Corrugated sheet is a metal product used for internal and external construction work. It is a steel sheet with a three-dimensional pattern on one side. The characteristics of the original rolled products are determined by GOST 19903-2015. The dimensions and other properties of corrugated sheets with diamond and lentil patterns are regulated by GOST 8568-77. Rolled steel with lentil and rhombic corrugation has an anti-slip surface, which is important for ensuring the safety of personnel in industrial and agricultural enterprises, in warehouses, and passengers in transport.

Types of relief sheets

Such metal products are produced by hot deformation on mills using rollers, which produce a smooth surface on one side and a corrugated surface on the other. In the mass version, carbon steels St0, St1, St2, St3 of various degrees of deoxidation are used for these products. Rolled products for use in conditions where decorative, hygienic qualities, and corrosion resistance are important, are made from stainless steels AISI 321, AISI 201, AISI 316, AISI 430.

In addition to the material used in production, these sheets differ in:

- the type of riffles and the option of their placement;

- the thickness of the workpiece used for the manufacture of corrugated sheets;

- number of projections per 1 m

2.

Products meet the following requirements:

- the height of the corrugations is 10-30% of the thickness of the original sheet or rolled products; in metal products with a thickness of 5 mm or more, the height of the corrugations must be at least 1 mm;

- the dimensions of the diagonals of the rhombuses are in the range of 25-30x60-70 mm;

- the distance between the lentils is 20, 25, 30 mm.

Corrugated metal sheet dimensions:

- length – 1.4-8.0 m in increments of 50 mm;

- The width of the finished corrugated sheet is 0.6-2.0 m, pitch is 50 mm.

1m weight table

2

corrugated steel sheet with lentil corrugation or diamond pattern

| Corrugation "rhombus" | Lentil corrugation | ||||

| Thickness of the original sheet metal, mm | Width of ribbed base, mm | Weight 1 m 2 , kg | Thickness of the original sheet metal, mm | Width of ribbed base, mm | Weight 1 m 2 , kg |

| 2,5 | 5 | 21,0 | 2,5 | 3,6 | 20,1 |

| 3,0 | 5 | 25,1 | 3,0 | 4,0 | 24,2 |

| 4,0 | 5 | 33,5 | 4,0 | 4,0 | 32,2 |

| 5,0 | 5 | 41,8 | 5,0 | 5,0 | 40,5 |

| 6,0 | 5 | 50,0 | 6,0 | 5,0 | 48,5 |

| 8,0 | 5 | 66,0 | 8,0 | 6,0 | 64,9 |

| 10,0 | 5 | 83,0 | 10,0 | 6,0 | 80,9 |

| 12,0 | 5 | 99,3 | 12,0 | 6,0 | 96,8 |

This is interesting: Anchor bolts for concrete: types, sizes, installation

Methods for producing corrugated sheets

Corrugated products are created using the method of hot deformation and cold pressing. In the first case, the steel billet is heated to the required temperature and passed through rollers, one of which has a stencil. Raised bumps are printed on only one side of the sheet. On the other hand, the surface remains smooth.

When using the second method, special presses are used. After processing the workpiece, the corrugations are visible on both sides of the product. On the working surface the image is raised, and on the reverse surface it is depressed.

Finished products are cut on all sides. In accordance with GOST standards, there should be no delamination on the edges of corrugated sheets. Jagged edges are allowed on the rolled edges. They should not extend the sheet beyond the established width dimensions. The presence of traces of mechanical damage on the surface of the products is not allowed. To control technical parameters, one roll or two sheets are selected from the batch

Types of corrugation patterns

Manufacturers offer the following types of patterns:

- "Diamond" . This is the simplest pattern, consisting of grooves that are located perpendicular to each other.

- "Duet" . This pattern differs from the previous one in the double arrangement of riffles.

- "Quartet" and "Quintet" . These are complex designs that have a decoratively attractive appearance.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the USSR Ministry of Ferrous Metallurgy

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated April 13, 1977 No. 926

3. INSTEAD GOST 8568-57

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

5. The validity period was lifted according to Protocol No. 5-94 of the Interstate Council for Standardization, Metrology and Certification (NUS 11-95/

6. EDITION with Amendments No. 1, 2, 3, 4, approved in October 1978, January 1981, June 1987, June 1989 (IUS 11-78, 1-81, 11-87, 11 -89/

Corrugated steel rhombic and lentil form sheets. Specifications

MKS 77.140.50 OKP 09 7000

Date of introduction 1978-01-01

Information data

1. DEVELOPED AND INTRODUCED by the USSR Ministry of Ferrous Metallurgy

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated April 13, 1977 N 926

3. INSTEAD GOST 8568-57

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 380-94 | 1.12; 2.2 |

| GOST 7566-94 | 3.3; 5.1 |

| GOST 14637-89 | 3.1 |

| GOST 19903-74 | 1.9; 1.10; 1.12 |

5. The validity period was lifted according to Protocol N 7-95 of the Interstate Council for Standardization, Metrology and Certification (IUS 11-95)

6. EDITION (September 2004) with Amendments No. 1, 2, 3, 4, approved in October 1978, November 1980, June 1987, June 1989 (IUS 11-78, 1-81 , 11-87, 11-89), Amendment (IUS 2-2003)

An amendment was made, published in IUS No. 12, 2005

Amendment made by database manufacturer

This standard applies to hot-rolled steel sheets with one-sided rhombic and lenticular corrugation for general purposes.

(Changed edition, Amendment No. 4).

Assortment

1.1a. Rolled sheets by thickness are produced:

- high accuracy - A,

- normal accuracy - V.

(Introduced additionally, Amendment No. 4).

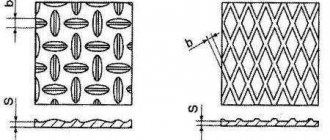

1.1. The shape, dimensions, maximum deviations and weight of 1 m² of sheet with rhombic and lentil corrugation must correspond to those indicated in Figures 1, 2 and in the table.

Damn.1

Damn.2

| Sheet base thickness s, mm | Maximum deviations in sheet thickness at width, mm | Width of ribbed base b, mm | Angle at the top of the riffle φ, degrees | Ribbon length l, mm | Radius of curvature of grooves R, mm | Arrangement of corrugations on the plane of the sheet φ1, deg | Weight of 1 m² sheet, kg | Limit deviations by weight, % | |||||||||

| from 600 to 1000 | St. 1000 to 1500 | St. 1500 to 2000 | St. 2000 to 2200 | ||||||||||||||

| normal accuracy | high accuracy | normal accuracy | high accuracy | normal accuracy | high accuracy | normal accuracy | high accuracy | Nom. | Prev. off | Nom. | Prev. off | ||||||

| Diamond knurling | |||||||||||||||||

| 2,5 | ±0,25 | ±0,18 | ±0,25 | ±0,18 | — | — | — | — | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 21,0 | ±10 |

| 3,0 | ±0,25 | ±0,23 | ±0,25 | ±0,23 | — | — | — | — | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 25,1 | ±10 |

| 4,0 | +0,3 -0,7 | ±0,30 | +0,3 -0,7 | ±0,3 | +0,3 -0,7 | ±0,3 | +0,3 -0,7 | ±0,3 | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 33,5 | ±8 |

| 5,0 | +0,3 -0,7 | ±0,35 | +0,3 -0,7 | ±0,35 | +0,3 -0,7 | ±0,35 | +0,3 -0,7 | ±0,35 | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 41,8 | ±6 |

| 6,0 | +0,4 -0,8 | +0,4 -0,6 | +0,4 -0,8 | +0,4 -0,6 | +0,4 -0,8 | +0,4 -0,6 | +0,4 -0,8 | +0,4 -0,6 | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 50,1 | ±9 |

| 8,0 | +0,4 -0,8 | +0,3 -0,8 | +0,4 -0,8 | +0,3 -0,8 | +0,4 -0,9 | +0,3 -0,8 | +0,4 -0,9 | +0,3 —0,8 | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 66,6 | ±5 |

| 10,0 | +0,5 -1,0 | +0,4 -0,7 | +0,6 -1,0 | +0,4 -0,7 | +0,6 -1,0 | +0,5 -0,9 | +0,6 -1,0 | +0,5 -0,9 | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 83,0 | ±3 |

| 12,0 | +0,6 -1,1 | +0,5 -1,1 | +0,7 -1,1 | +0,6 -1,0 | +0,7 -1,1 | +0,6 -1,0 | +0,7 -1,1 | +0,6 -1,0 | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 99,3 | ±3 |

| Lentil corrugation | |||||||||||||||||

| 2,5 | ±0,25 | ±0,18 | ±0,25 | ±0,18 | — | — | — | — | 3,6 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 20,1 | ±10 |

| 3,0 | ±0,25 | ±0,23 | ±0,25 | ±0,23 | — | — | — | — | 4,0 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 24,2 | ±10 |

| 4,0 | +0,3 -0,7 | ±0,3 | +0,3 -0,7 | ±0,3 | +0,3 -0,7 | ±0,3 | +0,3 -0,7 | ±0,3 | 4,0 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 32,2 | ±8 |

| 5,0 | +0,3 -0,7 | ±0,35 | +0,3 -0,7 | ±0,35 | +0,3 -0,7 | ±0,35 | +0,3 -0,7 | ±0,35 | 5,0 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 40,5 | ±6 |

| 6,0 | +0,4 -0,8 | +0,4 -0,6 | +0,4 -0,8 | +0,4 -0,6 | +0,4 -0,8 | +0,4 -0,6 | +0,4 -0,8 | +0,4 -0,6 | 5,0 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 48,5 | ±5 |

| 8,0 | +0,4 -0,8 | +0,3 -0,8 | +0,4 -0,8 | +0,3 -0,8 | +0,4 -0,9 | +0,3 -0,8 | +0,4 -0,9 | +0,3 -0,8 | 6,0 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 64,9 | ±5 |

| 10,0 | +0,5 -1,0 | +0,4 -0,7 | +0,6 -1,0 | +0,4 -0,7 | +0,6 -1,0 | +0,5 -0,9 | +0,6 -1,0 | +0,5 -0,9 | 6,0 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 80,9 | ±3 |

| 12,0 | +0,6 -1,1 | +0,5 -1,1 | +0,7 -1,1 | +0,6 -1,0 | +0,7 -1,1 | +0,6 -1,0 | +0,7 -1,1 | +0,6 -1,0 | 6,0 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 96,8 | ±3 |

Notes:

1. The thickness of sheets with one-sided rhombic and lentil corrugation is determined by the thickness of the base of the sheet s in millimeters.

2. For sheets rolled in sheet rolling mills, in the middle part of the sheet width, a base thickness of 0.2 mm above the plus limit deviation is allowed.

3. The width of the base of the grooves b, the angle at the top of the grooves φ, the diagonals of the rhombus t1+t2), the angle of location of the grooves on the plane of the sheet φ1, the distance between the grooves t, the length of the grooves l, the radius of curvature of the grooves R on finished sheets are not controlled and are given for calculations in the manufacture of tools.

4. The weight of 1 m² of sheet is determined by the nominal dimensions of the sheets, the height of the corrugations equal to 0.2 sheet thickness, the small diagonal of the diamond equal to 27.5 mm, the larger diagonal of the diamond equal to 65 mm. Steel density is 7.85 g/cm³.

5. (Deleted, Amendment No. 4).

(Changed edition, Amendment No. 2, 3, 4, Amendment).

1.2. Corrugated steel is produced in sheets and rolls with one-sided rhombic or lenticular corrugation.

(Changed edition, Amendment No. 3).

1.3. The height of the corrugations on the sheets should be 0.1-0.3 of the thickness of the base of the sheet, but not less than 0.5 mm. At the consumer's request, sheets with a base thickness of 5 mm or more must have a corrugation height of at least 1.0 mm.

(Changed edition, Amendment No. 2).

1.4. Sheets with rhombic corrugation are made with diamond diagonals (25-30) x (60-70) mm. The configuration of the corrugations and the location of the large diagonals of the diamond along or across the sheet are set by the manufacturer.

At the request of the consumer, it is allowed to produce a sheet with a different ratio of the diagonals of the rhombus.

(Changed edition, Amendment No. 2, 3).

1.5. Lentil corrugated sheets are manufactured with a distance between corrugations of 20, 25 and 30 mm.

1.6. Sheets are manufactured in widths from 600 to 2200 mm and lengths from 1400 to 8000 mm with a gradation of 50 mm.

1.7. At the request of the consumer, it is possible to produce sheets of other sizes.

(Changed edition, Amendment No. 3).

1.8. Sheets are produced according to sizes:

- indicating dimensions for thickness in accordance with the dimensions indicated in the table, and for width and length within the limits specified in clause 1.6 - form I;

- with indication of thickness dimensions within the limits specified in the table, without indication of width and length dimensions - form II;

- indicating dimensions that are multiples in width and length of the dimensions specified by the consumer within the limits established in clause 1.6 - form III;

- indicating the measured dimensions within the limits specified in clause 1.6 - form IV.

(Changed edition, Amendment No. 1).

1.9. Maximum deviations in the length and width of sheets are in accordance with GOST 19903.

At the request of the consumer, sheets and rolls are manufactured with maximum deviations;

+20 mm - in width for rolled products over 1000 mm with uncut edges;

+15 mm - in length for sheets over 2000 to 6000 mm and over with a thickness of 4.0 and 5.0 mm;

+25 mm - with a thickness of 6.0; 8.0; 10.0 and 12.0 mm.

(Changed edition, Amendment No. 3, 4).

1.10. Deviations from flatness - according to GOST 19903 for normal and improved flatness.

(Changed edition, Amendment No. 4).

1.11. (Deleted, Amendment No. 1).

1.12. Requirements for rolled products produced in rolls, as well as the width of the rolls, are in accordance with GOST 19903.

Examples of symbols:

Hot rolled sheet of steel grade St3sp according to GOST 380* with one-sided rhombic corrugation, size 3.0x1000x2000 mm, normal thickness accuracy, improved flatness with rolled edge:

* The document is not valid on the territory of the Russian Federation. Valid: in terms of requirements for long and shaped castings GOST 535-2005; regarding grades and chemical composition GOST 380-2005; regarding the requirements for plates GOST 14637-89, hereinafter in the text. — Note from the database manufacturer.

Rhombus sheet V-K-PU-3.0x1000x2000 St3sp GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil leaf V-K-PU-3.0x1000x2000 St3sp GOST 8568-77

Hot-rolled steel grade St3sp according to GOST 380 with one-sided rhombic corrugation, size 3.0x1000 mm, high precision, with rolled edge:

Roll rhombus A-K-3.0x1000 St3sp GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil roll A-K-3.0x1000 St3sp GOST 8568-77

(Changed edition, Amendment No. 2, 3, 4).

Technical requirements

2.1. Sheets and rolls are manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Sheets and rolls are made from carbon steel of ordinary quality, grades St0, St1, St2 and StZ (boiling, calm and semi-quiet) with a chemical composition in accordance with GOST 380.

By agreement between the manufacturer and the consumer, it is allowed to produce rolled sheets without rationing the content of chromium, nickel, and copper.

2.1, 2.2. (Changed edition, Amendment No. 4).

2.3. At the request of the consumer, it is possible to produce sheets from steel of other grades.

(Changed edition, Amendment No. 3).

2.4. Sheets rolled on sheet rolling mills are cut on four sides.

2.5. Sheets and coils rolled on a continuous rolling mill may be supplied with rolled longitudinal edges.

The notches on the edges should not extend the sheet beyond the nominal dimensions in width.

2.4, 2.5. (Changed edition, Amendment No. 1).

2.6. The surface of the sheets should be free of rolled and ingot films, indentations, scale shells, rolled bubbles, cracks and dirt. There should be no delamination on the edges of the sheets.

2.7. Ripples, scale, rust, prints, and individual films are allowed on the surface of the sheets, the depth of which does not exceed the maximum deviations in thickness.

Acceptance rules

3.1. Sheets and rolls are accepted in batches. The batch consists of sheets of one type of corrugation. Determination of the batch - according to GOST 14637.

3.2. To control the size and quality of the surface, two sheets or one roll are selected from the batch.

3.3. If unsatisfactory control results are obtained for at least one of the indicators, repeated control is carried out on a sample selected in accordance with GOST 7566.

Test methods

4.1. Surface inspection is carried out without the use of magnifying devices.

4.2. The thickness of the base of the sheets and the height of the corrugations are measured at a distance of at least 100 mm from the corners and 40 mm from the edges.

The dimensions at any measured point should not take the sheet thickness beyond the maximum deviations.

4.3. The height of the corrugations h is determined as the difference between the dimensions of the total thickness of the sheet s+h and the thickness of the base of the sheet s.

The sheet is corrugated. Lentils. Rhombus.

GOST 8568-77

The standard applies to hot-rolled steel sheets with one-sided rhombic and lentil corrugation for general purposes.

The shape, dimensions, maximum deviations and weight of 1 m of sheet with rhombic and lentil corrugation must correspond to those indicated in Fig. 1, 2

Corrugated steel is produced in sheets and rolls with one-sided rhombic or lenticular corrugation.

Rolled sheets by thickness are produced:

high accuracy - A,

normal accuracy - V.

Examples of symbols:

Hot rolled sheet made of St3sp steel with one-sided rhombic corrugation, size 3.0x1000x2000 mm, normal thickness accuracy, improved flatness with rolled edge:

Sheet rhombus V-K-PU-3.0x1000x2000 St3sp

GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil leaf V-K-PU-3.0x1000x2000 St3sp

GOST 8568-77

Hot-rolled steel grade St3sp with one-sided rhombic corrugation, size 3.0x1000 mm, high precision, with rolled edge:

Roll rhombus A-K-3.0x1000 St3sp

GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil roll A-K-3.0x1000 St3sp

GOST 8568-77

Corrugated sheets in the warehouse of the MetalTechService Company are presented in the following assortment:

| Size, mm | steel grade |

| 5, 6, 8, 10 | 3 PS/SP |

Corrugated steel sheet GOST 8568-77 . Corrugated steel is produced in sheets and rolls with one-sided rhombic or lenticular corrugation.

There are two types of corrugated sheet :

The height of the corrugations on the sheets should be 0.2 - 0.3 of the thickness of the base of the sheet, but not less than 0.5 mm.

Sheets with rhombic corrugation are made with diamond diagonals (25-30) x (60-70) mm. The configuration of the corrugations and the location of the large diagonals of the diamond along or across the sheet are set by the manufacturer. Pzhya with lentil corrugation are made with a distance between corrugations of 20, 25 m 30 mm.

Sheet metal with lentil corrugation A-1-PV-StZsp2-6x600x6000 TV 14-2-818-88 with a rolled edge, one-sided corrugation is made of carbon steel with a chemical composition in accordance with GOST 380. The height of the reefs on the strip is 1.5 mm at a distance of 40 mm from the side edge. Sheets are manufactured in widths from 600 to 2200 mm and lengths from 1400 to 8000 mm with a gradation of 50 mm.

By agreement between the manufacturer and the consumer, it is possible to produce sheets of other sizes.

Depending on the purpose, sheets are manufactured:

- measured length;

- multiple measured length;

- measured length with a remainder of no more than 10% of the batch weight;

- a multiple of the measured length, amounting to no more than 10% of the mass of the batch;

- of unmeasured length.

The remainder is considered to be sheets of length within the unmeasured range that remain when cutting into dimensional and multiples of dimensional.

Corrugated sheets are produced at enterprises from carbon steel grades BStO, BSt1, BSt2 and BStZ in accordance with GOST 8568-77. Corrugated sheet is a steel sheet on the smooth side of which a certain pattern is formed. Corrugated sheets are produced with a width of 600-2200 mm, a length of 1400-8000 mm and thickness from 2.5-12.0 mm. Corrugated sheets are made in sheets and rolls; they differ in steel grade, type of pattern and overall dimensions of the sheet. In our warehouse we have corrugated sheets with different pattern heights from 0.5 mm, while the distance between the corrugations is from 20 to 35 mm. The production of corrugated sheets can be with an indication of the dimensions required by our consumers, also with an indication of the type of pattern, the height of the pattern.

Applications of Metal Corrugated Sheet:

This type of sheet metal is very often used as an anti-slip floor covering. It is also often used for the manufacture of steps and decking, interior decoration, and for setting up fencing according to safety requirements.

The sheet is corrugated and has a wide range of applications . It is used as a floor covering, its structure prevents slipping, and molds are made from corrugated sheets for the production of reinforced concrete products that require corrugation, for example, such as road slabs.

MetalTechService supplies sheets with lentil and diamond corrugations from the warehouse.

Our company’s delivery terms are beneficial for the client for several reasons:

- low price,

- We provide cutting services,

- cutting, drilling.

This offer is not a public offer and is for informational purposes only. Please check product availability and prices with managers.

You can buy corrugated sheets in one of the following ways:

Supply contract.

Enterprise card.

Contact Information

620102, Ekaterinburg, st. Volgogradskaya, 193, office. 309

Phones:

+7 +7 +7

Email:

© MetalTechService | Privacy and Personal Processing Policy data

TECHNICAL REQUIREMENTS

2.1. Sheets and rolls are manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Sheets and rolls are made from carbon steel of ordinary quality, grades St0, St1, St2 and StZ (boiling, calm and semi-quiet) with a chemical composition in accordance with GOST 380. By agreement between the manufacturer and the consumer, it is allowed to produce rolled sheets without rationing the content of chromium, nickel, and copper.

2.1, 2.2. (Changed edition, Amendment No. 4).

2.3. At the request of the consumer, it is possible to produce sheets from steel of other grades. (Changed edition, Amendment No. 3).

2.4. Sheets rolled on sheet rolling mills are cut on four sides.

2.5. Sheets and coils rolled on a continuous rolling mill may be supplied with rolled longitudinal edges. The notches on the edges should not extend the sheet beyond the nominal dimensions in width.

2.4, 2.5. (Changed edition, Amendment No. 1).

2.6. The surface of the sheets should be free of rolled and ingot films, indentations, scale shells, rolled bubbles, cracks and dirt. There should be no delamination on the edges of the sheets.

2.7. Ripples, scale, rust, prints, and individual films are allowed on the surface of the sheets, the depth of which does not exceed the maximum deviations in thickness.

Technical specifications according to GOST 8568-77

Corrugated sheet GOST 8568-77 with rhombic or lentil corrugation is produced:

- made of carbon steel of ordinary quality

- from carbon and low-alloy structural steels, classified by yield strength - C235, C245, C255, C275, C285, C345, C345K, C440, C590, C590K.

Sheets are produced to ensure the required properties (for this purpose, rolled products can be subjected to heat treatment):

- high flatness (the type of which can be specified in the order)

- with resistance to delamination.

According to GOST 8568, products are manufactured with corrugations with a height of 0.1 - 0.3 from the thickness of the base of the sheet, but not less than 0.5 mm:

- rhombic corrugation - with diamond diagonals (25-30) x (60-70) mm

- lenticular corrugation - with a distance between corrugations equal to 20, 25 or 30 mm

This is interesting: Features of the production and operation of welded beams

Application areas of corrugated sheet

This rolled metal is used in construction, industry and everyday life:

- For external and internal finishing of vertical enclosing structures - walls, partitions.

- At industrial enterprises, warehouse areas, as well as in other places with an increased risk of injury for the construction of passages, ramps, observation platforms, and the manufacture of steps. Such metal products are in demand at such critical facilities as oil platforms and power plants.

- In the automotive industry - for the production of non-slip coatings.

- In road construction - for the construction of bridges and crossings.

- Metal products made from stainless steel are used to solve design problems in construction and architecture.

Classification and features of medium-carbon steel grades

Application of expanded metal sheets for staircase equipment

Dimensions, weight and calculation of expanded metal sheets

Application

The sheet is characterized by high strength and wear resistance. The steel alloy is resistant to corrosion and mechanical stress. To improve the technical properties of the product, galvanizing is used. Corrugated sheets are used as flooring in non-residential buildings. Sheets with lentil corrugations, made in accordance with GOST standards, are used for finishing building structures, ramps, stairs, paths and bridges. Steel products are used for lining refrigerators and freezers.

For finishing industrial premises, sheets with a thickness of at least 4 mm are used. Products used for exterior and interior decoration are thinner. The rolled products are stored in the cabins of freight and passenger elevators. The use of anti-slip corrugated sheets reduces the likelihood of industrial injuries and prevents accidents.

Weight m2 of sheets according to GOST 8568

In order to calculate the cost of 1 sheet, you need to know the weight of the product of the required cutting. To calculate, we will use data on the theoretical weight of 1 m2 of rolled steel depending on the thickness of the sheets (these values are defined in GOST 8568):

| Diamond knurling | Lentil corrugation | ||

| Sheet thickness, mm | Weight of 1 m2 sheet, kg | Sheet thickness, mm | Weight of 1 m2 sheet, kg |

| 2,5 | 21,0 | 2,5 | 20,1 |

| 3,0 | 25,1 | 3,0 | 24,2 |

| 4,0 | 33,5 | 4,0 | 32,2 |

| 5,0 | 41,8 | 5,0 | 40,5 |

| 6,0 | 50,1 | 6,0 | 48,5 |

| 8,0 | 68,0 | 8,0 | 66,9 |

| 10,0 | 83,0 | 10,0 | 80,9 |

| 12,0 | 99,3 | 12,0 | 96,8 |

ASSORTMENT

1.1. The shape, dimensions, maximum deviations and weight of 1 m² of sheet with rhombic and lentil corrugation must correspond to those indicated in the drawing. 1, 2 and in the table.

Changed edition. Change No. 2 .

1.1a. Rolled sheets by thickness are produced:

- high accuracy - A,

- normal accuracy - V.

Changed edition. Change No. 4 .

Crap. 1

Crap. 2

| Sheet base thickness s, mm | Maximum deviations in sheet thickness at width, mm | Width of ribbed base b, mm | Angle at the top of the riffle φ, degrees | Ribbon length l, mm | Radius of curvature of grooves R, mm | Location of corrugations on the plane of the sheet φ1, deg | Weight of 1 m² sheet, kg | Limit deviations by mass, % | |||||||||

| from 600 to 1000 | St. 1000 to 1500 | St. 1500 to 2000 | St. 2000 to 2200 | ||||||||||||||

| normal accuracy | high accuracy | normal accuracy | high accuracy | normal accuracy | high accuracy | normal accuracy | high accuracy | ||||||||||

| Nom. | Prev. off | Nom. | Prev. off | ||||||||||||||

| Diamond knurling | |||||||||||||||||

| 2,5 | ±0,25 | ±0,18 | ±0,25 | ±0,18 | — | — | — | — | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 21,0 | ±10 |

| 3,0 | ±0,23 | ±0,23 | 25,1 | ±10 | |||||||||||||

| 4,0 | +0,3 | ±0,30 | +0,3 | ±0,3 | +0,3 | ±0,3 | +0,3 | ±0,3 | 33,5 | ±8 | |||||||

| -0,7 | -0,7 | -0,7 | -0,7 | ||||||||||||||

| 5,0 | +0,3 | ±0,35 | +0,3 | ±0,35 | +0,3 | ±0,35 | +0,3 | ±0,35 | 41,8 | ±6 | |||||||

| -0,7 | -0,7 | -0,7 | -0,7 | ||||||||||||||

| 6,0 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | 50,1 | ±9 | |||||||

| -0,8 | -0,6 | -0,8 | -0,6 | -0,8 | -0,6 | -0,8 | -0,6 | ||||||||||

| 8,0 | +0,4 | +0,3 | +0,4 | +0,3 | +0,4 | +0,3 | +0,4 | +0,3 | 66,6 | ±5 | |||||||

| -0,8 | -0,8 | -0,8 | -0,8 | -0,9 | -0,8 | -0,9 | -0,8 | ||||||||||

| 10,0 | +0,5 | +0,4 | +0,6 | +0,4 | +0,6 | +0,5 | +0,6 | +0,5 | 83,0 | ±3 | |||||||

| -1,0 | -0,7 | -1,0 | -0,7 | -1,0 | -0,9 | -1,0 | -0,9 | ||||||||||

| 12,0 | +0,6 | +0,5 | +0,7 | +0,6 | +0,7 | +0,6 | +0,7 | +0,6 | 99,3 | ±3 | |||||||

| -1,1 | -1,1 | -1,1 | -1,0 | -1,1 | -1,0 | -1,1 | -1,0 | ||||||||||

| Lentil corrugation | |||||||||||||||||

| 2,5 | 0,25 | ±0,18 | ±0,25 | ±0,18 | — | — | — | — | 3,6 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 20,1 | ±10 |

| 3,0 | 0,25 | ±0,23 | ±0,25 | ±0,23 | 4,0 | 24,2 | ±10 | ||||||||||

| 4,0 | +0,3 | ±0,3 | +0,3 | ±0,3 | +0,3 | ±0,3 | +0,3 | ±0,3 | 4,0 | 32,2 | ±8 | ||||||

| -0,7 | -0,7 | -0,7 | -0,7 | ||||||||||||||

| 5,0 | +0,3 | ±0,35 | +0,3 | ±0,35 | +0,3 | ±0,35 | +0,3 | ±0,35 | 5,0 | 40,5 | ±6 | ||||||

| -0,7 | -0,7 | -0,7 | -0,7 | ||||||||||||||

| 6,0 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | 5,0 | 48,5 | ±5 | ||||||

| -0,8 | -0,6 | -0,8 | -0,6 | -0,8 | -0,6 | -0,8 | -0,6 | ||||||||||

| 8,0 | +0,4 | +0,3 | +0,4 | +0,3 | +0,4 | +0,3 | +0,4 | +0,3 | 6,0 | 64,9 | ±5 | ||||||

| -0,8 | -0,8 | -0,8 | -0,8 | -0,9 | -0,8 | -0,9 | -0,8 | ||||||||||

| 10,0 | +0,5 | +0,4 | +0,6 | +0,4 | +0,6 | +0,5 | +0,6 | +0,5 | 6,0 | 80,9 | ±3 | ||||||

| -1,0 | -0,7 | -1,0 | -0,7 | -1,0 | -0,9 | -1,0 | -0,9 | ||||||||||

| 12,0 | +0,6 | +0,5 | +0,7 | +0,6 | +0,7 | +0,6 | +0,7 | +0,6 | 6,0 | 96,8 | ±3 | ||||||

| -1,1 | -1,1 | -1,1 | -1,0 | -1,1 | -1,0 | -1,1 | -1,0 | ||||||||||

Notes:

1. The thickness of sheets with one-sided rhombic and lentil corrugation is determined by the thickness of the base of the sheet s in millimeters.

2 For sheets rolled in sheet rolling mills, in the middle part of the sheet width, a base thickness of 0.2 mm above the plus limit deviation is allowed.

3. The width of the base of the grooves b, the angle at the top of the grooves φ, the diagonals of the rhombus t1 + t2, the angle of location of the grooves on the plane of the sheet φ1, the distance between the grooves t, the length of the grooves l, the radius of curvature of the grooves R on finished sheets are not controlled and are given for calculations when tool making.

4. The weight of 1 m² of sheet is determined by the nominal dimensions of the sheets, the height of the corrugations equal to 0.2 sheet thickness, the small diagonal of the diamond equal to 27.5 mm, the larger diagonal of the diamond equal to 65 mm. Steel density 7.85 g/cm³.

Changed edition. Change 2, 3, 4. Amendment. IUS 2-2003. Amendment. IUS 2-2005

1.2. Corrugated steel is produced in sheets and rolls with one-sided rhombic or lenticular corrugation.

Changed edition. Change 3.

1.3. The height of the corrugations on the sheets should be 0.1 - 0.3 of the thickness of the base of the sheet, but not less than 0.5 mm. At the consumer's request, sheets with a base thickness of 5 mm or more must have a ribbed height of at least 1.0 mm.

Changed edition. Change 2 .

1.4. Sheets with rhombic corrugation are manufactured with diamond diagonals (25-30) × (60-70) mm. The configuration of the corrugations and the location of the large diagonals of the diamond along or across the sheet are set by the manufacturer.

At the request of the consumer, it is allowed to produce a sheet with a different ratio of the diagonals of the rhombus.

Changed edition. Change 2, 3 .

1.5. Lentil corrugated sheets are manufactured with a distance between corrugations of 20, 25 and 30 mm.

1.6. Sheets are manufactured in widths from 600 to 2200 mm and lengths from 1400 to 8000 mm with a gradation of 50 mm.

1.7. At the request of the consumer, it is possible to produce sheets of other sizes.

Changed edition. Change 3 .

1.8. Sheets are produced according to sizes:

- indicating dimensions for thickness in accordance with the dimensions indicated in the table, and for width and length within the limits specified in clause 1.6 - form I;

- with indication of thickness dimensions within the limits specified in the table, without indication of width and length dimensions - form II;

- indicating dimensions that are multiples in width and length of the dimensions specified by the consumer within the limits established in clause 1.6 - form III;

- indicating the measured dimensions within the limits specified in clause 1.6 - form IV.

Changed edition. Change 1 .

1.9. Maximum deviations in the length and width of sheets are in accordance with GOST 19903-74.

- At the request of the consumer, sheets and rolls are manufactured with maximum deviations:

- +20 mm - in width for rolled products over 1000 mm with uncut edges;

- +15 mm - in length for sheets over 2000 to 6000 mm and over with a thickness of 4.0 and 5.0 mm;

- +25 mm - with a thickness of 6.0; 8.0; 10.0 and 12.0 mm.

Changed edition. Change 3, 4 .

1.10. Deviations from flatness - according to GOST 19903 improved flatness.

Changed edition. Change 14 .

1.11.(Excluded. Amendment 1.)

1.12. Requirements for steel produced in rolls, as well as the width of the rolls, are in accordance with GOST 19903.

EXAMPLES OF CONDITIONAL NOTATIONS

Hot rolled sheet of steel grade St3sp according to GOST 380 with one-sided rhombic corrugation, size 3.0 × 1000 × 2000 mm, normal thickness accuracy, improved flatness with rolled edge:

Rhombus sheet V-K-PU-3.0 × 1000 × 2000 St3sp GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil leaf V-K-PU-3.0 × 1000 × 2000 St3sp GOST 8568-77

Hot-rolled steel grade St3sp according to GOST 380 with one-sided rhombic corrugation, size 3.0 × 1000 mm, high precision, with rolled edge:

Roll rhombus A-K-3.0 × 1000 St3sp GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil roll A-K-3.0 × 1000 St3sp GOST 8568-77

Changed edition. Change 4 .

Steel sheets with rhombic and lentil corrugation. Specifications

| Designation: | GOST 8568-77 |

| Status: | active |

| Type: | GOST |

| Russian name: | Steel sheets with rhombic and lentil corrugation. Specifications |

| English name: | Corrugated steel rhombic and lentil form sheets. Specifications |

| Date of text update: | 06.04.2015 |

| Description update date: | 01.06.2019 |

| Publication date: | 01.09.2004 |

| Effective date: | 01.01.1978 |

| Last modified date: | 12.09.2018 |

| Reissue: | reissue with amendments and changes. 1 |

| Area and conditions of application: | This standard applies to hot-rolled steel sheets with one-sided rhombic and lenticular corrugation for general purposes. |

| Instead: | GOST 8568-57 |

| List of changes: | No. 0 from (reg.) “Introduction date postponed” No. 0 from (reg.) “Introduction date postponed” No. 1 from (reg.) “Validity period extended” No. 2 from (reg.) “Validity period extended” No. 3 from (reg.) “Validity period extended” No. 4 from (reg.) “Validity period extended” |

| Is located in: | All-Russian Classifier of Standards → Metallurgy → Iron and steel products → Rolled steel sheets and semi-finished products Classifier of state standards → Metals and metal products → Ordinary quality carbon steel → Sheets and strips All-Russian Classification of Products → Rolled ferrous metals, finished, including blanks for export → Rolled sheet metal and tin |

| Application #0: | Change No. 1 to GOST 8568-77 |

| Application #1: | Change No. 2 to GOST 8568-77 |

| Appendix No. 2: | Change No. 3 to GOST 8568-77 |

| Appendix No. 3: | Change No. 4 to GOST 8568-77 |

| Appendix No. 4: | Amendment to GOST 8568-77 |

| Appendix No. 5: | Amendment to GOST 8568-77 |

Applications to GOST

Change No. 1 to GOST 8568-77

| Designation: | Change No. 1 to GOST 8568-77 |

| Effective date: | 01.01.1979 |

The text of the amendment is integrated into the text or description of the standard.

Change No. 2 to GOST 8568-77

| Designation: | Change No. 2 to GOST 8568-77 |

| Effective date: | 01.03.1981 |

The text of the amendment is integrated into the text or description of the standard.

Change No. 3 to GOST 8568-77

| Designation: | Change No. 3 to GOST 8568-77 |

| Effective date: | 01.01.1988 |

The text of the amendment is integrated into the text or description of the standard.

Change No. 4 to GOST 8568-77

| Designation: | Change No. 4 to GOST 8568-77 |

| Effective date: | 01.01.1990 |

The text of the amendment is integrated into the text or description of the standard.

Amendment to GOST 8568-77

| Designation: | Amendment to GOST 8568-77 |

| Effective date: | 01.12.2005 |

Amendment to GOST 8568-77

| Designation: | Amendment to GOST 8568-77 |

| Effective date: | 15.11.2002 |

What is a diamond corrugated sheet?

Bumps on metal sheets, which are formed using corrugations, are not a decorative method, although such products have an attractive appearance. A corrugated surface, when compared to a smooth one, can provide significantly better grip on objects that come into contact with it. This property, in fact, determines the main purpose of sheets on which corrugation is specially applied.

Shape and dimensions of rhombic corrugation

Sheets with rhombus-shaped corrugations can be produced in various standard sizes, namely:

- thickness, measured without the height of the ribbed profile, is 2.5–12 mm;

- width – 600–2200 mm;

- the length of products, the pitch of standard standard sizes of which is 50 mm, is 1400–8000 mm.

The most popular size among consumers of this product is 1500x6000 mm.

Permissible deviations of dimensions and weight according to GOST (click to enlarge)

The corrugation on the surface of such sheets consists of intersecting lines. The dimensions of the diagonals of the rhombuses obtained by these intersections can be in the range of 25–30 and 60–70 mm. Meanwhile, these dimensions are not fixed; by agreement between the customer and the manufacturer, they can be changed, as well as the location of the pattern on the surface of the sheet.

The "Rhombus" sheet is successfully used in many areas. Elements of staircase structures, bridges and passages are made from corrugated metal sheets, they cover the floors in industrial facilities, and they are used to equip escalators in the metro and large shopping centers. In addition, products with corrugation in the form of diamonds are used to reinforce floors, wall partitions are erected from them, and containers are made that are used not only in industry, but also in agriculture.

The decorative characteristics of this material make it suitable for the design of various architectural structures, which is actively used by modern designers. In private construction and for design purposes, corrugated metal sheets of small thickness are used, and for industrial facilities thicker products are purchased.

Weight of corrugated sheet depending on the thickness of the base

Since Rhombus corrugated sheets are made of metal, they are distinguished by high strength, and if stainless steel is used as such metal (which is allowed by GOST requirements), then they also have exceptional corrosion resistance. The material of such sheets has not only the ability to withstand significant loads, but also ductility and good workability. These characteristics of metal sheets with rhombic (and any other) corrugation significantly expand the scope of their application.

In the domestic sphere, Rhombus corrugated sheets have also found wide application. For example, they are used to construct fences and various enclosures, to make gates and wickets, casings and containers for various purposes.

Meanwhile, it should be kept in mind: if corrugated sheets of ferrous metal are used for the manufacture of structures, they must be coated with protective compounds so that they do not lose their visual appeal and other characteristics after a short period of operation.