Plasma welding will increase efficiency and also reduce the time required for metal cutting. Devices for this type of welding are gaining increasing popularity among equipment used for plasma welding. You can watch the video by following the link on our website.

Many companies around the world are developing this market segment, producing both the devices themselves and related accessories. It also released its devices in Russia, which in all respects are worthy competition to foreign ones. Welding is carried out by machines, some of which are capable of cutting.

The essence of plasma welding

Plasma metal welding is based on the use of argon arc technology. The difference between these two technologies lies in the features of the arc. Unlike an electric arc, plasma has the form of a compressed plasma jet, which has powerful energy.

To understand what the essence of plasma welding is, you first need to consider what plasma is and the conditions for its occurrence. Plasma is the state of a gas when it is partially or completely ionized. This means that it can be based not only on neutral molecules and atoms, but also on electrons and ions that have a certain electrical charge and consist entirely of charged particles.

To transform a gas into a plasma state, it is necessary to ionize most of its molecules and atoms. To achieve this, it is necessary to apply a force to the electron that forms the basis of the atom that exceeds its binding energy with the nucleus and help break away from it. This is the essence of plasma welding.

Part of the equipment

Any modern equipment of this type can be classified into two different types. The main difference here lies in the characteristics of the arc produced.

In any case, the arc must necessarily provide not only high efficiency of the process itself, but also a relatively small area of temperature action on the working surfaces of the materials being processed.

The equipment used must fully comply with safety standards and ensure a relatively low consumption of protective gases used during operation.

Also, welding of this type must be able to connect thin-sheet steel surfaces with various non-metals.

In many ways, the characteristics of such installations are determined by the price, and the higher it is, the more functionality such a device has.

The video below shows in detail the process of plasma welding.

When you choose a device of this type, first of all you need to be guided by what kind of surfaces you plan to process with its help.

It should also be noted that this equipment is available in both manual and automatic versions.

In devices of this type, the main power element is a special inverter, which supplies current with certain parameters.

When using devices of this type, you can not only increase the overall speed of performing the relevant work, but also significantly reduce the amount of waste.

Video:

To operate the most ordinary plasma device, you only need electricity, as well as a stream of air of a certain pressure.

Also, the quality of the seam largely depends on the plasma torch used during the work process, which is, in fact, the main working tool.

More details about how a plasma device works are described in the video in our article.

Features and characteristics of the process

To understand what plasma welding is, it is worth considering its important features, namely how the process is carried out. During it, a very high temperature is usually applied in the welding area, which is formed by a forced reduction in the cross-sectional dimensions of the arc and an increase in its power indicators.

The result is plasma jet welding, in which temperatures can reach up to 300,000C. But with argon arc welding they can be only 5000-70000C. During the welding process, the arc takes on a cylindrical shape, which is what allows it to maintain the same power rating along its entire length.

During plasma welding, high arc pressure is observed on the surface of the metal elements being welded. This is what makes it possible to influence almost all types of metals and alloys.

It is worth noting! Plasma welding technology can be used with small amounts of electric current. The process can be carried out at 0.2-30 A.

All these features make this type of welding almost universal. It can be successfully used in hard-to-reach areas when connecting thin aluminum sheets without possible burns. A slight change in the distance between the electrode and the workpiece does not have a strong effect on heating, which means it does not affect the quality of the seam, as happens in other types of welding.

Due to the fact that during plasma technology a large depth of heating of parts is observed, this makes it possible to do without preliminary preparation of the edges. It is allowed to weld metals with non-metals.

As a result, there is an increase in work productivity, a decrease in the temperature deformation of the welded joint, which means that the structural part does not behave. But welding with a plasma cutter allows not only welding of metal structures, but also ensures high-quality cutting of metals and non-metals in different positions.

Welding machine "Gorynych"

Multifunctional welding "Gorynych" is one of the most popular welding units of domestic production. This is a really high-quality tool that allows you to do welding work at home with your own hands. It should be noted that the Gorynych line of equipment includes devices of various capacities (8,10,12A).

For household work, an 8A device is perfect; a 10-amp device is characterized by price/performance, but more powerful 12A equipment is already considered professional. The welding unit of the Gorynych brand is quite popular both in Russia and in Ukraine (in particular, in Zaporozhye), and in Belarus.

Advantages and disadvantages

Plasma welding and cutting is a popular technology that is used to weld structures of different sizes. This process has a number of positive qualities:

- increased plasma temperature, which can reach up to 300,000C;

- small cross-section of the arc;

- in contrast to gas welding, the speed of metal with a thickness of 5 to 20 cm using plasma technology is three times higher;

- there is a high precision of welded joints that are obtained during the melting process;

- the quality of the work performed does not require additional processing of the edges of the products;

- The plasma welding process can be used on almost any type of metal. For example, it can be used to cook products from Zaporozhye steel, copper, aluminum, cast iron;

- during welding work, the metal is not subject to deformation, even when cutting out complex shapes;

- plasma technology involves cutting a metal surface that has not undergone preliminary preparation. For example, it can be used in cases where there is rust or paint on the product;

- there is no need to use argon, acetylene, or oxygen. This allows for significant savings;

- there is a high degree of safety of the work being carried out. This is due to the fact that gas cylinders, which emit toxic fumes, are not used during welding. They can also explode if used and stored incorrectly.

The plasma welding process has some disadvantages:

- during its implementation, partial dissipation of energy into space occurs;

- requires the use of plasma-forming gas;

- The plasma torch must be cooled using water;

- high cost of welding machines.

Purpose of the manipulator

In addition to rotators, there are other types of additional welding equipment - tilter, positioner, manipulator. It is worth talking in particular detail about manipulators, because they are most often used in production and at home.

The manipulator can move or rotate the part in any direction that is necessary for welding work. It is more versatile than a spinner.

A significant advantage of modern manipulators is their ease of readjustment. If desired, it is not difficult to adjust the operation of such devices.

To do this, you just need to reconfigure the software, that is, change the working program, after which the tool will begin to move along a new trajectory. The connection line or seam line in this case will also undergo changes.

The modular design of most manipulators common today allows you to easily change the orientation of the working tools. As a result, the same device can be used in different welding technologies.

Principle of operation

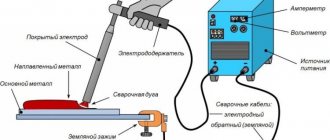

Before you start plasma welding, it is worth considering its operating principle. During the process, a powerful electric discharge is supplied, which turns the working medium into a plasma one. A gas is formed that has a high temperature.

Due to the impact on the metal surface of a flow of ionized gas conducted by an electric current, the metal base melts. During heating of the arc, the gas undergoes ionization, the level of which increases with increasing temperature of the gas.

A plasma jet, which usually has an ultra-high temperature, increased power, is all formed from a usually arc after compression, blowing into the arc. It is formed using a plasma-forming gas, which is often argon, and in rare cases hydrogen and helium are used.

Direct plasma welding

What is direct plasma welding? This method is common; it is carried out thanks to an electric arc that is formed between the electrode and the work product.

Plasma welding technology has some characteristic features:

- Plasma welding of aluminum must be performed with the utmost care. This is due to the fact that this metal melts at a temperature of 660.3 degrees.

- It is imperative that you carefully monitor the process to prevent it from going missing.

- The instructions for welding machines always contain a table indicating the recommended current strength for each type of metal. For example, plasma welding of stainless steel is performed at medium current, and for steel at high current.

Note! In a direct action arc, the arc is initially ignited at low currents between the nozzle and the workpiece. After the plasma touches the part being welded, a main direct arc is formed.

The arc is powered using alternating or direct current with straight polarity. Its excitation is performed by an oscillator.

Indirect plasma welding

Before you begin, it’s worth considering what indirect plasma welding is. During this method, plasma formation is carried out in the same way as with direct technology. The difference is that the power source is connected to the electrode and nozzle, as a result of which an arc is formed between these elements, and a plasma medium appears at the exit of the torch.

The plasma flow rate is controlled by gas pressure. The secret is that the gas mixture, when transitioning to the plasma state, increases its volume 50 times and thanks to this it flies out of the apparatus in the form of a long jet. The energy properties of the expanding gas, together with thermal energy, make plasma a powerful source of energy.

The advantages of indirect welding include:

- ensures a smooth workflow;

- allows you to significantly save costs on electric current;

- due to the fact that high pressure is applied during the welding process, gas mixtures practically do not splash;

- This type is great for welding and cutting metals.

Important! Plasma welding and cutting of metals must be carried out using the correct modes. They must supply the correct current, take into account the types of materials being welded, their thickness, and the diameter of the plasma torch nozzle. Different types of gases must be used to cut different materials.

Practical implementation

Schematic diagram of a plasma welding machine.

Often, when making a homemade plasma welding machine, the nozzle is machined from copper. If there is no alternative, this option is possible, but the nozzle becomes a consumable even when only a standby current passes through it. It will have to be changed frequently. If you can get a small piece of molybdenum or tantalum round timber, it is better to make a nozzle from them. Then you can limit yourself to periodic cleaning.

The size of the central hole in the nozzle is selected experimentally. You need to start with a diameter of 0.5 mm and gradually bore it to 2 mm until the plasma flow is satisfactory.

The nozzle is screwed into a hollow cooling jacket, which is connected to the central electrode holder through a fluoroplastic insulator. Coolant circulates in the cooling jacket. As such, in the warm season you can use distilled water; in winter, antifreeze is better.

Diagram of the control unit of a plasma welding machine.

The cooling jacket consists of 2 hollow copper tubes. The inner one with a diameter and length of about 20 mm is located at the front end of the outer tube with a diameter of about 50 mm and a length of about 80 mm. The space between the ends of the inner tube and the walls of the outer tube is sealed with thin sheet copper. Copper tubes with a diameter of 8 mm are soldered into the jacket using a gas torch. Coolant flows in and out through them. In addition, a terminal must be soldered to the cooling jacket to supply a positive charge.

A thread is made in the inner tube into which a removable nozzle made of heat-resistant materials is screwed. An internal thread is also cut at the extended end of the outer tube. An insulating ring made of fluoroplastic is screwed into it. The central electrode holder is screwed into the ring.

An argon supply tube of the same diameter as for cooling is soldered through the wall of the outer tube into the space between the cooling jacket and the fluoroplastic insulator.

Liquid from the windshield wiper reservoir circulates through the cooling jacket. Power is supplied to the pump of its electric motor through a separate 12 V rectifier. There is already an outlet for the supply on the tank; the liquid return can be cut through the wall or lid of the tank. To do this, a hole is drilled in the lid and a piece of tube is inserted through the pressure seal. Rubber hoses for liquid circulation and argon supply are connected to their tubes with clamps.

Scheme of plasma powder fusion.

The positive charge is taken from the main power source. A suitable electronic ballast is selected to limit the current through the nozzle surface. The supplied electric current must have a constant value in the region of 5-7 A. The optimal current value is selected experimentally. This should be the minimum current that ensures stable combustion of the pilot arc.

The pilot arc between the nozzle and the tungsten cathode can be excited in one of two ways. Using an oscillator built into the welding machine or, in the absence of one, using a contact method. The second option requires a more complex design of the plasma torch. During contact excitation, the central electrode holder is made spring-loaded relative to the nozzle.

When the rubber button of the rod connected to the electrode holder is pressed, the sharp end of the central tungsten cathode contacts the conical surface of the rod. During a short circuit, the temperature rises sharply at the point of contact, which allows an arc to be initiated when the cathode is pulled away from the anode by a spring. The contact must be very brief, otherwise the surface of the nozzle will burn.

Excitation of current by a high-frequency oscillator is preferable for the durability of the structure. But purchasing it or even manufacturing it makes a homemade welding machine for plasma welding unprofitable.

During operation, the positive terminal of the welding machine is connected to the part without ballast. When the nozzle is within a few millimeters of the workpiece, electrical current is switched from the nozzle to the workpiece. Its value increases to that set on the welding machine, and the formation of plasma from argon intensifies. By adjusting the argon supply and welding current, you can achieve the required intensity of plasma flow from the nozzle.

Design and principle of operation of the plasma torch

During the plasma welding process, a special device is used that acts as a plasma generator, it is called a plasma torch. This device uses electrical energy to convert gas into welding plasma, which is then used to create a welding arc.

Two types of devices are used, which operate according to the scheme of indirect and direct arc conversion. The plasma torch for plasma welding is direct-acting, when a tungsten electrode is used as the cathode, and the surface to be welded is used as the anode. This is what causes the arc to take on a cylindrical shape.

The main components of the plasma torch include:

- Tungsten electrode (cathode). It forms one connection with the plasma-forming gas supply device.

- Body part of the device.

- Nozzle with shaping tip.

- Heat-resistant insulator.

- Cooling system using a water jet.

- Starting device.

To excite the main arc, a cable with a positive charge is connected to the metal surface from the device. The resulting arc ionizes the gas, which flows from the cylinder or compressor into the chamber under pressure. When heated during ionization, the gas expands and is ejected from the chamber space in the form of a jet with high kinetic energy.

It is worth noting! To facilitate ignition of the main arc, an auxiliary electrode is built into the plasmatron chamber area, which acts as an anode. When the plasma torch is connected to the network and started, this electrode receives a positive charge and forms an arc with the tungsten cathode.

Do-it-yourself oscillator for a plasma cutter: diagram, video, homemade for plasma

page » DIY » Plasma cutter » Oscillator

An oscillator for a plasma cutter is a device for non-contact initiation of an arc and stabilization of its combustion. It receives these options thanks to the conversion of electricity parameters.

Homemade oscillator for a plasma cutter: a little theory

The appearance of the electronic unit of a factory-made oscillator is shown in the figure.

Welding oscillator brand VSD-02, used to stabilize the arc. East. https://met-all.org/oborudovanie/svarochnye/svarochnyj-oscillyator-svoimi-rukami.html.

Modern oscillators are divided into two classes of action:

continuous action. This class adds a high frequency current (150...250 KHz) and a high voltage value (3000...6000 V) to the welding current. Under such conditions, the arc will ignite even without the electrode touching the surface of the workpieces being connected. Moreover, it will burn very steadily even at low values of welding current (due to the high frequency of the current generated by the oscillator)

And, what is also important, electricity with such characteristics is not dangerous to the health of the worker working on this device;

pulsed. The electrical circuit of this class may provide for its parallel or serial connection.

Examples of electrical circuits are shown in the figure.

Parallel and serial connection of the oscillator. East. https://met-all.org/oborudovanie/svarochnye/svarochnyj-oscillyator-svoimi-rukami.html.

Devices that are connected to the electrical circuit of the plasma cutter in series are more effective. This is explained by the fact that their circuit does not use high voltage protection as unnecessary. The use of an oscillator, in addition, allows you to expand the options of the plasma cutter and process “problem” metals or alloys:

- aluminum;

- “stainless steel”, etc.

DIY oscillator for plasma cutter

An oscillator, which is easy to make with your own hands if desired, most often refers to continuous-action devices. Let's look at the design of the gadget.

In general, the oscillator consists of the following main components:

- oscillatory circuit. It plays the role of a spark generator of damped oscillations. The oscillatory circuit consists of the following components: storage capacitor;

- inductor. Its role is usually performed by the winding of a high-frequency transformer;

arrester;

choke coils;

high frequency transformer.

Important Requirements

Perhaps for many, plasma arc welding will seem like a simple process that can be easily performed the first time without much experience. However, during it it is imperative to follow all the important rules of technology. The main errors include:

- belated replacement of replaceable components of the plasma torch;

- use of parts with low quality or defects;

- the use of incorrect modes that reduce the service life of elements;

- lack of control over the parameters of the plasma-forming gas;

- the use of high or low cutting speed compared to the intended mode.

All these important requirements apply to the plasma welding process, as well as its subtypes - microplasma welding, air plasma welding and other methods. It is imperative to use a welding machine that can provide the necessary characteristics of the welding current. You will need a burner, a non-consumable electrode, a set of hoses for supplying or circulating coolant and other important components for operation.

The plasma welding process is considered a popular technology, which is actively used in various fields of industry - mechanical engineering, instrument making, manufacturing of high-precision parts, jewelry, and so on. This method is highly accurate and allows you to obtain an even seam of excellent quality. But still, it must be carried out taking into account important rules and requirements.

Plazarium LLC

The installation uses an inverter circuit that ensures stable, autonomous operation of the arc. The unit is equipped with temperature control sensors. Other advantages are small dimensions, light weight, low cost of consumables.

Here is a list of foreign manufacturers of plasma equipment:

Fubag (Germany). The products of this brand are distinguished by their high efficiency, practicality, ergonomics and quality of work.

BlueWeld (Italy). The line includes equipment with contactless start, manual welding units, etc. All installations have the following advantages - environmental friendliness, simple operation, economical energy consumption, functionality.

Aurora (PRC). Products of this brand have such advantages as relatively low cost, sufficient wire length, contactless start option, and versatility.

Our offer

On our website you can buy a plasma cutter in just one click, simply by moving it to the “Cart”. Our managers will contact you to clarify payment terms. We have our own courier service that delivers orders throughout Moscow and the Moscow region. We are also always ready to help organize the delivery of cutters to any other region of Russia. For your convenience, we provide various forms of payment for the ordered goods.

You can check prices for plasma cutters and their availability in the store’s warehouse by calling the phone number listed at the top of the page. Our managers will contact you and provide any additional information about plasma cutters.