Is it possible to shorten

The chain on the saw breaks, this is a common occurrence and there is no need to be upset. Manufacturers have made sure that chains can be repaired and shortened. On sale are spare links for chains of different types and sizes, rivets for chains, riveting and riveting machines.

Using machines, you can rivet a chainsaw chain at home even for those who have never done anything like this.

Important: chain repair, even the highest quality, does not guarantee that it will last forever. The links wear out evenly, so at any moment the chain can break in another place.

Chains are available for sale in coils of 50-100 meters, which you can buy and rivet yourself.

Coils are beneficial for professionals who use chainsaws every day, for example, forest fellers or sawmill workers.

Video material

A chainsaw, like any tool, requires careful attention. In addition, when purchasing it, you should pay attention to the manufacturer and seller. As a rule, instruments purchased in branded stores require repairs much less often.

Good evening. I was puzzled by the question of how to properly shorten the chain? Does this make sense? Will there be increased wear when using a stretched sprocket chain and tire? Thank you all in advance.

Take it to a service center and have it shortened. There are specialists there and the appropriate equipment. If you throw out one link in such a way that the chain still fits on the bar, there will be no increased wear. If the chain has stretched, your sprocket has already failed. How many chains do you have?

I definitely won’t take it to the service department, it’s easier to buy a new one and not bother. Isn’t it possible at home? A stretched one will have a tooth life of 50-60%, and a quantity of 5 chains from Shtil. It will be nice for the soul to restore it yourself, but how?

krot. wrote: I definitely won’t take it to the service, it’s easier to buy a new one and not bother. Isn’t it possible at home?

Really, probably. But is the game worth the candle? I mean, is the result worthy of such hemorrhoids? » > In the service department, shortening a chain costs mere pennies.

A stretched one will have a tooth life of 50-60%, and a quantity of 5 chains from Shtil. It will be nice for the soul to restore it yourself, but how?

It seems to me that something is happening with your tire lubrication if the tooth life is 50 - 60 percent, and the chain is already stretched, don’t play around.

I do not see the point. By the way, I shortened it at Druzhba, but the speed there was not the same as that of modern saws. I would not.

newzubok wrote: Take it to a service center and have it shortened. There are specialists there and the appropriate equipment. If you throw out one link in such a way that the chain still fits on the bar, there will be no increased wear. If the chain has stretched, your sprocket has already failed.

Exactly what will not follow the asterisk.

valerich wrote: Exactly, that will not follow the asterisk.

Why the fright? Shortening the chain by one tooth will not change the chain pitch, but the chain has already stretched and worn in along this sprocket. The game is worth the candle when three chains work alternately, and for some reason one is stretched ahead of time. I had this happen once when something got clogged in the tire lubrication system. I washed it with gasoline and diesel fuel, restored the lubrication and threw out one link at the service center. Then I brought all 3 chains to zero, changed them and changed the sprocket, as usual.

krot. wrote: I definitely won’t take it to the service, it’s easier to buy a new one and not bother. Isn’t it possible at home? A stretched one will have a tooth life of 50-60%, and a quantity of 5 chains from Shtil. It will be nice for the soul to restore it yourself, but how?

Why didn't you like the service?

newzubok wrote: I threw out one link in the service.

Have you missed anything? I've been with chainsaws of the year since 1982. Give me a chance to improve?

Read also: What is the difference between a nut and a bolt?

Not wait. It's time for me to sleep. Tomorrow I have to go to work at 9:00. In general, you can’t throw out one link. It just won't rivet. The Druzhbovsky chains came with spare links and I riveted them myself. That's why I know. We send modern ones for service, because we know little. But the principle is the same. Good night!

Shortening the chain is as easy as shelling pears. Connecting links with rivets are sold for 3 hryvnia apiece for all chains, which are also branded. Shtilevskie chains are also suitable for Oregon, the main thing is the same step (we have the same price in Nadvirna, maybe somewhere else). The head of the rivet is carefully cut off on the chain with a grinder, the tooth is thrown in and the chain is riveted into place. I do this often, work| for about 5 minutes.

valerich wrote: Have you confused anything? I've been with chainsaws of the year since 1982. Give me a chance to improve?

I didn't mix anything up. I just thought that I was talking to technically literate people who understand what is meant by “one link”. Exactly the same as for a bicycle chain or a motorcycle chain.

You have to go to the service specifically and the issue is not money, but time. Yes, and I like to do it myself. And the chain stretched due to working without oil, my friends tried (last time with this saw)

By the way, blunt chains also stretch well. In general, cut with stretched chains. the sprockets wear out quickly, then when you put a new chain on the old sprockets, there is no gutt either. If the sprockets are not worn, then it is better to buy another chain, I understand that the toad is pressing, but a chain is better than then a tire with a sprocket.

Dimon 35 wrote: By the way, stupid chains also stretch well. In general, cut with stretched chains. the sprockets wear out quickly, then when you put a new chain on the old sprockets, there is no gutt either. If the sprockets are not worn, then it is better to buy another chain, I understand that the toad is pressing, but a chain is better than then a tire with a sprocket.

Dim, why are you scared about the tire? I agree about the asterisk. I also agree that if the sprocket is almost new. (Damn, why should it be almost new. The tooth life is 50%, if three chains worked evenly on the sprocket in alternation, the sprocket is already worn enough). I had a similar situation, I shortened the chain and finished off all three chains on the old sprocket, and then bought three new chains and a new sprocket.

Why does it stretch?

Saw owners often ask the question: “why does the chain on a chainsaw stretch?” Let's try to answer it. A saw set can stretch for several reasons.

- The oil pump is faulty or incorrectly adjusted. Limited or no oil supply results in excessive heat during operation. The hot chain stretches several times faster.

- Working in adverse conditions. Dust, dirt, and soil get on the headset during operation. The dirt particles act as an abrasive material and gradually rub the joints of the links, causing it to stretch.

- Using poor quality chain lube. Often, the oil used to lubricate the chain is not the oil recommended by the manufacturer, but used oil from the car engine. The “working off” contains metal particles, which can also give the effect of an abrasive material.

- The chain is new. Manufacturers of chainsaws specially make adjustment screws on the saw, since the stretching process is inevitable.

- Natural stretching as a result of prolonged work.

Stretching is inevitable, the question is how quickly it will happen. You can extend the service life by using high-quality lubricating oils, carrying out timely diagnostics of the oil pump and taking breaks in operation.

Such measures can significantly reduce the likelihood of sprains, but not completely eliminate them.

Recommendations for extending service life

The approximate service life of a branded tire is equal to the total service life of 3 high-quality saw chains; the drive sprocket varies depending on its condition.

Experts recommend using a set of several circuits. This method allows you to reduce the loss of working time, which is spent on periodic sharpening of chains, as well as optimize the wear of the saw mechanism as a whole. Accelerated tire wear is a consequence of unqualified maintenance of the chainsaw and its illiterate operation.

The main factors for early tire failure:

- excessive chain tension or discrepancy between its pitch and the characteristics of the drive sprocket crown, which initiates the rapid development of the groove and shanks;

- applying significant force when sawing hard or frozen wood;

- the tire heats up and wears out intensively due to lack of lubricant supply, due to a malfunction or incorrect adjustment of the standard oil pump;

- saving money on the use of low-quality chain oil or oil surrogates such as waste.

Forced consumption of the saw set resource occurs when soil or sand gets into it, or when a new chain operates on a worn drive sprocket.

The chain has stretched, what should I do?

If the chain has stretched, but the wear of the links still allows it to be used, you can rivet it and continue working. Determining the number of links that need to be removed is not difficult. To do this, install a bar on the chainsaw, tighten the tension screw to its extreme position, and take measurements. Having determined the required length, you can begin riveting.

Riveting chains for chainsaws is carried out using auxiliary tools and special machines. Let's take a closer look at what tools are needed to reduce or increase the length of the chain.

Repair standards and restrictions

Recommendations for fixing ground rivets by electric welding do not take into account changes in the structure of the metal due to even short-term high-temperature effects of the welding arc.

Grinders stuck by welding or heated by an abrasive wheel, the connecting elements of the chain are less wear-resistant, which significantly affects their reliability.

- A tight connection of adjacent links is accompanied by additional loads on the engine and kinematics of the chainsaw.

- The lack of a smooth movement of the chain makes it difficult for the headset to enter the cut; the possibility of kickbacks and other traumatic moments cannot be ruled out.

- “Over-tightened” and loose connections of a repaired chain are more susceptible to breaks when there is a sudden change in load.

The simplest machine in design for repairing chainsaw chains justifies its cost by being able to completely rivet a damaged chain in a short period of working time and restore its performance to a level of up to 90%.

Chinese-made chainsaw chains are essentially copies of European models, so the above repair recommendations are valid for the entire Chinese chain range.

Tools required for work

When starting riveting, the first thing you need to do is remove the link from the chain; for this you will need to rivet the rivets. For riveting, you will need an anvil, a hammer, a thin bit, a vice, a grinder with a grinding wheel or emery cloth. These tools do not allow for quality work, but everyone has them. A more cultured and gentle way is to remove the rivets using a special punch.

There are several designs of punches; we’ll tell you about the most popular.

Rivet punch

A punch is a machine that is used to remove rivets.

It is mechanical and works on the principle of a press. The kit includes a special anvil, in which grooves are selected for installing the headset with different pitches. There are also replaceable tips with which the rivets are extruded.

Important: the size of the rivets in different types of chains is different, so when buying a punching machine, make sure that the kit includes several tips that are used for different types of fittings.

We invite you to watch a video that shows how to rivet a saw chain using a mechanical punch.

After the chain is riveted, it is necessary to remove the old link, install a new one and rivet it. For this purpose, a riveting-rolling machine is used. It is electric, so it costs much more than a punching machine.

Riveting and rolling machine

The machine is equipped with a gear motor with high torque.

Used for riveting and rolling headsets in increments from 1/4″ to 0.404″. The cutting depth of chains that can be riveted using this machine is from 1.1 mm to 2 mm (0.043″ - 0.080″). Special rotating inserts and anvils for different types are supplied with the machine. Inserts and anvils are marked. Marking “A” means that the inserts are designed for a headset with a pitch of 3/8″ and 0.404″. “B” is for 1/4″ and 0.325″.

The machine works as follows. The saw chain with a new link and rivets is installed in the guide inserts. The repair link with the rivets installed in it is pressed by the working roller against the anvil, after which the engine is turned on and the roller begins to rotate, gradually crushing the rivet, at this moment the machine operator slightly increases the pressing force of the roller by tightening the adjusting screw. For clarity, we suggest watching a video about the operation of a riveting-rolling machine.

It is not profitable to use such a machine for riveting houses, because it is expensive. If you do not need to rivet regularly, you can do without it. Let's look at how to shorten a chainsaw chain with your own hands without using expensive machines. You need to start by riveting and removing the link.

The advantage of the machine is that the rivets riveted with its help are practically no different in quality from those riveted in the factory.

Share on social media networks:

Of course, it is safe to say that in virtually every private home there is, of course, a chainsaw, especially if you live in a private home or have a dacha. Just like any other instrument, it must be treated with care. Some owners encounter a common problem - the chain stretches due to long-term operation. The reason for this is the heating of the metal, after which it increases in volume. Let's find out how to shorten

a chainsaw chain at home, because there is an option to simply make a mistake with its length when purchasing. And most importantly, after such a procedure, the connection of the chain links remains just as strong for our client.

How to remove a link without using a machine

There are several ways to remove rivets.

- Sand off using sandpaper. Carry out the work carefully, trying not to damage the neighboring, whole link.

- Grind off using a grinder.

- Cut with a chisel. To do this, the chain must be clamped in a vice by the guides, so that it is possible to cut the rivets on the connecting link.

After the rivet heads have been ground off or cut down, the following steps must be taken to separate the link. Place the bits between the connecting plates and hit them with a sharp movement with a hammer. The plates should come off the rivet body that passes through them.

Important: if it is necessary to replace a working tooth, then the connecting links will have to be riveted on the left and right of it.

Now let's figure out how to rivet it back.

If there is a need to shorten

Often, when working in the forest or on a remote construction site, you will not be able to find a replacement for a stretched chain.

Having taken into account all the advice, and having made sure that it is necessary to shorten the chain, it is important to know the sequence of actions and possible replacement methods

There are not many of them and they depend on how many links need to be removed and under what conditions the repair will be carried out.

This is important to know: a chainsaw chain consists of cutters and connecting links, which are connected with rivets in the factory. The shortened chain should be connected in the same way, but using homemade rivets

Each link (the cutter and the links connecting them) has two such rivets. If nearby “native” connecting links are damaged, you can use elements from any other similar circuit of any equipment, even automotive equipment. You just need to file the profile, especially at the bottom, where it has a small groove.

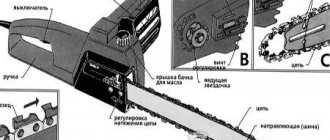

Chainsaw circuit diagram

The easiest way is to take a long chain, in which several segments can be removed without problems. This way, at least, it becomes possible to use family links. They can be removed using a hacksaw, but it is better to use sandpaper.

Initially, you need to grind off unnecessary rivets, and then cut off the excess area. To do this, you need to pry it with a knife and knock out the rivets from the unnecessary links using a homemade knockout.

When connecting a new chain, you have to make homemade riveting of the links. The rivets themselves can be bought at the store, but if you don’t have them, use steel wire, or better yet, a short bolt with a flat head. Riveting is done on a rigid base (metal workbench or vice). Alternately threading through the elements of future rivets, use a hammer to flare them from the reverse side.

You may also be interested in the article on sharpening a chainsaw chain with your own hands. You can read about the types and characteristics of modern chainsaws here.

And in this article you can find out how to repair a Shtil 180 chainsaw.

How to rivet

To connect, you will need a repair link. Spare links can be found at any store that sells chainsaws and consumables for them. When buying spare links, you must take into account the type of chain, pitch and profile. Links from different types of headsets are not interchangeable. It is not recommended to use a donor link with an old one. The rivets on it are already ground off and for a normal connection you will have to sharpen the top plate.

The link with rivets is installed on the chain and placed on the anvil with the open side up. After this, the top plate is put on the rivets and lightly tapped with a hammer so that it fits as tightly as possible. After this, you can begin to flatten the rivets. For this, an anvil, a bit and a hammer are used.

The set is placed on the anvil, the bit is placed on the rivet and a sharp blow is made with a hammer. The second rivet is riveted in the same way. As a result, in the protruding part of the rivet there should be a thickening that will reliably hold the upper plate of the link, preventing it from coming apart.

At the last stage, it is necessary to check that the chain link moves and is not jammed during riveting.

Important: if the work is not carried out correctly and the repair link does not work, then such a chain cannot be installed on a chainsaw.

Let's look at what can happen if you rivet incorrectly.

Step-by-step installation algorithm

Not all modern chainsaws are equipped with an installation wheel, which significantly simplifies the procedure for installing the saw blade. Systems with an adjustment wheel are generally rare among household chainsaws.

Therefore, it is very important to know the technology and sequence of installing a chain on a chainsaw

Key points to note:

- Prepare a flat surface on which you will assemble the chain and bar. This will minimize the chance of damage to the chainsaw or loss of small parts. A tire is laid out on the prepared surface and a chain next to it in parallel.

- Remove the sprocket guard, on modern chainsaws it is enough to unscrew the wing nut, on older models you may need a spanner of the appropriate size.

- At the base of the guide bar, turn the tension sprocket all the way to the right. Only in this position is the chain installed.

- Then the chain is placed sequentially, link by link, onto the locking groove on the guide bar. Install the chain from the top of the guide, gradually turn it so that the bar is always on top and the chain is on the bottom, this will allow it to always be taut and fit into the guide groove without problems. When performing this step, be sure to wear thick protective gloves, because your fingers will touch the cutting edge. If you look from above, the cutter is always located forward towards the end of the guide bar.

- Place both the bar and chain on the drive sprocket.

- Secure the chain sprocket cover in place. Make sure all mounting pins line up with the holes. Incorrect installation with distortions or not completely can cause extraneous noise and rattling.

- Make sure that the guides fit into the special mounting groove.

- After installation, check that the chain is secure on the chainsaw and on the bar. Everything should be securely fastened without any backlash.

An important point is the degree of chain tension after installation. Setting the correct tension is very simple and takes no more than three minutes. First you need to loosen the nuts on the protective cover. Using a freely rotating adjusting screw, set the correct tension so that the chain does not pull more than 3-5 mm from the edge of the guide bar.

All that remains is to tighten the nuts and check the tension. If adjustment is necessary, adjust the tension again.

How to install a bar and chain on a chainsaw, see the following video, which presents a clear algorithm of actions:

Consequences of poor quality repairs

The consequences of poor-quality repairs can be very sad; the chain at the moment of rupture can injure the operator. Of course, modern saws are equipped with all kinds of protection. For example, catchers are installed on them, which are designed to protect the operator in an emergency, and the right hand, which is on the chain line, is hidden behind the body.

But the protection does not provide a 100% guarantee, therefore, before using the repair chain with maximum load, you need to test it on light work, sawing a couple of branches or boards.

Also, the consequences of poor-quality repairs can affect the performance of the chainsaw. Let's look at what mistakes can be made during repairs and how they will affect the operation of the saw.

Errors when repairing circuits

- The step does not match. The reason is that the installed working link is not suitable for the main parameters: pitch, link thickness. If such a headset is used for work, then as a result you will need to replace the drive sprocket and saw bar, since the sprocket on the bar will break.

- Another option for a mismatch in pitch is to install the working tooth in the opposite direction. It is extremely rare, but it still happens, especially among those who are repairing for the first time. The consequences are similar to the first point.

- The chain is longer than the bar. With this everything is clear, the adjusting screw will not be enough for tension, the chain will dangle and wear on the drive sprocket will increase.

- Briefly speaking. Such a headset cannot be installed; it will need to be riveted and extended.

- The connecting link is slightly longer. Similar to the first point, the pitch will change, which will lead to the destruction of the driving and driven sprocket.

In conclusion, I would like to pay special attention to the quality of articles on this topic. On the pages of websites on the Internet there is information on how to repair a saw chain using welding. Such instructions are written by incompetent authors who themselves do not understand what they are writing about.

Repairs can be made by welding, but these are not saw chains, but gear chains designed to transfer force from one sprocket to another.

These can be found in the mechanisms of agricultural machines, conveyors and other units.

Monitoring the performance of the electric saw track brake

To protect the working person from damage by a chainsaw, a braking device is used. With its help, the tool is stopped until the tire hits the worker’s body.

The structure of a typical chainsaw.

Stopping the chain depends on two conditions:

- speed when braking;

- tool startup time.

The saw is started using 2 methods: contact and inertial. To protect the operator from throwing up the chainsaw, the brake is equipped with a shield against which the operator’s hand rests. Some saws have protective strips that mask the cutting part of the tool.

A chainsaw is a necessary thing in the home and garden, helping to quickly and efficiently carry out various work with wood. Like any electrical device, it periodically fails and requires diagnostics.

The result of the last event is often the conclusion that it is necessary to repair the chainsaw tire - the mechanism that experiences most of the load during operation.

Useful tips

You can increase the service life if you alternate manual sharpening with the use of a special machine. The latter allows you to align sharpening angles on the machine as accurately as possible. The stitching depth should not be large.

It is necessary to observe safety measures that allow you to cut wood of any size with maximum efficiency and with a minimum level of danger to humans:

- Before assembling the chain tool and installing the headset, it is recommended that you read the instructions for use. This is due to the fact that each tool has its own characteristics.

- When working with a saw, you must wear gloves and safety glasses.

- For work, it is recommended to choose close-fitting clothing made from natural dense materials and the most reliable shoes.

- It is necessary to cut wood using a chainsaw in a stable and safe position, and the material itself must also be positioned as stably as possible. Installing a toothed stop on the log will help ensure stability.

- During operation, the saw must be held with both hands and the cutting process must be constantly monitored.

Modern chainsaws are used in domestic and industrial settings

At the same time, it is important to maintain productivity and high efficiency indicators of the tool, which directly depend on the condition of the sharpened chain set

How do you sharpen a chainsaw chain: do you prefer artisanal methods or do you trust this task to professionals?

Chain adjustment on Husqvarna, Makita, Partner chainsaws

Below are video clips on how to adjust the tension of the cutting set on chainsaws from different manufacturers.

- Instructions for Husqvarna chainsaws

- Instructions for chain saws Partner

- Algorithm for setting headset tension for a Carver chainsaw

As you can see, the adjustment principle for chain saws of different brands is almost the same. The most important thing is to correctly perform the setup procedure so that the cutting set does not sag or is overtightened.

Tensioning the saw set and why this procedure is needed at all

During operation of a chainsaw, not only the engine, but also the saw unit heats up. This is due to the movement of the chain along the plane of the bus, as a result of which thermal energy is released, which entails the expansion of materials. The tire is large in size, due to which heat is quickly dissipated, and the cutting headset heats up to high temperatures and cools very slowly. The quality of cooling of the part is especially reduced when sawing hard wood of large diameter.

As the circuit heats up, its size increases due to linear expansion from exposure to high temperatures. As a result, the chain sag relative to the bus, which entails the possibility of the headset falling off. The consequences of its flying off the tire while working with a tool are extremely unfavorable, and therefore it is very important to always check the degree and quality of tension of the cutting set before operating the unit. This applies to absolutely all brands of chainsaws Shtil, Husqvarna, Echo, Partner, Makita and others. Moreover, tension should be taken into account not only on chainsaws, but also on electric saws.

The reasons why you need to maintain the quality of chain tension are as follows:

- Reduced efficiency of sawing wood. A tool with a loose chain has lower productivity. This is manifested by the fact that the time for cutting wood increases.

- Increased load on the engine, clutch, sprocket and tire - and this applies not only to a loose chain, but also to an overtightened one.

- Wear of the chain itself - if you operate the unit with an incorrectly tensioned headset, this entails accelerated wear. This is due to the fact that the temperature increases, so the teeth become dull faster and the links wear out.

- Unsafe operation of the tool - operating the unit with a loose or overtightened headset is not only harmful for the chainsaw, but also dangerous for the sawyer. In addition to falling off the tire while moving at high speed, the chain can also break (if it is over-tensioned), which ultimately can lead to fatal consequences.

Now you understand how important the procedure for tensioning the cutting set of a chainsaw is. And here it doesn’t matter how high quality the tool or chain is, because loosening the tension of the headset is a natural process.

Interesting to know! With frequent changes in temperature and use of the tool, not only the teeth of the chain become dull, but also the links stretch. It is by stretching the links (increasing the diameter) that it is necessary to carry out the procedure for adjusting the degree of tension.