Sizes of grinders

Angle grinder (grinder) VORTEX USHM-150/1400E. Photo 220Volt

A grinder is an angle grinder used for processing and cutting durable materials . It is used in construction, dismantling and repair work . The popularity of the tool is due to its relatively low cost and wide capabilities . The grinder is considered one of the most popular tools due to its versatility. It is popular among both professional builders and ordinary users. This instrument received recognition due to the huge variety of types, sizes and their price category.

Device, principle of operation, additional functions

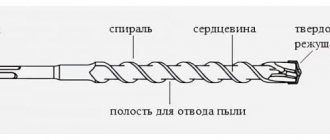

An angle grinder consists of a cylindrical body, an electric motor placed inside, and a shaft located at right angles to the rotating axis of the operating disk. The connection is made using a gear mechanism (gearbox) .

During operation, the grinder should be held with one hand. , an additional handle is screwed into its front part .

Construction of the grinder DIOLD MSHU-1,2-01-150. Photo VseInstruments.ru

One of the main parameters of an angle grinder is the outer diameter of the grinding or cutting wheel . Based on this feature, they can be divided into one- and two-handed:

- One-handed - do not have a main handle. Circle diameter 100, 115, 125 mm. Weight up to 2.5 kg;

- Two-handed - the main handle is located at the back. There is also an additional handle. The size of the circle is 125–230 mm, and the weight of the machine is 2.5–6 kg.

The disk is attached to the elongated gearbox rod (shaft) and tightened with a special nut. For better fixation of the disc, use an SDS quick-clamping nut , which can be unscrewed without having a special tool. The side that will press the disk depends on the function of the disk itself, since the nut is double-sided.

Crumbs of the processed raw material in the form of sparks pose a danger, therefore, on the user’s side, the cutting wheel is covered with a special protective casing .

The angle grinder (grinder) MAKITA GA6040C has all the functions presented. Photo 220Volt

For safety and additional convenience, manufacturers add unique functionality to the tool:

- smooth start. Allows you to protect the tool from excessive loads during startup. The function prevents the device from jerking when it is turned on;

- balancing system. Dampenes vibration that occurs during uneven rotation of disks;

- protection against accidental start. It is an additional button, pressing which unlocks the main power button of the device;

- speed support under load. Provides ease of processing of parts, stabilizes the speed of rotation of the disk with any change;

- selection of rotation speed. Allows you to enable the required mode for a specific process.

The angle grinder operates using a removable battery or electrical network. In the latter case, a network cable is used that extends from the transverse edge of the device.

Classical

All budget angle grinders are usually equipped with a so-called classic nut. It consists of a pressing and rotating part. Installed on the tool and tightened using a special pin wrench. As a rule, it is included in the delivery package of the angle grinder. You just need to keep this key at hand at all times! It’s not for nothing that many craftsmen even tape it with electrical tape to the wire of the grinder. After all, there is no other way to remove the disk. Almost all clamping nuts have the same diameter and distance between the holes for the key pins.

Pros : affordable cost, versatility, interchangeability, low profile for grinding work.

Cons : requires the use of a key, difficult to unscrew if jammed.

Marking

Most manufacturers mark the grinder with special sets of letters and numbers indicating the technical parameters of the device. There are no generally accepted rules for creating abbreviations: the manufacturer independently comes up with an algorithm.

Angle grinder Makita 9565CV. Photo 220Volt

Knowing the decoding of the markings, it is easier to choose the right angle grinder and the equipment that matches it.

As an example of labeling, let's present you with the Makita brand system:

The letters at the beginning indicate the type of tool, and the letters at the end indicate additional options:

- A – engine brake;

- B – double insulation;

- C – constant electronics;

- D – device with a DC motor;

- E – improved housing type;

- F – superflange;

- K – presence of a case;

- L – reduced spindle speed;

- N – gearbox type;

- P – panel switch;

- R – modernized design;

- S – starting current limitation (“soft start”);

- V – speed control;

- Z – no accessories.

Measures to prevent jamming

A vice is needed to clamp the tool during the destruction of the disk.

To prevent the clamp from jamming, you must adhere to the following recommendations:

- Before using the grinder, you must place a washer between the head and the disc. It will prevent the nut from jamming even after prolonged use of the tool.

- The working circle must be installed correctly so that it stands level. Its front part should be placed on the support flange and not touch the nut.

- It is necessary to monitor the tightening force. Do not tighten the nut too much so that it does not jam during loading.

Many angle grinder owners are faced with a situation where the disc lock begins to clamp. To solve this problem, you need to figure out which way to unscrew the grinder disk and what methods can be used to remove the clamp. Using the recommendations above, tool owners can easily cope with this annoying problem.

Kinds

Any grinder has a general principle of operation, but is divided into several main types, which differ in size and other characteristics. The variety of types allows them to be used in absolutely any conditions.

By type of food. Network angle grinders are the most used type of grinders used in enterprises creating metal structures. Also great for cutting brick, tile, wiring and replacing plumbing. Depending on the power, they are divided into household and professional. This tool operates on a voltage of 220 Volts.

Cordless angle grinder Metabo W18 LTX 125 + 3.5 Ah LiHD + charger ASC 55 T0333. Photo VseInstruments.ru

Advantages: the ability to choose the case size for any size of disk; light weight; high power; affordable price; large selection of attachments; high-speed rotation; long service life.

Disadvantages: poor performance when the voltage drops; a long wire may interfere with movement around the work area; high degree of energy dependence.

This type is very popular among all users.

Cordless angle grinders are similar in structure to mains ones, but differ in a large compartment for mounting the battery. They are manufactured in a small case, which acts as a handle, for ease of use, and is equipped with disks from 125 to 150 mm.

Advantages: compact body; convenient storage: the grinder is sold complete with a case; light weight; fast rotation speed; high degree of user protection; special handle that reduces vibration during operation.

Disadvantages: operating time is limited by battery capacity; support only small disks; high price.

Due to their autonomy, the models are used remotely from the power source and do not require electricity at all. It is only suitable for short tasks as the battery needs to be recharged.

Gasoline angle grinders. Large in size due to the fact that the internal combustion engine and fuel tank are located inside. To use the tool, there is a built-in auxiliary handle and a frame-handle. This device is equipped with large diameter discs. Used for cutting concrete, stone and metal in environments where there is no electricity.

Advantages: quick cutting of large objects; work with large diameter circles; autonomous use; long-term performance thanks to gasoline refueling; stand, for use as a cutting machine.

Disadvantages: additional costs for fuel for refueling; loud noise made by the instrument; work only with large disks; inconvenient to use in hard-to-reach places.

The device produces loud noise; hearing protection is required.

Network angle grinder (grinder) HITACHI G15VA. Photo 220Volt

Pneumatic angle grinders are manufactured without an engine. By means of the action of air currents on the blades inside the housing, a high speed of rotation of the disk is obtained. They just trigger the torsion of the axis with the disk. Before starting work, a valve is used to allow air access to the internal channel.

Advantages: minimal weight; continuous use for a long time; does not require cooling as it does not overheat; safe in conditions of high humidity; high rotation speed; cheap repairs; The device is silent (the noise comes from cutting).

Disadvantages: expensive device; requires additional devices (for example, a compressor).

This type is the lightest of all and does an excellent job throughout the day. Additional equipment required for use.

Purpose: professional and household. The main difference between these two types is the duration of continuous operation. Household tools are designed to work for about 10 minutes, with breaks of 15-20, for a total of about 2-3 hours a day. The main advantage of household grinders is their low price. Therefore, if you plan to perform small jobs at home, you should choose an inexpensive model. Sometimes semi-professional and industrial grinders are also noted, the latter are used for continuous work in production conditions.

The power of an angle grinder varies from 500 to 2700-3000 W. The higher the power of the tool, the greater the range of work that can be performed with its help. To carry out work at home, an angle grinder with a power of up to 1200 W will be sufficient. An increase in power inevitably leads to an increase in the weight of the tool.

The rotation speed of the disk, limited to 11,000 rpm, directly depends on its diameter. The larger the size, the lower the speed required. For angle grinders with 115 and 125 mm discs. the maximum speed is 10,000-11,000 rpm, for 150-180 - no more than 8500, for 230 - up to 6650.

Each type is unique in its own way and is suitable for a specific type of activity.

Self-balancing

This is a type of quick-release nut. The type of design and installation method is similar to those described above. The main difference is the metal balls inside the case. The mechanism is somewhat reminiscent of a bearing. When rotated, the balls are evenly distributed throughout the interior, helping to reduce vibration. The self-balancing quick-release nut not only makes work more comfortable, but also increases the service life of the disc and the grinder itself. This solution is offered by the manufacturer Metabo.

Pros : quick installation and removal without a key, comfortable operation, increased service life of equipment and tools.

Cons : high price - sometimes comparable to the cost of budget angle grinder models.

Dimensions of angle grinders: small, medium and large, the best option for home and not only

The main characteristic by which the size of the grinder is determined is the diameter of the disc, which creates a certain thickness and depth of the cut.

Angle grinder Enkor USHM-1800/180EM 50166. Photo VseInstruments.ru

Cutting wheels are divided into several groups:

Diameter 115 and 125 mm. These types are intended for:

- cutting steel, concrete, asbestos, ceramic tiles and some metals;

- cleaning the surface from rust, oxidation, old paint on metal or wood;

- gating electrical wires, grouting ceramic tiles;

- sharpening of piercing and cutting tools;

- grinding and polishing surfaces.

Diameter 150 and 180 mm . These types of angle grinders are intended for:

- cleaning parts from rust and paint;

- cleaning weld seams;

- cutting round and sheet metal;

- concrete cutting;

- grinding and polishing surfaces.

Diameter 210 and 230 mm. Such models easily cope with the most difficult tasks and are suitable for any work on a large scale.

External and landing, maximum and minimum diameter of disks

To choose the right angle grinder, you should first study the various types of discs and attachments . Each type of work has its own type. The equipment is selected according to the required size and function.

You should select a disk according to the rules : the size of its external attachment should not be larger than the permissible value for a given model. It must clearly correspond to the parameters of the grinder.

Grinder discs have fixed sizes: 115, 125, 150, 180 and 230 millimeters.

Important! Another important parameter, in addition to the diameter, is the thickness of the disk, which usually ranges from 1 to 1.5 mm or more.

The bore diameter is the size of the rod on which the disc is mounted. Modern devices have a bore diameter of 22.2 mm.

Brands and types of angle grinders

Angle grinder Bosch GWS 22-230 H. Photo 220Volt

When choosing an angle grinder, the user first of all pays attention to the manufacturer’s brand . The most popular manufacturers are: Makita, Interskol, Bosch and Lepse .

Users of angle grinders divided them into conditional types (depending on the work performed):

- for cutting (concrete, steel, stones and other metals);

- for grinding;

- for polishing;

- for gating;

- for cleaning parts;

- for sharpening tools.

For each type of work there is its own type of grinder and suitable discs.

Makita: 230 and others

The Makita brand is one of the leaders in the production of tools. The Makita range of grinders is presented in the 5 most popular diameters: 115, 125, 150, 180 and 230 mm .

Interskol: 230, 180 and others

Bulgarian Interskol 125/700. Photo 220Volt

The Interskol company specializes in creating household angle grinders , but some of their models are also used in production. The main motto of the brand is quality = price. The Interskol range of grinders consists of 6 devices:

- UShM-150/1300;

- UShM-230/2300M;

- UShM-125/900;

- UShM-230/2600M;

- UShM-180/1800M;

- UShM-125/1100E.

The Interskol grinder is the best option for those who want a powerful and functional tool for a small amount.

125

Grinders, with a disc size of 125 mm, are the most popular type among all models. This type is most popular for home use . The cutting depth that this blade is capable of is 35 mm.

Angle grinder AEG WS8-125S 4935451296. Photo AllInstruments.ru

Quick-clamping

Increasingly, modern angle grinders use keyless disk fastening. This saves time in serial work, when you need to change several cutting wheels in one shift. The same system was also appreciated by amateurs who use one grinder for different operations and in the process change attachments for cutting, stripping, and grinding. In such cases, a quick-release nut eliminates the need to struggle with a wrench and other devices. The standard type of fastening allows you to install this element even on an old angle grinder instead of a key one.

It is worth saying that the keyless nut for an angle grinder does not have a universal design. Each manufacturer develops its own system with patented elements. Let's look at the most well-known options.

Pros : easy installation and quick removal without a key, minimal risk of jamming.

Cons : high cost compared to key nuts; good clamping is not always ensured when using non-original products.

What other sizes are there?

When talking about the size of grinders, we often mean not only the dimensions, but also other dimensions, such as length and height.

Grinders are divided into several groups:

Small (household) . The length of the device is about 270, and the height is 100 mm. Disc diameter 115 or 125 mm. Power ranges from 500 to 1200 W. Such angle grinders are used mainly in domestic conditions for no longer than 20 minutes of continuous use.

Important! It is strictly forbidden to install a circular saw blade on a small grinder. This can result in serious injury.

Average (professional) . The length of the instrument is about 350, the height is from 120 to 130 mm. Circle size from 150 to 180 mm. Power ranges from 1200 to 1500 W. Such a tool can work continuously for up to 50 minutes. The scope of use of such angle grinders is industrial production and work on construction sites.

Angle grinder Zubr Professional USHM-P125-1400 EPST. Photo VseInstruments.ru

Large (industrial). The length of such a tool reaches 400, and the height ranges from 140 mm. and higher. Power reaches 3000 W. Disk diameter is from 210 to 230 m. This model can easily cope with the heaviest tasks and is suitable for absolutely any work on a large scale.

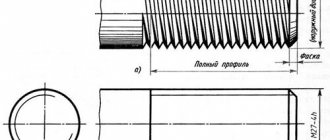

Pressure flange thread

The pressure flange is a threaded ring of predominantly oval or round shape. The flange of the angle grinder is made in a special way: from certain grades of steel with strict adherence to the production plan.

Thread size M10:

- rod diameter along the thread crest: 10 (mm);

- pitch (largest): 1.5 (mm);

- outer diameter (d): 10 (mm);

- average diameter (d2): 9.026 (mm);

- internal diameter at the bottom of the cavity (d3): 8.160 (mm).

Thread size M11:

- rod diameter along the thread crest: 11 (mm);

- pitch (largest): 1.5 (mm);

- outer diameter (d): 11 (mm);

- average diameter (d2): 10.026 (mm);

- internal diameter at the bottom of the cavity (d3): 9.160 (mm).

Angle grinder (grinder) HITACHI G13SD with M14 thread. Photo 220Volt

Thread size M12:

- rod diameter along the thread crest: 12 (mm);

- pitch (largest): 1.75 (mm);

- outer diameter (d): 12 (mm);

- average diameter (d2): 10.863 (mm);

- internal diameter along the bottom of the depression (d3): 9.853 (mm).

Thread size M14:

- rod diameter along the thread crest: 14 (mm);

- pitch (largest): 2 (mm);

- outer diameter (d): 14 (mm);

- average diameter (d2): 12.701 (mm);

- internal diameter along the bottom of the cavity (d3): 11.546 (mm).

Thread size M15:

- rod diameter along the thread crest: 15 (mm);

- pitch (largest): 1.5 (mm);

- outer diameter (d): 15 (mm);

- average diameter (d2): 14.026 (mm);

- internal diameter along the bottom of the cavity (d3): 13.160 (mm).

For example, the Makita 224415-9 support flange has the following characteristics:

- diameter – 42 mm;

- thread type – M14.

Suitable for angle grinders 115–230.

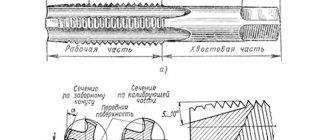

Key

A wrench is a special tool for changing attachments on a grinder. The tool is made of high-strength steel for long service life. The diameter of the nuts that the wrench can unscrew is usually indicated after the letters “KR”.

Nuts

Quick-release nut for angle grinder Makita 115\125\150\230. Photo 220Volt

A special clamping nut is produced together with the grinder. It secures the grinding or cutting disc .

Nuts are divided into two types:

- unscrewable with a key;

- unscrewing by hand.

For example, the FIXTEC AEG 4932358225 nut with a standard spindle thread type (M14) has the following parameters:

- length – 150 mm;

- width – 100;

- height – 20;

- thickness – 8.

This equipment is suitable for grinders with a cutting wheel size of 115/150.

Protective casing

DEWALT DWE46150-XJ protective casing for angle grinders 115/125 mm. for roughing work with dust removal. Photo 220Volt

The cutting wheel is a rather traumatic tool, so mandatory equipment for an angle grinder is a protective casing, which acts as a barrier between the user and the disc . Average casing sizes range from 117 to 232 mm. For example, the GWS 125 protective housing from the Bosch brand has the following parameters:

- length – 150 mm;

- width – 110;

- height – 61.

This model is suitable for a huge number of angle grinders.

floating

Another type of elements with key fastening is floating clamping nuts for angle grinders. The design consists of two parts that are not connected to each other. This is a washer and a protruding part with a hexagonal profile. To tighten and unscrew such fasteners, you can use a regular spanner wrench of a suitable diameter. Although some elements still have holes in the “skirt” for a classic grinder key. Such a nut with a moving washer is used on many domestic instruments and on some budget models from foreign manufacturers.

Pros : no need to use a pin wrench, low risk of sticking to the disk during operation, affordable price.

Cons : the high profile of the hexagonal element does not allow you to work with the entire surface of the disk; it is impossible to unscrew it without a key.

Criterias of choice

To choose the right grinder, you need to know exactly what it is for and how often it will be used.

Amateur and professional models. There is a big difference between these tools. Professional models can work continuously throughout the working day. All equipment is made with high quality, and the device is comfortable to hold in your hand. The models also have a number of additional functions. An amateur grinder will not be able to work for a long time without interruption: its motor quickly overheats. The manufacturer saves on the quality of the case and individual parts. Such devices do not have additional useful functions. But such grinders are quite budget-friendly.

Household grinder (angle grinder) DeWALT DWE 4051 with a disk diameter of 125 mm and a power of 800 W. Photo 220Volt

Disc diameter. For each type of work there is a recommended disc diameter:

- minor work: grinding, cutting thin metal, plastic or slate – 115 mm;

- minor work: grinding, cutting pipes, tiles, stone and polishing surfaces - 125 mm;

- cutting stones, steel and concrete. It is inconvenient to perform small work with such a disk - 150 mm;

- professional tasks: construction work, cutting thick pipes and concrete - 180 mm;

- heavy work: construction tasks with heavy materials – 230 mm.

The size of the cutting wheel affects the power, weight and choice of material it will work with.

Engine power. The higher the motor power, the easier it is to cut hard material. For simple work, a 600 W grinder is suitable. For heavy, complex work, it is better to choose an angle grinder from 1000 W.

Disk rotation speed. The decisive parameter when choosing an angle grinder is the rotation speed of the circle. Your choice should be made at the optimal speed for a particular task. A good bonus would be to buy a grinder with a speed controller.

The handle should fit clearly in the hand, be convenient and comfortable. When polishing the surface, the device catches and pulls out of your hands. To make it easier to hold, manufacturers screw in a second handle-bracket.

Replaceable discs and attachments. The choice of disks is determined by the tasks for which the angle grinder is intended. There are discs for cutting, grinding, leveling and polishing.

Power supply type . There are two types of power: from the electrical network and from the battery. It is best to purchase an angle grinder that is powered from the mains: the batteries run out quickly.

Based on these criteria, you can choose the ideal grinder for your type of activity.

Superflange

Another type of quick-release nuts. One of the most popular examples is MAKITA Ezynut . Looks similar to Bosch SDS-clic or Metabo Quick. Its main feature is the movable lower part (springs are installed inside) and the sealing ring, which moves at a small angle along with the disk. This makes it easier to unscrew the top nut. Compared to other quick-release nuts, this one has a larger diameter and thickness. There are also holes for a pin wrench. But they are not universal - you need a proprietary unscrewing tool if you cannot remove the nut manually.

Pros : easy to install and unscrew, reliable design.

Cons : high price; due to the increased size, such fasteners are not suitable for some painstaking work.

Sterlingg ST-10995 – small grinder with a power of 300 watts

The Sterlingg angle grinder is designed for grinding and cleaning products made of stone, metal and other materials. The grinder is used in construction and metalworking. The device operates at a speed of 11,000 rpm and is suitable for use by both right and left hands. Technical characteristics Country of manufacture – China Power supply – mains Voltage – 220 V Power consumption – 300 W Maximum disk diameter – 115 mm. Maximum disk rotation speed – 11000 rpm Network cable length – 0.9…

AEG WS 2200-230DMS – professional angle grinder with motor protection from dust

The AEG WS 2200-230 DMS angle grinder is equipped with a powerful 2.2 kW electric motor, the windings of which are coated with epoxy material to protect against abrasive dust. Convenient service hatches are provided for simplified access to the motor brushes. The tool has a wear-resistant gearbox in a flat metal housing. This makes it possible to work in confined spaces. The standard spindle can accommodate cutting discs with a diameter of up to 230 mm. The grinder is equipped with an adjustable protective guard, as well as an additional…

How to change a disk if it is jammed?

What to do if the wheel on the grinder is jammed? This can happen, for example, when, as a result of work, pieces of the workpiece being cut sharply clamp the rotating disk. This often leads to its destruction.

It can be very difficult to unscrew a nut that is tightened as a result of rotation if the circle is stuck.

- One such method would be to use two gas keys at once. The remainder of the disk must be broken off with pliers. With one key you need to clamp the part of the rod located under the disk, and with the other you need to unscrew the flange.

- Sometimes, to gain access to the gas key to the grinder rod, you have to disassemble the gearbox.

- There are reviews of penetrating lubricant: a nut treated with this composition should turn in a few minutes.

- There are also more exotic methods. For example, heating a jammed nut with a gas burner. As a result of expansion, the heated nut will be easier to turn.

- Sometimes, in order to avoid unnecessary impact on the parts of the grinder, it is better to completely crumble the remains of the disk, remove the protective casing and use a hacksaw to cut out all the remains of the circle between the clamping devices.

INGCO AG30008 – powerful angle grinder with aluminum body

The INGCO AG30008 angle grinder is used for cleaning, cutting and grinding various materials. The powerful model is perfect for both home and professional work. The aluminum body effectively dissipates heat under load and ensures long service life. Description and application The INGCO AG30008 INDUSTRIAL angle grinder is used for cutting, grinding materials and dry concrete work. This powerful, but at the same time quite light and easy-to-use model will become an indispensable assistant as…

What is needed for the remodel

Converting a cartridge to a grinder without a turner is not easy, but in principle it is possible. It should be noted right away that the accuracy of manual alteration will not be ideal and you will still need to spend time on adjustment and polishing.

PHOTO: YouTube.com For modifications, it is better to take a 1.5-10 mm drill chuck with a B12 cone fit - this is the best option, you just need to drill it out and cut the thread for attaching the bits

The tools you will need are a drill on a stand with drill bits of different diameters. Prepare pieces of timber to secure the chuck during operation.

DAEWOO DAG 2600-230 – powerful angle grinder with soft start

The DAEWOO DAG 2600-230 angle grinder is used for grinding, cutting and cleaning metal products and other materials. The work attachment can be changed quickly and safely thanks to the spindle lock function. To preserve the workpiece material and reduce the load on the network during startup, the torque and load of the electric motor are temporarily reduced. The disc is covered with a metal casing, thanks to which the operator is protected from accidental contact with the cutting element, and the flight of small chips and sparks into the eyes and…

How to replace the nut

The grinder is a very dangerous power tool. Therefore, replacement of parts and components should be approached with special care. If the clamping nut has been lost, do not replace it with a regular M14 hex nut. The pressing surface of such a fastener is insufficient to securely fasten the tool. It is better to contact a service center or buy a standard clamping nut in a specialized store.

If you are far from the benefits of civilization, for example, in the country, you can use a lathe located in the household. If he is not there, perhaps a familiar turner with a machine lives next door. Turning a nut and cutting threads is not a difficult task even for a professional turner.

Bison Master UShM-230-2600 PM3 – powerful Russian grinder

A universal tool for use in repairs and construction. Equipped with the highest power motor on the market for maximum productivity, as well as a working disc with a diameter of 230 mm. for efficient processing of large surfaces. Description and application The angle grinder BISON MASTER USHM-230-2600 PM3 is useful for household repairs and construction. When using special wheels, it is suitable for cleaning, grinding and cutting metal, stone, and concrete. Equipped with a high-power engine. Specially…

Video description

Video on how to choose the correct direction of rotation of the grinder disk:

- Excessively long operation. Any disk has a limited period of use. The closer it is ground to the base, the higher the risk of it breaking.

- Improper use. When a cutting wheel is used for sanding, its thickness and strength quickly decrease, making it more likely to break.

- Presence of a defect. A crack, break or chip may be present on the wheel even when it leaves the factory, and may arise during operation.

Note! From a safety point of view, the angle grinder should rotate to the side clockwise - if you look at the open side of the disk. The reason for this is simple: if the disk jams, it is almost impossible to hold the device, and in this direction it will simply go away from the user, and not towards him, as in the opposite direction of rotation, that is, counterclockwise.

Makita 9069 – comfortable, reliable, safe grinder

The Makita 9069 angle grinder is used for grinding, cutting and cleaning metal products and other materials. The tool is equipped with a 2000 W motor. Long-term continuous operation of the grinder is ensured by fixing the start switch. The spindle locking feature allows for quick and easy disc replacement. The additional handle can be installed in three positions, which allows you to work with the tool in hard-to-reach places. Replaceable carbon brushes are easy to replace yourself. Spare parts cost...

What solution to the problem is offered by specialists and amateurs + (Video)

- Install a newspaper gasket under the nut;

- Place a gasket from a plastic bottle under the nut;

- Replace the nut with a nut of a different design.

What is a newspaper gasket? This is a paper washer the size of a nut. It is put on the installed disk, and a nut is screwed on top. This piece of paper was a stumbling point, because the safety inspection always spoke about the harmfulness of such a decision.

Representatives of safety authorities treat the installation of gaskets made of any other materials in the same way:

- Cardboard;

- Paronitis;

- Gaskets made of various plastics;

- Rubber gaskets of various thicknesses.

But there is a solution that does not contradict safety requirements and allows you to install and remove the disk normally. This is a special nut that consists of two elements - a nut and a pressure washer. The use of such a nut does not require any shims, because with it the disk does not jam.

If you don’t have a special key at hand, then craftsmen suggest doing without a key. This does not mean that you can do without a key at all, but use a “gas key” or other device. To do this, you need to hold the latch, tighten the nut with a gas wrench and unscrew it. This way you can replace a jammed disk, but this is a very inconvenient operation for one person.

There are also suggestions to hold the disk with your hand and unscrew it. Maybe, but it’s unlikely that you’ll be able to change broken disks this way. It is better to use wrenches that are designed for removing and installing disks.

Some foreign power tool manufacturers, such as Bosh, produce grinders with easily removable nuts. They securely fix the disk on the tool shaft and are easily and quickly removed to replace the disk.

Makita GA9050 – powerful and reliable angle grinder

The Makita angle grinder is a reliable grinder for working with metal and stone materials. The tool is used for dry cutting, cleaning and polishing surfaces. Thanks to the reduced gearbox housing, the cut is deeper than most models from the manufacturer. Purpose The tool is intended for grinding, stripping and cutting metal and stone materials without the use of water. The Makita GA9050 angle grinder is used for cutting small pipes and grinding various surfaces. Engine…

Advantages and Disadvantages of Pressure Fasteners

Floating fastener

In such a nut, the lower segment and the upper are not dependent on each other, they rotate on their own. It is used in angle grinders instead of a standard nut. The advantages of such a fastener are:

- it does not require a specialized wrench to unscrew (a regular open-end wrench or a simple socket wrench will do);

- The circle is not pressed tightly, therefore, the clamping fastener unscrews freely.

There is probably only one drawback - its cost is slightly higher than the standard one.

Regular nut

Practiced in various modifications of the instrument. Included in the package of cheap angle grinders. Advantages of the fastener:

- presses the circle firmly;

- low cost.

- a specially designed key is required for unscrewing;

- often spontaneously sticks to the circle, and special skills or equipment are needed to unscrew it.

Superflange fastening element

A specialized nut with a moving internal element, made by Makita. Advantages:

- makes it possible to freely remove the circle no matter how tightly it is tightened during work;

- increases user efficiency.

The downside is that the cost is significantly higher than that of other fasteners for angle grinders.

Self-locking nut

Replaces conventional clamp fastener. Advantages:

- no special key required for unscrewing;

- can be easily dismantled;

- high wear resistance;

- durable.

- quite expensive;

- may sometimes stick to the circle and in this case it should be turned away as usual.

Fastening element with auto-balancer

The structure contains bearings inside the nut. During operation, the bearings are dispersed internally and balance vibration processes. Advantages:

- the grinding disc works 50% longer;

- no vibration;

- increases the service life of the tool.

The disadvantage is the high cost.

Resanta USHM-180/1800 – grinder with soft start and long-term warranty

The angle grinder Resanta UShM-180/1800 75/12/8 is used for processing and cutting various building materials. Changing the grinding discs is quick and safe thanks to the spindle lock. The cover protects the operator from dust and sparks. Its position can be adjusted without the use of additional tools. Design and principle of operation 1. Switch 2. Drive shaft 3. Side handle 4. Gear housing 5. Housing 6. Protective casing 7. Spindle lock 8. Accidental start protection button 9. Speed controller (for…

Bosch GWS 18-125 SL – high efficiency and maximum comfort

What makes the Bosch GWS 18-125 SL Professional angle grinder different? First of all, high power! The 1800 W motor is designed to handle the toughest tasks! The tool also has excellent controllability. The anti-vibration handle ensures operation with less effort, and the KickBack Control, power button lock, soft start, protective cover, and overload protection are designed to improve the user experience. The excellent weight-to-performance ratio of the tool on the long-handled angle grinder market is noteworthy...

SKRAB-56001 – mini grinder with speed control

Miniature angle grinder cutting machine (grinder) SKRAB – 56001, the prototype for which was the RONCXiN SIJ-LX-DM3612, which received well-deserved appreciation from the public.

This was the first small-sized model of an angle grinder on the Russian market. Purpose Mini grinder SKRAB 56001 is used for cutting, grinding, engraving, polishing metal, wood, plastics, stone. A fairly economical electric motor with a power of 280 W develops a rotation speed of 6000 to 12000 rpm, allowing for very thorough processing... Page 1 of 51