the fuel system, as gasoline vapors may ignite and cause irreversible damage.

Alcohol solution of iodine

We are talking about the idea of an ordinary pharmaceutical alcohol solution of iodine. In this tandem, alcohol, also known as ethylene, and iodine, as an element of the periodic table, equally distribute among themselves the functions of freeing fasteners that have become soured in rust. Alcohol has a high penetrating ability, and iodine interacts with iron oxides and other iron compounds formed upon contact with the external environment. Thus, these two substances weaken the rust, making it easier to free the rusted bolt or nut. To avoid getting your hands dirty and for convenience, it is better to apply iodine to the connection using a syringe.

Methods for removing a bolt

Below are the most effective ways to remove damaged bolts and screws.

With damaged edges

When deciding how to unscrew a bolt with stripped edges, you need to consider whether there is access to it, its location, and what tool you can use. Based on these factors, you can use one of the following methods:

- Using a chisel. The method is suitable for large bolts that have easy access. All you need is a hammer and chisel. The chisel is applied tangentially to the head and sharp blows are applied to it. The method is simple, but it rarely achieves the desired result. It should only be used when there is no other tool at hand.

- If there is free access to the location of the fastener, you can use a universal adjustable wrench. This tool allows you to securely clamp even a round head. If you use small adjustable cobra-type wrenches, which have sharp notches on the working surfaces, you can unscrew the smallest bolts. Such a tool can help out in many cases, but it must be new. In a worn tool, the notches can no longer provide reliable adhesion to the metal, and the key will slip.

- If the edges are not severely damaged, then socket wrench heads can help out. For these purposes, the ring wrench profile must have 12 edges (there is an asterisk inside the head, not a hexagon). Unscrewing is done as follows. Select a head one size smaller than the size of the bolt, and use a hammer to press it onto the torn edges, then unscrew it in the usual way.

- This method involves using a hacksaw for metal, with which a cut is made on the head of the bolt for a flat screwdriver. The depth of the cut should not be more than 75% of the height of the bolt head; with a greater depth, one of the halves may break off.

- If you have a file or grinder at your disposal, you can restore smaller turnkey edges. If you have an open-end wrench, it is not necessary to cut out a hexagon; it is enough to make two parallel edges.

- If you can use welding at the location of the fastening, this will greatly facilitate the task. In this case, you can put a nut of a suitable diameter on the head and weld them together, and then use regular wrenches.

With the head torn off

Very often, when disassembling old threaded connections, you can not only damage the edges of the bolt, but also tear off the head. Then the question arises: how to unscrew the broken bolt. If you have separated parts and the broken bolt protrudes from the body of the part, then you can use all of the above methods.

How to unscrew a bolt with a torn head if the body of the bolt does not protrude from the part? There are several options for solving this problem.

- It is best to use a special tool - an extractor. The extractor is made of a cylindrical metal rod, at one end of which there is a conical thread of opposite cutting, and at the other - a square shank. In order for it to be used, a hole must be drilled in the center of the bolt. The hole diameter is 2-3 mm less than the thread diameter. After this, you need to take an extractor of a suitable size and hammer it into the hole with a light blow. Rotating the extractor by the shank, unscrew the remaining bolt.

- If you have a left-hand thread tap, you can successfully use it as an extractor. The only difference is that the diameter of the hole must be the same as for threading. The exact value can be found in the corresponding tables.

- If you still can’t unscrew the fragment, you can try to remove it this way. Drill a hole in the bolt with the largest possible diameter, being careful not to damage the threaded connection. Then take the appropriate tap and cut a thread in the hole. During this process, the threads are cleaned and any remaining bolt residue is removed.

Ways to unscrew rusty parts at home

Removal using a socket or spanner

If the rust layer is not too large, use a socket or socket wrench. In this case, the tool must have 6 or 12 contact points. Next, you need to alternately tighten and loosen the threads with fairly sharp movements. If this doesn't help, scrub the surface with a wire brush and then apply one of the lubricants mentioned above. Once the product has started to work, take a hammer and lightly tap the fastener to knock off the top layer. Then use the key again, the clamp should loosen. To enhance the effect, you can put a pipe on the wrench or use a tool without a ratchet with a long handle. But be careful when working, bad and old tools can break right in your hands.

Use muscle power and this tool

Exposure of nuts and bolts to high temperatures

Alternatively, you can use heat to remove the part. Take a blowtorch and use it to heat the mount

It is important to heat only one side of the bolt or nut so that it expands from the heat and damages the rust layer. If you don’t have such a tool at hand, you can use an ordinary candle

After heating, pour cold water over the part, and then pick up the key again. The only disadvantage of such methods is that they spoil the hardening of the metal.

Do not use this method near flammable objects or rubber gaskets.

How to unscrew with a screwdriver using a mixture of gearbox oil and acetone

A mixture prepared with your own hands is effective. It consists of 50% automatic transmission oil and 50% acetone. The lubricant must be used several times over several hours, leaving it for at least 40 minutes each time. Sometimes the bolt is intended for a screwdriver, in which case take the same tool or a chisel and hammer. Then use blows to try to loosen the fasteners. If you are not afraid of extreme methods, use zinc or sulfuric acid. Initially, you need to make a small rim of plasticine or wax around the fastener. Then put a piece of zinc into the formed recess and pour the chemical element on top. In a day the problem will be solved. In the same way, you can unscrew a stuck screw on the mixer.

Tightening until it stops

An important method is the so-called “method by contradiction”: in order to loosen the fastening of a stuck part, you should not unscrew it, but, on the contrary, try to screw it tighter, until the end. This will make the bolt or nut move more freely, which will ultimately help in removing the rusty fastener.

Complete dismantling

If all these methods are unsuccessful, then the fastening will need to be destroyed. There are several ways to do this. If you are working with a bolt, you need to drill it out and cut a new thread. You can also use a special tool, such as a nut puller. He tightens the part, under pressure it cracks, thanks to which the nut can be removed with a regular wrench. The most radical way is to use a grinder. Simply cut the bolt lengthwise using a metal saw.