Question: Chainsaw Husqvarna 340 symptoms are as follows. If you hold the throttle to max. picks up maximum speed and holds it for 3-5 seconds after which it drops almost to idle and so again you release the handle, press it picks up speed and drops again.

Answer: If you haven’t climbed into the carburetor, then look at the filter in the tank and the mesh in the carburetor. And also the air filter and carburetor settings.

Question: The Husqvarna 340 chainsaw only works at maximum speeds, at medium speeds it choke and stalls almost immediately, you have to constantly add gas.

Before the breakdown, a peculiarity appeared in the operation: when you sharply press the gas, or when you do not have time to lower the gas, and the tree runs out, it begins to squeal almost to the point of whistling. What could have happened?

Today it won't start at all, there is a spark. The candle is dry. I removed the carburetor, the membranes are intact, the metal mesh is clean, the filter in the tank is clean.

I looked through the carburetor window - the piston was free of scuffing and had a matte color. I blew everything out as best I could, put it back together, with 50 jerks it started and stalled, I unscrewed the spark plug, the spark plug was wet, but not damp.

Again I pulled it 30 times, it started up and started running at speeds above average with the choke pulled to the limit, I pushed the choke in, squealed, accelerated, as soon as I let off the gas it stalled, I can’t start it anymore.

I had never worked on suction (at the maximum position) before - it stalled right away. The saw is 4 years old, sawed rarely, did not adjust anything, screws L and H are in the factory positions. Never had any problems. What else could it be?

Answer: Does the throttle valve of the Husqvarna 340 chainsaw close completely when starting? If not, you need to eliminate the air leak through it. Also try changing the spark plug.

There is also a rubber insert between the carburetor and the cylinder, it cracks, and there is also air leakage.

If no one has turned screws H and L, (especially H), then look for air leaks and do not use the saw until you find it! Piston is under threat.

An impulse hose goes to the carburetor. Disconnect it from the carburetor, lower it into a container of gasoline and pull the starter cord.

If bubbles appear, then look for a leak at the place where the carburetor connects to the intake pipe; if there are no bubbles, then either the crankshaft seals or the gasket between the crankcase and the cylinder.

Or maybe you just need to adjust the carburetor, and there are no more breakdowns. After all, we need to start looking for and eliminating the cause from the most probable and from simple to more complex.

It is very, very rare that a saw will outlive its life at the factory settings, without adjusting the carburetor at least a little.

Question: what is the role of the valve located in the carburetor of the Husqvarna 340 chainsaw?

Of course, my location is a little different; I can’t even get to it with a screwdriver. As I understand it, there is a rubber plate with a spring located in the center of the carburetor nozzle. What is it for?

Answer: To begin with, with the carburetor covers, gaskets and membranes removed, check whether the needle valve allows gasoline to pass through.

You need to pour gasoline onto the carburetor mesh, or better yet, carburetor cleaner, and press the needle valve lever from below.

The purifier must pass. Do the same on the reverse side - pour the cleaner into the needle area and press. It should leak through the mesh.

To check the impulse tube, you need to remove the carburetor strut; it is attached at the bottom with two self-tapping screws.

It is a little difficult to put the stand in place so that the tube sits in its place in the cylinder. It will be easier (and most importantly – visible) if you remove the starter.

If the carburetor and pipe are in order, most likely you need to disassemble the engine - something is wrong with the piston or seals.

Question: My Husqvarna 340 chainsaw recently started stalling if I let off the gas suddenly after cutting. This started after I cleaned the air filter.

The saw may have been working for some time with the air filter falling off. I took it apart and noticed this. Perhaps some debris got into the carburetor. If there is no load, then you can accelerate and reset - it won’t stall. And if you drink longer and quit, it stalls.

HUSQVARNA

Technical characteristics of Husqvarna 340

Cylinder volume (cm3) – 45 Max. power, (kW) – 2.0 Max. power (hp) – 2.7 Fuel tank volume (l) – 0.5 Oil tank volume (l) – 0.25 Chain pitch length (inch) – 0.325 Drive thickness. teeth (mm) – 1.3 Bar length (inch) – 15 Bar length (cm) – 38 Dry weight, without cutting equipment (kg) – 4.7 Chainsaw classification – household Country of origin – Sweden

Home page » Carburetor adjustment for Husqvarna 340 chainsaw

Related Posts

The best information about adjusting carburetors on a chainsaw

Greetings to you dear and most faithful readers of my blog. In this article, I decided to look at how to adjust the carburetor on a chainsaw. After all, it seems to me that you have more than once encountered the problem that your “darling” let you down when you needed it most. And because you and I are economical and don’t want to waste money on something we can do ourselves, let’s learn how to adjust the carburetor on our chainsaws with our own hands, without hiring professional repairmen. And as you'll soon see, it's quite easy to do. You don’t even need to do anything special like that. I specifically looked at the adjustment of carburetors of all recognizable brands of saws, each of which has its own tricks and aspects, and in my opinion this is the best information on the network!

Types of plunger pumps

Plunger pumps installed on modern chainsaws are:

Unregulated pumps are usually installed on household-grade tools, for example Yamamoto CS-4552, Husqvarna 135 Mark II, Kruger GCSK 35-45, Husqvarna 120 Mark II. Such units provide a stable supply of working fluid regardless of operating conditions. They have a simple but reliable design. Their disadvantages include the lack of adjustment of the supply of lubricant to the friction surfaces.

Adjustable pumps are installed on chainsaws of semi-professional and professional classes, such as powerful chainsaws from Energomash, American McCulloch, Procraft, Parma. They have a more complex design.

The adjustment function is necessary when the saw is operating under difficult operating conditions, when the amount of working fluid specified by the manufacturer is not enough to properly lubricate the saw set. In addition, it may be needed when the plunger is slightly worn, when the pump cannot provide enough oil to lubricate the bar and chain.

So let's get started!

What is still useful for you?

- Firstly, a summary of the operation of the device itself.

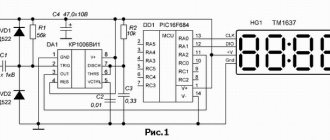

- Secondly, the tachometer. Why exactly it will be useful to us, we’ll look at it a little later.

- Thirdly, a screwdriver.

Surprisingly, this is all we will need.

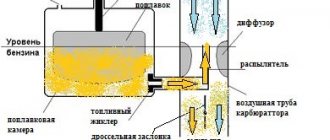

First, take a close look at the structure of your saw. What you need to do first is find where the carburetor jets are located, and what is even more important than the jets is the adjusting screws. Usually there should be two or three screws. One of them regulates idle speed, and the other two regulate low and high speed.

Specifically, you will need to adjust them, or tighten them, or unscrew them in order to enrich or lean the fuel mixture.

If you need to lean the mixture, then simply turn the regulator clockwise; if you want to enrich it, then turn it counterclockwise.

To adjust the idle speed, the screw that is responsible for this also needs to be turned clockwise in order to increase the speed, or, as you already guessed, in the opposite direction to reduce them.

What does an oil pump consist of and how does it work?

The pump housing is located on the outside of the saw housing, under the centrifugal clutch drum of the gasoline saw. The drive mechanism of the oil pump is rigidly connected to the saw chain clutch. This means that the higher the engine speed, the more lubricant is supplied to the chain and chainsaw bar.

Unlike the plungers used on car pumps, the operating mechanism in chainsaws can be disassembled and reassembled without much effort. The pump body has two calibrated holes located opposite.

One hole is connected to the oil tank and serves to draw lubricant from the tank. The other communicates with the main line leading to the saw set. At the end of the plunger there is a longitudinal segmental groove to capture the working fluid.

Oil is supplied by rotating the plunger around its axis. The segment cut first opens the hole connecting the pump to the oil tank. At the same time, a vacuum is created in the pump chamber and a portion of oil is drawn into it.

Further rotation of the plunger closes this channel and creates excess pressure in the system. Passing the segment cutout through the discharge hole opens it, and the working fluid is supplied to the line to lubricate the chain.

When adjustment may be needed

With proper use, a good Shtil 180 chainsaw (or no matter what other) should serve you well for a long time. But anything can happen...

The most common prerequisites:

- The fixing screws are loose

- The engine is worn out (in this case, adjusting this chainsaw, like Goodluck, or Sturm, will only help for a while, as a rule, it is better to immediately take it for repairs)

- The carburetor is clogged (in this case it will also have to be cleaned).

Is disassembly necessary?

You can adjust the carburetor of a chainsaw without any disassembly at all; in rare exceptions, you only have to remove the air filter cover. There is a considerable amount of contradiction here: on the one hand, the chainsaw is designed for unhindered access to the adjustment mechanism, on the other hand, it is recommended to access it as little as possible.

True, experienced fellers and sawers always carry a flat-head screwdriver with a long blade and periodically adjust the carburetor. This is explained simply: during the manufacture of a chainsaw, its carburetor undergoes rough adjustments designed for a certain composition of air and fuel. It is clear that the conditions at the work site are different from those on the bench.

When changing the brand of gasoline or, for example, increasing air humidity, an experienced chainsaw user will always adjust the quality of the mixture for greater performance and less wear on the piston part. But this, we repeat, requires considerable experience in working with a specific chainsaw and knowledge of the peculiarities of its behavior. In addition, the adjustment is incredibly fine - the screws are tightened only 1/10. 1/20 turn.

Another reason for adjustment is carburetor repair or replacement. In any case, adjustment of the mixture quality should be carried out only if the serviceability of the carburetor is reliably known (no debris, gaskets are not poisoned), the air filter is clean, the spark plug, clutch and ignition system are in perfect order. Otherwise, there is a high probability that the malfunction will be eliminated in a moment and the adjustment will suddenly become incorrect, and the engine will begin to wear out.

Step-by-step setup

“Partner 350” is regulated similarly to many models of chainsaws.

In this model we have three regulators:

- Low speed – L

- Large – H

- Singles – T.

When released from production, these chainsaws are set to deliver more consistency than is needed. This should only happen during the first hours of work.

When the engine warms up, it is better to reconfigure it. At idle speed, tighten screw T counterclockwise until the chain stops, then adjust any of them in order: L, H, T.

Troubleshooting

As a conclusion, we will describe typical malfunctions associated with incorrect carburetor adjustment and methods for eliminating them:

- The engine does not start or starts and stalls after a few seconds. Obviously, the reason is the incorrect adjustment of the mixture quality at low speeds; it is too lean. If the carburetor is working properly, you need to enrich the mixture a little by unscrewing screw L 1/2 turn, and then complete the adjustment with screw T.

- The engine noticeably loses power under load. In this case, the carburetor produces a mixture that is too rich at high speeds. Screw H needs to be tightened 1/8 of a turn; if the engine load is still not sufficiently supported, but progress is noticeable, tighten it a little more.

- The engine “sings” at maximum acceleration without load. The mixture at high speeds is too lean, the speed is too high.

- The engine stalls if you apply gas after idling. The mixture is too lean or rich, or more precisely, you can tell by the condition of the candle.

Please note that carburetor settings may be lost due to strong vibration. For this reason, a successfully selected adjustment must be remembered by counting the turns and position of each adjustment screw

If you have determined the best type of gasoline and oil ratio, save a small portion of this mixture so that in case of problems you can check whether the problems are related to the quality of the fuel and incorrect adjustment, or whether the cause is a malfunction of the chainsaw.

rmnt.ru

09.02.17

Adjustment of the Urals

It is slightly different in that it should not be carried out at sharp maximum speeds, but should be ensured that the chain picks them up quickly, but smoothly, without moving along the tire.

In any case, you should take the adjustment very seriously, because if it is done incorrectly, the saw will not stay with you for a long time. Take care of your tools and if you are not confident in your abilities, it is better to take them to a professional.

Any of them, even strong Friendship, needs attention and care. And then the chainsaw will be your faithful assistant for many years to come.

When purchasing a HUS365 chainsaw, you should be prepared for the fact that after a month of using it, you will not want to deal with any saw other than this brand. This is explained by its reliability, affordability, and most importantly, ease of operation.

Evaluation parameters and scope of application

The tool's high center of gravity, narrow configuration and flat body bottom contribute to the slow accumulation of fatigue. The user rating obtained during the survey is evidence of the high reliability, power and versatility of the model.

For a 10-point scale, the average was 8.3.

The characteristics of the tool determine its use in a wide range of household works, including:

- firewood preparation;

- preparation for installation of construction timber;

- formation of crowns of ornamental and fruit trees;

- independent production of wooden items for interior design and landscape design.

The saw successfully copes with single-pass, standard, longitudinal and diagonal sawing of hardwood with a diameter of up to 30 cm. The compact design makes it possible to work in hard-to-reach places, which is especially valued in construction technologies.

Video for a snack

Good luck and see you again! Andrey Noak was with you.

Why do you need to adjust the Husqvarna carburetor

The carburetor is one of the fundamental mechanical components that make up a chainsaw. His tasks include mixing fuel with air and supplying the acquired composition to the engine. Husqvarna 137 carburetor adjustment, DIY chainsaw repair too. But during the operation of the chainsaw, situations arise when adjusting the Husqvarna carburetor becomes necessary. Depending on the circumstances, the carburetor of chainsaw model 142 and other series is adjusted to prevent the following situations:

- the presence of interruptions in the operation of the motor, accompanied by its shutdown;

- unnecessary consumption of fuel during work.

Since the carburetor affects the quality of the fuel, in the first case the need for carburetor options saw 137 or other professional series, such as Husqvarna 240 or 260, implies an impact specifically on a sufficient amount of combustible raw material entering the carburetor for mixing with the air mass. It is clear that the greatest productivity is possible only with a certain ratio of these substances. The second point in adjusting the carburetor mixer of a chainsaw is caused by a lack of incoming air, which provokes the injected gasoline to fail to burn and be released in the form of thick smoke. A timely change of characteristics with your own hands to reduce the amount of injected fuel will allow you to significantly more quickly reduce the consumption of this product.

Features of working with a chainsaw Partner p340s

There is a list of safety rules that must be followed when working with the Partner 340 chainsaw. First of all, this applies to work clothing, it must be thick to protect it from the saw in the event of a breakdown.

Also, safety precautions for working with the Partner 340 chainsaw concern the sawing process. The following requirements must be adhered to:

- Before carrying out work, it is necessary to calculate the direction of fall. This takes into account the direction of the wind, the slope of the soil and the tree itself.

- The area around the tree must be cleared of bushes, foreign objects, and undergrowth. The space located at a 45 degree angle behind and on the sides of the tree is removed.

- The safe distance from a falling tree is two tree lengths. There should be no strangers in this area.

What fuel is used in Partner 340 chainsaws?

The fuel mixture for Partner 340 saws is a mixture of AI-95 or AI-92 gasoline in combination with oil for two-stroke engines. The proportion is 1000:20 grams. This ratio must be applied after engine break-in. To do this, the fuel mixture is formed by mixing one liter of gasoline with 35 grams of oil. The running-in volume is 1.5-2 tanks.

How to properly adjust the carburetor on a Husqvarna chainsaw

How to tune the carburetor on a chainsaw Husqvarna Carburetor adjustment

on a chainsaw using 3 THL screws.

- The chainsaw accelerates very slowly;

- The equipment does not achieve the maximum power, and under load it rapidly drops;

- The engine often stalls;

- The chain saw makes a lot of noise when operating;

- The chainsaw releases an unusual amount of smoke, increasing with each load step.

Read:

If you see any of the listed deviations, the carburetor of the 435 scythe or a slightly strengthened copy of the Husqvarna 55 saw must be urgently adjusted. Timely service also predicts the absence of waste for a complete replacement of spare parts and units of the drive and fuel system of the chainsaw motor. Therefore, if there are difficulties in the operation of the Husqvarna 340 carburetor system and all other lines, the options will help out both the chainsaw, the work processes, and the owners’ resources. Adjusting a Husqvarna carburetor like a Husqvarna 240 or 260 like a chain on a chainsaw or. If necessary, you can order the infusion of devices, replace spare parts, and also purchase a line for a trimmer with advice on its independent installation.

How to repair a drive brake

So, how to repair the drive mechanism brake . It serves for emergency braking of the saw chain to avoid injury to the operator, in our person - the lumberjack. This is one of the safety systems that is designed on the tool. On “horned” analogues of chainsaws, this system is absent as unnecessary, and that’s understandable. In addition to the safety of the operator himself, the chain braking system serves to preserve the mechanism itself when jammed. Brake failure is rare; the causes of the failure are infrequent maintenance of the saw, lack of cleaning, wear due to a long service life, and improper use of the tool during sawing.

When does this braking system engage? Most often, the brake is automatically activated during kickback, when the sawyer touches an object (wood) with the tip of the tire, and a sudden obstacle or impact appears. In another case, the chain brake is activated when the bar is clamped in the cut, and the lumberjack tries to free the chainsaw with sudden movements. From an inertial impact, protection is triggered - stopping the chain. Also, the (operator) lumberjack can turn on the brake of the chainsaw himself - manually, using the upper lever (screen), also known as the recoil handle. This is necessary, as a rule, in case of “whims” of the tool, when the chain continues to rotate without gas supply, or in case of clutch or carburetor malfunctions.

Working principle of the brake

Let's consider the principle of brake operation. The design of the mechanism is simple and unpretentious. This is a purely mechanical process. The starting switch for the brake system is the lever (screen) we have already mentioned, which is a durable element on the upper front surface of the chainsaw above the muffler. The screen is located just behind the operator’s hand, almost close, it is connected to the lid. But, since we rotate the tool while working, the screen may not be behind the hand.

General picture of the braking system

Sliding lever without spring in cocked state

Sliding lever without spring when the trigger is released

Sliding lever without a spring with the trigger releasedThe screen is fixed by a return spring at the base of the mount and a trigger switch. When the tire hits or rebounds, the screen touches and rests on the sawyer’s hand and further along the chain he turns on the trigger, which is interconnected with the screen. In the normal position, the trigger compresses the spring (not to be confused with the return spring), and when triggered, it opens it and secures it with a locking latch (latch). The sliding lever, which is located inside the spring, in turn tightens the metal strip. A metal band is placed around the clutch basket (clutch drum) and it tightens (clamps) the drum, which stops rotating. The chainsaw chain stops.

Do-it-yourself Husqvarna carburetor adjustment

Husqvarna gasoline saws, is adjusted in a similar manner, because all products have the same set of devices. For example, if systems in the 236 series of gas-powered tools are being adjusted, the process is accompanied by a search for high idle speeds by slowly turning the adjusting screws L - affecting the low-speed jet, T - on the high-speed jet and H - idle adjustment. The do-it-yourself adjustment process consists of several periods, which involve turning the L and H screws that control the throttle valve for supplying the combustible mixture and adjusting the T screw that adjusts the idle speed. Depending on the entered parameter, the saw is adjusted in the following sequence:

- After warming up, turn the L screw to high idle speed. As such are found, you should turn in the direction of decreasing the rotation speed by ¼ turn of the screw. How is the Husqvarna 142 carburetor adjusted? If the chain begins to spin, the accompanying adjustment of screw T is made against the clock until the chain stops.

- Adjustment of screw H on the chainsaw carburetor takes place during a 10-second period of engine operation at full speed, making ¼ turn. If the critical load is not reached, the operation is repeated. An undertuned setting will result in a saw squeal, while an exaggerated performance will cause the muffler to produce more smoke.

- idle speed screw T is carried out by turning the clock as the clock progresses until the chain begins to rotate. As this happens, the screw is tightened back until this mechanism stops.

Naturally, adding carburetor options will allow your tool to work very productively, but you should not forget about lubrication. “Kosa Motors” advises purchasing special-purpose chainsaw oil for mechanisms, because timely service will give the tool an additional high-quality service life.

The cutting wheel and grinding wheel have a wide range of application, and the wheels themselves are effective and easy to use

Knives differ in the number of teeth, as well as in the material of production. But the most important question is the grass on which we will work.

Husqvarna 142 in operation

We prepared the fuel mixture on the basis of AI 92 gasoline and Husqvarna HP branded two-stroke oil in a ratio of 50 to 1. It is interesting to note here that if oil added in the specified ratio is not available, the manufacturer allows the short-term use of high-quality oil diluted with gasoline in the ratio 33 to 1.

We operated the Husqvarna 142 for about an hour. It is ideal as a household chainsaw: almost complete absence of vibrations in the hands, a completely bearable noise level and, most importantly, excellent cutting abilities. Fresh pine and dry birch trunks with a diameter of 26 cm were repeatedly sawed in an average of 7 s each. The dry oak yielded a little more slowly; It took approximately 14 seconds to cut a log with a diameter of 24 cm. The cutting speeds are slightly lower than those of the professional chainsaws that we tested, but these are saws of a different order of cost. Husqvarna 142 is not afraid of working at full power; high speeds are even recommended in the instructions. The brake works perfectly - the chain stops instantly.

Read also: Grippers for metal sheets

Then an analysis was made of reviews from Husqvarna 142 owners on three specialized forums

We took into account only those publications whose authors have been registered for a long time and do not use a chainsaw professionally, i.e. not every day for several years. The results of the analysis were not surprising and are briefly as follows: the piston group is reliable, the tire is strong, the saw is comfortable and unpretentious to fuel

Failures occur infrequently, but are caused by the deadline for replacing consumables or errors in preparing the fuel mixture

The results of the analysis were not surprising and are briefly as follows: the piston group is reliable, the tire is strong, the saw is comfortable and unpretentious to fuel. Failures do occur infrequently, but are caused by the deadline for replacing consumables or errors in preparing the fuel mixture.