Any car owner knows well that his vehicle has an additional window with arrows and numbers - a tachometer. Meanwhile, many car enthusiasts do not attach importance to this and do not even imagine what it is needed for. However, if there was no need for a tachometer, then the designers would not place it on the dashboard. What is the device used for? What is this device and what does it show?

Principle of operation

Drivers who do not understand the mechanical components of the engine must know how the tachometer works in a car. This will help them understand what this device is intended for.

The operation of the motor is based on the transformation of movement (from translational to rotational). This is facilitated by gases that expand and “turn on” the pistons. They, in turn, use connecting rods to spin the crankshaft. Its speed is precisely shown by the tachometer.

The driver, by pressing the gas, forces an increased amount of fuel into the combustion chamber. The pressure increases accordingly, thereby increasing the crankshaft speed and instrument readings.

To make it even clearer how the device functions, we will give a simple example. Let's say the information in the engine documentation reads: 135 horsepower at 3500 rpm. These values indicate that the engine will achieve maximum acceleration at a given crankshaft speed. Low rotation rates will reduce efficiency, which means the machine will move more quietly.

Experts say that if the driver monitors the tachometer readings and switches gears in time, he will achieve effective acceleration. But it is still not recommended to carry out such manipulations constantly. If the speed increases, it means that fuel consumption will also begin to increase. In addition, high speeds will lead to rapid wear of parts. It is best not to “crank” the motor to maximum values. This will help save fuel and extend the life of parts and oil fluid.

What is this?

A tachometer is a device located on the dashboard of a vehicle. It is installed not only in cars, but also on motorcycles and motor boats. The device was first created in 1903, when an American engineer built a cyclometer. The invention made it possible to calculate bicycle mileage. But what is a tachometer for in a car? The tachometer helps to monitor the operation of the engine, since there is a risk of engine damage when operating at high speeds.

Advantages of the device:

Helps extend the “life” of the engine.

Regulates the amount of fuel consumed.

The driver gets the opportunity to set the correct driving mode.

There is no shock effect on the transmission during gear shifting.

It turns out that the tachometer shows the car owner the best moment when to change gear. If the car has a manual transmission, then the device shows the moment of maximum load (the arrow “approaches” the red zone). The adjustment can be made while driving or at idle speed.

If the driver follows the indications, that is, starts and ends the movement within a given range of rotation of the crankshaft, then the engine resource will increase to the maximum.

In addition, the owner has the opportunity to independently diagnose the functioning of the motor. If the “engine” is working properly, then when it starts, the needle approaches 1000-1200 rpm, and after a couple of seconds drops to 600-800 rpm. A jumping arrow indicates that the motor is not operating properly.

How to use a tachometer correctly?

Not everyone knows what the numbers on the tachometer mean. They are especially important for a driver who cares about the engine of his car in winter. The data shows the readiness of the engine for full operation. This is important because some modern and Soviet cars do not tolerate starting well without warming up. As a rule, drivers wait until the antifreeze temperature is optimal and then start driving.

With a tachometer, it is much easier to control the optimal moment to start moving. You can start driving when the needle on the device reaches 750-800 rpm at idle start (in some brands of cars this figure may be higher). At this moment, the engine is already warmed up, and minimal fuel is consumed for this.

For optimal overclocking, you must adhere to the following algorithm:

Speed ranges

Let's start in order. The very first rule that you must remember: when changing to another gear, be sure to depress the clutch first. The pedal is released after the desired speed has been reached. Beginners find it difficult to navigate, and during switching they lose control of the vehicle.

In order to change gears on time and make the vehicle move more dynamically and economically, a scale of the so-called speed range was developed. So there is the following gradation, which tells us when and at what speed we move the gearshift lever to the next position.

The photo shows the values for the most intense overclocking. For measured driving, the values are given below (these are approximate values, specific numbers depend on the transmission ratio of your car):

- 1st gear, driving mode from 0 to 20 km/h;

- 2nd, 20–40 km/h;

- 3rd, 40–60 km/h;

- 4th, 60–80 km/h;

- 5th, over 80 km/h.

However, the specified speed limits apply to vehicles without transported cargo and when driving on roads with normal pavement. If you are driving off-road or the car is additionally loaded, then you need to change gears a little later, giving the car the opportunity to accelerate well. This is especially true for situations when you have to climb a steep slope.

How to use the information

The instrument scale contains information about the crankshaft rotation speed. By squeezing the gas pedal, the speed increases. The tachometer needle moving into the red zone indicates that the engine has reached the peak of its power and is operating in emergency mode.

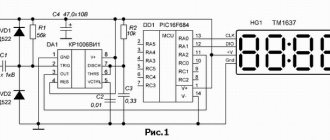

Connection diagram

The tachometer indicates the critical speed for a particular engine. When the crankshaft rotates at the maximum speed for the engine, vibration increases and heating accelerates - this can damage the pistons, liners, and break or stretch the timing chain.

Based on the readings of the device, switching during transmission, the driver can:

- reduce fuel consumption;

- reduce wear of piston group parts;

- choose the right travel mode.

Each tachometer is customized for a specific class and engine type, so they cannot be reinstalled on different car models.

Important nuances

Ideally, the car should drive without jerking, moving from one speed to another. When buying a used car or a new car, all buyers always look at such a detail as the type of gearbox used. Objectively, the easiest car to drive is considered to be an automatic transmission. But it is important to understand that there are a number of types of gearboxes, and not a simple division into manual and automatic. We recently studied with you the features of sequential gearboxes, and also got to know the variator in more detail. I advise you to re-read and update your own knowledge regarding automobile gearboxes. In terms of reliability and durability, classical mechanics still firmly holds the first position.

When used correctly, the car can accelerate quite quickly, squeezing the maximum out of the installed engine. But when the engine is powerful, and the driver does not know how to shift correctly, then no amount of horsepower will help you.

One general principle applies to all manual transmissions. It consists in the fact that first the clutch is depressed, then the speed is switched, after which the clutch pedal is lowered.

This is interesting: Car air conditioning from the cigarette lighter - we take the “weather” with us!

We accelerate according to the tachometer

Many drivers use the following scheme:

- acceleration is carried out in first gear (from idle speed to 3800 per minute) and switching to second gear;

- there is an inevitable drop in the number of revolutions from 3800 to 2300;

- acceleration in second gear (rpm increases from 2300 to 3600) and transition to third;

- drop in the number of revolutions from 3600 to 2400;

- acceleration in third (increase in speed from 2400 to 3500), switching to fourth;

- reduction in speed from 3500 to 2500;

- acceleration in fourth, etc.

When the need for maximum acceleration arises, it requires turning the engine at maximum speed (about 5500 rpm). Acceleration will be faster, but fuel consumption will also increase and wear on engine parts will increase.

It is, of course, possible to accelerate at idle speed. But such an action reduces the life of the motor significantly. Fuel consumption increases noticeably.

Why is it needed in a car?

In response to the question posed, I would like to immediately say that the proper use of a tachometer allows you to use the engine’s capabilities at 100%!, but absolutely without compromising the latter.

Video - an example of self-installation and connection of a tachometer:

If you look at the technical characteristics of any car, you can see that in the description of its parameters there are such lines as maximum power and maximum torque. Moreover, both of these indicators are based on values depending on engine speed.

For example: “125 hp.” at 3500 rpm" or "470 Nm at 4000 rpm". This means that the engine develops its maximum declared power precisely at this crankshaft speed (or, accordingly, the greatest traction force). And before and after the specified values, the power or effort will be less.

Thus, by maintaining the engine crankshaft speed within the limits specified in the specification and changing gears in time, you can obtain, for example, the best acceleration - the entire “herd of horses” will be involved.

However, while being carried away by maximum acceleration, one should not forget about efficiency and engine life.

Maximum power implies slightly increased fuel consumption, although lower than when the engine is “overclocked.” Therefore, when driving, using speeds slightly lower than the maximum power, you can get quite serious savings, especially when traveling long distances.

We recommend: Tiptronic – what is it and how to use it

The advantage of such operation is the increase in the resource of the internal combustion engine, because maximum power also implies maximum wear.

Important! Frequent and excessive reduction of engine speed not only does not lead to fuel savings, but, on the contrary, to an increase in consumption. As well as a significant reduction in the resource of the internal combustion engine itself.

So, what did we find out? Having a tachometer in a car allows you to at least:

- get maximum power;

- get the best traction force;

- save fuel;

- increase engine life.

Malfunctions on Priora

Speedometer.

If the speedometer on a Priora stops working, the first thing you need to do is temporarily remove the terminals from the battery.

Did not help? – Then look for a fault in the device circuit. First, check the integrity of the instrument panel fuse.

If it burns out, replace it (but first make sure that all contact connections are intact).

If the problem persists or the fuse is normal, check all the wires on the path from the speed sensor to the instrument panel. This can be done using a multimeter.

If there are no complaints about the wiring, check the motion sensor with a special scanner. If there are malfunctions, the element must be replaced.

The serviceability of the motion sensor can be determined by the behavior of the odometer. If the speedometer does not work, but the odometer counts kilometers, then the sensor is working, and the breakdown must be looked for elsewhere.

For example, problems may be in the soldering on the dashboard circuit board or, even worse, in the gearbox. But this can only be found out at a service station with the help of a qualified technician.

Tachometer.

As for the tachometer on the Priora, there are three causes of malfunctions:

- violation of the tachometer supply circuit. In this case, you need to carefully crimp all the tips and replace damaged wires (if any);

- violation of the functionality of the controller (the signal does not reach the tachometer). Only replacing the device will help here;

- failure of the tachometer itself. This option is the most expensive, because it is not possible to change the device separately - you need to buy a new panel.

Construction and details

Everything about the carburetor: what it is, types, structure, principle of operation, what it is needed for, diagram and photo Since the diagram is simple, I did not develop a printed circuit board. All parts, except the milliammeter, were installed on a universal breadboard measuring 30 mm×50 mm. The photo shows how the elements of the circuit are placed.

A three-pin connector is used to supply the supply voltage and input signal. The milliammeter scale is printed on a printer and glued on top of its standard scale.

The board with the parts is secured in the cover of the strobe housing with screws. The milliammeter is installed in a rectangular window cut out in the housing cover and secured with silicone.

This design for placing the tachometer provides easy access to the strobe board; just remove the cover and disconnect the connector.

How to connect a digital tachometer?

Not all cars are equipped with a digital instrument system. However, automakers produce special kits that you can install yourself. The standard set usually consists of a digital display and a wiring harness that connects to the ECU and power.

There are also special kits that include an additional idle speed sensor and an external optocoupler. Their use is only advisable on sports cars; for normal driving, a standard set of devices will be sufficient.

Connecting such a tachometer is not always done through the computer. Many kits provide for mounting the device separately from the controller. Such a set of devices will have more accurate readings than a direct connection to the control unit.

Types of devices

Car tachometers are classified:

- by the method of signal processing;

- connection method;

- operating principle.

Mechanical

The device is used on low-speed engines. The design of a mechanical tachometer is extremely simple. A cable sensor is installed on the camshaft or crankshaft. The torque is transmitted to the gear and through a cable to the moving coil of the device through an electromagnet, which is the main part of the mechanical structure. Changing the crankshaft rotation speed changes the magnetic field, which deflects the instrument needle.

A mechanical tachometer has the greatest error - up to 500 rpm.

Analog

An analog device is 50% more accurate than a mechanical one. It has the same graduated speed scale, but differs from mechanics in the way the signal is transmitted. The main elements of an analog device are a magnetic coil and a sensor. The analog tachometer is connected not to the crankshaft, but to the engine ignition coil.

The ignition coil converts voltage from 12V to 24,000V to produce a spark. Simultaneously with the supply of a pulse to the ignition coil, the pulse also goes to the electrical circuit of the analog tachometer and enters the electromagnet winding. The more pulses enter the circuit, the higher the induction. The deflection of the jackal's needle occurs under the influence of a changing magnetic field. Analog ones show an error of up to 250 rpm.

Digital

The digital tachometer today is considered the most reliable - the error is up to 100 rpm. The processor receives data from the crankshaft sensor and idle speed sensor. For this purpose, the design of the digital device includes an optocoupler (optocoupler) - a sensor for counting the intervals between pulses. The design of a digital tachometer uses the following elements:

- optocoupler;

- CPU – central processor, the node performs calculations from sensors;

- liquid crystal display – displays information on the dashboard;

- microcircuit – resets processor data.

Digital tachometer

There are several types of connecting a tachometer to a car, depending on the engine class and model.

On gasoline engines, the connection is made through the ignition coil. The tachometer has two outputs: to the ECU (electronic control unit), to the crankshaft position sensor. The connection goes through the following stages:

- The tachometer is installed on the dashboard.

- Negative, the wire is connected to the ground of the car.

- The red wire is connected to the positive of the ignition switch.

- The device input wire is connected depending on the ignition system. If the ignition system is contact, the distribution of the spark among the cylinders is regulated by the distributor, and the tachometer is connected to the distributor breaker. If the ignition system is non-contact, the tachometer input is connected to the voltage switch.

For diesel engines, the tachometer is connected to the generator, since the crankshaft speed is read not from the ignition coil, but from the generator terminal. This is due to the operating procedure of diesel internal combustion engines, which are less revving than gasoline ones. Each diesel tachometer connected to the generator is calculated for a specific gear ratio between the engine and the generator.

A tachometer for a diesel engine is not so simple, but...

Since the operating principle of a diesel engine is completely different from the operating principle of a gasoline engine, in particular, in the absence of coils and spark plugs, the principle of connecting the tachometer is completely different here. Although, in any case, you need to get the number of revolutions from somewhere.

In most cases, to calculate the number of crankshaft revolutions in a diesel engine, the number of revolutions of the generator is taken as a basis.

To connect a (mostly electronic) tachometer to a diesel engine, you need to find the terminal marked "W" on the car's alternator.

The bottom line is that this terminal allows you to obtain pulsed values of the alternating current of the generator. And the higher the pulse frequency, the higher the crankshaft speed.

The only inconvenience is the calibration of the tachometer. After all, in order for the tachometer to show the necessary (and accurate!) values, you must first set the initial values. As a rule, a diagnostic stand is used for this, which allows, when connected to an on-board computer, to first take readings from the control unit, and then calibrate the tachometer itself.

The second most popular method is to connect a tachometer to the terminal of the EGR control unit, which has an output for connecting a tachometer. In this case, information for the tachometer is taken based on the readings of the operation of the exhaust gas recirculation valve.

Switching process

When driving straight and during a turn, the driver needs to change the current speed set on the mechanics.

This is done according to a certain algorithm, which can be represented as follows:

- With a tight movement, the clutch pedal is pressed to the floor with the left foot;

- At the same time, you must release your foot from the gas pedal;

- smoothly but quickly select the desired gear on the box;

- when passing the lever, you first return to neutral, and then to the required speed;

- then the clutch is released;

- at the same time, work begins with the gas pedal so as not to lose speed and revolutions;

- After the clutch is fully released, good gas is added.

There are no strict and rigid restrictions in terms of the sequence of transitions at speed. Nobody forces you to shift in a strictly specified order, from 1st to the last gear.

But if you skip speeds, then you will have to spend more time accelerating and the speed will begin to drop.

DIY electronic tachometer

With the wide possibilities of the electronics market, it is not difficult to make a tachometer circuit at home using a multimeter. Moreover, the results obtained in such circuits are accurate in assessing the overall operating condition of the system being measured.

Circuit diagram using IC 555:

- The pulse is taken out from the scooter's spark plug and fed to the end of R6.

- The transistor responds to impulses in accordance with triggers.

- The transistor activates monostability with each incoming pulse.

- The monostable remains on for a certain moment, and when triggered, generates an average on-time output that is directly proportional to the average startup speed.

- The capacitor and resistor at the output of the IC combine the result so that it is directly read by a 10V voltmeter.

- R3 is adjusted so that the output generates an accurate interpretation of the RPM feed rate.

The above adjustment is made using a conventional tachometer. Parts for manufacturing are widely available and can be purchased at any radio supply store. List of parts for the homemade version:

- R1 = 4K7.

- R2 = 47E.

- R3 = 100 KB, may be variable.

- R4 = 3K3.

- R5 = 10K.

- R6 = 470 K.

- R7 = 1K.

- R8 = 10K.

- R9 = 100K.

- C1 = 47n.

- C2 = 100n.

- C3 = 100n.

- C4 = 33uF / 25V.

- T1 = BC547.

- IC1 = 555.

- M1 = 10V FSD meter.

- D2 = 1N4148.

- C5 with any value between 3.3uF and 4.7uF.

Before you make a tachometer with your own hands, you need to complete the installation documentation. A simple circuit designed using readily available elements with a rubberized MOC7811 opto-isolator module and two seven-segment displays measures disk speed in RPS. This circuit calculates RPS from 00 to 99; if larger values are needed, another decade counter is added.

The circuit diagram contains IC555, MOC 7811, IC CD4081, IC CD4069 and IC 4033 and a seven-segment LTS 543 display unit. On the first timer IC 555, configured as a monostable multivibrator, it generates a clock pulse when switch S2 is pressed, green LED 1 indicates the detection time .

Tachometer installation methods

Today there are only two options for installing tachometers. In the standard configuration of the car, this method is always the same, but if the driver wants to replace the device with another or he is simply dissatisfied with the location, then he will have to take the second path. The installation is as follows:

- On the car panel (standard) . In the vast majority of cases, the tachometer is located to the side of the speedometer. The device is part of the basic equipment of the car and, according to many car enthusiasts, it is located, from a practical point of view, not in the best way;

- The device is placed behind the panel . In this case, the tachometer is mounted on the dashboard of the car, i.e. higher than all other car devices. Firstly, this is an interesting design change. Secondly, such a tachometer is more noticeable. There is only one problem: today, most tachometers on the market are analog, the information from which is more difficult to read than from digital ones.

Each of the options is good in its own way, so here the driver should rely on his preferences. Modern tachometers are equipped with backlighting - this huge advantage also has a disadvantage. Remote devices “loom” right in front of the eyes and can tire the driver. And if the tachometer is located close to the speedometer, then it will not attract undue attention to itself.

How the device works and what it measures

The tachometer is a very important component of the car. It helps to use engine resources to the fullest without consequences. Each engine has its own technical characteristics, which indicate the highest torque and maximum power depending on the speed. It is these parameters that the tachometer measures, giving the driver the opportunity to maintain speed within acceptable limits and change gears in a timely manner. So, for example, you can achieve the best acceleration, traction gain and even fuel economy.

Note: a constant decrease in speed significantly increases fuel consumption and reduces the life of the internal combustion engine.

The principle of operation of the tachometer is simple: the device captures and records the number of impulses from the sensors and displays the received data in the form of certain values (hours, minutes, seconds, meters). The accuracy of the device is approximately 500 rpm and varies depending on the type of device. Tachometers are divided according to the principle of data display and installation method. According to the second criterion, they are standard and remote. Remote tachometers are used primarily in motorsports for thorough speed correction. The device also signals the achievement of certain indicators. Let's take a closer look at the varieties of tachometers we are used to.

Is it possible to determine the speed of movement using the device?

As already mentioned, tachometer values can be displayed in different quantities:

- In time (hours, minutes, seconds);

- In distance (kilometers, meters, centimeters, etc.);

- In units;

- In speed (m/s, km/h).

To determine the speed using the tachometer, you just need to change the way the information is displayed on the display. Note that this is only possible in those models that display different quantities. You can also find out the speed on earlier models by examining the existing device and comparing the units of measurement.

Which tachometer to choose

Car tachometers use magnetic induction during the measurement process, which controls the pointer needle on the dial. They require periodic calibration and repair. The error when measuring using an analog device is 10% (500-600 rpm). This type of device is more common; when driving a car, it is its readings that are more easily perceived by the eye.

A digital tachometer displays measurement data on an electronic display. There are digital tachometers that completely imitate the appearance of analog ones with arrows, but more often there are simple ones - with a digital panel. The error in measurements using them is 3-4%, which is much lower than that of analog equipment.

Indispensable when determining car economizer thresholds, or when adjusting interaction with electronic units. In short, accurate measurements cannot be made without this device.

By location, you can distinguish between a standard and remote tachometer. Standard models are so called because they are usually included in the set of vehicle devices. If the tachometer is pointer, then it is located next to the speedometer, and a digital tachometer is often attached to other devices.

It makes sense to purchase a remote one if the car is not equipped with a tachometer. Typically used in motorsports where precise control of engine speed is required.

Where is the tachometer used?

Although a tachometer is usually called a device located in a car, its range of uses is very wide. It is widely used to read the speed of rotation of moving parts in mechanisms, machines, units (disks, various shafts, etc.).

In addition, the device is used in calculating the wear of mechanisms, equipment elements, raw materials in the operation of conveyors, liquid and gaseous media in pipes. When running in machines and machines, to measure the operating time of equipment.

The test result can be translated into measurements in meters and minutes that only the driver can understand.

Varieties

Many drivers are interested not in what the tachometer measures, but in how exactly it does it. The accuracy of determining the speed depends entirely on the sensor. Today, devices are classified according to the method of displaying data or the method of installation. The latter are divided into built-in and contactless. On sports cars, non-contact tachometers are mainly used to determine the speed as accurately as possible and adjust it.

Mechanical, analog and digital tachometers are installed on cars today. They all have their own characteristics and operating principles. For example, the mechanical type has already lost its relevance. It was used in the 20th century, since there were simply no other options for measuring revolutions. Today, such a tachometer can be found on very old cars or motorcycles.

The design of the device includes a cable connected to the crankshaft. The operation of the device was based on the fact that the gear and cable interlocked with each other. Tachometers were successfully installed on old low-speed engines. They had rather low accuracy due to the fact that the cable consisted of wire. The thread was twisted, which led to incorrect calculation of the transmission torque. The error level was 500 rpm.

The analog tachometer was invented later. The mechanism of action has been changed. Its operating principle was similar to a mechanical one, but the revolutions were displayed by an arrow on the dial. The values were read using the energy supplied to the magnetic coil. There was a sensor on the crankshaft that calculated the number of revolutions, after which an electrical signal was created that passed to the coil. She deflected the arrow and showed the result. Compared to a mechanical device, an analog one is more reliable, but still not accurate. Its error is 500 rpm. The advantages of such a tachometer include the absence of a cable and simple installation.

It's no secret that even expensive cars install an analog type of device. It is familiar to the driver’s eyes, and quickly calculates readings. With its help, the car enthusiast will be able to catch the moment to change gears, as well as help the engine achieve optimal operating mode.

Another type of tachometer is digital, it works with a small error (100 rpm). A special sensor counts the revolutions and then redirects them in the form of signals to the instrument panel. The device includes a processor, converter, optocoupler and several other essential elements. The connection method is different, depending on what type of engine the car has. On gasoline engines, installation is carried out through an ignition coil, on diesel engines - using a generator.

When to switch

Switching should be smooth, but at the same time fast.

Many are rightly interested in when exactly it is necessary to switch from one speed to another. Although there are different cars and boxes, there are averages. Namely:

- The first speed is intended mainly for starting, and is not used for active driving. The current speed here is from 0 to 20 kilometers per hour;

- The second speed is accelerating and is used for movement at low speed in the range from 20 to 40 kilometers;

- The driver must switch to third when he needs to accelerate from 40 to 60 kilometers per hour;

- The fourth is suitable for speeds from 60 to 80 kilometers per hour;

- Fifth and sixth speed for driving over 80 kilometers per hour.

These numbers are approximate and average, as there are a number of other factors that affect driving.

The presented diagram is relevant for cars that are not loaded and move along the road without resistance in the form of sand, deep snow or steep inclines. If there is such resistance, then it is recommended to switch to the next gear a little later.

Motorists and driving instructors have developed a useful reminder that they recommend that a beginner remember. The bottom line is this:

- It is always recommended to use first gear solely for starting;

- After the start, you should immediately turn on second speed;

- Second gear serves as acceleration speed on a manual transmission;

- The third is optimal when overtaking;

- The fourth performs best when driving in urban conditions;

- The fifth and sixth are used for expressways, highways and highways.

You can also shift out of order if necessary, shifting from high to low to apply engine braking.

There are a number of visual videos on the Internet about how to properly operate the gearshift lever on a manual car. Both high and low gears are discussed in detail.

What does a tachometer measure in a car?

The purpose of the device allows you to use the resources of the car engine without consequences - that’s what the device is used for. The tachometer greatly helps reduce wear on engine parts. Each engine has individual technical characteristics that determine its final performance. These parameters depend on the maximum permissible torque and maximum power, adjusted for speed. A tachometer is a device for measuring the listed parameters.

Thus, the main function is to provide the driver with data on the basis of which the number of rotations can be monitored and the gear used (lower or higher) can be changed in a timely manner. This applies to vehicles with manual transmission.

Here are some examples of the usefulness of a tachometer:

- If the engine constantly operates at low speeds (up to 2000 rpm) , then fuel consumption will be low, but some problems may occur. If you abruptly engage a high gear, the internal combustion engine will begin to work under high load. The combustible mixture will not burn completely and as a result, carbon deposits will form on the cylinders, pistons and spark plugs. And when operating at low speeds, poor lubrication of the unit components with oil occurs, as a result of which their wear increases.

- If the engine constantly operates at high speeds (over 4000 rpm) , this will greatly increase gasoline consumption. The engine will overheat, its components will wear out faster, and the oil will quickly lose its performance properties.

The most optimal indicator for the engine: from 1/3 to ¾ revolutions of maximum power. And this indicator can be read in the technical documentation of your car brand.

In total, there are 3 zones of tachometer operation: green, yellow and red. If the rotation indicator is in the green zone, then the car will have weak dynamics. If the indicator is between the green and red zones, then the engine will consume more fuel, but the power will be maximum.

Attention! Understanding how your car's tachometer works can improve its productivity. Numerical indicators displayed on the display help the owner achieve better vehicle acceleration and traction with minimal fuel consumption.

The general principle of operation of the device is simple. It consists of recording the number of pulses coming from certain sensors. Such indicators are transformed through special mechanisms into individual values. In this case, the engine tachometer has only relative accuracy. For older devices it is conventional, reaching 500 rpm. Electronic devices read data with less error. A constant decrease in rotational power leads to increased fuel consumption and wear of internal combustion engine parts.

Another good article: Car bumper: what is it, types, where is it located, what is it for

Interestingly, diesel engines have a smaller rotation range. For example, the green zone for proper gear shifting starts from 1500 and reaches 4000 rpm. And for large trucks this figure is even lower - from 1500 to 2500 rpm. Therefore, it is best to change gears in the green zone in order to reduce fuel consumption and increase the service life of the internal combustion engine.

Additionally, the tachometer is used for adjustment repairs at idle speed. I note that when starting the engine, the speed should not exceed 900 rpm. And if the start is carried out on a cold basis, then the indicator can reach 1500 rpm. If the revolutions are above 1000 revolutions, and the car is standing still, then this may indicate a breakdown in the idle speed regulator, which will lead to significant consumption of gasoline. At idle, the values should be constant without fluctuations from 500 to 1500 rpm!

The main function of the tachometer

The main function of the tachometer should be considered to facilitate the selection of the correct gear, which, of course, extends the life of the engine. We can talk for a long time about what the engine speed should be when changing gears, during forward motion, and when braking (accelerating). It should be remembered that practical advice for a diesel truck will not apply to a 16-valve gasoline engine in a passenger car. Let's limit ourselves to the main ones.

At low speeds there is less fuel consumption, but this is only partly true.

The engine pull at low speeds is not high. If it is necessary to overtake or overcome any serious climb, a lover of this style will be forced to press the gas pedal to the floor. In this case, the mixture becomes richer, and all the savings achieved fly out into the exhaust pipe.

Another aspect: engine life. At first approximation, the answer is obvious: lower engine rotation speed means lower relative speeds of movement of parts, which naturally reduces wear. But there are pitfalls. The operation of the oil pump is directly related to the number of revolutions. Low engine speeds lead to “oil starvation” of the liners. They are starting to wear out. In this case, wear will progress as the gaps increase.

You should know that when driving at low speeds, shock loads are inevitable, both in the engine and transmission (try to release the clutch pedal with low gas, the car will jump unnaturally), which also does not lead to anything good.

The other side of the coin: long-term operation when the tachometer needle is near the red sector (more than 4000 rpm) will not benefit the engine.

The cooling and lubrication systems involved in the process operate without the slightest margin of safety. If non-critical defects occur (the radiator is clogged, the thermostat has failed), the arrow indicating the engine temperature moves to the red zone. Poor quality oil or lubrication channels clogged with dirt will cause scuffing on parts. The problems can be even more serious: even the camshaft fails. Fans of fast driving should absolutely not lose sight of the tachometer and temperature gauge readings. A fully serviceable motor, filled with high-quality oil, will withstand maximum loads without difficulty. Yes, its resource is reduced, but without catastrophic consequences.

As always, you should stick to the golden mean. The required number of revolutions depends on the specific situation. Experts note that the optimal mode is in the range from a third to three-quarters of the number of revolutions at maximum power. As a rule, for most modern passenger cars the figure is from 2500 to 4000 rpm.

The design and principle of operation of the tachometer

The structure of tachometers of different types is discussed in the table “How different types of tachometers are constructed.” If the table is not completely visible, then move it to the left.

| View | Design |

| Mechanical | The main part is a cable, using which the device is connected to the engine crankshaft. The other side of the circuit component is located behind the instrument scale. During the rotation process, the central pulley wraps around inside the casing, and the torque is transmitted to the gears, which provoke the movement of the arrow. |

| Analog | There are no visual differences between mechanical and analog devices. Externally, these devices look the same, but the device of the second one is more complex and this allows for increased accuracy. The device itself consists of 4 components: sensor, magnetic coil, pointer, scale. |

| Digital | Electronic – accurate when compared with other options. It consists of an optocoupler, processor, sensor and digital display. |

Interesting! Which sensor is responsible for the tachometer? These are the crankshaft and idle speed sensors, as well as the electronic control unit.

The functionality of the devices is ensured according to the following scheme:

- After activation of the ignition system, the engine starts. The fuel mixture ignites in the chamber, which provokes the movement of the connecting rod.

- The chain component starts the rotation of the engine crankshaft.

- The tachometer sensor is in the desired position, on one of the circuit sections.

- The mechanism independently reads the number of rotations, creates impulses and transmits them to the control panel of the device. There this signal moves the pointer drive.

- The arrow moves along the scale with the desired resistance and displays a numerical value.

How a tachometer works

In simple words: the crankshaft sensor reads its revolutions and transmits this data to the control unit, which sends a signal to the tachometer.

The accuracy of the devices varies and depends on the type of sensors used. Visually, they are all similar, the main differences are in the way they connect and process data.

Video: How the tachometer works

In this video, the expert talks about the principle of operation of the tachometer, why in some cases it can work without voltage in the on-board network, and in what cases it cannot do this.

About mechanics and automatic machines

Despite the fact that automatic transmissions have ceased to be a curiosity for our fellow citizens, traditional mechanics are still popular and widespread. To avoid having to spend money on a new gearbox, it is important to understand the basic rules and techniques for smooth gear shifting.

The mechanics are designed to smoothly and evenly distribute the torque produced by the engine. A manual transmission, which is commonly called mechanical, usually includes from 4 to 6 different gears, but most often on modern cars there are 5. This is not counting the reverse speed, which is also called reverse. It is the clutch that is the connecting element between the engine and the gearbox. In engagement with the crankshaft, which constantly rotates, is the gearbox input shaft. It is the clutch that allows these units to be separated and connected again without jerking.

What malfunctions can there be

A mechanical type tachometer may be faulty if its structural elements are damaged. For example, if deformations occur, the cable breaks, or play appears. As for electronic devices, there may be several causes of failure. Let's look at them in more detail:

Electrical wiring is damaged, incl. signal wire.

The contacts have oxidized, or they have loose contact.

The elements of the measuring unit are damaged (burnout of microcircuits, swelling of resistors).

If the device is connected to a generator, then the generator itself is not working. A problem is indicated by a low battery indicator. It happens that the needle starts jumping without any reason. The driver should carefully inspect the wiring, engine components and the device itself.

If the device indicators do not change even when the accelerator pedal is pressed firmly, then it is necessary to check the integrity of the wiring. The tester will help the driver with this.

The main mistakes of beginners - what to avoid

There are other recommendations that allow you to understand what a particular gear in a manual transmission is intended for. We need the first to get the car moving, the second to accelerate, and the third to overtake. The fourth and fifth are used respectively for traveling on city roads and country highways.

Beginning drivers make the same typical mistakes. They can't tell by ear that it's time to change gear. Because of this, the engine operates at too high speeds, the car loses speed, and control of movement is lost. Often, beginners cannot get going because they release the clutch pedal too sharply. As a result, the car jerks and stalls. This leads to accelerated wear of some transmission and clutch components. Beginners are often late in turning on second speed. They start the car from a stop, and then accelerate it, forcing the engine to roar annoyingly. At the same time, you can quickly switch from 1st gear to 2nd almost immediately after starting off.

Experienced instructors always teach beginners to take their foot off the clutch pedal immediately after the pedal is released. Firstly, in this case the clutch wears out faster. Secondly, the leg gets much more tired. At the same time, placing the foot on the floor gives the driver an additional point of support and does not put as much strain on the spine. Beginners often suffer from the fact that when changing driving modes, the left hand involuntarily turns the steering wheel, especially if it is in the wrong part of it.

Is it necessary to purchase a tachometer and how to choose the right device?

The requirement to have a device for determining the angular velocity of the motor shaft is not regulated in regulations. The driver makes the decision independently, based on personal needs and financial capabilities. If you replace an old tachometer, you must select a new one taking into account the technical characteristics of the car.

If the car owner has decided to install the device, you should pay attention to the following manufacturers:

- Helios (Russia);

- Multitronics (Russia):

- CEM (China);

- KET Gauge (China - Taiwan).

Is it possible to prevent damage?

The vehicle's tachometer gradually wears out even with careful driving and proper car care. Compliance with a number of recommendations allows you to increase the service life of not only the engine speed sensor, but also other vital structural elements.

Timely gear changes

The tachometer in cars with a manual transmission is designed specifically for this purpose.

Untimely switching results in the engine being subjected to extreme loads. In this case, fuel is consumed unevenly, and the engine resource is not fully used, which leads to overheating and subsequent breakdowns. Therefore, when the tachometer needle approaches the lower or upper limit, it is necessary to switch the speed.

Using quality fuel

Stable engine operation is ensured only when using high-quality gasoline. Wanting to save money, many drivers use low-quality fuel, the composition and properties of which differ from those declared.

Such gasoline negatively affects the pumping system of the car, subjecting it to increased load. In this case, the engine itself is negatively affected, the rotation speed of which does not correspond to the actual fuel consumption.

Warm up the engine thoroughly

The quality of the tachometer largely depends on the operating conditions of the vehicle. Climatic factors are of key importance in this matter. One of the main reasons why the speed sensor wears out faster is driving with a cold engine in the winter season. To reduce the negative load on the sensor, as well as create favorable conditions for stable operation of the motor, thorough warming up before travel is necessary.

Minimize vibration

Strong shaking while driving negatively affects all structural elements of the car, especially the engine and chassis. Also, intense vibration can affect the quality of fixation of tachometer elements and other sensors. In addition, vibration load worsens the quality of fixation of terminals and contacts, which in turn can lead to failure of individual devices due to power failure.

Timely maintenance

A car is a complex multi-component system in which failure of exactly one of the elements inevitably leads to damage to others. Therefore, it is strongly recommended to carefully monitor the condition of the vehicle, and if signs of malfunction are detected, send the car to a service center.

This approach will increase the life of the vehicle and prevent premature failure of the elements most susceptible to breakdowns. Repairing minor problems in a timely manner reduces the risk of more serious damage and therefore saves money on repairs.