Marking of bolt strength class

For a long time in our country, all hardware was produced in accordance with GOST 22353-77, but today its rules are no longer relevant. All technical characteristics of bolts comply with GOST R 52644-2006. However, in the bins of grandfather's balconies, as well as in warehouses and workshops, bolts with the old markings are still found. And they are sometimes found on an industrial scale. Therefore, let's say a few words about the Soviet GOST and what the old markings meant.

It is represented in two parts: letters at the top and numbers at the bottom. The letters indicate the mark of the factory where the hardware was manufactured, for example, WT, Ch, L, OC, D and others. This is usually followed by numbers reflecting the temporary resistance of the hardware in MPa, divided by ten. Next are the letters again, by which we can determine the level of resistance of the fastener to aggressive environmental conditions. For example, HL would indicate that the bolt is designed for cold climates. The numbers below indicate the heat number.

Sometimes you can see an arrow on the bolts pointing in a counterclockwise direction. This means that you are holding hardware with a left-hand thread. If the thread is right-handed, then the designation is simply missing.

How to prepare high-strength bolts, nuts and washers for use

From practical experience, we can say that at construction sites no one ever prepares these fasteners for use. Bolts are usually delivered to the site in factory lubricant and are immediately put into use. However, this is wrong and old-school craftsmen know a few tricks on how to prepare high-strength fasteners for work.

Old forgotten secrets of preparing high-strength bolts for use

Before use, these fasteners must be boiled in water with household laundry detergent or detergent solution. This is done in order to remove factory oil, scale, dirt, visually inspect the bolts for cracks, and run rejected bolts and nuts. Before installation into the structure, you need to lubricate the threaded part with oil. Sometimes, after boiling, it is recommended to dip the bolts in a mixture of gasoline and oil.

A high-strength bolt is installed with two washers, one on the bolt side and the other on the nut side.

Modern marking of bolts by strength

The new GOST has changed little both in the arrangement of symbols and in their semantic meaning. At the top we can still see the maker's mark. Next comes the swim number.

The strength class of the hardware is indicated below according to the new GOST. Here you can also find the letter S, which says that we have a high-strength bolt with a hex head with an increased size. The designation of the class of resistance to harmful atmospheric influences also remains. It comes last.

Austenitic steel grades

Brand A1

The increased sulfur content defines this brand as a material with lower corrosion resistance compared to others. However, its main advantages are high wear resistance and hardness. It serves as a material for the manufacture of elements for the mechanical engineering industry or movable type connections (pins, cotter pins, regular and spring washers, some self-tapping screws). The purpose of fasteners made from grade A1 is to operate in environments characterized by dryness and low aggressiveness. It is necessary to take into account the lack of resistance to corrosion in acids or environments containing chlorine (sea water, swimming pools, etc.).

Brand A2

It is the most common and versatile type of stainless steel, which is called “food steel”. This name is due to its popularity in the production of cutlery and tableware. This type of stainless steel can be used in damp rooms, in water, outdoors, in certain types of alkalis and acids that have low concentrations. The steel grade cannot be used in high concentrations of salts or acids. Areas of application include the food, mechanical engineering and instrument making industries.

Brand A3

Its basis is steel grade A2. The chemical composition may also consist of titanium, niobium or tantalum, which results in increased corrosion resistance at temperatures exceeding 350°C, at which point A2 may show signs of corrosion. Fasteners made of grade A3 are not widely used due to the fact that the relevance of its use arises exclusively at high temperatures, where fasteners made of martensitic heat-resistant steels are used in greater quantities.

Brand A4

It differs in structure from grade A2 in the presence of molybdenum in it, which significantly increases resistance to corrosion in acids and environments containing the chlorine element (sea water, swimming pools). In all other respects, these brands are similar to each other, so fasteners made from grade A4 can become a replacement for fasteners from grade A2. It can also be used in industries with more aggressive operating conditions: shipbuilding, chemical, paper, nuclear, oil and gas industries. Steel grade A4 is called acid-resistant.

Brand A5

The performance of this steel is the best among all austenitic grades. The chemical composition of A5 can be supplemented with titanium, niobium or tantalum. This contributes to a significant increase in corrosion resistance at temperatures exceeding 350°C, where conventional A4 grades may show signs of corrosion and reduced strength. Fasteners are produced exclusively in hardened form and represent the most expensive and rare replacement for the A4 brand.

| Steel grade according to GOST R ISO 3506 | Analogues according to DIN | Analogues according to GOST | Analogues according to AISI |

| A1 | 1.4305 | 12Х18Н9 | 302 |

| A2 | 1.4301 1.4306 1.4303 | 08Х18Н10 04Х18Н10 03Х18Н11 06Х18Н11 03Х18Н12 | 304 304L 305 |

| A3 | 1.4541 | 08Х18Н10Т 12Х18Н9Т 12Х18Н10Т | 321 |

| A4 | 1.4401 1.4404 1.4436 | 03Х17Н14М3 | 316 316L 319 |

| A5 | 1.4571 | 08Х17Н13М2Т 10Х17Н13М2Т 10Х17Н13М3Т | 316Ti |

Markings

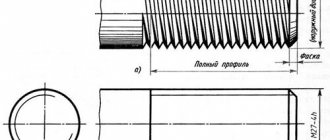

If you are not a professional builder, you should not delve into the jungle of bolt classifications. It is important to know that, as already mentioned, the numbers on the head of the bolt indicate the strength class. Usually these are two numbers written with a dot, for example, 3.6 or 10.9.

The first number indicates the load on the threaded connection that the hardware can withstand. More precisely, this is one hundredth of the nominal value of the tensile strength of the hardware. The measurement is carried out in MPa.

Example: if you see 8.8 on a bolt, this means that the tensile strength of the bolt will be 8×100 = 800 MPa.

The next figure indicates the ratio of the yield strength to the tensile strength multiplied by ten. From two numbers you can calculate the yield strength of the material. To do this, they are multiplied by each other, and then by another ten.

Example: we return to the same 8.8. 8×8 x 10 = 640 N/m.

It is important to understand that the maximum working load limit of a bolt is the yield strength. When calculating a bolt connection for a given load, use a coefficient of 0.5-0.6 from the yield strength. For example, if an M14 bolt of strength class 8.8 has a cross-sectional area of about one square centimeter and a body diameter of about 12 mm, then its tensile strength will be 8 tons, its yield strength will be 6.4 tons, and its design load will be 6.4× 0.5 = 3.2 t.

Stainless steel bolt markings

Among the markings on a bolt made of stainless steel, the marking of the steel itself, A2 or A4, comes first. Next comes the tensile strength, for example 50, 60, 70, etc. These numbers also indicate one tenth of the tensile strength of carbon steel, measured in MPa.

Corrosion resistance of stainless steel

Stainless steel is able to maintain its anti-corrosion properties only in the presence of oxygen, under the influence of which a protective oxide layer of chromium (chrome oxide film) is formed on the surface of the stainless steel. Such a layer is able to isolate the surface of the metal and prevent it from interacting with aggressive substances. The layer always self-heals in the presence of oxygen, but if the chromium oxide layer is damaged or destroyed, corrosion inevitably occurs. There are several types of corrosion of stainless steel.

Crevice corrosion

This corrosion occurs in the gaps between the stainless steel and other material, for example, seals, gaskets, etc. Due to loose contact or severe surface roughness, an aggressive substance can penetrate into the gaps. The access of oxygen to such places is limited, and the protective oxide layer of stainless steel will be destroyed by the aggressive environment, without the ability to self-heal. The surface of the metal will begin to oxidize under the influence of an aggressive substance, and corrosion will occur, which will result in rust on the surface and further destruction of the stainless steel. The smoother the surface of the products and the smaller the gap between them, the less chance there is for crevice corrosion to occur. Often found on fasteners used in seawater, where current speed and lack of oxygen can accelerate crevice corrosion processes.

Pitting (pitting) corrosion

This type of corrosion occurs most often due to damage to the stainless steel surface, causing the protective oxide layer to become damaged. The unprotected surface of the stainless steel begins to interact with the environment, which will lead to the formation of dark spots or dots. If the first signs of corrosion are not removed, the stains will form rusty pits with subsequent destruction of the surface. Also, pitting corrosion can arise from the heterogeneity of the structure of the material or the presence of inclusions of other substances in the material, which often occurs when manufacturing technology is violated. Increased porosity of the structure, strong roughness and the presence of scale can also provoke this type of corrosion. An increase in temperature will significantly accelerate the process of pitting corrosion.

Galvanic corrosion

Any metal naturally has a certain electrical potential. If a conductive medium appears between the metals, then a movement of charged particles occurs from one metal to another, i.e. a current arises between them. The metal that donates electrons will be destroyed slowly or quickly, but the other metal will not undergo changes. Thus, a galvanic couple is formed. There are acceptable galvanic couples, the reaction between which is very weak and slow, and unacceptable ones, the reaction between which will quickly lead to the destruction of one of the metals. If we are talking about stainless steel fasteners, then they cannot be used in structures where a galvanic couple with copper and its alloys may occur. The surface layers of stainless steel in such a pair will quickly begin to form rust. It is also not recommended to use stainless steel with aluminum, but this recommendation only applies to the use of the two materials in a humid environment or in water. An increase in temperature accelerates the processes occurring in galvanic couples, which can aggravate the course of corrosion.

Magnet testing of stainless fasteners

Products made from martensitic and ferritic grade stainless steel are magnetic. Austenitic steel products can also be magnetic. If a magnet is attracted to products of grades A1-A5, then this is not an indicator of the quality of the material. This is also evidenced by the international standard ISO 3506 (GOST R ISO 3506 in the Russian Federation). According to the standard, all austenitic stainless steel fasteners are non-magnetic under normal conditions, but some magnetic properties may appear after cold working or other mechanical treatment. Each material is characterized by its ability to be magnetized, this also applies to stainless steels. Only a vacuum can be completely non-magnetic.

Conclusion

Currently, among stainless steel fasteners, the most popular are products made from austenitic steel grades A2 and A4, because they most often satisfy customer needs. To solve more complex problems where high strength is required, products made from C1 martensitic steel are used, but finding such products from suppliers will be much more difficult. Fasteners made of ferritic steel grade F1 are used extremely rarely for a specific client task.

Nut strength markings

The same rules apply to nuts as to bolts. The marking itself is located on the side of the nut. It is supplied in abbreviated form, so the full designation must be looked at on the packaging.

First of all, there is the name of the product, then the accuracy class. But it, however, is not always indicated, since at the end of the description there is a state standard according to which this type of nut is manufactured, where all the necessary information is written down. The following is the type of thread: K - conical, T - trapezoidal, M - metric. The diameter of the nut in millimeters is also written here. Sometimes in this place they also give the thread pitch in millimeters, which is indicated only in cases where the thread is very small and the direction of the thread if it is left.

Next comes the strength class and coating value in microns, indicated as a number from one to thirteen. And finally, the state standard, which was already mentioned above.

Nuts have seven strength grades: 4, 5, 6, 8, 9, 10, 12. As with a bolt, the strength grade indicates one-hundredth of the tensile strength, which is the recommended value for evenly distributing pressure on the fastener.

But there are also differences from the markings of bolts: the indicated strength classes are only suitable for standard and high nuts. On the side of the low nut you will see other designations: 04 and 05. They say that this hardware is not intended for high loads.

INPO: Technical Library

Chemical composition of stainless steel and compliance with standards

Stainless steels include a group of corrosion-resistant steels containing at least 10.5% chromium and low carbon content. As an example, here is a simple table of various alloys with iron.

| Cast iron | Fe + C > 2% |

| Carbon steel | Fe + C 5% |

| Stainless steel | Fe + C 10.5% |

In addition to Chromium as the “main stainless component,” stainless steel may contain Nickel, Molybdenum, Titanium, Niobium, Sulfur, Phosphorus and other alloying elements that determine the properties of steel.

Correspondence table of the main grades of stainless steels and chemical composition

Source: pellete.ru