We found a domestic Ural chainsaw in the garage. My husband took it apart, cleaned it, says it’s like new and should work. What kind of oil to pour into the Urals to try to turn it on. What kind of gasoline will this chainsaw work optimally on?

The Ural chainsaw is considered a descendant of the Druzhba chainsaw - a reliable and worthy unit. If adjusted well and used regularly, such a saw almost always shows stable operation.

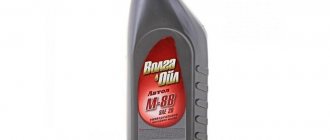

As for gasoline, previously AI-76 grade was poured into such a chainsaw, but now A-80 can be poured. As for oil, you can use domestic M8-B or any other imported oil for a two-stroke engine. Oil should be added to gasoline in a ratio of 1:25.

First of all, read the operating instructions for your domestic chainsaw.

What kind of oil and in what proportions, a whole chapter of instructions is devoted to this topic.

You write about the Ural chainsaw; the best option would be Avtol (this is M-8B motor oil).

If you mean oil for preparing a fuel mixture for a chainsaw, then the proportions are 1:20 (oil to gasoline).

The same oil can also be poured into the chainsaw gearbox.

Since the Ural chainsaw is a descendant of the Soviet Druzhba chainsaw, and Avtol (M8-B oil) was popular during the Soviet Union (recommended for use in GAZ, ZIL, etc. cars, including Ural ), then it is considered the best option for such a chainsaw, plus, the price is completely affordable.

When purchasing oil, pay attention to the labeling; GOST must be indicated there.

GOST for this oil is GOST 10541-78.

M-12TPU, MGD-14M, etc. oils are also suitable, these are all domestic oils, you can also use imported ones, but domestic ones are better.

Because You are not logged in. To come in.

Because The topic is archived.

1.1. Gasoline saws such as “Druzhba”, “Ural”, “Electron”, etc. are mechanized tools and are designed for felling and opening trees and trimming thick branches when clearing power line routes. 1.2. Using saws to perform other extraneous work, incl. in an individual household, it is strictly PROHIBITED. 1.3. Gas-powered saws available for use in departments must be assigned by written order to an employee /one or more/ who have undergone training, are familiar with these instructions, have a mark on the labor safety certificate and are allowed to perform work with a gas-powered saw. 1.4. The specified employee is responsible for the safe use of the saw and its technical condition. 1.5.The use of a gas-powered saw by another person is strictly prohibited.

2. Rules for safe operation of a gas-powered saw.

2.1. It is strictly forbidden to work with a faulty and unregulated gas-powered saw. 2.2.When starting the engine, do not wrap the cable around your hand. 2.3.When starting the engine, the saw chain should not touch any objects. 2.4. To avoid accidents and damage to the saw by a falling tree when felling, do not cut through the tree. You should leave 3-4 cm of unfinished water. 2.5. When crosscutting logs, you should avoid clamping the upper branch of the chain. As a result of this clamping, the saw is thrown towards the sawyer. 2.6.When moving from tree to tree, the chain must be turned off. 2.7. Work on installing the chain and adjusting its tension should be done using gloves with the engine not running. 2.8. Carry out all saw work wearing gloves and a protective helmet. 2.9.After refueling the saw with fuel and oil, carefully remove any remaining fuel and oil from its surface and wipe it dry. 2.10. It is prohibited to fell a tree over which another one hangs, as well as felling strongly overhanging / inclined / trees due to the exceptional danger of this operation for the life of the sawyer and assistant. 2.11. When felling trees, only the sawyer and his assistant can remain at the saw; the rest must be at a distance of at least 50 m from the working saw. The assistant is obliged to warn the sawyer with a signal/voice/ about the beginning of the tree's fall. 2.12. Before the end of sawing when felling, the sawyer and his assistant must carefully monitor the direction of the falling tree, quickly moving away with the saw to the side, but not against the butt of the falling tree. 2.13. It is prohibited to cross a moving chain. If the chain breaks or runs out, immediately release the gas and turn off the engine. Place the saw chain on the bar only when the engine is not running. 2.14. During operation, the engine is constantly in the hands of the sawyer, close to the respiratory organs, so leaded gasoline cannot be used as fuel. 2.15. Smoking is prohibited while refueling the saw. 2.16. It is PROHIBITED to refuel the saw at a distance closer than 20m from an open fire. 2.17. The carburetor must be adjusted in such a way as to ensure the least contamination of the breathing zone by exhaust gases, as well as stable idle engine speeds at which the saw chain does not move along the bar. 2.18. When transporting over a significant distance (more than 20m), the chainsaw engine must be turned off and tightly covered with a special cover. 2.19. Tree felling using a gas-powered saw should be carried out only in a prepared cutting area, where dangerous trees, hanging, dead, with a rotten trunk, or strongly inclined trees, should be removed. 2.20. Before felling trees, the work area should be cleared; in winter, to quickly escape from a falling tree, two paths, 5 to 6 m long, should be laid in the snow. in the direction opposite to the direction of felling. It is prohibited to climb onto chopped or sawn trees. 2.21.Before cutting down trees, it is necessary to use guy wires to prevent them from falling onto the wires. In cases where it is necessary to take measures to prevent felled trees from falling onto the wires, and also if cutting off branches is associated with the possibility of them falling on the wires or the dangerous approach of people and live parts, work on clearing the route must be carried out along with disconnecting and grounding the line. 2.22. If a tree falls on the wires, it is prohibited to approach it at a distance of less than 8 m before the voltage is removed from the overhead line. If after sawing the tree does not fall, it should be forcibly felled using felling devices or a wedge driven into the cut. 2.23. Group felling of trees with preliminary cutting and felling using the fall of one tree onto another is prohibited. First of all, rotten and burnt trees should be felled,

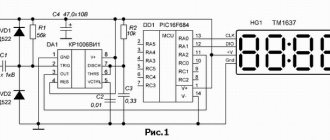

3. Construction of gasoline-powered saws.

3.1. Gasoline saws “Druzhba”, “Ural”, “Druzhba-Altai” consist of the following main components: engine, clutch, gearbox, sawing apparatus, frame with handles and starter controls. 3.2.The main components of the engine are: crankcase, cylinder, crankshaft assembly with connecting rod, piston, cooling system, power system and ignition system. 3.3. The clutch consists of a drive disk, on the rim of which two cut cast iron rings are installed, and a driven disk with an L-shaped rim. 3.4.The gearbox consists of a housing and two bevel gears: driving and driven, which are installed in the housing on ball bearings. 3.5.The sawing apparatus consists of a bar and a saw chain. 3.6.The frame consists of a steering wheel with handles and a stand. They are connected to each other with a vibration damping device consisting of a spring and a hinge with coil springs. 3.7. The power system consists of the following components: gas tank, tap and carburetor. When the tap is open, fuel is supplied from the gas tank to the carburetor by gravity through the gas line. 3.8.The chain saw engine is started by a removable starter, which consists of a pin, ratchet, brakes, shaft, drum, bolts, housing, spring, cable, bushing and handle.

Read also: 10 Amperes how many kilowatts at 380

ATTENTION! A flywheel with three magnets cannot be installed on the Druzhba-Altai saw engine from the previously produced Druzhba-4 engines with a contact magneto. The spark on the electrodes of the spark plug created by the MB-1 magneto from the engines of the Druzhba-Altai saws appears at 400 rpm of the flywheel, so it is not recommended to check for the presence of a spark by turning the flywheel by hand. 3.9. The sawing apparatus consists of a bar and a saw chain. The tire is attached to the gearbox using a key, stud and nut. The movement of the saw chain is carried out by an asterisk. To regulate the tension chain there is a tensioning device.

4. OPERATION OF CHAINSAWS.

4.1. Re-preserve the chain saw in a warm room at a temperature not lower than 15-20 ° C in the following order: 4.1.1. Unscrew the spark plug, remove the muffler and carburetor / without disconnecting the gas control cable /; 4.1.2. Pour 50-100 cm3 of pure gasoline into the cylinder and crankcase through the hole for the spark plug and the suction pipe of the cylinder and turn the crankshaft 10-15 revolutions to remove oil from the cylinder and crankcase; 4.1.3. Rinse the spark plug, muffler and carburetor in gasoline, dry them and put them in place. Remove grease from the outer surfaces of the remaining parts and components of the saw with a rag moistened with gasoline and wipe dry. When re-opening the saw, do not allow oil or gasoline to get into the fan, magneto parts, high-voltage wire or capacitor socket.

5. PREPARING THE SAW FOR WORK.

5.1. ATTENTION! To avoid engine damage, starting it without an attached gearbox is strictly PROHIBITED. 5.2.When preparing the saw for work, generously lubricate the driven sprocket of the bar, immersing the end of the bar for 10-15 minutes. into heated automobile oil used for the fuel mixture. Place the tire on the stud without securing it completely. 5.3.Turn the tire around the stud with the free end up. Place the saw chain onto the driven sprocket of the bar and the drive sprocket of the gearbox. 5.4. Turn the bar and chain towards a horizontal position. Turning the bar up or down at a slight angle from the horizontal position, install the upper and lower branches of the chain in the guides under the bars. After this, install the tire on the gearbox key. 5.5.Tighten the saw chain by rotating the tensioner screw. After tensioning the chain, tighten the nut all the way. A correctly tensioned chain should move freely along the bar without much force or jerking, and when the chain is pulled from the bar with a force of 10-N, it should move away from the bar by 2-3 mm. When the chain is tensioned, there must be a gap of at least 1 mm between the end of the bar and the shoulders of the driven sprocket. For a new chain, after a short period of operation, its tension should be adjusted again. Weak chain tension causes it to fall off the saw bar. 5.6.3Pour fuel into the gas tank. The amount of oil and gasoline in the fuel should be in a ratio of 1:15. Mix the fuel thoroughly. 5.7.3 fill the saw carburetor with fuel. The same must be done if there is a break in work for more than 15 days.

6. STARTING AND STOPPING THE ENGINE.

6 .1..To start the engine: 6.1.1.Open the fuel valve by turning the valve handle down. 6.1.2. Fill the carburetor fuel chamber with fuel by pressing the carburetor enrichment button until fuel appears through the hole in the air filter. 6.1.3.Install the starter on the saw 6.1.4.Holding the saw with your left hand by the right handle of the frame, press the gas lever, rest your left foot on the “foot” of the body, and sharply pull the starter cable towards you with your right hand. Pull the cable to a length of no more than 80 cm. Do not start the engine with the gearbox disconnected. 6.1.5. When the engine is overfilled with fuel, starting it becomes difficult. In this case, the engine must be “blowed out”. To do this, remove the spark plug, close the fuel valve and turn the crankshaft with the starter several times. Replace the spark plug, open the tap and start the engine. 6.1.7.After starting the engine, remove the starter from the saw. 6.1.8. Warm up the engine for 1-2 minutes at idle speed. Check engine operation at low and medium speeds. The engine must run smoothly, without interruption. It is forbidden to give the engine maximum speed at idle. 6.1.9.Check the minimum stable engine speed when the throttle control lever is released. The adjustment is made with a screw that limits the rotation of the lever towards closing the throttle. Normal idle speeds are those at which the engine runs steadily and the saw chain remains motionless. After adjustment, the screw must be locked with nuts. After this you can start working. The described starting procedure applies to the case of a cold start. A warmed-up engine starts without any special preparation with a slight enrichment of the working mixture by pressing the carburetor enrichment button. 6.2. To stop the saw motor:

6.2.1.Lower the gas control lever 6.2.2.Slightly pull or press the carburetor enrichment button until the engine stops completely. 6.2.3. Close the fuel valve.

7. RUN-IN OF THE NEW CHAIN SAW.

7.1.When working with a new saw, at the beginning of its operation, intensive running-in of all its rubbing surfaces occurs. It is recommended to run in a new saw at idle speed with a short re-throttle until 2-3 tanks of fuel are used up. 7.2. To protect the engine from overloads, during the first 25-30 hours of operation, avoid engine overheating and clutch slipping. After finishing the break-in, adjust the throttle stroke until it is fully open, if necessary, move the cable into the lever and secure it with a screw, then check the throttle adjustment for minimum stable engine speed at idle.

8. GENERAL RULES FOR SATTING.

8.1. Before touching the saw chain to the wood, bring the strand stop into contact with the wood. 8.2.Insert the saw chain into the tree smoothly, without excessive force, while simultaneously increasing the engine speed. 8.3. When sawing, do not allow the cutting tool to skew into the cut. 8.4. Do not allow the engine to run for a long time at high speeds when the saw chain is stopped. If the chain gets jammed in the cut, turn the engine to low speed or stop it and release the chain from the jam. 8.5. At the end of the cut and when moving from cut to cut, reduce engine speed to the minimum at which the saw chain stops.

Read also: What silicone glue glues

9. TECHNIQUES OF WORKING WITH A SAW.

9.1.First, cut the tree from the direction it falls with two cuts (one lower is horizontal, the other upper is at an angle of 30° to it) located at a distance of 4-6 cm from one another. Remove wood from the cut. ATTENTION! Do not knock the wood out of the cut with the tire blade or gear stop. 9.2.On the opposite side of the tree, make the main cut at the level of the upper edge of the inclined undercut. 9.3. At the very beginning of the tree falling, quickly remove the saw from the cut.

9.4. At the beginning of sawing, place the saw stop so that the bar becomes inclined, with the end up at an angle of 50° from the horizontal plane. After this, cut, tilting the saw forward relative to the stop to the maximum possible inclined position / up to 600 /. Then move the wood saw fence down and repeat the above technique. This technique is usually repeated several times, depending on the diameter of the trunk of the tree being sawn.

10. MAINTENANCE.

10.1.Daily: 10.1.1.Before starting work, check the serviceability of the saw, the tightness of the gas system, the fastening of the carburetor to the cylinder, and the tightness of all fasteners. 10.1.2. Lubricate the starter cable with technical Vaseline or Constalin or Lithol lubricant. In the absence of these oils, you can lubricate with M-8B automobile oil 10.1.3. Clean the carburetor air filter and fan mesh 10.1.4. Before starting work and after every hour of working with a saw, lubricate the driven tire sprocket by immersing it in heated oil. I0.1.5.In case of jamming of the driven tire sprocket, if dirt, sawdust, or resin gets into it, rinse it thoroughly in gasoline and lubricate it by immersing it in heated oil. 10.1.6. Lubricate the bushings of the frame articulated joint and the axis of the throttle control lever with two to three drops of liquid oil. 10.1.7. After work, clean the intercostal space of the cylinder and all components and parts of the chain saw from sawdust and dirt. Remove compressed sawdust from the bar groove and drive sprocket recesses. Clean the saw chain from sawdust, sulfur and dirt and place it in oil. Failure to promptly clean the intercostal space from sawdust and dirt leads to poor cooling of the cylinder, overheating and premature wear of the chrome coating.

10.2. Every 25 hours of operation:

10.2.1. Wash the strainers of the gas tank and carburetor in gasoline, and drain the gasoline sediment from the carburetor. 10.2.3. Remove carbon deposits from the combustion chamber of the cylinder channels and windows, from the piston grooves, from the piston bottom and rings. When removing carbon deposits from parts and assemblies mechanically, marks and nadirs must not be applied to the cleaned surface. To remove carbon deposits, thoroughly rinse parts and components in gasoline. Untimely removal of carbon deposits leads to premature wear of the cylinder bore and piston grooves. 10.2.4. Disconnect the gearbox and wash the friction clutch with gasoline. 10.2.5. Check if there is lubricant in the gearbox cavity and add if necessary. The gearbox cavity must contain at least 50-60g of lubricant constalin or lithol. 10.2.6.Check the tightness of the flywheel mounting nut.

10.3 Every 50 hours of operation:

10.3.1.Carry out the work specified after every 25 hours of operation. 10.3.2.Clean the spark plug electrodes with a wire brush and check the gap between them. The gap should be 0.6-0.7mm. Adjust the gap by bending the side electrode. After cleaning, rinse the spark plug in gasoline.

10.4.Preparing saw chains. On gasoline-powered saws with increased saw chain speed, universal saw chains of the KEPU 10.26-16G brand are used, with the help of which it is possible to cut wood. Sharpening of saw chains is usually carried out in sawing workshops and pilot stations on sharpening machines. You can also sharpen the chain teeth with large cylindrical files with a diameter of 5 mm. Highly productive and economical operation of the saw largely depends on the high-quality sharpening of the teeth of the saw chain. The height of the limiting protrusions relative to the chain teeth should be the same and checked after 3-4 sharpenings of the chain. It is recommended that during breaks between work, place the saw chain in liquid lubricant, preferably heated, for some time.

Saws should be stored indoors or under cover. Before storing the saw, clean the saw from dirt and sawdust, drain the fuel from the tank, remove the saw chain and place it in oil. Apply a thin layer of oil to exposed areas subject to corrosion. For long-term storage, preserve the saw. ¶

Household and professional chainsaws are powered by two-stroke internal combustion engines running on a dosed mixture of gasoline and motor oil adapted to difficult operating conditions. The correct proportions of oil and gasoline for a chainsaw are one of the important conditions for stable traction characteristics of the engine and low-cost development of its designated resource.

The need to obtain sufficiently high power from a small-cc power unit forces chainsaw engines to be operated at high-speed modes, so increased demands are placed on the quality of both components of the fuel mixture.

Important Terms

The power plants in chainsaws are internal combustion engines, fueled by certain brands of gasoline diluted with the required parts of oil.

Knowledge and strict adherence to the composition of a combustible mixture is the key to long-term operation and productive use of small-scale mechanization units.

The main fuel component is AI grade. It is not recommended to use below or above 92 octane. Optimal for many types of mechanized sawmills, domestic or foreign made.

The ideal ratio of gasoline and oil for a chainsaw:

- increases the productivity of the unit;

- increases service life;

- creates money savings.

The instructions attached to the purchased goods indicate the consumption rates of fuel and lubricating fluid. Violation of the requirements leads to loss of power and premature wear of the internal combustion engine. The truth was obtained through research methods, empirically in our country and abroad.

Mixture proportion for “Calm”

The German family company Stihl has production facilities in many countries around the world. The office is located in Waiblingen. Among the range of products produced for the needs of forestry, small-scale mechanization equipment takes pride of place.

Today a liquid golden age has arrived for the Stihl chainsaw:

The manufacturer has set the oil dilution standard at a ratio of 1:50. The proposed proportion establishes the possibility of diluting 1 part of oil in 50 parts of gasoline. Or in a ratio of 1:40.

The calculation is simple. We know that 1 liter of flammable liquid equals 1000 milliliters. Divide the value by 50, we get 20 milliliters of oil. Using a similar algorithm, its volume is determined, recommended in a ratio of 1:40. Having made simple calculations, we get the value of 25 milliliters.

Proportions for Swedish Husqvarna chainsaws

What exact rate of lubricant is required to prepare the combustible mixture necessary for the normal operation of a two-stroke gasoline internal combustion engine? Buyers will learn about this from the instructions supplied with the product. But documentation is often lost among papers. In this regard, it would be useful to remember that manufacturers use transmission lubricant for mixing with gasoline. The Swedish company is known on all continents of the planet for supplying reliable goods to trade markets. Oil for Husqvarna chainsaws is strictly recommended by the manufacturer.

Depending on how much power is required to be obtained from the units, select the appropriate component dilution:

One liter of fuel is diluted with 40 to 50 parts of oil. These are the ideal proportions of gasoline and oil.

Along the way, we inform you that only unleaded gasoline of the AI-92 or AI-95 brands is used. A leaded combustible product is considered a poor choice for internal combustion engines, as it shortens the engine's service life.

Structure company of Husqvarna HP

The brand structure of the Swedish manufacturer Husqvarna HP includes a company that produces mechanized hand tools and lubricants for them, and effective chemical additives.

Chainsaw manufacturer Partner has developed an original ratio of fuel and oil for two-stroke power plants:

The mixing ratio of the fuel consistency is derived by the standard formula 1:50. This is a constant. That is, 20 milliliters per 1 liter of AI-92.

There are moments of non-compliance with the standard approach to dilution with a lubricant product of the company’s own production. This is when the internal combustion engine goes through the break-in stage. The fuel mixture allowed for the engine is 1:40.

Self-selection criteria

Fuel for a stihl chainsaw or another model should be purchased exclusively taking into account common recommendations. These include:

If fuel is used that is stored for a long period, this will negatively affect the traction characteristics of the internal combustion engine.

In addition, such operation causes small detonations, as well as the appearance of carbon deposits. All chainsaw users should not pay attention to low-octane mixtures, as they are characterized by low quality. In some cases, leaded fuel can be used. It can significantly extend the life of the device.

Two-stroke oil for chainsaws and scythes

Practice shows that an attempt to save on the quality of the fuel used leads to a significant reduction in the service life of the device itself. In addition, performance characteristics drop significantly.

Proportion for chainsaw Friendship

The pedigree for the Druzhba chainsaw began in 1953 with development at the Progress ZMKB. The production of goods was entrusted to two enterprises - the Siberian Instrument-Making Plant and the Perm Machine-Building Plant. Mass production of the mechanized product began, which is still the trend of the day, since the unit was systematically modernized.

Engines use low octane fuel. The unit shows the highest performance when filling the internal combustion engine with AI-76 and AI-80 gasoline.

It is recommended to dilute gasoline and oil according to the following algorithm:

Take 2 clean containers, dried from moisture with volume marks. Then the fuel is diluted with two-stroke oil in a ratio of 1:50. That is, the fuel is diluted with 20 milligrams of oil.

Petrol

Gasoline comes with an octane number no less than AI92. There is an option to also fill in AI95, alas, its quality at our gas stations is not civilized enough, if you do not know how to use 95, then it is still better to take AI92 gasoline to dilute gasoline in a chainsaw. It also makes no sense to take gasoline that has been sitting for a long time in a canister, tank or other container. Gasoline for making fuel into a chainsaw must be fresh, otherwise it loses its characteristics, namely the octane number, and if you run the chainsaw on such fuel, it will not produce a workable version of power. And the saddest thing in this case is that the failure of a chainsaw due to poor fuel is considered a non-warranty case and leads to expensive repairs. Sometimes it's easier to buy a new chainsaw than to repair it after a breakdown!

Need quality components

Practice proves the influence of the quality of the prepared mixture, taking into account the required proportions, on the service life of the tool, power, productivity:

- It is not recommended to use components that have expired.

- It is especially important for the components of gasoline and oil - do not use components obtained from gas condensates, since the molecular structure contains harmful water for internal combustion engines.

- Partial non-compliance of AI-92 with international standards. AI-95 grade is saturated with additives that dampen the detonation moments of internal combustion engines.

The noted disadvantages limit the operational life of hand-held chainsaws, the internal combustion engines of which operate on complex mixtures of combustible mixtures.

Why do you need to maintain the proportion of gasoline and oil?

Many buyers, when purchasing a chainsaw, are perplexed as to why the exact amount of oil and gasoline should be added to the oil recommended by the manufacturer. It's all about the subtleties of a two-stroke engine, which differs from its 4-stroke counterpart in a number of specific design solutions.

One of them: the production of a single-cylinder engine in which there is no crankcase for filling lubricating mixtures. This is seen as a technological success of its time.

You can imagine how the incoming combustible mixture loses oil molecules that settle on the cylinder stacks. Subsequently, it creates a sliding protective film in the rubbing components and parts of the internal combustion engine, reducing the physical contact of the piston rings with the cylinder wall, connecting rod and crankshaft.

To ensure maximum performance of the unit, long-term operation is achieved by the correct ratio of pure gasoline to the recommended oil. Violation of the rule guarantees a quick exit of the instrument from its functional state. A breakdown of the internal combustion engine will require significant funds for repair or replacement with a new analogue.

Many users of hand-held power tools consider the oil container present in the unit to be a reservoir for lubricant and power unit. This is fundamentally wrong. The lubricant is intended for the chain during operation. But only. The oil tank is a priori not connected by pipeline to the engine.

Lubricants

More stringent criteria for selecting an oil component. The best option is a mineral or semi-synthetic motor oil recommended by the manufacturer, designed for use in high-speed two-stroke air-cooled internal combustion engines.

The advantage of mineral oils is their lower cost. Their more expensive semi-synthetic and synthetic analogues compare favorably with improved performance characteristics and compliance with environmental standards.

Synthetics:

- maintain performance properties over a wide range of operating temperatures;

- do not form soot;

- contain detergents, antioxidants, preservatives and other additives useful for the operation of the power unit.

Rules for preparing the mixture

Even experienced lumberjacks do not always correctly prepare the fuel mixture for a chainsaw if the work is done in a hurry. The algorithm of actions is as follows:

- prepare a plastic container holding 2.5 liters or less;

- a measuring container must be present - many people use a regular medical syringe;

- First, fuel is poured into the container, and then a precisely measured portion of oil;

- The final task is to carefully dissolve the oil product by actively shaking the consistency.

When making a mixture of gasoline and oil, you should adhere to the prohibitive rules - you should not try to mix it in the gasoline tank of the tool.

It is recommended to store the finished flammable product for 14 days. If more, the oil will settle to the bottom of the container. A new shake of consistency will be required. Busy people often forget about this.

How to increase the service life of a chainsaw?

The chainsaw will be technically serviceable under one condition:

When purchasing a tool, read the manufacturer’s instructions and operating recommendations in detail.

Strictly adhere to and comply with the requirements for the selection of components for the formation of a combustible mixture consisting of gasoline and the recommended oil.

Oils intended for motor vehicles cannot be used to form the working product. This is strictly prohibited.

Friendship 4 is a legendary chainsaw that has been produced in two Russian cities since 1955: Perm and Biysk. Developed in 1953. It is worth noting that in 1958 an exhibition was held in Brussels in which the Druzhba 4 chainsaw took part, and it was there that it was awarded the “Gold Medal”. Surprised? Me too! I think for this reason alone it is worth reviewing this legendary instrument.

Oil

Read:

According to the classification of the American Petroleum Institute (API), the South American Petroleum Institute, oil for 2-stroke engines is classified as API-TB, in addition there are oils of the API-TC class, unfortunately they are designed to work with less load than most of our common chainsaws. If you take the power class according to the systematization of the Japan Automobile Standards Organization (JASO), then focus on the JASO- and JASO FD classes (see Table 1 below.). Do not under any circumstances use oils for four-stroke engines! Remember that in a two-stroke engine the oil must burn one hundred percent, which means it is better to take synthetic oil, as it produces less smoke and combustion residues. If you fill your chainsaw with oil for four-stroke engines, which will not burn completely and carbon deposits will appear upon completion, then your CPG will fail. The best thing to guide you when choosing oil for a chainsaw is the instructions for it.

Specifications

The chainsaw today is morally outdated, after all, half a century has passed, so you should treat its characteristics with understanding.

On a note. Friendship 4, although a rarity, to this day a large number of copies are in working order and are in demand among the population of the country and neighboring countries! This is due to the fact that very reliable chainsaws were released in the 60s.

Let's return to the technical characteristics of the Friendship 4 chainsaw:

- weight: 12 kg (it is distributed as evenly as possible throughout the entire body, for comfortable operation of the operator);

- tire: length 45 cm;

- chain pitch: 0.325 inch;

- fuel type: AI-92 gasoline + oil for 2T engines.

- fuel tank capacity: 550 ml.;

- oil tank capacity: 260 ml.;

- chain lubrication: only the Druzhba 4A chainsaw had automatic chain lubrication;

- make and model: MP-1 (single-cylinder, carburetor, two-stroke, air-cooled);

- working volume: 94 cubic meters cm.;

- power: 4 hp (2.94 kW);

- maximum crankshaft speed: 5200 rpm;

- Lubrication system: gasoline with oil;

- connection system with saw set: flange connection fixed with a clamp.

What is good about Friendship-4 and its main disadvantages

The two-stroke MP-1 engine, rated at 4 hp, which gave it the number 4 in its name, developed for this chainsaw in 1953 at the Zaporozhye “Progress”, was, and remains, so easy to repair and maintain that it ensured its success for many decades.

But Druzhba-4 did not deserve its popularity with a single engine. The layout, convenient for long-term work, allows the feller to work standing, in a comfortable position, cutting trees almost close to the ground, and is not repeated in any other saw, except for those that are only its modifications. How many were there? Significant - really one, when the saw acquired a new, more powerful (5 hp) engine, gearbox with a saw chain lubrication system and the name “Ural”. It’s not worth talking about little things like the shape of the tank. And the reduction in weight, which is still hardly the biggest drawback of this design, from 12.5 to 11 kg, cannot be called a significant achievement.

The saw, which received a gold medal at the Brussels exhibition in 1958, was mass-produced until the end of the 90s with minor changes:

- in the 60s, changes were made to the handle fastening;

- in the 80s, the carburetor (“Druzhba-4A”) was replaced and electronic ignition (“Druzhba-4A-Electron” was installed);

- in the 90s, another new carburetor (“Druzhba-4M”) was installed.

Modifications

During the entire production of the chainsaw, Friendship 4 has not undergone any major design changes. Let's see what minor changes have occurred in the design of the chainsaw:

- 1950 - 1960 . The first structural modification concerned a change in the mounting option for the handles; they began to be attached to the fan cover, and subsequently the fastening was moved to the clamp that connected the engine and gearbox.

- 1960 - 1980 . At this time, a modification of the chainsaw called Druzhba - 4A, which had two main advantages: a contact magneto and the well-known KMP-100 carburetor, entered the assembly line and was produced for 20 years. At the end of the 80s, the modification of the Druzhba -4A chainsaw was discontinued.

- Late 1980s. Release of the Druzhba-4M Electron modification. Electronic ignition was used for the first time.

- 1990s . Equipping the chainsaw with a modern (at that time) carburetor KMP-100U. Changes in the saw set - the use of modern type chains.

Many people are confused and say that a number of other changes were made to the Druzhba 4 chainsaw, such as a removable starter, a detachable crankcase and a removable cylinder, but they are deeply mistaken. All these changes were made on the Ural chainsaw, the basis of which was Druzhba.

Finalization of Friendship 4

Many Western chainsaw manufacturers produce tuning kits for their saws to increase power, and service centers have a separate price list with a list of possible modifications. Mainly found in petrol tool service centers in the USA and Germany.

It is also possible to modernize and replace components in order to improve the characteristics of saws from the Druzhba family.

Examples of what can be done:

- Install turbocharging to increase the rate of supply of the fuel mixture;

- Install a more modern carburetor;

- Increase the compression of the fuel mixture;

- Install an electric starter;

- Bore the internal combustion engine and install an enlarged piston;

- Install the decompression valve;

- Leave one piston ring to reduce cylinder running resistance.

Chainsaw device

For quick maintenance and effective repair of the Druzhba 4 chainsaw, you should know its structure. You can read in detail about the device and design features in the operating instructions. In it you can also find tips and tricks for repairing and troubleshooting yourself. For visual reference, we recommend looking at the photo below; it shows all the main components, numbered and signed.

Please note that in the lower right corner there is a diagram of the carburetor, which consists of only 15 parts. In the upper right corner is a general diagram, and on the left side is a cross section of the Druzhba-4A Electron engine.

Is it necessary to load the chainsaw during break-in?

Some tool sellers recommend that after purchasing a chainsaw, buyers carry out the process of grinding in parts with complete elimination of the load. It even goes so far as to have owners remove the chain and bar and let the engine run at zero load. Is this approach to the procedure considered correct? This approach is not recommended for the following reasons:

- Not only the internal combustion engine parts need grinding, but also the saw set, or more precisely, the chains, tires and sprockets.

- Idling will not allow you to achieve the required load, so after the end of the process, when work is performed at high speeds, the motor may jam.

- The rotation of the chain when starting the engine of a new chainsaw provides the optimal load value, so the tool runs in not only more efficiently, but also faster. To complete the grinding as quickly as possible, the tool is gradually loaded by sawing wood of a small diameter.

- Idling the engine causes a reduced amount of mixture to enter the combustion chamber. Its insufficient volume prevents optimal lubrication of moving parts, thereby increasing their wear.

That is why, before you start running in the chainsaw, you need to install the bar and chain on the tool and ensure the correct tension. Next, you will need to fulfill some more important conditions:

Prepare a benzine-oil mixture. Instructions for preparing the mixture for a chainsaw are described in detail here

However, when running in, it is important to maintain other proportions, as described in detail below. Fill the tank with chain oil, which lubricates the bar and chain. The chain can be placed in oil for several hours.

Interesting to know! The duration of grinding in chainsaw parts is measured not by the operating hours of the engine, but by the amount of fuel burned. To ensure effective running-in of the tool, it is necessary to burn at least 3-5 tanks of fuel. The maximum running-in duration lasts 6-8 burned tanks of fuel. The best option is to read the instructions, since each manufacturer indicates this information, which should be followed.

Trouble-shooting

The design of the Druzhba 4 chainsaw is so simple that it allows you to easily repair many components yourself. The weakest point of the saw is considered to be the ignition and carburetor. There are even more problems with the contact ignition system. Let's figure out why these malfunctions occur and how to fix them yourself.

Carburetor adjustment

The first cause of problems with the carburetor is spark plugs filled with fuel mixture. This does not mean that you need to immediately disassemble the carburetor. First of all, pay attention to the gasoline valve; sometimes it is enough to bend it a little inward. This operation will reduce the amount of fuel supplied.

If this does not help, then move on to a simple carburetor setup operation:

- Tighten the fuel screw all the way.

- Unscrew it back 3 full turns.

- Tighten the propeller all the way.

- Loosen the propeller 2 full turns.

Don’t forget to check the seals for leaks to eliminate the possibility of air being sucked into the system; this can also cause a malfunction when the chainsaw starts and stalls.

How to set the ignition

People come to repair the ignition very often, especially if it is a contact one. The problem is expressed in the problem of starting a hot engine. This is due to a weak ignition system. You can’t just set it up, here you need to know the approach to how to adjust the ignition on the Druzhba 4 chainsaw, because... there are pitfalls.

We invite you to watch a video, the author of which talks in detail about adjusting the ignition of a chainsaw.

In principle, there is nothing complicated. To adjust the contactless, it is enough to connect the marks of the housing and the ignition unit. When adjusting the contact there are many nuances, the process itself is complex, so it’s worth watching the video above, the author talks in detail about the process. Here are the first adjustment steps:

- Set the piston to BDC.

- Clean the contact.

- Check the gap - 0.3mm.

- If the gap is smaller, then unscrew the fastening screw and increase the gap to 0.3 mm.

- Tighten the screw and check the clearance again.

- Set the ignition trigger so that it fires less than 4 mm before TDC (how to do this is described in detail in the video above).

Note, in order to avoid constant problems with contact ignition, it is being converted to contactless.

Basic faults

Rarely, but still other malfunctions occur with the saw. For example, there is no spark at the spark plug or the chainsaw does not start at all. For a better understanding and assimilation of information on troubleshooting such faults, we recommend watching the video.

About safety precautions

Before starting to work with a chainsaw, it is necessary to carry out a number of measures aimed at the safe operation of the device:

- checking the tightness of the fuel system;

- checking the cylinder fastening;

- checking the carburetor is secure;

- checking the muffler is secured;

- checking the tightness of steel fasteners from the outside;

- lubrication of the driven tire sprocket by immersing it in oil for several minutes;

- lubricating the starter cable with lithol-24;

- cleaning the air filter mesh on the carburetor.

When working, you must remember to strictly and compulsorily adhere to the following safety rules:

It is prohibited to carry out work with one hand; work clothes must be durable and include gloves, work shoes, as well as a protective helmet and a special shield; Before refueling, the gas tank cap must be opened extremely carefully, which is due to the possible presence of gasoline vapors; work must be carried out on completely cleared sites, with reliable and strong support; you need to make sure that the chainsaw does not touch foreign objects during operation.

Do not refuel with the engine running. The saw should be transported after the protective cover has been placed on the bar.

What to do with spare parts

You won’t find spare parts for the Druzhba 4 chainsaw in stores; after all, it’s already a rarity. The only place where you can still buy them is at a flea market - a market where grandparents sell what they have lying around at home. Believe it or not, you can find many spare parts there in new condition. They lay there for a long time, but were never put on the saw.

Another place is bulletin boards, like Avito. They especially often sell chains and tires for Druzhba chainsaws.

The Druzhba 4 chainsaw is as simple as a Kalashnikov assault rifle, thanks to this it is durable (especially models from the 50s and 60s), easy to maintain and repair. The saw can be easily repaired in the field “on the knee” without special tools. On your farm, it will be useful for harvesting timber or firewood in small quantities. For professional work, it is still better to use modern saws. Everything said in the article is confirmed by numerous reviews from Internet users.

The seller provides the following guarantees:

1. For BMW passenger cars and SUVs – a two-year warranty for the entire vehicle without mileage limitation, according to the standards of the Vehicle manufacturer BMW AG from the date of first registration of the Vehicle; The warranty period for additional equipment that was not manufactured and/or installed by BMW AG is determined in accordance with the warranty conditions of the manufacturer and/or the company installing the relevant equipment; · A change in the owner of the car does not affect the Seller’s warranty obligations regarding the Car, go to BMW repair.

2. The warranty is void if: · The seller does not report the defect in a timely manner or does not provide the opportunity to immediately eliminate the reported defect; · The vehicle has been overloaded, misused or used for competition or rallying; · The vehicle is modified in a way that is not accepted by BMW AG; · The Seller did not take into account the instructions and rules for the operation and maintenance of the Car.

3. The warranty is not valid and costs are not covered in case of natural wear and tear of the Vehicle, as well as when replacing components in case of natural wear and tear (tires, spark plugs, windshield wipers, brake pads, discs, etc.). The warranty does not cover costs associated with periodic maintenance of the Vehicle, adjustments and inspections, as well as costs or damage resulting from the Vehicle's downtime.

4. The warranty becomes invalid upon expiration of the period specified in paragraph 1.

*BMW AG reserves the right to make changes to certain clauses of the warranty conditions. You can obtain more detailed information from our warranty specialists.

What type of oil should I use for a chainsaw chain?

The working element of a gasoline saw is a sawing apparatus consisting of a guide bar, a driven sprocket and a chain. In order to ensure maximum operating time and maximum efficiency of these elements, it is necessary to carry out timely maintenance in accordance with the manufacturer’s regulations.

Chain oil is a consumable material, the availability and quality of which directly affects the service life of the sawing machine.

Choosing a chain oil is not as difficult as, for example, oil for a two-stroke engine. Many experienced gas saw users agree that chain lubricant can be any type of oil. The exception is mining, since its beneficial properties have already been lost, so its use is unacceptable.

When choosing a lubricant for a chainsaw chain, you need to take into account its chemical basis. As with two-stroke oil, the fluid can be mineral, semi-synthetic or synthetic.

When working in conditions of negative temperatures, it is better to focus on the last two options, since this type of lubricant is capable of maintaining low viscosity in the cold. However, a low viscosity coefficient can also play a negative role in the summer. Oils with this property will provide too high consumption.

Chain lube is poured into a separate tank for gasoline tools. During operation, it is necessary to monitor the level and, if the required volume is not available, add oil. On the reservoir of every gasoline saw, without exception, there is a transparent area with which you can monitor the level.

Oil is supplied to the chain using an oil pump, which creates pressure. If there is no liquid in a special tank, the pump, running idle, may burn out.

This procedure will give a beneficial effect. Penetrating into the connecting elements of the chain links, the oil helps protect against corrosion and ensures the mobility of each link.

In the modern construction market you can find many offers from various manufacturers of chain oils. Cheap options are quite suitable for amateurs, but for professionals there are more expensive products.

REZER is a brand well known to many.

One of the leaders in the economy segment, the manufacturer offers a variety of consumables for gasoline saws. The optimal price-quality ratio will leave many consumers satisfied. A liter container called REZOIL LUBRIMAX can be purchased in stores for a price starting from 150 rubles.

Huskvarna. Many manufacturers of gasoline saws do not shy away from producing all kinds of consumables. Huskvarna is no exception. Chain lubrication oils under this brand are of organic origin, which means they are highly environmentally friendly.

Since oil, during the operation of a chainsaw, invariably ends up on the ground, this property is very beneficial for the environment. The products of this brand are in the middle price segment. A container with a volume of 1 liter can be purchased at a cost of 350-500 rubles.

Oregon. Despite the fact that gasoline sawing tools have never been produced under this brand, this brand is the leader in sales of consumables for chainsaws. This is facilitated by high quality at a reasonable price.

By forming a permanent film of oil, Oregon chain lube prevents corrosion from adversely affecting the saw chain, reduces vibration and prevents oil from splashing, which significantly reduces consumption. The cost of one liter of chain fluid will be about 300 rubles.

Stihl. The brand is famous not only for gasoline saws and other garden equipment. The company is closely involved in the production of consumables. Chain oils under this brand are highly environmentally friendly, since the products are made on a plant basis. Despite the high price (a liter container costs from 500 rubles), professionals often opt for Stihl.

Modern gasoline saws have special fuel needs. If you're new to the field and unsure about getting the best performance from your saw, the following information will be helpful.

For starters, Stihl and Husqvarna recommend using high octane unleaded gasoline. Both brands of saws are designed to burn fuel containing 89 octane or higher. An octane rating of around 87 will not be sufficient. We also do not recommend using very high octane aviation grade fuel.

What you should know about octane number

Low octane fuel may cost less, but it reduces the power and performance of your saw. Chainsaws have two-stroke, highly efficient engines. They can produce more energy per kilogram than many types of car engines - the engine needs high octane fuel to do this.

Some saw users don't realize that low octane fuel not only reduces performance, but can cause engine damage. Most people think the mixture of fuel and air should "explode" as soon as it enters the engine chamber. This is not true. The mixture of fuel and air begins to burn at the spark plug, passing through the entire combustion chamber through channels in the cylinder walls. This happens instantly, but the process must be complete.

The problem is that the spark plug does not ignite the fuel when the piston is at the top of its stroke. Using crankshaft compression ratios as a reference typically assumes fuel ignition at 20º before top dead center. Even when the fuel ignites early, peak cylinder pressure should not occur until the piston is 15º past top dead center. This means that the crankshaft rotates 35° during the operating time required for the flame. If the fuel explodes early and peak pressure occurs before the piston begins its downward movement of the cylinder, engine performance will be reduced. It's also easy to imagine the pressure that builds up on the engine's internal parts when this happens.

Octane number

The octane number of a fuel refers to its ability to resist detonation. If you fill the engine with fuel that does not have the octane rating provided by the designers, the engine will start to knock.

What you really need to know about octane is that today's saws require fuel with a minimum octane rating of 90. We suggest you run with 92 octane, which is readily available at all gas stations. So fuel with a higher octane rating than 92 will not provide any real benefit. And the additives contained in 98 gasoline only cause harm. Summarize:

- AI 92 - great for refueling chainsaws - we recommend

- AI 95 - also suitable for saws

- AI 98 - not suitable for refueling saws

Also, all brands of fuel with additives, such as super, euro, etc., are not suitable.

Only high-quality refills

Country gas stations located on the outskirts often mix gasoline with additives and water. As well as old gasoline, they are undesirable for garden equipment.

Pay enough attention to the choice of gas station; many gas stations near Moscow sell “low-quality gasoline, to put it mildly.” Low-quality gasoline from such gas stations is also detrimental to the fuel system of a chainsaw.

Operation and service of the Druzhba saw

Tools, equipment and technologyRecommendations for selection. Operation, repair and maintenance. Malfunctions and ways to eliminate them.

Chainsaw Friendship 4 won't start at all. How can you get out of this situation?

Install an imported spark plug, analogue A11 2. Fresh gasoline in a ratio of 15/1 with oil. Open the tap at the gas tank. Press the pump button on the carburetor (in the center of the diaphragm) and wait until gasoline flows. Press and hold the gas trigger and start by pulling the starter handle. If it does not start - Unscrew the spark plug and see if it is wet - if it is wet, then look for a spark - if not, then most likely the carburetor membrane is stuck - rebuild or replace the carburetor.

Where is the ignition timing adjusted on the Friendship 4 Electron chainsaw? I didn't find something. Should I buy it or is the current still weak? If so, which one should I take, imported?

You don’t need an imported one, take a standard domestic one. A10 or at worst A11, or better yet a couple. Electronic ignition is adjusted by moving the disk in the magneto (you will see for yourself there, two screws need to be loosened).

For the Druzhba-4M chainsaw and two-stroke oil. The instructions say that only AC8, and 2T oil is not allowed. Who mixes gasoline with what and in what proportion?

Any 2t oil in a ratio of 1:15 and everything is fine. Don't trust the instructions. Where does it say that you can’t use 2 tons of oil? I have such instructions, but this is not there. Friendship is good because due to low speeds it can consume any 2 tons of oil.

The problem is this: when the tire plunges to its full width, it jams, I have to twist the log 3-4 times just to file it, and it turns out that the top of the cut and the part that is in front of me goes straight, and the bottom of the tire that is at the exit in front of the log, leads to the left, which is why the cut turns out to be a figure eight and the tire jams. I took off the tire and didn’t seem to find any bends, but the chain itself somehow warped from the bottom to the front to the left, I changed the chain, it’s not new either, it’s about the same. You can only saw a thin log without twisting it, a little wider than the tire itself, and even then the bottom cut leads to the left if you don’t try to force it to the right. What's wrong?

Option one – the chain is sharpened incorrectly, option two – uneven wear on the edges of the groove.

Tell me how to adjust the idle speed of the engine on the Druzhba 4 Electron chainsaw?

It is recommended to adjust the idle speed of the chainsaw engine in the following sequence: start the engine and warm it up at low and medium speeds. Use the screw to set the minimum stable speed at which the saw chain does not move along the bar. If the engine smokes heavily (a sign of an overly rich mixture), then partially tighten the carburetor screw. At the same time, engine speed will increase and exhaust smoke will decrease. After this, you should again set the minimum stable engine speed by partially unscrewing the screw. After this adjustment, it is necessary to check the engine response. To do this, sharply press the throttle control lever all the way for 2-3 seconds. In this case, the chainsaw engine should quickly gain momentum. If the engine stops or has a “dip” in power, that is, it slowly picks up speed (lean mixture), then it is necessary to partially unscrew the carburetor screw. Check engine response again. After completing the adjustment, secure the screw with nuts.

Help me find the parameters for sharpening Soviet plate chains for the Druzhba 4 saw. My household machine does not sharpen these chains, only combined ones.

I could be wrong, I haven’t sharpened such chains for a long time, but it seems like this: the slope from the vertical on all teeth is 10 degrees, the angle of the external teeth, I remember, is 30 degrees, from the axis or perpendicular. The angle of the middle teeth is, like, 20. The angle of the internal (pushing) teeth is perpendicular to the chain axis. They sharpen only on the front edge, the top cannot be touched.

I have a Friendship 4 contact chainsaw, judging by the inscription on the snail, from 1965, well, the head and everything else looks fresh from 1985, but it looks like new). Yesterday, while I was starting it up, the ratchets licked, what’s on the starter, what’s on the saw itself, can I somehow restore it? And it even started and worked, so I sawed it yesterday and after I turned it off and wanted to start it again, there was such a problem with the ratchets. Tell me what to do?

Carburetor adjustment for different types of fuel

Today's saws are limited by caps on the adjusting bolts from rebuilding the carburetor. These protective caps are designed to keep the carburetor from running too rich or too lean, which would cause the saw's engine to emit excessive emissions. The adjustment range of these caps allows you to set the settings preset at the factory. Usually, for proper engine operation, this range of carburetor adjustments is sufficient, but not always. Sometimes, it is impossible to adjust the carburetor correctly because the caps are in the way and need to be removed and the carburetor adjusted again. We have special tools that allow us to remove limiters, reset range and reset settings.

You think: I'll just take these limiters and throw them away. This is not a good idea because the limit caps also hold the needles and keep the set adjustments from vibrating during use. Previously, adjustment needles were equipped with springs that kept tension on the threads. They kept the needle adjustments in place. Today's carburetors do not have these, so if the restrictor caps are removed, your carburetor will become out of adjustment.

Frequent carburetor adjustments

If you frequently adjust the carburetor, this is normal. Since the amount of oxygenation in the fuel can vary from tank to tank, keeping the saw properly adjusted is a constant challenge. This is made worse by the fact that today's saws are made as cheap as possible. This makes them less tolerant of misadjustments - especially on lean mixtures.

More about Octane

Another octane-corresponding element includes a mixture with oil. When oil is mixed with gasoline, the octane rating of the final mixture is lower than that of gasoline. This is one important reason to mix according to the manufacturer's specifications. Some people believe that by adding more oil they are doing their saw a favor. They do not suspect that this can lead to a decrease in the octane number of the mixture and all that it entails. Our advice is to mix to specification—and to do it precisely.

Stihl and Husqvarna have done extensive testing to create their petroleum oil formulations - and they are both very good. Saw manufacturers have developed special additives that improve its ability to mix and stabilize in the desired solution. These oils use synthetic base components. We consider Stihl Ultra 100% oil to be ideal.

It is also important to understand what proportions of oil should be added - 50:1. Only 1/50 of the mixture in the saw's fuel tank is oil. This small amount is enough to effectively lubricate the piston group

Why is oil not suitable for outboard motors?

Two-stroke outboard motor oil will not work well in your chainsaw. The reason is that a water-cooled boat motor provides lower temperatures than an air-cooled chainsaw. This means that oil from a chainsaw is also not suitable for a boat engine. Different temperature conditions, different lubrication needs.

How to properly store mixed fuel

We believe that any mixture that has been stored in a container for more than four weeks will be unusable. One reason for this is octane degradation in the fuel. Fuel is also susceptible to moisture or condensation. Using old fuel may cause engine damage.

How to properly store your saw

Whenever the engine does not start for more than a month, the fuel must be removed. This means emptying the tank and starting the saw to exhaust any remaining fuel in the carburetor. The best way to preserve the carburetor is to remove the fuel as described and then flush and partially fill the tank with clean gasoline. Pump the carburetor with fuel using a pump or starter (if fuel pumping is not provided). After the rubber cap is filled with gasoline, drain the remaining gasoline from the tank. Gasoline will not deteriorate for a year or more.