Threaded connections are widely used in technology and have a number of advantages:

- ease of assembly and disassembly of the structure;

- the ability to replace only faulty components;

- the permissibility of reusing parts after dismantling.

The disadvantage of conventional fixation methods: under the influence of axial loads, the connection weakens, even to the point of separation of parts - this explains why a thread locker is needed and why it was invented.

In the 50s of the 20th century, the American scientist Vernon Krible created the liquid adhesive resin (anaerobic sealant-glue) “loctite”. Since 1997, he has been the copyright holder of this brand.

How long does it take for red thread locker to cure?

If you have dealt with flax strands, then remember what a hassle it is. Winding takes at least an hour - the connection cannot be assembled the first time, you definitely need to unwind it and wind it again, then remove the protruding threads and cover the thread with paint to make it look more or less aesthetically pleasing. And this is subject to professional experience working with flax. What can we say about amateurs? An ordinary person - the owner of an apartment or house - needs a material for everyday life that will cope with the problem in a matter of minutes and will be as easy as possible to use.

Anaerobic sealants meet these requirements. Nowadays, when everything has to be done quickly, these innovative polymer gels come to the rescue in a variety of situations - both during planned repairs and in emergency cases.

| alt=”linen” width=”400″ /> | alt=”linen” width=”340″ /> |

Anaerobic sealant is a viscous gel that hardens inside the threaded joint. Where there is no access to oxygen. As long as the sealant is used in an open space, it is pliable and spreads easily along the threads. Does not spread and holds its shape well. Due to the gel structure, the time for applying the sealant and twisting the joint is only 20-30 seconds.

Technology

The sealant is produced in a tube with a flat neck and comes with a fiberglass brush. Before applying the gel, it is recommended to degrease and wipe the threads.

What to do next?

• Open the package, shake the tube • Apply the gel directly from the tube to the thread with the neck • Distribute evenly over the entire surface with a brush • Collect the joint • Remove excess with a brush and transfer to the next thread

How much to wait

The polymerization time inside the joint depends on the type of sealant used. On average it is 15 minutes.

PlumberGel Green

— Cures in 20-30 minutes — The softest sealant for sealing metal joints up to 1.5 inches in diameter — Suitable for pipes located in hard-to-reach places. If necessary, it can be dismantled without much effort using a plumber's wrench or wrench.

StopmasterGel Red

- Fastest - hardens in 5 minutes - Works with metal and flange connections up to 3 inches - Forms a very strong connection - Requires heating with a hair dryer for dismantling

After the sealant has hardened, the connection is checked with a pressure of 0.5 atmospheres. A working pressure of 10 atmospheres is allowed to be applied after 1 hour for SantekhmasterGel Green and Blue, and after 20 minutes for StopmasterGel Red. A pressure of 40 atmospheres is allowed after 24 hours for Green and Blue, and after 4 hours for Red.

Subtleties of the process

It is important to consider the ambient temperature when twisting connections. The values above are given for temperatures from +18 °C. The optimal temperature for installation is from +15 °C. If the mark on the thermometer is lower, you need to additionally warm up the connection.

| alt=”stopmaster gel” width=”700″ /> |

All these values are recommended by the manufacturer, but they are relative. The hardening time of the gel varies in different areas of its application. Let us remind you that anaerobic sealants are suitable for:

• Plumbing and heating • Liquefied and natural gas • Drinking water

However, practice shows that buyers of sealants use them not only according to the instructions:

• Repair of musical instruments, flashlights, bicycles and motorcycles • Sealing of industrial pumps, laboratory equipment • DIY installation of heated floors and country water supply

In cases where there is no threat of water leakage or gas leakage, you can check the strength of the connection within 2-3 minutes.

Let's summarize the advantages of modern anaerobic sealants

• Simple and convenient application • Can be dismantled at any time after twisting • Economical consumption • 100% tight with a 20-year guarantee • Thread protection from rust • High connection strength even at pressures of 50-100 bar

Buy only high-quality and proven anaerobic sealants to keep your home safe from leaks. You can purchase modern sealants directly from the manufacturer on our website.

How to use?

As mentioned earlier, anaerobic sealant cures very quickly. However, despite this, working with it is not difficult and even a beginner can cope with it. To achieve the desired effect, you just need to follow the instructions for using the product, because the sealant is sold completely ready for use and does not need to be pre-prepared or mixed with solvents. It is better to completely clean the working surface in advance, and then degrease it - this will enhance the reaction and the composition will set much better.

Instructions for use:

- We take the container with the composition and shake it thoroughly, thereby mixing the contents.

- Open the container and apply the product around the perimeter of the connection.

- Next, we completely screw in the elements to which the sealant was applied.

- The excess must be removed immediately, without waiting for the composition to dry.

- Let the sealant dry, leaving it for about half an hour (the gel dries differently, depending on the diameter of the joint being processed and the room temperature) and then check it under a pressure of 10 atmospheres. If the ambient air temperature does not reach + 15°C, the sealant must be heated. If after checking there are no leaks, then a day later you can test for functionality under a pressure of 40 atmospheres.

To ensure maximum bonding, the composition can be applied to both surfaces, that is, inside and outside. But this must be done carefully so as not to apply too much sealant. If plastic pipes are processed, they must be treated with a special activating agent before work. Quite often, a brush is included with the container, which greatly simplifies the application process.

Product Description

ABRO Threadlok is a thread locker available in two versions. Blue is intended for those connections that require a certain mobility and frequent assembly and disassembly. It is removable, that is, when dismantling it is easy to remove the remaining product.

Red is intended for fixing connections that do not require frequent disassembly. It is irremovable, that is, after a single application it remains forever.

Both products give the connection vibration resistance and mechanical resistance. They also protect against water ingress and corrosion.

They are chemically stable towards most substances. Also, both of these products are resistant to temperature fluctuations, do not spread in the heat and do not crumble in the cold.

Both products are designed for securing threaded connections.

Liquid or paste threadlockers, which should you choose?

It all depends on the type of connection. For small diameter bolts, liquid thread locker is used. It spreads evenly over the surface and is held in place by surface tension forces.

Paste-like compounds are used on large-diameter fasteners. In addition to the fact that they hold well over a large area of application, the coefficient of friction when twisting is reduced.

Plastic compounds are also used for sealing. They are not used as glue, but cracks and other defects can be repaired.

Blue composition

- metal fasteners 6-20 mm;

- hydraulic and pneumatic fittings;

- valve cover bolts, as well as oil pan.

In addition, these are grower washers located in various other locations.

Specifications

| Parameter | Value/Units |

| Physical type | Blue liquid |

| Smell | Weak |

| Shear strength | 112 kg/cm 2 |

| Operating temperature range | -59°С…+149°С |

| Diameter of fixed parts | 6-20 mm |

| Setting time | 20-30 minutes |

| Final polymerization time | 24 hours (at room temperature) |

| Relative density | 1.1 g/ml |

| Flash point | >93˚С |

| Boiling temperature | >149˚С |

| Solubility in water | Insoluble |

Release form and articles

Thread locker blue (removable) / ABRO Threadlok Removable Medium strenght (blue):

- TL-342 (tube) 6 ml.

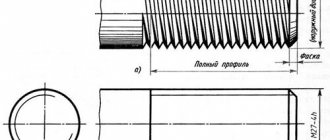

Red composition

- metal fasteners 9.5-25 mm;

- assembly pins;

- transmission and suspension bolts;

- power unit fittings.

In addition, it is applicable to any other parts where you need a reliable, strong connection, but do not want to use reinforcement with a second nut or welding.

Specifications

| Parameter | Value/Units |

| Physical type | Red liquid |

| Smell | Characteristic |

| Shear strength | 210 kg/cm 2 |

| Diameter of fixed parts | 9.5-25 mm |

| Operating temperature range | -59°С…+149°С |

| Setting time | 20-30 minutes |

| Final polymerization time | 24 hours (at room temperature) |

| Relative density | 1.1 g/ml |

| Flash point | >93˚С |

| Boiling temperature | >148˚С |

| Solubility in water | Slightly soluble |

| Auto-ignition temperature | Not self-igniting |

Release form and articles

Thread locker red (non-removable) / ABRO Threadlok Permanent Hight strenght (red):

- TL-371 (tube) 6 ml;

- TL-571 (bottle) 50 ml.

Properties

In general, they have similar qualities:

- fixing and sealing any threaded connection;

- ensuring vibration resistance of fasteners;

- creating a connection with shear resistance up to 112 kg/cm 2 (for blue) or 210 kg/cm 2 (for red);

- stability towards various chemicals;

- protection against rust and corrosion;

- resistance to temperature fluctuations.

The blue clip can be removed using hand tools. Red cannot be removed by anything: to disassemble the connection it should be heated to +150C.

We compare threaded fasteners from different manufacturers

In terms of composition, any thread locker consists of the same components. When you go to a specialized store, you will see a lot of offers: “Permatex”, “Abro”, “Loctite”, “Wurth”.

Almost all manufacturers of automotive chemicals have these sealants in their product range. Why, with the same declared characteristics, does a tube of a good fixative (according to the sellers) have a different price?

The most expensive segment is sealants used by automakers. Permatex compounds are used for permanent connections. On the conveyor belt, the glue is packaged in barrels, but exactly the same product is offered on the shelves in small containers. Manufacturer Abro offers economical prices . This does not mean that sealants with this logo are of low quality, just that the chemical concern has organized mass production in various countries, which reduces production costs. The blue composition of this brand is used not only as a thread locker, but also as a sealant for sealing defects in welds.

Loctite 270 has gained popularity among car enthusiasts due to its resistance to petroleum products. The chemical composition allows it to be applied to lightly soiled surfaces. Special additives enhance adhesion when processing neutral surfaces: stainless steel, galvanized, anodized coatings, aluminum.

Video review of the most popular thread lockers

Instructions for use

Here's how to properly use Abro thread locker:

- Prepare the details. Remove dirt from them and degrease the threads.

- Shake the container with the sealing compound. Remove the cap and cut off the tip.

- Apply a few drops of the product to the threads.

- Connect the parts and tighten. The composition sets only in the absence of air, so the tightest possible connection should be ensured.

- Before using the structure, you must allow the latch to set. This is at least 20-30 minutes.

Avoid contact of product with eyes and skin. In case of contact, wash immediately with soap and water. Work in a well-ventilated area.

Sealing with FUM tape or plumbing thread

Due to their ease of use, these materials have gained high popularity. To seal most threaded connections in an apartment, it is enough to wrap the number of turns of tape indicated in the instructions around the pipe and tighten it with a wrench. In this case, special care is not required when laying; on the contrary, many manufacturers recommend winding it slightly obliquely. The connection with such a seal can be easily disassembled if necessary.

At the same time, fum tape does not tolerate vibrations, does not cling well to small threads, and can be damaged by rough cutting. It is not recommended to seal pipes of significant diameter with it.

Reviews

Vladimir, 42 years old

I used the Abro non-removable clamp to install the ratchet bolt on the crankshaft. He helped me a lot. As for the undeletable, of course, it is said loudly. But it is really very durable, making the connection vibration-resistant and reliable.

Igor, 28 years old

A reliable thing, it forms something like crystals that firmly hold the connection. Disadvantages: it is inconvenient to apply, the container volume is small.

Alexander, 47 years old

I use the blue retainer not only in the car, but also at home. An irreplaceable thing in everyday life. Perfectly fixes any bolts.

Sealing with linen thread

This method is the oldest. This is exactly how pipe connections were sealed in Soviet apartments. If the store does not have other sealants, then flax and plumbing paste are sure to be found. But this seal has a number of significant disadvantages:

- According to the rules, flax is used in combination with drying oil and red lead. Lead prevents corrosion of the joint, and drying oil fills the pores of flax like a polymer. But finding high-quality ingredients is quite difficult, so red lead is often replaced with iron, which only accelerates the oxidation of metal components. Some craftsmen get out of the situation by using silicone-based automotive sealants.

- The difficulty of laying linen thread on the thread. What is so easy for experienced plumbers can cause a lot of difficulties for a non-specialist. It is unlikely that you will be able to wind the flax correctly onto the joint the first time, and any error in performing this operation will lead to the seal not lasting very long.

- Len does not tolerate changes in working conditions very well. Therefore, in heating systems, its strands will collapse much faster. Also, this type of sealant does not react well to aggressive environments.

- The high hygroscopicity of the material leads to its swelling, which is why connections that are not strong enough can simply burst. For example, it is not recommended to use flax when sealing aluminum radiators.

How long does red thread locker take to dry?

In general, the method of fixing threaded connections using various compounds (paint, glue...) is not new for a long time and is widely used in industry, but mainly in unloaded units.

The emergence of specialized products was a real revolution in this area and made it possible to ensure reliable fixation under both normal and increased loads. At the same time, there was no need for a large number of different locking parts, and the assembly process was significantly simplified.

Mechanical fixation of screws using locknuts, spring washers, toothed rings, cotter pins means that the user must have a very large stock of fastening elements for all occasions, which, as is known, do not provide a seal to the threads and do not prevent rust, but are reused in most cases it is impossible.

To anyone who knows these problems, it is clear why specialists are increasingly using a more modern and reliable method - fixing threads with Permabond glue.

Permabond adhesives not only provide greater thread security, in most cases they also provide greater savings.

To fix threads, high-temperature adhesives are also used, which act as sealants for threaded connections. Such adhesives are new phosphate compositions, which are characterized by high adhesive ability to refractory materials, increased heat resistance and gas tightness.

Permabond HH131 High Temperature Adhesive is a high-strength anaerobic adhesive that is extremely resistant to high temperatures.

The material hardens in an airless environment between tightly fitted metal parts. Used to secure and seal bolts, nuts and screws where long-term assembly is required.

For example, pipe sealants Permabond A1058 and Permabond A126 are used for use in fire protection systems. They provide a sealing and hardening gasket that will withstand the critical burst pressure ratings of most pipes.

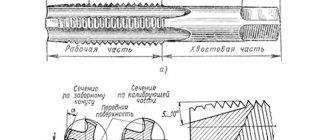

Fixing and sealing screws

- Fixing screws with Permabond glue replaces a whole warehouse of mechanical fixing elements and frees you from dependence on thread sizes. In addition, the connection using Permabond glue is performed with a conventional tool; without the risk of self-unscrewing

- When the Permabond adhesive cures, it creates a seal that protects the threaded joint from corrosion, which would inevitably cause it to fail.

To fix the threaded connection, anaerobic Permabond adhesives are used, which cure only when air is displaced from the gap and in contact with the metal. Otherwise, these adhesives remain liquid.

What fixes the connections?

Grover [1].

This is a spring split washer used as a locking element. Grovers cannot be used on deformable materials such as aluminum and its alloys, as well as copper or bronze.

Polymer insert [2].

A bushing is inserted into a special groove, which is deformed when the nut is screwed onto the thread. Once tightened, the polymer insert increases friction, preventing the connection from loosening due to shaking. The disadvantage of such fasteners is the limited number of assembly/disassembly operations.

Folding washer [3].

Such washers are usually made of mild steel and equipped with claws. One of the legs is bent to the edge of the nut, which must be secured against unscrewing, and the other is fixed, if possible, on the part being tightened. It is clear that such parts are disposable.

Glue or cosmetic varnish [4].

Nail polish or glue are often used for locking threads. The main advantage of such techniques is simplicity and confidence that things won’t get worse. But these drugs do not work as intended, so you should not expect serious protection from them.

Cotter pin [5].

A metal rod is inserted into the through hole and its ends are bent. As long as the cotter pin is in place, the nut will not come off. It is clear that cotter pins can only be used with special nuts and bolts that have a hole. In addition, they will not help fix the bolt or stud in the body of the part.

Nut with safety collar.

Those who dealt with the front hubs of Zhiguli cars probably remember a large nut, the thin collar of which had to be bent into the grooves of the axle in two places. The disadvantage of this solution is the need for a special part such as a bolt and a rather rare nut.

Lock-nut.

The most primitive solution in the fight against self-loosening is locknuts. The additional nut is pressed against the main one and locks it. This solution cannot be used everywhere - sufficient space is required on the threaded part of the stud or bolt.

Product Description

ABRO Threadlok is a thread locker available in two versions. Blue is intended for those connections that require a certain mobility and frequent assembly and disassembly. It is removable, that is, when dismantling it is easy to remove the remaining product.

Red is intended for fixing connections that do not require frequent disassembly. It is irremovable, that is, after a single application it remains forever.

Both products give the connection vibration resistance and mechanical resistance. They also protect against water ingress and corrosion.

They are chemically stable towards most substances. Also, both of these products are resistant to temperature fluctuations, do not spread in the heat and do not crumble in the cold.

Both products are designed for securing threaded connections.

Fixing threads in “hiking” conditions

Situations often arise when you have to decide what to replace a thread locker with when it is not possible to purchase the product you are looking for. Options for fixing compounds:

- nail polish;

- bakelite varnish;

- lacquer;

- nitroenamel;

- silicone sealant.

Treatment with epoxy resin will create a structure that is difficult to disassemble.

But, it's better not to take risks. For critical connections, use original, proven chemical compositions, and not self-made thread lockers.

Thread locks: red L271 and blue L243

Hi all. In today's review we will talk about a thread locker that I purchased on Aliexpress. The main purpose of this product follows from its name. The applied fixative prevents spontaneous loosening of threaded connections, whether they are bolts clamped with nuts, screws, screws or self-tapping screws. First of all, thread lockers are used in components that are subject to vibration, temperature changes, or where you need to tighten them once and, as they say, forget about them. Simply put, their main areas of use are in the car (for example, in the brake system or when attaching pulleys to shafts), household appliances, kitchen utensils (handles of pans, lids) and so on. Personally, I periodically had the handles of my frying pans unscrewed. Not completely, but the weakened connection led to the fact that the frying pan “danced” separately from the handle. The same applied to the lids of frying pans/pots. Their hands also had to be tightened periodically. The last straw was a loose nut on the car's recently replaced stabilizer bar. Before finding the culprit of the knock, a lot of time and money was spent replacing the silent blocks of the rear suspension.

I found the item I needed on Aliexpress, costing only $1. Despite the fact that delivery was more expensive than the goods, the seller skimped on a full-fledged tracking number, so the package was tracked only in China.

It took the parcel about a month to get from China to Belarus. At the post office they gave me a small bag inside which contained the goods I ordered. The delivery set included: two tubes with a fixative, two pieces of 3M double-sided tape (as I understand, a free gift

) and a note of gratitude from the seller.

So, the kit includes two fasteners: red and blue. They are supplied in plastic tubes, each weighing about 3.5 grams. At first it may seem like very little. But you should take into account the fact that to fix one threaded connection, 1 drop of the substance is enough. So 3.5 grams should last a long time.

The blue retainer is designated L243 and is considered a “split” retainer. That is, in order to unscrew a connection reinforced with a clamp, you do not have to use thermal effects or excessive loads. The main application area for L243 is connections that are not exposed to high temperatures or connections subject to vibration.

Red clamp - L271. It is considered more reliable than blue and is classified as “one-piece”. In order to unwind the connection reinforced by this clamp, it will have to be heated.

Simply put, any thread locker is nothing more than glue for joints. True, depending on external conditions, you can choose the desired degree of fixation. So, by and large, any polish (even nail polish) or paint (almost any) can act as a kind of fixative. But, as they say, this is not our method

So, since the theory is over, then it is time to move on to practical tests. We will use two M6 bolts and nuts for them as connections.

The bolts were found in a toolbox. It is clear from them that they have been there for a long time: although there is no corrosion yet, a lot of dirt has already accumulated on the threads. In order to bring the test conditions closer to reality, it was decided not to clean the threads, but to apply the fixative as is. By the way, in order to apply it you will have to cut off the tip of the tube. It also doesn’t hurt to shake the contents of each tube thoroughly.

So, drop a drop of each retainer onto the bolt threads. After they spread along the thread, the blue fixative began to flow down, and the red one remained in an even ring. The substance of the fixatives is similar to a liquid-liquid gel. But looking at how they drain, we can conclude that the red fixative is more viscous.

We tighten the nuts. It’s not very visible in the photo, but in reality, most of the blue retainer was collected behind the nut, but the red one was evenly distributed under the nut, as well as in front and behind it.

Having placed the bolts on their sides and left them like that for a few minutes, it became clear that it was necessary to apply not 2 drops of the retainer, but one (at least for connections with small diameters), since a decent part of it simply dripped onto the ground.

I didn't find any information on the product description page about how long the fixative should take to dry. Just in case, I decided to leave it for a day and only then try to unwind it.

To be fair, it is worth noting that during this time the red fixative dried (absorbed? :)) so much that it became barely noticeable on the thread:

But blue hasn't changed that much. If you run a toothpick over it, the retainer claws perfectly, remaining on the piece of wood:

To check the reliability of the resulting connection, a home “stand” was used, consisting of an ordinary and

Before moving on to using the keys, I tried to unscrew them by hand, because I also twisted them by hand. Nothing worked for me; neither the red nor the blue lock gave way. Intermediate conclusion - they work))

It was time to use the levers, which were the keys. I decided to go from a force of 0 Nm up in increments of 1 Nm.

So here it is. The blue retainer failed under zero load. In reality, it is, of course, not zero, because the torque wrench itself, used instead of a lever, created the force. But there was no click, which means the specified parameter was not achieved. After turning the nut back and forth, it became clear that the retainer was simply being cut off in layers.

Next in line is the red L271. To be honest, after reading on the product page the phrase “In Red One 271, It is very difficult to Unscrew a bolt with it,” I thought that the maximum force of my torque wrench of 25 Nm would not be enough. I was already wondering how and what I would use to heat the bolt, when suddenly:

With a force of 7 Nm, the connection gave way and began to unwind. Perhaps the connection was loosened by the previous 6 approaches, or maybe 7Nm is enough for the red clamp to come apart. But be that as it may, it is clear that the red lock is more reliable than the blue one.

As a short summary, the clamps work. Personally, I expected more from them, but even taking into account the fact that none of them met my expectations, I will not argue with the fact that these compounds strengthen the connection. I think that if I had removed any debris from the threads before applying the fixative, the result would have been even better. Well, if the nut was not located in the center of the thread, but was clamped with force, then, it seems to me, the effect would be more productive. But then it would not be possible to determine the exact force that is necessary to “break” the latch.

I haven’t figured out where to use the blue retainer yet, but I coated all the bolts and screws that secure the handles of the frying pans and their lids with red. I hope this stops them from unwinding spontaneously.

That's all. Thank you for your attention and your time.

Colors

The most important criterion by which one can immediately draw a conclusion about what the sealant is used for and what properties it has is color. Anaerobic thread sealants are produced in several colors.

Blue

Typically, blue anaerobic sealants are only suitable for metal pipes and parts. The joint turns out to be resistant to all kinds of influences, be it water, gas, antifreeze, gasoline and the like. The blue retainer is a high-quality seal that has only recently begun to be used in domestic conditions. Previously, it was only available in industrial production, for example, in the construction of defense structures, rockets, and spaceships. Application is limited only by the diameter of the pipes: it should not exceed two centimeters. Dismantling can be carried out without special equipment by applying medium mechanical forces.

Red

Red sealants are needed to seal worn, worn out threads. Red sealants are also used to seal joints of ferrous metal pipes. Red fasteners set faster than others, but this does not in any way affect their strength properties. They are resistant to high pressure and temperature changes. The diameter of the pipes that can be sealed with this anaerobic gel is no more than 3 cm. Dismantling will necessarily require heating the joint. When repairing, it is not necessary to remove excess sealant from the threads; you can apply a new layer directly on top of them.

Green

Green sealant is a low-strength variety. It is suitable for temporary connections of both plastic and metal pipes. When dismantling it, no effort will be required: it will be enough to unscrew the connection as usual. Manufacturers claim that the difference between the blue and green options is small, but this is not the case. Blue is resistant to all kinds of influences and vibrations, which cannot be said about green. The green sealant can be used to seal pipes up to 3.81 cm (1.5 inches) in diameter. The important point is that the threads must not be damaged.

Blue composition

- metal fasteners 6-20 mm;

- hydraulic and pneumatic fittings;

- valve cover bolts, as well as oil pan.

In addition, these are grower washers located in various other locations.

Specifications

| Parameter | Value/Units |

| Physical type | Blue liquid |

| Smell | Weak |

| Shear strength | 112 kg/cm2 |

| Operating temperature range | -59°С…+149°С |

| Diameter of fixed parts | 6-20 mm |

| Setting time | 20-30 minutes |

| Final polymerization time | 24 hours (at room temperature) |

| Relative density | 1.1 g/ml |

| Flash point | >93˚С |

| Boiling temperature | >149˚С |

| Solubility in water | Insoluble |

Release form and articles

Thread locker blue (removable) / ABRO Threadlok Removable Medium strenght (blue):

- TL-342 (tube) 6 ml.

Red composition

- metal fasteners 9.5-25 mm;

- assembly pins;

- transmission and suspension bolts;

- power unit fittings.

In addition, it is applicable to any other parts where you need a reliable, strong connection, but do not want to use reinforcement with a second nut or welding.

Specifications

| Parameter | Value/Units |

| Physical type | Red liquid |

| Smell | Characteristic |

| Shear strength | 210 kg/cm2 |

| Diameter of fixed parts | 9.5-25 mm |

| Operating temperature range | -59°С…+149°С |

| Setting time | 20-30 minutes |

| Final polymerization time | 24 hours (at room temperature) |

| Relative density | 1.1 g/ml |

| Flash point | >93˚С |

| Boiling temperature | >148˚С |

| Solubility in water | Slightly soluble |

| Auto-ignition temperature | Not self-igniting |

Release form and articles

Thread locker red (non-removable) / ABRO Threadlok Permanent Hight strenght (red):

- TL-371 (tube) 6 ml;

- TL-571 (bottle) 50 ml.

Household use

Before using the thread locker, you must carefully read the attached instructions. Graduation by properties does not always correspond to the usual color indication (red, blue, green). The manufacturer can color the containers and packaging in his own way, according to his classification.

Application rules

The principle of application is the same for everyone, but it is better to carry out the actions according to the instructions on the packaging:

- Remove the part to be fixed.

- Clean the thread surface from dirt and degrease with a cleaner.

- To speed up the chemical reaction, apply an activator in the following cases:

- work with passive metals;

- Perform fixation at temperatures below 15°C.

- Allow the activator to dry.

- Applying anaerobic fixative to threads:

- Through hole - squeeze drops onto the screw thread, where the nut is installed.

- Non-through hole - distribute drops on the surface of the blind hole.

- Sealing joints - apply a fixative to the visible part of the mating parts.

Read also: Connecting wires in the junction box of a double switch

It is advisable to avoid contact of the bottle nozzle with metal to avoid clogging the tube opening.

Connect the parts. The structure is ready for use after

Disassembling the connection

The method of disconnecting fixed parts corresponds to the strength of the clamp:

- Small or medium degree - disassemble using a tool.

- High degree - before disassembling, heat the interface to

230°C for 5 minutes.

Residues of glue are removed with a cleaner, acetone. If necessary, clean with a metal brush or additionally heat the surface with a hair dryer or gas burner.

Classification

There are many thread lockers available today. Each manufacturer supplements, changes the chemical composition, introduces other chemical components, adapting its properties for a specific solution to the problem. Products on the market: thread locker Mannol, Loctite, Permatex, Loxeal, Permabond, Devcon, Euroloc, Rite-Loc Abro. The choice must be made based on solving a specific problem, and not asking the question: which thread locker is better.

Main characteristics:

- According to the degree of viscosity. The smaller the cross-section and filling cavity, the more fluid the composition should be. There are:

- pasty;

- gel;

- liquid.

- According to the operating temperature of operation of the joint fixed with anaerobic glue. Varies from -200°C to +300°C.

- The rate of polymerization is the curing time of the composition.

- According to the permissible maximum connection diameter.

- By degree of strength: pulleys; tool holders; couplings; on low-strength metals (brass, aluminum and their alloys).

Degree Application area Example Low Connections that are subject to subsequent dismantling and are not subject to high loads. - adjusting and installation screws, with a countersunk head;

Average In structures whose parts are dismantled infrequently, but are subject to high vibration. - press;

- gearboxes;

- pumps;

- engines.

High Can be used in flange, bushing, threaded connections, which will be dismantled in exceptional cases. - transmissions;

- railway, road, bridge structures;

- rocket and space technology.

Properties

In general, they have similar qualities:

- fixing and sealing any threaded connection;

- ensuring vibration resistance of fasteners;

- creating a connection with shear resistance up to 112 kg/cm2 (for blue) or 210 kg/cm2 (for red);

- stability towards various chemicals;

- protection against rust and corrosion;

- resistance to temperature fluctuations.

The blue clip can be removed using hand tools. Red cannot be removed by anything: to disassemble the connection it should be heated to +150C.

How to remove fasteners and sealant?

When using sealants with a high level of fixation, the question arises: how to unscrew a bolt or nut without damaging the fastener? Many users apply too thick a layer in an effort to ensure greater reliability.

The excess is useful for sealing, but not for threaded connections. The retainer that is squeezed out from under the nut does not work and must be removed. Then there will be no problems with unscrewing.

If the connection is too strong, the removal method is selected depending on the type of sealant:

- Blue compounds are removed mechanically. It is necessary to extend the tool with a lever (for example, a pipe) and apply constant force without jerking. The main thing is to catch the moment of failure, after which the nut goes easily. It is pointless to use mechanical force (for example, tapping or vibration). Fixatives easily resist such methods.

- Local heating is required to separate parts treated with red compound. The packaging usually indicates the heat resistance: for example, 150°. When the nut is heated with a heat gun (300° - 500°), the retainer is destroyed. Heating can also be used to clean the threads of sealant residues before applying a new compound.

Disassembling a threaded connection with Loctite thread locker

Application of Permabond glue

When securing a threaded joint with Permabond products, a drop of liquid adhesive is applied directly from a plastic tube to the threads of the nut or screw. When a screw or nut is tightened, the liquid adhesive fills all the cavities in the threaded joint and cures to form a hard plastic.

The resulting threaded connection can withstand shock and vibration, is leak-tight and corrosion-resistant, and is permanently stable until dismantling, which again is carried out with ordinary hand tools.

Connection characteristics:

- Converts simple nuts into self-locking ones

- Ensures complete tightness of the threaded connection

- Most threaded parts can be reused

- Reproducible torque/preload ratio

- Controlled strength of cured adhesive

- Oily screws and nuts (as supplied) may be used for assembly.

Advantages of Permabond glue:

- Simplifies and speeds up installation

- Stops leakage and corrosion

- Savings by reducing the number of fixing elements in stock

- Controlled clamping force on screws, nuts or spacer bolts

- Easy to disassemble - just a simple tool required

Thread sealant - plumbing sealant for threaded connections

Threaded connections used in plumbing, heating and gas supply systems must be completely sealed. It is almost impossible to achieve this only due to the quality of the thread itself, without the use of additional materials. There are several methods of sealing, but recently anaerobic sealant for threaded connections has gained enormous popularity among craftsmen. Why?

Naturally, the main task of such seals is to completely seal the joints. The material used must completely prevent the leakage of water or gas through the threaded gap. But a high-quality seal must have other important properties:

- It should not contribute to corrosion of the elements being connected. On the contrary, the material applied to seal threaded connections is designed to protect these vulnerable areas from damage caused by exposure to water or aggressive substances.

- All sealing materials, including sealants, must have good adhesive properties to prevent them from being squeezed out of joints under pressure of water or gas.

- It must be resistant to temperature changes and withstand vibration vibrations.

- The materials used to seal the pipes should not significantly impede the assembly or disassembly of the connection. It is very convenient if after dismantling the sealant can be easily removed and reapplied.

Another important feature that you should pay attention to when choosing a sealant or sealant for threads is ease of use. Very often such connections are located in hard-to-reach places where any manipulation is difficult. In such cases, sealants have a clear advantage, since they do not require such careful and thorough application as sealing tapes or linen.

Instructions for use

Here's how to properly use Abro thread locker:

- Prepare the details. Remove dirt from them and degrease the threads.

- Shake the container with the sealing compound. Remove the cap and cut off the tip.

- Apply a few drops of the product to the threads.

- Connect the parts and tighten. The composition sets only in the absence of air, so the tightest possible connection should be ensured.

- Before using the structure, you must allow the latch to set. This is at least 20-30 minutes.

Avoid contact of product with eyes and skin. In case of contact, wash immediately with soap and water. Work in a well-ventilated area.

Non-curing sealants

They are produced in the form of thick and viscous pastes consisting of polymers and synthetic resins. This consistency allows them to provide high-quality sealing of connections and calmly withstand vibration loads. Such sealants are often used in combination with other sealants.

Important! Non-hardening sealants cannot be used in high-pressure systems - the composition will simply squeeze out of the thread. They also do not tolerate exposure to aggressive materials well.