Without exaggeration, the hydraulic press is one of the 100 greatest inventions of mankind. The appearance of such a machine was facilitated by Pascal’s law, which was formulated back in 1653. The first such device was patented by the English inventor, one of the founders of hydraulic engineering, Joseph Bramah, in 1795.

At first, the hydraulic press was used to lift heavy loads and obtain natural oils and juices, as well as form hay bales. Over time, the design of hydraulic presses has changed and modernized. Since 1820, the unit began to be used in the metalworking industry for pressing pipes. 55 years later, a stamp and a movable traverse appeared in the design, which contributed to the introduction of the technology into the military industry.

Thanks to the saving of metal, simplicity of design, speed of production and optimal performance, the press is widely used in the production of automobiles, marine vessels, aviation and agricultural equipment.

Varieties and characteristics

Main characteristics of a hydraulic press (parameters of each model are shown in the drawing):

- compression force (tons);

- handle force (Newtons);

- operating speed (millimeters per second);

- working stroke (centimeters);

- oil pressure in the hydraulic drive (Megapascal);

- drive power (kilowatts);

- dimensions and weight (millimeters and kilograms).

This range of parameters defines two types of drives:

- pump drive – does not use the principle of energy storage;

- pump-flywheel and pump-accumulator drives - use energy accumulation during periods between working strokes.

The service station uses different types of hydraulic presses: tabletop, vertical, electrohydraulic and pneumohydraulic (capable of developing a force of up to 100 tons).

According to the method of functioning, hydraulic presses are divided into two groups:

- automatic;

- manual.

Manufacturers make units with closed and open frames for working with elements of non-standard shapes. Based on the dimensions, there are desktop and floor-standing models. Depending on the bed, there are 2 types of presses: rack-mount and column-mounted. By type, two categories of devices can be distinguished: universal and specialized (special purpose).

Types of hydraulic presses

- Centrifugal presses are used for stamping seats and removing bearings, as well as for other assembly, repair and high-pressure production work.

- Assembly presses use high pressure to hold or assemble parts.

- C-frame presses are streamlined in size, have a press shape that resembles the letter “C,” and typically consist of a single press.

- Compression molding presses use two plates that are pushed together to compress the material in a mold.

- Forging presses are machines that force metal blocks into the shape of a product using a mold, extreme force and pressure, and sometimes heat.

- H-frame presses , sometimes called four-column presses, are shaped like the letter "H" and can often handle more than one application at a time.

- Hydraulic presses are industrial machines that use fluid pressure to apply force to an object.

- Lab presses are smaller, disposable presses used primarily in research laboratories and other short and test run situations.

- Lamination presses

- LIM presses are presses that work with plastics created through the injection molding process.

- Mechanical presses are used to cut, stamp, shape, or assemble materials using tools or dies attached to guides or dies.

- Platinum presses are large industrial hydraulic presses that use two large heated steel plates to crush, compact, shape and form a variety of products.

- Pneumatic presses use energy transfer in the form of a stream of compressed air to control their movements. Some typical applications are cutting, stamping, bending and forming.

- Power presses are machines that use tools and dies to cut, stamp, and shape metals.

- Press brakes are manual, mechanical or hydraulic presses that cold work sheet metal into bent or bent shapes. Here you will find a press break calculator.

- Stamping presses are devices that use stamping dies.

- Proper presses apply pressure to the metal to straighten it.

- Tablet presses are used to compress powdered materials into tablets or briquettes.

- Transfer presses are hydraulic presses that automatically move parts from one stamping process to another using feed rod fingers.

- Vacuum presses are hydraulically driven industrial systems that use air pressure to provide the necessary force and air removal required for lamination.

Application and practical features of work

The wide range of power and design solutions of hydraulic presses allows them to be used for a variety of tasks: stamping, trimming, flanging, embossing, pressing, stitching, calibrating, bending, forging and even lamination.

Areas of use:

- industrial production;

- waste disposal (horizontal installations);

- repair of vehicles and special equipment;

- locksmith work.

Using such equipment, you can work with pipes and metal profiles, plastic and ceramic products, carbon and carbon-graphite electrodes, as well as produce rubber parts, cables, electrical insulating materials, various finishing and building boards and much more.

Features of various models:

- glycerin pressure gauges are characterized by increased accuracy, durability, vibration suppression and a wide measurement range;

- the winch mechanism is indispensable for adjusting the working surface;

- automatic rod return function significantly improves productivity;

- the safety valve will prevent excess pressure;

- chrome plated rod eliminates corrosion processes;

- modern units are equipped with progressive CNC.

In addition, the designs do not include various modules that protect against overloads, which has a positive effect on the price of pressing equipment. It is also noteworthy that the position of the moving table has no effect on the pressure value.

Hydraulic presses

A hydraulic press is a pressure pressing machine that uses hydraulic pressure, or fluid pressure, through a cylinder to apply force to an object.

Hydraulic presses are based on Pascal's principle, according to which pressure in a closed system will act with equal force in all areas.

As the most common and most efficient type of industrial press, hydraulic presses have high lifting or compressive force that cannot be achieved with pneumatic or mechanical presses.

Application of hydraulic presses

Hydraulic presses are manufactured to enable manufacturers to stamp metal material onto a variety of finished parts. They can also perform other metal forming processes such as bonding, forging, stamping, cutting, forming, deep drawing and blanking.

Some of the industries that rely most on hydraulic press services include: Automotive, Packaging, Home Appliances (e.g. Microwave Oven Parts, Dishwashers, Refrigerators, etc.), Ceramics, Aerospace, Military and Defense, Manufacturing food and beverages, cellulose, etc.

Some of the most common applications for hydraulic presses include making beverage cans and making auto parts.

History of the hydraulic press

The hydraulic press was invented in England in 1795 by Joseph Bramach, who became involved in the study of liquids after developing the flush toilet. For this reason, hydraulic presses are sometimes called Brahm presses. He based his invention on a concept known as Pascal's principle, or Pascal's law, which maintains constant pressure throughout a closed system.

Brahma invented the hydraulic press at a time when there were very few of them. Thus, he paved the way for hydraulic engineers after him. Those who followed this path have since invented dozens of variations of the original Brahma model.

How does a hydraulic press work?

A hydraulic press begins to operate when hydraulic fluid is forced into a small double-acting cylinder (slave cylinder) using a hydraulic pump or lever.

Inside this hydraulic cylinder there is a sliding piston that acts on the fluid as a compressive force. It forces it through a pipe into a larger cylinder (the master cylinder), where the fluid is compressed again by a larger piston.

larger piston forces fluid back into the smaller cylinder. As the fluid moves back and forth, the pressure builds until it becomes so great that it can contact and press against the support, backing plate, or die. When it does this, it deforms the material into the desired shape of the product.

To stop the overload, once the set pressure is reached, the fluid then activates a valve which activates pressure reversal. With this press design, there is no need for a complex guide system, since the die tends to guide the press itself.

Advantages

Among the advantages of hydraulic presses, the main ones are:

- significant gain;

- the ability to implement different technological processes;

- high design reliability and safety;

- ease of work under a given mode;

- ease of control and low noise level;

- the ability to connect any hydraulic equipment to the drive (buckets, jackhammers, grippers, circular saws);

- speed and practicality.

Before purchasing such equipment, you should pay attention to the material of the frame structure, the quality of the seams, the presence of a return piston, the serviceability and reliability of the pressure gauge and hydraulic system, and also check the possibility of adjusting the height of the working area.

Types of hydraulic presses

Platform press

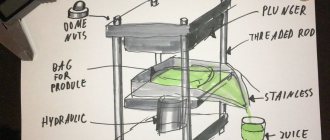

There are many different types of hydraulic presses; each has its own set of applications, although there is some overlap. Presses that use a plunger and a strong, stable surface are classified as plate presses .

C-Frame Hydraulic Press

The C-shaped hydraulic press is named for its C-shaped frame; This frame is narrow but strong and allows the press to take up less floor space than others. As presses that can be designed for manual or automatic use, C-frame presses can be used for a variety of industrial operations, including forming, straightening, punching, stamping, drawing and riveting.

H-Frame Hydraulic Press

The H-frame press is also named after its frame; This is a welded H shape. Similar to C-frame presses, this type of press is used for industrial applications such as embossing, crimping, bending, stamping and trimming. However, unlike C-frames, H-frames can handle multiple operations.

Extrusion press

Extrusion presses are a type of press that metalworkers and other manufacturers use to extrude parts and products. Extrusion extrusion is a process in which a press forces a die through the material to create a fixed cross-sectional profile.

Lamination press

Laminating presses are manually operated compression presses One is used for heating and the other for cooling, which speeds up the lamination process by simultaneously cooling one board and heating the other.

Vacuum press

Vacuum presses have several specialized applications, such as applying films to various materials, as well as sealing layers of materials in plastics for the electronics industry, credit cards and ID cards.

Stamping press

Stamping presses , like laminating presses, have specialized applications and are used for two main purposes: forming or cutting materials by deforming with a die for the metalworking or automotive industries.

Transfer Press

Transfer presses operate by automatically feeding flat plastic, rubber or metal blanks into the right end of the press. From there, the feed rod fingers pick up the part and move it from die to die. They are used for stamping and molding of plastic, rubber and metal, for example in the medical and aerospace industries.

Press brake

A press brake is used to bend, fold, or otherwise cold process sheet metal. It usually consists of two C-shaped frames on the sides, a movable beam at the top and a lower tool mounted on a table.

The hydraulic press brake differs from other types of press brakes by having two synchronized hydraulic cylinders on C-shaped frames; they move the beam. In automatic mode, this type of press is known as a CNC press brake.

Hydraulic Forging Press

Forging presses are used only for metal. They force metal blocks into shape using closed or open molds, force, pressure, and sometimes heat. This combination stretches the metal to its yield point without breaking or cracking. Forging presses are most popular in automobile production.

Non-hydraulic presses

A standard industrial hydraulic press is a type of power press. Power presses can be pneumatic, hydraulic or mechanical. Alternatives to hydraulic presses include mechanical presses, electric presses, and pneumatic presses.

Mechanical press

Mechanical presses are driven by a flywheel that stores energy and then releases it, thereby transferring the energy to the main caliper through mechanisms such as a crank, cam, pivot joint, or tumbler. In a mechanical press, the stroke of the slide is adjusted within the limits of daylight.

In addition, strokes are also classified by the number of guides or pistons, which can be single, double or triple acting.

Fully electric press

All-electric presses are a relatively recent development that offer more efficient drive systems by mechanically linking the plunger to the drive motor. This ensures that the controller can provide a signal to the motor for a specific speed.

If the motor is not overloaded, this speed will be achieved. Additionally, eliminating hydraulic fluid fluctuations is beneficial because hydraulic fluid changes over time and temperatures, which can even change within a single day.

Pneumatic press

Pneumatic presses serve applications similar to hydraulic presses, including broaching, metalworking, crimping, stamping, bending and punching. They can have stroke cycles up to 400 beats per minute.

Even at high stroke speeds, pneumatic presses can provide controlled flow rates, making them ideal for applications where material flow or piston speed is critical.

Pneumatic presses do not convert rotary motion into linear motion, so they have fewer moving parts than hydraulic or machine presses.

However, pneumatic presses use compressed air to produce motion and are not capable of the extremely high pressures of hydraulic presses.

Hydraulic press device

The basic form of a hydraulic press consists of the basic components used in a hydraulic system and consists of a set of double-acting cylinders, pistons, also called punches, hydraulic pipes and a stationary support or die.

One cylinder is small and the other is large. The pair are called the slave cylinder and the master cylinder, respectively.

Pistons are mechanical devices that provide pushing or thrusting motion. Finally, the anvil or die is the preformed part that gives the substrate its final shape.

Advantages of hydraulic presses

The force achieved with hydraulic presses is unmatched; the same force cannot be achieved by either mechanical or pneumatic presses. However, these are not the only advantages of hydraulic presses. Others include:

- Low initial investment and operating costs - Because hydraulic presses are simple and have few moving parts, they are inexpensive to purchase and easy to maintain and troubleshoot, especially compared to other available options. If any parts break, they can be easily replaced without disassembling the machine. In addition, hydraulic equipment and consumables can be easily accessed worldwide, meaning less downtime and lower maintenance costs for you.

- Operation - Unlike presses that only transfer full power from the bottom, hydraulic presses can transfer full power at any point during the stroke. This eliminates the need to purchase an unnecessarily heavy press, such as a 200 ton press , only to provide less force, such as 100 tons, throughout the entire stroke. This benefit is especially useful when drawing.

- Ease of Operation and Built-in Safety - A hydraulic press rated for 100 tons or less will produce that much pressure regardless of any mistakes made in the setup. In this regard it is reliable. In addition, you as an operator do not have to worry about overloading, die breakage and press failure. These presses are designed in such a way that when the hydraulic press reaches a set pressure, it opens the safety valve at that limit; therefore there is no danger of overload.

- Control and Flexibility – You can control and adjust many things in a hydraulic press to suit your needs. Examples include: duration of pressure retention, direction, force of impact, speed, and force release.

- Lower operating noise – Because hydraulic presses do not have flying wheels or many moving parts, they produce much less noise than mechanical presses. In fact, modern hydraulic presses with a properly installed pumping system exceed current federal noise control standards.

- Long machine life - Built-in overload protection is also good for tools. Since the pressure is always the same, there is no danger of damaging the instruments due to overload. The absence of shock, vibration and impact helps auxiliary equipment such as press brakes and machine guards last longer.

Hydraulic press loads

Most machines are designed to handle extremely heavy loads, measured in tons. However, hydraulic press manufacturers have complete control over this and can design presses to handle any size load.

For example, while they can design presses that can withstand a maximum load of 3,500 tons, they can also design machines with a maximum load of only 15 tons.

Presses are typically made from stainless steel and other durable materials such as high-strength steel alloys, aluminum and brass.

They are available in both single and multi-station configurations. Single-position presses consist of a single set of pressing tools, a die and a punch, located inside the table.

Multi-station presses have multiple sets of pressing machines that either perform the same operation on many materials or perform different pressing operations on the materials as they move between stages.

To customize your machine, manufacturers can change the press ton limit, increase or decrease the length by mm, increase or decrease the fold by mm, die shape, hydraulic fluid type and much more.

Safety and Compliance Standards

What to consider

Maintenance plays a big role in keeping hydraulic equipment running optimally and efficiently. To keep your car in great shape, take the following precautions.

- Avoid Leaks - It is a fact that a leaky machine operates well below its capacity. For best results, your operator should regularly check seals around O-rings, press cylinder, hydraulic lines, hose end fittings and valve seats.

- Don't exceed your load limits - it's pretty simple; Do not use a heavier ton load than your press is designed for. If you exceed your hydraulic press's ton limit, you risk stress on the machine, breakdown, or even injury to workers.

- Keep the machine well oiled. To ensure smooth operation and reduce wear, hydraulic machines must be adequately lubricated, especially around the seals. Also make sure that the hydraulic fluid you use is the same type as specified in the operator's manual.

- Check the speed of pressure build-up - a press in good condition can create working pressure in half a second. Alternatively, if the press takes more than two to three seconds to generate the set pressure, the press has a problem with either the pump or the relief valve. The problem is mainly due to insufficient pump revolutions per minute. Occasional valve problems include dirt in the line and an opening that is too wide.

- Listen to unfamiliar machine sounds - You should immediately investigate any unfamiliar sound, find the source and correct it. The most common source of noise during press operation is valve movement. Noises also sometimes occur due to insufficient lubrication.

- Checking the electronic elements of the machine . The most common electrical problems with hydraulic presses involve coils and relays. Please note that they have a finite life cycle and need to be replaced from time to time. (Coils have a life cycle of 3 million strokes, and relays are rated for 1 million strokes.) Replacement reduces troubleshooting effort and downtime. A record should be kept using an hour meter and a cycle counter that is not reset because they help in servicing the machine.

- Check other parts of the machine - You also need to take care of fittings, loose wires and hoses, as worn hoses and improperly crimped fittings can cause plumbing failures in any machines.

- Maintain Oil and Temperature During Operation - The easiest way to extend the life of hydraulic presses is to maintain oil and temperature during operation. If the press machine is running with low oil levels and/or dirty oil, you risk damaging it or shortening its life. The best way to determine if there is dirt in the oil is to test the oil. If there are dirt particles in the oil, the filter should be replaced. Ideally, the operating temperature of the press is about 120 ° C; if it gets higher, the operation starts to break down. To maintain optimal temperatures, use air and water coolers. Take proper care of these units, especially the radiator, which tends to collect dirt.