Metal packaging tape, produced in accordance with GOST requirements, can be made of ordinary and galvanized steel. This tape is successfully used for packaging cargo for various purposes, including heavy and bulky ones. In addition, with the help of this tape, loads are secured during transportation.

Roll of steel packing tape

Classification according to GOST

There are two main classifications of packing steel tape:

- The first classification is based on the condition of the material. The letter “N” denotes a tape made of hard-worked materials, the letter “M” - from soft materials, and the combination of letters “PN” - from semi-hard-worked materials.

- The second classification is based on the accuracy of width and thickness. In this case, the letters “Ш” and “Т” are used for designation.

When choosing, you need to take into account the characteristics of the cargo that you plan to transport, and also take into account the transportation distance.

Tape sizes

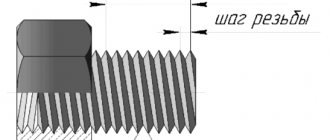

Steel metal tape for packaging construction materials is usually very thin. Its thickness can vary from a couple of hundredths of a millimeter to almost two millimeters. The width also varies , but no less than 1.5 cm and no more than 5 cm. GOST allows deviations in thickness and width, which depend on the accuracy. For example, the thickness may vary by approximately 0.1 mm, and the width by 1 mm.

The customer may request that packaging tape of non-standard sizes be made especially for him. In this case, the width can be increased many times, but the thickness usually does not exceed 0.4 mm.

Quality checking

High-quality steel is used for production, which meets the requirements of GOST . The quality of the finished product is checked using various methods. Typically, a caliper and a micrometer are used for this.

A tape that is less than 2 cm wide is measured in the middle part, and when measuring wider metal strips, they are measured 1 cm from the edge. When measuring packaging tape, do not forget about such a value as crescent shape. The fact is that the edges of the strip are rarely straight: they are often curved.

In order to find out how curved it is, you need to attach 1 meter of the product to a straight line, and then use a regular ruler to measure the curvature parameter. To determine the quality of the finished product, it is not at all necessary to use any special tools or other devices.

You can simply examine it with your own eyes and draw some conclusions. Visual inspection of finished rolls is usually carried out like this: several turns are unwound, and then carefully inspected.

For tensile testing, pre-prepared samples are used , which are also a steel strip, but with already specified parameters.

How such work should be carried out is stated in GOST. In order to draw a correct conclusion about the quality of the finished steel strip, during testing it is necessary to use different samples that were taken from the same roll.

About company

Welcome to the site

Since 2002, we have been producing and selling steel packaging and stamping tape, manufacturing additional roofing elements, and also offering supplies of black rolled and sheet metal from leading domestic manufacturers.

Buy steel tape.

Having our own unique production allows us to quickly and efficiently fulfill consumer orders.

Do you want to buy steel packaging tape in Moscow. Or you need to buy cheap stamping tape . Our own production allows us to fulfill your order with minimal costs, and therefore the price of steel tape will pleasantly surprise you. We are ready to produce steel tape from rolled black and galvanized steel with a thickness of 0.3 mm to 2.5 mm and a width of 10 mm to suit the Customer’s dimensions. Packing tape is always available . For regular customers, a flexible system of discounts and deferred payment.

You can obtain more detailed information on delivery terms and prices by contacting our managers by phone +7 (495) 728-66-47 , +7 (499) 136-88-75 or Send a request .

Buy rolled metal

We offer supplies of cold-rolled steel , galvanized steel , galvanized steel with polymer coating , hot-rolled steel from leading Russian and foreign metallurgical plants. Rolled steel produced by NLMK, MMK, Severstal, etc. Direct deliveries from manufacturing plants allow us to ensure a low price for this type of product. Delivery by road and railway transport is possible. The extensive experience of our specialists in this field allows us to guarantee the quality of the supplied products.

To obtain detailed information on availability and prices today, call tel. +7 (495) 728-66-47 , +7 (499) 136-88-75 or Make a request .

Additional roofing elements

One of our activities is the production and sale of additional roofing and facade elements. Snow retainers, ridges, valleys, wind strips, caps, ebbs are an example of additional elements produced by our organization. Additional elements are used for roofing, fences, siding and parapets. We are ready to offer standard additional elements or we will manufacture them according to customer drawings.

Contact us by phone. +7 (495) 728-66-47 , +7 (499) 136-88-75 or Submit a request and we will definitely fulfill your request.

Hand tools for packing with steel strips

To tighten the cargo when packing with metal strips and then fasten the strips together, machines for packing with steel strips are used. Manual strapping tools are widely used in factories and warehouses for packing various cargo. We offer the following packaging tools: M4K , MUL-15 , M4N , M4S .

The main advantages of our company:

- own production

- wide range of products

- convenient payment scheme

- low prices

- discount system % of order volume

- Individual approach to every customer

- fast order fulfillment times

- delivery to a place and time convenient for you

Steel Tape Packing

Before shipping to the customer, metal packaging tape is stacked in stacks of several rolls each. Each stack is then wrapped with strips of metal or wire.

They can be pre-treated with a special substance to provide protection from the negative effects of the external environment. Polymer film or waxed paper can be used for packaging .

Hard-worked and soft type

Cold-worked steel strip is characterized by increased rigidity and strength. It is advisable to use such a product when transporting heavy objects.

Cold-worked packaging is produced by squeezing steel without preheating. As a result, it becomes softer and acquires the necessary plasticity, but its surface, on the contrary, hardens and becomes stronger.

The mild type is produced from low carbon steel by cold rolling. The strength of such a product is quite high, but during transportation it can stretch and lengthen, which will inevitably lead to its weakening. Suitable only for working with medium-heavy loads.

If the base material, that is, steel, is coated with a zinc or polymer protective layer, then its original positive properties will not be lost even after many years. Material with an anti-corrosion coating easily withstands the negative effects of water and humid air, and is also not afraid of temperature changes.

What materials is the bandage tape made from?

The main raw material is high-quality low-carbon steel or stainless steel AISI 201, A-2, which has high strength and resistance to adverse weather conditions (temperature changes, high humidity).

The most common grades of low-carbon steels are manufactured according to GOSTs 380-88, 1050-88, 16523-89:

- Steel 70.

- Steel 10.

- 08 KP.

- 08 PS.

- 1 PS.

- Steel 45.

- 60С2А.

- 51HFA.

Steel strips that have undergone additional heat treatment maintain geometric parameters, retain the shape of the packaged product, and do not deform it during loading/unloading, transportation, or storage. Metal packaging does not change its properties and retains its original shape in frost and heat.

Metal tapes treated with zinc, anti-corrosion varnish or special polymer coatings are used to fasten products that are stored for a long time in the open air or in large refrigerated compartments.

Galvanized products do not rust, remain unchanged when in contact with aggressive chemicals, and have increased strength and tear resistance.

Main advantages

One of the most important benefits of steel packaging tape is its strength. This product withstands various mechanical impacts well and does not deform during transportation. All this guarantees that the cargo will remain safe and sound during transportation.

Another significant advantage is low temperature resistance. Even in extreme cold, the properties of the product do not change, so you can safely use it even when you need to transport some cargo in winter.

The high popularity of steel packaging tape is also due to the fact that these metal strips are easy to use. Even at the production stage, special holes are made on its surface to simplify the packaging of goods.

To connect the ends of the tape, you may only need staples, but often you can do without any additional materials at all.

Types of steel packaging tapes

Depending on the accuracy of execution, the packaging material is marked with the letters T and Ш:

- W – accuracy of tape width 15 – 50 mm;

- T – thickness accuracy 0.2–1.8 mm;

- There are no markings on standard precision products.

Classification of low-carbon steels depending on the physical state of the material:

| Tensile strength (N/mm2) | Elongation level (%) | |

| N – hard-worked | 60 | not indicated |

| PN – semi-hardened | Z5 | from 7 |

| M – soft | 25 | from 17 |

Steel strips are produced in three stages:

- Cutting.

- Heat treatment, galvanizing.

- Applying varnish or other coatings.

- Packing in rolls.

Winding of rolls is carried out in several ways: single-, double-, multi-row, “jumbo”. The ends of the winding are fixed with interlocking perforated joints.

Advice: When choosing packaging material, you need to know the technical characteristics of the goods (dimensions, weight, product category). It also doesn’t hurt to know the quality of the road surface, distance, travel time.

What is cold-worked steel

Metal hardening (hardening of the surface layer) is performed in two ways:

- Mechanical processing (plastic deformation of metal workpieces by external mechanical influence, for example, cold hardening, “firing” of parts with shot from hard grades of steel).

- Heat treatment (plastic deformation, stamping of soft plastic tape, annealed in a special furnace).

A little theory: As a result of hardening, the internal parameters of the metal change: the structure of low-carbon steels, the crystal lattice, the phase composition. The outer layer of cold-worked metal acquires additional strength and hardness.

Tape Tightening Tools

When using bandage metal strips, manual, pneumatic, and mechanical devices are used. The market offers various models produced by well-known manufacturers. These machines greatly facilitate work with packaging material and provide reliable fastening of goods with sharp edges and corners.

Enterprises that produce products in small volumes use hand-held tools. Manual packaging machines like M4K-10 are relatively inexpensive. The mechanisms are easy to operate, do not require special skills, are reliable and durable.

Tip: Experienced craftsmen recommend using designs with a ratcheting mechanism. These manual machines are easy to use. The working material does not need to be pushed, it is fed using a ratchet mechanism, the design includes a long handle and a built-in cutter.

To perform packaging operations in large volumes in a short time, more complex tools are used: mechanical or pneumatic.

These devices are much more productive than their manual counterparts and work with large-sized products. When packing large, heavy loads, it is advisable to use mechanized tools that evenly secure the bandage tape in each zone.

Power tools

Depending on the shape and weight of objects, locking and lockless devices are used, powered by mechanical or pneumatic drives.

Objects with flat surfaces are tied with steel tape using the punched fastening method using combined tools that are in demand when tying various building materials:

- pipes;

- lumber;

- furniture blanks;

- reinforced concrete slabs;

- fittings;

- double-glazed windows, etc.

When tying large-sized round-shaped loads or other complex configurations, locking machines with tensioner-seals are used. Here the ends of the tape are secured using special metal locks.

Important: Universal combined mechanisms perform several functions in one cycle: tensioning, fastening, cutting the ends of steel strips, forming locking joints called “dovetails”. “3 in 1” devices are easily adjusted to the parameters of steel belts: thickness, width. Such tools are easy to use; the master does not have to put in too much effort.

Steel strip weight formula

Formula for calculating strip weight: m = ρ × a × t

- ρ – metal density, kg/m3;

- a – tape width, mm;

- t – tape thickness, mm.

Strip steel

- This is one of the common types of rolled metal with a transverse rectangular section and a low profile. The tape is widely used in all industries, construction and energy.