Hand chainsaws are currently widely used both for felling trees, cutting branches and further collecting firewood, and in the construction of wooden houses and various buildings for household purposes. Like any other tools, these devices (quite reliable) require regular maintenance and sometimes adjustment. For example, a tachometer for a chainsaw will allow you to easily not only check the characteristics of a newly purchased tool, but also make subsequent adjustments to the carburetor yourself.

Homemade tachometer for chainsaw

This article will focus on a tachometer using a PIC controller PIC16F684. Information is displayed on an LED indicator module with a TM1637 chip. The input pulse shaper is implemented on the KR1006VI1 microcircuit. The schematic diagram of the device is shown in Figure 1.

The main element of the circuit is the PIC16F684 microcontroller. This controller is capable of functioning normally at a supply voltage of 3 volts, i.e. from two batteries of one and a half volts. In this case, the current consumption of the circuit is within six milliamps. The indicator module, implemented on the TM1637 chip, is also operational at a reduced supply voltage, although the brightness of the segments naturally decreases, but is sufficient for working with a tachometer.

At the input of the pulse shaper, made according to the classical scheme and implemented on the DA1 KR1006VI1 timer, counting pulses from the sensor are received through a differentiating chain - R1, C1. Diodes VD1 and VD2 protect the input of the microcircuit from excessive voltages and simultaneously release only positive pulses. The duration of the generated output pulse depends on the ratings of the RC chain R2 and C3. The time constant of this circuit is equal to the product of C by R = 10000 Ohm x 0.00000033 Ф = 3.3 milliseconds. Thus, the maximum frequency of input pulses should be no more than F = 1/T = 1/0.0033 ≈ 303Hz. For a two-stroke engine this will correspond to 303 x 60 ≈ 18181 rpm. Quite enough for us. From above, the numerical value of the revolutions is not limited by anything, so keep this in mind. Minimum speed = (1/65536 x2) x 60 = 457.76 ≈ 460 rpm. If the minimum speed is less than this value, then solid dashes will appear on the display. For my Husqvarna 395XP saw, the maximum speed is 12500. It was for this that I had to develop this circuit. The old woman sometimes requires repairs and maintenance, after all, it’s already 19 years old and she’s already sawed through kilometers of boards and bars, plus firewood. You can see my sawmill with this saw in “Homemade mobile sawmill.” And so, let's move on. If you experience errors in the indicator readings, you may have to install an additional quenching resistor in series with the input capacitor, the value of which you will select experimentally. When experimenting with my saw, I simply brought the wire with the “crocodile” 15 centimeters closer to the candle.

From the output of the driver, pin 3 of DA1, pulses are supplied to the RA2 input of the DD1 microcontroller. The engine crankshaft speed is calculated by measuring the repetition period of the input pulses from the sensor. The measurement is performed 16 times, then the arithmetic mean of the period is found. Next, the controller recalculates the period into revolutions per minute. Since I have a module with a “hour” indicator at my disposal, a colon is used to display tens of thousands of revolutions. For example, 12500 rpm will look like 12:50, less than 9999 rpm will be 9999 as usual.

When the device is turned on, segments D will be displayed on the indicator in all digits. When ignition pulses are applied to the input, the actual shaft rotation speed will begin to be displayed; after the signal is removed, the number of revolutions of the last measurement will remain on the indicator.

I don't have time to design and customize the case for this device, so everything was mounted in the case from an old lazy one. Unnecessary holes were simply sealed with duct tape and painted over with black paint. I think you will do better.

An ordinary “crocodile” was used as a pulse sensor. In real measurements there is practically no constancy of readings; this is due to the specifics of the operation of a two-stroke engine. Although, when pulses are supplied to the input from a generator with a frequency of 100 Hz, the indicator displays 6002 ... 6004 rpm.

That's all. Good luck. K.V.Yu.

Tachometer for chainsaw. How to adjust a chainsaw carburetor using a tachometer

Hand chainsaws are currently widely used both for felling trees, cutting branches and further collecting firewood, and in the construction of wooden houses and various buildings for household purposes. Like any other tools, these devices (quite reliable) require regular maintenance and sometimes adjustment. For example, a tachometer for a chainsaw will allow you to easily not only check the characteristics of a newly purchased tool, but also make subsequent adjustments to the carburetor yourself.

The principle of operation of a tachometer for a chainsaw

A tachometer is a device that measures the number of engine revolutions in one minute. It is almost impossible to connect a mechanical device to a tool with a gasoline engine (and it is not necessary). A modern tachometer for a two-stroke chainsaw engine is a digital device that reads pulses from a spark plug insulator or high-voltage wire at the moment of spark formation (without direct contact). The built-in microprocessor converts the pulses into engine speed. The readings are displayed on an easy-to-read LCD display. Depending on the manufacturer and design features, the price of such devices varies from 950 to 6,500 rubles.

Installation and configuration of the device

First you need to purchase the device itself and the connecting cable.

Most often it is advised to buy a branded cable, which is already equipped with everything. Let's analyze the installation with a Yamaha tachometer, which has a fuse for power surges. Take measurements on the boat first so you know what length of harness you will need. One part of it is connected to the connectors on the remote control machine or to the ignition switch. Despite the fact that the dashboard is nearby, there is a risk of missing.

The main stage is installing the device into a panel, usually a non-removable one. The best option is when the panel is located at a certain angle. Do not place the device on horizontal places. Draw the outline of the future hole and mark its center, and then work with a drill.

The second stage is mechanical processing, before this you should disconnect the battery and do not forget about the safety rules. After all the work done, all that remains is to connect a few wires and lay out the harness.

The last stage is connecting the device and setting up the device. Setting up the tachometer is setting its operating mode. First you need to check the accuracy of the number of revolutions and if the indicators do not match, you need to bring everything back to normal using the instructions. If the tachometer is universal, then the operating mode selector must be set to the position corresponding to the number of pulses per motor revolution.

Review of common boat models

- Yamaha is a digital device that consists of a waterproof housing. Designed for standard installation, has an 86mm opening. The screen shows the current and maximum engine speed, as well as engine hours. The price of this device is 23615 rubles.

- Mercury is an analog device designed for installation on all Mercury engines. Consists of a waterproof case and a pointer dial. Cost 5620 rub.

- Suzuki is an analog device for the motor, which is installed in a regular hole in the dashboard of a boat (86 mm). It has glass that does not fog up and displays up to 7000 engine rpm. There is no operating mode selector, because all Suzuki engines are equipped with 12-pole generators. Price 4400 rub.

Additional Information

6000 rpm tachometers are designed for use with certain gasoline engines. 7000 rpm and 8000 rpm tachometers are required for use with gasoline outboard engines. Devices for motors with a 20-pole generator no longer exist. The number of electrical pulses at one time is equal to 1/2 of the number of poles of the alternator. Many pre-1977 outboards may be equipped with an alternator and have a unique SEND wire in the ignition system. All modern devices can work with these motors

To do this, you need to disconnect the wire from the ignition system and connect it to the rectifier contact. Later, you should check that the number of poles of the engine alternator corresponds to the number of poles of the tachometer. Due to certain alternator noise, some motors may require the installation of a non-polarized capacitor. It is very important to study the diagrams; many subtleties are written there. Connection must be done carefully

Wired tachometers for chainsaws

The most common devices for monitoring chainsaw engine speed are models with a wired connection. Their popularity is due to their low price. Various models of electronic tachometers for chainsaws from the Chinese manufacturer Runleader now cost 950-1850 rubles.

To measure engine speed with such a device, it is necessary to provide access to the high-voltage spark plug wire, which (depending on the model) can be connected in two ways:

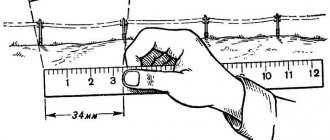

- using the clamp located at the end of the cord included in the kit;

- using a winding (5-6 turns of the free end of the cord around a high-voltage wire), fixed with a plastic clamp or insulating tape.

Which one should you choose?

If you need something cheaper, then you should take a closer look at the Kebidumei tachometer. If you plan to regulate the engine speed of the chainsaw, on average, at least once a month, then it is better to choose Runleader with more powerful functionality. For daily work, it is better to buy a non-contact laser tachometer WHDZ; although it is much more expensive, it will still improve productivity. This is exactly what we use in our workshop, by clicking on this link you can buy it on Aliexpress for a promotion, we bought it from this seller, everything arrives without problems, quickly, properly, the price is the lowest.

It doesn’t matter for which chainsaw you plan to use an electronic tachometer, be it the famous Shtil, Husqvarna or Russian Carver, any of the above will be suitable for all tools.

There are also more expensive tachometers for chainsaws, for example from such well-known brands as Shtil, but their prices are also steep, 7-10 times higher than top ones from China.

Stihl tachometer

Wireless engine speed meters

More convenient to use are tachometers for chainsaws, which allow you to control engine speed without connecting a wire. Such measuring instruments measure engine speed at a distance of 15-20 cm from the insulating cap of the spark plug. The undoubted advantage of such measuring devices is that when adjusting the carburetor there is no need to dismantle the protective casing and air filter. But these devices are much more expensive than their wired counterparts.

On the Russian market, the most affordable wireless tachometers are from the leading ones and Shtil: Husqvarna PET-302 and Stihl EDT-9.

These devices are quite versatile. Measurements can be taken at different distances from the spark plug cap:

- at a distance of 5-10 cm, when using only the device itself;

- 15-20 cm by connecting a short antenna wire (15 cm long) to the device;

- 1.2 m, using a measuring cord with a clamp for attaching to the high voltage wire of the spark plug.

Required materials and tools

To assemble a simple dial tachometer for setting up a chainsaw, you will need a minimum of electronic components:

- Dial level indicator from a tape recorder.

- Fixed resistor 1.8 kOhm. Deviation up or down is allowed up to 1.5 kOhm or 2.2 kOhm.

- A variable resistor with a resistance of 10 kOhm or another with a slight deviation.

- 1 µF permanent capacitor. The face value is also not critical.

- Two semiconductor diodes of any brand.

- Wires.

The circuit can be assembled on a suitable piece of plastic or Krasis. If desired, installation can be done on a special universal circuit board or made independently by etching on textolite or getinax.

A housing for the device is not required, but it is still recommended to select a small plastic box.

Among the tools you need to have on hand is a knife, a soldering iron with solder, and tweezers.

In what cases is it necessary to adjust the chainsaw carburetor?

Along with such preventive maintenance as replacing spark plugs, fuel or air filters, the need to adjust the chainsaw carburetor periodically arises. This must be done when:

- the new chainsaw operates unstably on the fuel available to the user;

- the saw does not start;

- idle speed is too high or too low;

- the saw starts and immediately stalls;

- fuel consumption declared by the manufacturer has increased significantly;

- when one or more adjusting bolts are loosened;

- after repairing the carburetor or replacing it with a new one.

What to pay attention to before starting adjustment work

Before starting any adjustment work, you must carefully read the instructions for the chainsaw. It indicates the engine speed (at idle and the maximum permissible) that must be set when adjusting the carburetor for the correct operation of the tool. The period of uninterrupted operation largely depends on this.

The air filter must be thoroughly cleaned or replaced. You should also make sure that the spark plug is in good condition and that the required gap between the electrodes is set.

Important! Before setting up, warm up the saw at idle speed for 8-12 minutes.

Setting up carburetors for low-power chainsaws

Low-power chainsaws (for example, the quite popular MS170 and MS180 models from Stihl with an engine capacity of 30-32 cm³) are usually equipped with carburetors with only one adjusting screw.

On the body it is designated by the Latin letters LD. It is designed to adjust engine speed in idle mode. Setting up such a carburetor can be done either with or without a tachometer to measure the speed of the chainsaw:

- tighten the adjusting bolt until it stops;

- unscrew it two turns;

- we start the chainsaw.

If the idle speed is too low (this is indicated by the tachometer readings or unstable engine operation), then turn the screw until the saw chain begins to move. Then unscrew it ½ turn back (that is, in the opposite direction).

If the idle speed is too high and the chain begins to move immediately after starting the engine, then turn the screw until it stops and make another ½ turn in the same direction.

On trains and light rail

Rail vehicles commonly use speed sensors, otherwise called wheel impulse generators (WIG), speed sensors or tachometers. Common types include opto-isolating slotted disk sensors and Hall effect sensors.

Hall effect sensors typically use a rotating target attached to a wheel, gearbox, or motor. This target may contain magnets or may be a gear. The teeth of the wheel change the magnetic flux density of the magnet inside the sensor head. The probe is positioned so that its head is at a precise distance from the target wheel and it detects teeth or magnets passing through its surface. One problem with this system is that the required air gap between the target wheel and the sensor allows iron dust from the vehicle's subframe to accumulate on the probe or target, interfering with its operation.

Optoisolator sensors are completely enclosed to prevent penetration from the external environment. The only exposed parts are the sealed connector and drive yoke, which is attached to the slotted disc through a bearing and seal. A slotted disk is typically sandwiched between two printed circuit boards containing a photodiode, phototransistor, amplifier, and filter circuits that produce a square output wave pulse train tuned to the clients' voltages and pulses according to rotational requirements. These types of sensors typically provide 2 to 8 independent output channels that can be sensed by other systems in the vehicle, such as automatic train control systems and drive/braking controllers.

Adjusting the chainsaw carburetor using a tachometer

The largest number of chainsaws "Husqvarna", "Shtil", 'Partner', "Champion" (as well as from numerous Chinese manufacturers) have three spring-loaded adjusting screws on the carburetor.

They are designated by Latin letters and are intended:

- L – to regulate fuel supply at low speeds.

- H – to set the amount of fuel at maximum speed.

- T (for some LA models) – decrease or increase the supply of the air-fuel mixture at idle.

To carry out the work, you will need a thin slotted screwdriver and a tachometer to adjust the chainsaw.

On a note! To make it easier to count the revolutions of the adjusting screws, it is better to apply a clearly visible mark on the handle of the screwdriver in advance.

The setup algorithm is quite simple:

- If you have a wired tachometer, remove the protective casing and air filter to provide free access to the high-voltage wire. This is not necessary when using a wireless meter.

- We start the chainsaw.

- We connect the tachometer (or bring the wireless device close enough to the spark plug).

- By rotating screw L we achieve the highest idle speed. Then make ¼ turn counterclockwise.

- If the chain moves in this mode, then by rotating the screw T (LA) we achieve its complete stop.

- Press the accelerator handle all the way.

- Let the saw work in this mode for 8-10 seconds.

- Based on the tachometer readings, use screw H to set the maximum speed recommended by the manufacturer.

- Using the adjusting bolt T, set the required idle speed.

- By pressing and releasing the gas handle, we make sure that the tool operates smoothly in all modes, without dips or jerks.

- Turn off the tachometer.

- Reinstall the air filter and protective cover.

Adjustment principles

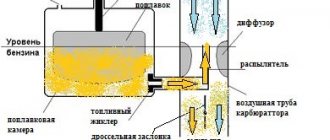

Rotation of the adjusting screws L and H changes the capacity of the air channels. By tightening these screws we reduce the amount of air, and accordingly the amount of fuel entering the cylinder increases, this process is called enrichment (fuel-rich mixture).

By unscrewing the screws we increase the amount of air and lean the mixture. A two-stroke engine is very sensitive to the quality of the air-fuel mixture. If there is a lot of air, the speed increases, but the thrust becomes lower. If there is not enough air, then the engine does not develop speed and full power, this is called choking.

In practice, this can be assessed by how the saw engine responds to pressing the gas handle. It goes into overdrive, the revs are too high, which means there is too much air. And vice versa, if when you press the gas the engine does not pick up speed and smokes, then there is not enough air.

Purpose

A tachometer is an electronic device designed to record the number of revolutions per minute in a given situation of a two-stroke engine. It is important to note that the list of preventive maintenance includes periodic adjustment of the carburetor. Such manipulations will be relevant if:

the new device is unstable;

the equipment does not start at all;

after starting, the power plant immediately stalls;

idle speed is too low or, conversely, high;

fuel consumption increased;

the adjusting screws have become loose;

repairs have been made or a new carburetor has been installed.

It turns out that the main task of the described portable device is to provide the ability to configure the power unit of the saw with your own hands as accurately as possible.

Summing up

The tachometer is a useful device; it allows you to fine-tune the chainsaw carburetor, as well as check whether the current idle speed and maximum speed settings correspond to the factory ones. In case of deviation, identify the malfunction in time and eliminate it.

It is worth remembering that if the carburetor adjustment is violated, the maximum speed may increase (more than 13 thousand), above the permissible value, which in turn will lead to damage to the saw engine. A person will not hear this by ear, but the tachometer will allow you to see it.

(3 ratings, average 2.67 out of 5)

Design and principle of operation

The vast majority of tachometer models for the equipment described are digital measuring instruments . During operation, such a device reads pulses from the spark plug insulator of a two-stroke internal combustion engine or a wire. The indicators are recorded at the moment of spark formation. The received data is processed and converted into revolutions by an integrated processor. At the same time, they are displayed on a miniature display.

Currently, wired models have become the most common. The increased popularity of these devices is primarily due to their relatively low cost. At the same time, non-contact tachometers are more convenient to use. With their help, readings are taken at a distance of 15-20 cm from the spark plug cap and high voltage wire.

Purpose of an electronic device for measuring revolutions

Using a tachometer, it is possible to find out the number of engine revolutions in one minute. It is a device that reads pulses from the spark plug insulator or high-voltage wire when sparking occurs. There is a microprocessor inside it that converts pulses into revolutions. All results are visible on the screen.

The main task of the tachometer is to accurately adjust the chainsaw carburetor in all operating modes: idle, maximum power.

For those who still want to set up a chainsaw carburetor without a tachometer, we strongly recommend reading the article about setting up a Chinese saw; it will warn you against serious mistakes.

This is what an overheated chainsaw piston looks like, which has collapsed as a result of overheating due to operation at speeds exceeding the maximum permissible.

Carburetor adjustment is necessary in the following cases:

- the chainsaw operates erratically;

- the saw immediately stalls after it is started;

- the saw does not start;

- idle speed is too high or too low;

- the carburetor has been repaired or has been replaced with a new one;

- fuel consumption has increased significantly;

- One or more adjustment bolts have become very loose.

The following are types of tachometers for chainsaws.

Tachometers can be wired or wireless. The latter are more expensive than the former.

If a wired type is used, then it is necessary to provide access to the high-voltage wire of the spark plug. The disadvantage of such devices is that it is necessary to remove the cover and air filter in order to have access to the wire. The connection can be made:

- Due to the clamp located at the end of the cord.

- Using a winding, which is fixed with insulating tape or a plastic clamp.

Tachometers without a wire connection are more convenient to use. This type of device allows you to measure engine speed at a distance of 15-20 cm from the insulating cap.

Below is an overview of the best brands of tachometers.

This is the cheapest tachometer, it doesn’t even come with a crocodile, you just have to wind the wire instead. But the price is good.

The simplest tachometer, without a crocodile

The following functionality is worth noting:

- has a large LCD display;

- there is a reset function to zero hours;

- reads up to 10,000 hours, and then resets to zero;

- capable of counting up to 99,999 revolutions per minute;

- service time setting can be programmed;

- there is a reminder function to remind you to change the oil;

- This type of tachometer can work on all engines, the engine type can be selected using buttons S1 and S2;

- There is a splash protection function.

We recommend watching a video review of this tachometer, ordered from China; the author talks about the device in an interesting and detailed manner. He talks about the functionality, settings, disassembles the device itself to show what is inside and at the end shows an example of working on a gas mower (in principle there is no difference with a chainsaw).

Thanks to a more powerful processor, it has better functionality, works faster, but also costs more. It looks more solid in your hands, the plastic is stronger, and the buttons are easier to press. The build is much better than the previous one. For frequent use it will be much better than the first option

Features worth noting:

- engine hour display function;

- can only be used with a gasoline internal combustion engine;

- To connect, you need to wind the contact wire around the spark plug wire. The wire length is 1.5 meters;

- The device does not work with 4-stroke engines, but it is not needed for chainsaws.

This chainsaw tachometer is more suitable for fans of “wireless technology”. Its main advantage is the ability to measure revolutions without using wires. Saves a lot of time, because... allows you to measure engine speed almost at lightning speed.

- has a large digital LCD display.

- the body has a special shape, due to which it fits comfortably in the hand;

- there is a function for automatically saving values in the device memory;

- The case is hard, made of ABS plastic.

Model overview

Today, in the relevant market segment there is a sufficient range of products from different manufacturers. Taking into account the availability and good price-quality ratio, Chinese tachometers are in well-deserved demand.

The list of popular ones, for example, includes the Kebidumei . This most budget device is not even equipped with an alligator clip, and therefore you will have to wind the wire when connecting. In addition to the most affordable cost, it is worth highlighting the following points:

presence of a large display;

performing measurements up to 10 thousand hours with automatic reset of the counter;

reading indicators up to 99,999 revolutions;

possibility of programming maintenance time;

engine oil change reminder function;

versatility (the type of internal combustion engine is selected using the “S1” and “S2” buttons);

protects the device from splashes.

Pulse Engine is another cheap option, with many similar characteristics to the previous one. The main difference is the presence of a crocodile for ease of connection.

Runleader is a chainsaw tachometer model with extended functionality. Provided with a more efficient microprocessor. The device works much faster, but it will cost more. Main features, in addition to increased reliability:

display of engine hours on the screen;

Suitable for use only with two-stroke gasoline power plants;

connection involves winding the device wire (length 1.5 m) around the spark plug wire.

WHDZ is a non-contact laser-type tachometer, the main competitive advantage of which is, of course, the lack of a wired connection. As a result, measurements can be taken almost instantly, which significantly reduces engine setup time. The model is equipped with a large and high-quality monitor.

Another important detail is the option to save measurement results in the device’s memory.

How to use the Chinese Kebidumei tachometer?

Below are instructions for using an electronic tachometer using Kebidumei as an example:

- Before setting the operating mode of the device, the saw motor must be turned off.

- Turn on the device by pressing button S1.

- To select the operating mode of the device, you need to press the S1 button and hold it for 4 seconds. At this time, the display will display the following numbers: 01, 02, 03, 04. Information about the modes: 01 is intended for working with engines in which the pulse is applied to one spark plug once per operating cycle, symbol 02 - once per 2 operating cycles , 03 - once every 4 cycles of operation, value 04 - the tachometer function is disabled and the engine hour meter is turned on on the display.

- To activate the countdown mode until service, you must press and hold buttons 1 and 2 together for 4 seconds. Two segments with numbers from 00 to 09 will appear on the screen. They can be changed. The device automatically turns on the engine hour mode.

- To view the current time until service, you need to press and hold the S2 button.

- To reset the hour meter to zero values, you must press and hold the S1 button. You must hold the button above the date until the numbers 05 appear on the display.

Do-it-yourself tachometer for a chainsaw

2 years have passed since the purchase of the chainsaw, the speed of the working stroke has “gone”, the official Husqvarna service center in Saratov does not know how to set it up properly, so I decided to do it myself.

But I couldn’t determine the rotational speed from the sparking frequency, I drank all the beer in the garage, but I still didn’t understand how to calculate it, can you help?

Assembled the adjustment stand:

Following the advice on the forums, I built a capacitive coupling (I wrapped the signal probe around the handle, I didn’t really believe that it would work, however.)

I started the chainsaw and started to warm it up: (frequency 510Hz)

The numbers were puzzling, but they are strictly consistent and change strictly from changes in revolutions with the frequency of the frequency meter. more warm-up (frequency 520Hz):

After warming up, I went to idle (frequency 400Hz):

Operating speed (frequency 13300Hz and 13700Hz):

According to logic, you need to convert the frequency in hertz (times per second) into rpm, and since it’s a 2-stroke engine, divide it by 2. So, no matter how much you divide or multiply, the result is nonsense. It turns out that the speed and frequency on the generator correspond 1:1, but how can this be?

__________________ [Links only visible to registered users. ]

[Links only visible to registered users. ]

yeahhhhh. You're pretty confused.

reveal a terrible secret: why such a tweezer?

Esicho: I have rebuilt my chainsaw once in 8 years. ito. aurally.

I have never adjusted my saw in 12 years. But having bought a Huksvarna scythe, after 2 years I encountered the problem of adjusting the carburetor (the engine is basically the same, the adjustments are the same). I was too lazy to take it to the service center, so I did it on my own. I started with the adjustment at low speeds (2 screws next to each other, one is responsible for low speeds, the other for medium speeds, the manual says which is which). So, with the car warmed up, I sharply increase the gas, and it tries to stall. This means the mixture is lean, unscrew the small (or medium, I don’t remember) screw COUNTERclockwise, well, about a quarter to begin with. We check how the speed is gained when the damper is opened sharply - the reaction should be almost immediate. If the engine is not going to stall, but is reluctant to pick up speed, then this screw needs to be tightened a little clockwise. In this way, tuning the engine at low (medium) speeds is quite simple and quick. The situation is more complicated at high speeds. It somehow didn’t work out for me to do this procedure intuitively, by the power delivered at high speeds, or by the sound of operation (as some specialists advise). But after thinking a little, I can suggest the following method, maybe not very fast, but in my opinion IMHO very effective - the scythe did not work so “predatorily” even in the first months. So, the trick is this. You need to listen to how the engine operates at high speeds when the gas in the tank runs out. If the engine speed increases before stalling, then the mixture at high speeds is too rich, the high speed adjustment screw must be screwed in clockwise, and if the speed drops slightly before stalling, the screw must be turned out. I tightened the screws in quarter turn increments. To adjust the carburetor in this way, I used 3 fills (tank). But you still have to work! But then my braid gained a “second wind.”

This is my personal experience, maybe it will help someone.

3000 idle and

11500. 12000 full throttle. I calmed down, but not for long: in the evening I started sawing a tree, after a minute of work, all the defects were repeated: the chainsaw at full throttle starts to stall after a few seconds - switching to idle and full throttle again saves the day. So I finished sawing the tree, constantly gassing it.

Tells me that there is a problem with the fuel somewhere. (the gas tank vent valve or fuel intake is clogged) or somewhere else. The weekend is coming soon - I'll be back in the garage looking for the cause of the problem.

__________________ [Links only visible to registered users. ]

[Links only visible to registered users. ]

Related Posts

- The correct sharpening angle for circular saw blades

- Husqvarna 365 xp chainsaw does not start

- Champion 241 saw starts and stalls

- How much oil does a chainsaw need?

- How to properly disassemble a Partner 350 chainsaw

Tachometer for chainsaw. How to adjust a chainsaw carburetor using a tachometer

Hand chainsaws are currently widely used both for felling trees, trimming branches and future firewood collection, and in the construction of wooden houses and various buildings for household purposes. Like any other tools, these devices (quite reliable) require constant maintenance, and from time to time, options. For example, a tachometer for a chainsaw will allow you to effortlessly not only check the properties of the newly acquired tool, but also make the following carburetor adjustments without the help of others.

The principle of operation of a tachometer for a chainsaw

A tachometer is a device that measures the number of engine revolutions in one minute. It is virtually impossible to connect a mechanical device to a tool with an internal combustion engine (well, it’s not necessary). A modern tachometer for a two-stroke chainsaw engine is a digital device that reads pulses from a spark plug insulator or high-voltage wire at the moment of spark formation (without a specific contact). The integrated processor converts the pulses into engine speed. The readings are shown on a comfortably readable LCD monitor. Depending on the manufacturer and design features, the cost of such devices varies from 950 to 6,500 rubles.

Wired tachometers for chainsaws

The most common devices for controlling chainsaw engine speed are models with a wired connection. Their popularity is justified by their low price. Various models of electric tachometers for chainsaws from the Chinese manufacturer Runleader currently cost 950-1850 rubles.

What to buy

Buying a tachometer for any outboard motor is quite simple these days. And there is a choice. An affordable device from China or buy an expensive but branded speed meter?

Strictly speaking, both of these devices have the same properties:

- Quite clear image on the display.

- Corresponds to the engine stroke indicators.

- Easy to use.

In addition, there are tachometers that can display, in addition to engine speed, such indicators as:

Most often, universal models are installed. There is a tachometer in the trade plus an hour meter for a marine engine, which, in addition to revolutions, also shows other useful information. This way you can monitor engine wear and prepare for repair or maintenance work on this engine.

It is clear that universal tachometers will require the installation of additional specialized sensors, the installation of which is quite complicated.

For the majority of users, the following are important:

- technical characteristics of the meter;

- ease of installation work for the selected type of device;

- tightness;

- sizes (the more compact the better);

- price.

For digital devices on a boat engine, the following is also relevant:

- speed of message updating;

- brightness and image accuracy.

We have already told you that the range of tachometers from various manufacturers is quite extensive.

But if the boat has an engine from a brand, say, “Mercury,” then, obviously, it is important for the owner that devices from the same company are installed on the dashboard in order to maintain the design of the boat in the same style. In addition, original parts are a priori of higher quality and reliability, despite their high cost.

Although, it must be admitted that for suspended units the terms “original” and “non-original” are very conditional. Manufacturers of such motors, as a rule, do not have a production base for the production of measuring equipment. There are third-party partner companies for this.

For example, there is this one. It is quite well known as a manufacturer of aftermarket measuring equipment for the powerboat market. And, nevertheless, meters for Mercury engines are produced by Teleflex Marine.

So, let's summarize. It is not at all necessary to focus on an expensive brand of meter, but rather to focus on a boat device that, in appearance, most closely matches the overall design of the vessel, and not its engine. Of course, a very important factor is the price between the “original” and “non-original” device.