To supply oil to lubricate the chainsaw chain, the tool uses a special pump, which delivers lubricant to the saw bar in a dosed manner, depending on the number of engine revolutions.

The system uses oil to lubricate the chainsaw chain, which has increased adhesive properties; this is necessary for uniform distribution of oil along the entire perimeter of the bar and retention on it even at high rotation speeds of the chain. Let's take a closer look at the oil supply system implemented in modern chainsaws.

Lubrication system design

Depending on the brand of chainsaw, the parts of the lubrication system may vary slightly in design, but their total number and connection diagram remain the same.

The main components of the lubrication system are:

- an oil tank located, as a rule, in the engine crankcase.

- The filter element is installed in the tank.

- The oil line is a small diameter hose made of oil-resistant rubber.

- The heart of the system is the oil pump.

- The worm gear transmits force from the engine to the pump.

- The chainsaw tire can also be considered an element of the lubrication system, since it has special holes for supplying oil. By the way, the chain itself is involved in transporting oil and, accordingly, also has some elements designed specifically to provide lubrication.

Operating principle of the oil pump

The vast majority of imported and domestic chainsaws are equipped with a valveless oil supply pump located on the chain side of the crankcase. Thanks to the segment cutout (flat) on the cylindrical surface and the rotation of the plunger from the drive shaft through the worm gear, lubricating fluid is supplied to the tire.

Chainsaw pump plunger

As the chainsaw oil pump drive rotates, the plunger first releases oil into the injection chamber, and after turning 90°, it closes the inlet hole and pushes out the lubricating fluid in a reciprocating motion. In order to impart one axial movement per revolution, an eccentric mechanism is installed at the end of the plunger, which operates on the principle of a car's camshaft. The amount of axial stroke of the shaft is limited by an annular protrusion with a profile configuration.

Feature of independent troubleshooting

A complete independent repair of chainsaw chain lubrication, all things being equal, requires knowledge of the interaction of all elements of the system, the availability of tools and plumbing skills.

Restoring the operating parameters of many chainsaws involves partial or complete dismantling of the component equipment. To perform complex repair work, it is better to use the capabilities and technical potential of service workshops.

Parts with broken threads and damaged spline joints, as well as non-separable structures that come with the lubrication system of popular Shtil 180 chainsaws and other similar models must be replaced.

If, when the tank is filled, oil does not flow into the headset structure, the reason should be sought in the pump itself. Dismantling and disassembling the mechanism will help identify faulty parts and eliminate the problem by replacing them.

Adjusting the Oil Supply to the Chainsaw Chain Partner

How to repair the oil supply to a chainsaw

During prolonged operation of the chain saw, some of its elements and components may become unusable. One of the most vulnerable components is the oil pump. In this regard, many saw owners have a question about how to repair the oil supply for a chainsaw.

Oil pump task. apply lubricant to the chain. this is necessary for its smooth movement along the guide. When the oil pump breaks down, the chain's lubrication is impaired and therefore the chainsaw's efficiency decreases. In some cases this leads to a broken circuit. To prevent negative aspects, it is necessary to timely repair the oil supply. How to do it?

Operating principle and design of the pump

Oil pumps can be made of metal and plastic. They are also divided into two types, which differ in their design:

The pump is activated by the drive sprocket. When the chain moves, oil is supplied to a special channel located on the guide. At idle speed (when the drive sprocket does not rotate), the pump does not supply lubricant. this is done to save money.

The speed and volume of lubricant supplied to the chain directly depend on the speed of the sprocket. Some chainsaw models include a manual adjustment system with a special screw located on the body of the device. On expensive models the feed

oil is adjusted automatically during operation.

Major problems with oil supply

When operating a chain saw, two types of problems are possible when supplying lubrication to the chain:

CHAINSAW PARTNER DOES NOT OPEN OIL ON CHAIN.

In this video we will take a closer look at the power pump partner of the chainsaw

, find out why

the chainsaw partner

doesn't.

How to regulate the oil supply to a chainsaw

can someone use my first channel:.

- Insufficient oil consumption, which can be caused by various reasons. If measures are not taken in a timely manner, the quality of work will noticeably deteriorate, and the scheme itself may become completely useless.

- Excessive amount of oil. In this case, after prolonged work under the saw, you can collect puddles of fat. This not only affects the consumption of oil, which will need to be constantly poured out, but also negatively affects the environment.

Both of these problems need to be addressed as soon as possible after they are discovered. This will extend the life of the saw and reduce lubricant consumption.

Fixing problems

If oil enters the chain in excessive quantities, not only while the saw is running, but also at idle, it is necessary to perform manual adjustment (if the pump design allows this possibility). This is done using a screw that is located on the case near the guide, usually on the bottom or side. By tightening the screw, the oil supply decreases and the weakening. vice versa. If the adjustment does not help, you need to check the functionality of the pump and also inspect the tire. it is possible that a gap forms at the point of its connection with the body, through which the oil

flows past the chain.

Lack of oil can be caused by several reasons, for each of which there is a solution:

- Oil pump malfunction. As a rule, it consists of unsuitable masonry. To replace it, you must carefully disassemble the pump so as not to damage its moving parts. A new gasket is then installed, after which the pump is mounted and installed in place.

- Damage to the oil supply hose. If the pump gasket is in order, or replacing it did not lead to results, check the tightness of the hose. If it is faulty, it must be replaced. Otherwise, it won't hurt to clean it and seal it with sealant.

If the cause is not due to pump failure, all conductive openings and passages for blockages must be checked and, if necessary, cleared of foreign objects. This can be done with a jet of compressed air.

Don't want to mess with a chainsaw, but need to regulate the oil flow? Contact our specialists for help, who will diagnose and repair your chain saw, if necessary. adjust and adjust the lubricant level. Your saw will be as good as new!

Practical recommendations

Lubrication hole layout.

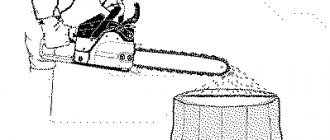

Before you start using chainsaws, you need to check the lubrication system of the chainsaw chain. For this purpose, it is necessary to hold the end of the tire by placing a sheet of paper under it. When the speed increases, an oily strip should form on the sheet.

Proper lubrication of the chain greatly increases the life of the chainsaw headset. If there is not enough oil, the device will operate dry. The cutting set will quickly break. The friction of the parts should be minimal, so all guides and hinge joints should be covered with an oily film.

When the chain moves along the guide bar, the lubrication system must provide a constant flow of oil. This function is performed by the oil pump. With its help, the required amount of oil is supplied to the guide bar and its groove.

The driving links of the chain spread oil over the total length of the groove. A guarantee of proper chain lubrication is considered to be:

- fine tuning of the oil pump;

- completely filled oil tank;

- correct choice of oil.

Before starting work, it is necessary to constantly monitor the operation of the lubrication system. The correct supply of lubricant is determined by the sides of the chain; they must be lubricated at all times.

Basic parameters of a chainsaw chain.

The need for lubricants is always different. It all depends on what needs to be cut. When the length of the cut reaches large values, the tree has high hardness and thick bark, it is necessary to have a large supply of oil.

If the cutting set smokes or the chain stops, we can talk about a lot of heating. The main reason is lack of lubrication. Other reasons may be:

- dullness of the chain;

- strong tension.

Chainsaw Partner 350 – malfunctions and their elimination

Failures of Partner garden tools can occur for various reasons, the most common of which are improper operation and mechanical shock. To eliminate the malfunction, you will need to determine its exact cause in advance. After this, you can begin repairing the instrument yourself.

Chainsaw Partner 350 starts and stalls

There may be several reasons for this malfunction. Most often, the engine of the tool starts and immediately stalls due to a clogged factory breather, as a result of which fuel does not enter the engine cylinder in sufficient quantity for operation. To fix the damage, you will need to remove and clean the breather. If it is damaged, then it will need to be replaced.

Another reason is the missing connection between the spark plug and the electrical wiring cap. This can happen due to mechanical shock or the formation of carbon deposits from engine oil on the spark plug. To repair the Partner 350 chainsaw, the spark plug will need to be removed and cleaned. In some cases, completely replacing the spark plug may help.

The third reason for the malfunction is that the standard muffler of the chain saw is severely clogged. Over time, carbon deposits form on its walls, which prevents exhaust from leaving the engine. As a result, gases accumulate inside the engine and interfere with its proper operation. To fix the damage, you need to remove the muffler and clean it with compressed air. You will also need to disassemble the engine and bleed its cylinder.

Chainsaw Partner 350 will not start - how to fix the problem?

When this breakdown is detected, the first thing that needs to be inspected is the condition of the air filter. If a large amount of dust has accumulated on it, the filter will need to be washed using clean gasoline.

Another common cause of malfunction is problems with the ignition system. To repair the chain saw, you need to remove its left protective cover and set the correct clearance between the flywheel and the ignition coil.

In some cases, replacing the fuel mixture will help solve the problem. To do this, you will need to drain the used fuel and fill the tank with a new mixture of pure gasoline and motor oil.

What to do if the chain on the Partner 350 chainsaw is not lubricated?

If the chain for the Partner 350 chainsaw is no longer lubricated with oil, this can lead to overheating of the bar and rupture of the saw set. Ignoring this problem also risks increasing the load on the engine, which can lead to engine failure.

The first thing you need to inspect if there is no lubrication on the chain is the oil pump. Over time, the teeth on its drive wear out, which can also occur due to clogging of the pump. It is usually impossible to restore the element, so it is best to replace it.

Often, lubricant does not reach the chain of the Partner 350 chainsaw due to clogged oil pipes. In this case, the hoses will need to be replaced by treating the joints with the fittings with sealant.

Fills a candle on a Partner 350 chainsaw

This common problem is encountered by chainsaw owners who add too much motor oil to the fuel mixture. It does not have time to burn in the cylinder, so part of the lubricant settles on the spark plug and other important elements of the garden tool.

To fix the breakdown, you need to remove the factory spark plug, clean it of carbon deposits and dry it. After this, you need to blow out the cylinder of the factory chainsaw engine by sharply pulling the starter cable several times.

Next, you need to inspect the condition of the carburetor and fuel hoses. Often oil gets on the spark plug due to loss of tightness of the system. This occurs as a result of a break in one of the tubes or a breakdown of the oil pump. To repair a Partner 350 chainsaw, you will need to replace all faulty fuel system parts. After this, you need to install the spark plug in place, start the engine of the tool and check its operation at idle, low and high speeds.

One of the important chainsaw systems, without which work is impossible, is the forced lubrication system of the chainsaw chain. It's no secret that when the saw is running, the chain rubs against the chainsaw bar, which causes it to heat up and cause premature wear. To soften friction, the chain mechanism must be constantly lubricated.

Lubrication system design

Depending on the brand of chainsaw, the parts of the lubrication system may vary slightly in design, but their total number and connection diagram remain the same.

The main components of the lubrication system are:

- an oil tank located, as a rule, in the engine crankcase.

- The filter element is installed in the tank.

- The oil line is a small diameter hose made of oil-resistant rubber.

- The heart of the system is the oil pump.

- The worm gear transmits force from the engine to the pump.

- The chainsaw tire can also be considered an element of the lubrication system, since it has special holes for supplying oil. By the way, the chain itself is involved in transporting oil and, accordingly, also has some elements designed specifically to provide lubrication.

How to repair a chainsaw

To repair a chainsaw, you need to become familiar with its internal structure, the operation of all mechanisms, and study the lubricant supply system. When the chainsaw is running, the following problems may occur.

The tightness of the hoses may be broken. To solve this problem, you need to disassemble the tool and replace the hoses. If there are no spare parts, you can degrease the old hose and its seat. Install self-tightening clamps at the connection between the hose and the tube. The field of this tightness will be restored.

Sometimes the oil filter gets clogged. It needs to be cleaned periodically. The oil supply can only be repaired if the chain is dry. This usually occurs due to clogged channels. They must be thoroughly cleaned. This phenomenon occurs very often.

When it is difficult to start a chainsaw, and sometimes it is simply impossible, you need to diagnose the device. First, the spark plugs and air filter are checked. All parts must be thoroughly dried before reinstallation.

Chainsaw fuel system: 1 - fuel filter, 2 - carburetor, 3 - manual pre-priming pump.

If there is fuel on the spark plugs, we can talk about its excess. The main cause of this problem is poor carburetor adjustment or improper starting. The fuel supply valve may be closed. To fix the breakdown, you need to make sure that there is enough fuel in the gas tank and check how well the combustion chamber is functioning. If the spark plugs become unusable, they must be replaced.

The fuel supply may have stopped due to a clogged breather. A vacuum forms in the gas tank, which blocks the fuel supply. This phenomenon occurs when the channels are clogged, the carburetor is poorly adjusted and the air filter is clogged. These problems require repair of the valve, which equalizes the pressure during the supply of gasoline. The breather is cleaned with a sharp needle.

To adjust the carburetor you need to find the optimal speed value. To do this, you need to tighten or, conversely, unscrew the adjusting screws. This setting must be performed exactly according to the Shtil chainsaw repair instructions.

The filter mesh in the carburetor is cleaned, all channels are purged, the functionality of the membrane is checked, no ruptures are allowed.

Due to its complex mechanism, work with the carburetor must be carried out carefully and in perfect cleanliness. Its normal and good work depends on this.

To ensure proper operation of your chainsaw, you need to constantly care for it. It requires constant cleaning of the air filter and lubrication of the chain, and always with new, fresh oil.

When the tool is put away for long-term storage, it is necessary to drain all gasoline and remove chain oil. In this case, the chainsaw will work without breakdowns for a long time.

How to properly install a chain on a power saw

Chains

2. Now check whether the chain is located freely on the guide. Please use work gloves for this. If the chain sags at the bottom, then it is too loose, and you need to tighten the chain using the tension screw.

Read:

3. If the chain on the underside of the bar does not slack, but can still be pulled through easily, then it is optimally tensioned. It should also still be possible to pull it up a little. To avoid the risk of injury from contact with a sharp chain, you should always wear work gloves.

You can tension the chain comfortably and without tools with the STIHL quick chain tensioner. Many STIHL chain saws are already equipped with this technology. You need to do this:

Release the sprocket cover by hand using the wing nut. When the adjustment wheel located above is rotated to the left, the saw chain tension decreases; when the adjustment wheel is rotated to the right, the saw chain is tightened. When the chain sprocket cover is tightened, the guide bar is locked automatically.

When you want to replace the chain, you must thoroughly clean the groove of the guide bar from dirt in advance. The chain has stretched. Why does the chain on a chainsaw stretch so that the chain falls off the bar. If there is heavy dirt deposits in the groove, the chain could otherwise easily come off the bar. In addition, there is a danger that the chain adhesive oil will be prematurely absorbed into the dirt and not reach the especially loaded underside of the tire. Extreme heat and wear on the chain and bar can result from this. You can clean it using, for example, a thin screwdriver or other sharp object. The new chain needs to be run in for a few seconds before being applied to the wood.

ATTENTION:

Since the chain contracts slightly again after cooling, the chain should never be tightened or replaced while hot. Otherwise, it may cause severe damage to the guide bar or engine crankshaft. After completing the work, it is recommended to slightly release the chain tension again.

This is especially important in frosty weather.

Clutch

At low speeds, elements with friction linings (1), having a degree of freedom in the circular direction, are attracted to the center of the shaft by springs (2) and do not transmit rotation to the drum (3), connected to the sprocket driving the chain. When the chainsaw engine speed reaches values at which the centrifugal force exceeds the force of the springs, the friction segments are pressed against the inner surface of the drum and begin to rotate it. As a result, the drive sprocket begins to rotate, driving the saw chain.

As you can see in the photo, the sprocket is located behind the clutch.

On other chainsaws, the sprocket may be located on the outside of the clutch.

The main advantage of this type of coupling is that when the chain jams, the chainsaw clutch slips without stopping the engine or causing damage to the devices that transmit movement from the motor to the chain.

Oil supply system

In the Stihl chainsaw, oil is supplied to the chain by a special system. The patented OILOMATIC system, found on various STIHL chainsaw models, is an exclusive feature. Such an incredible addition cannot be found in all models from other manufacturers. For this reason, more and more people are choosing Stihl saws. What is this system? This is a specially designed groove designed to direct oil to critical wear areas. This superior lubrication feature gives the customer extended chain life with a reduced tendency to stretch.

A further development of the OILOMATIC system is the oil reservoir next to the OILOMATIC channel. These reservoirs are filled with oil as the drive links pass the guide bar inlet and are emptied by centrifugal force acting at the nose of the bar. This provides more oil for distribution to the chain, groove and rails. The system protects the saw from premature wear. Simply put, it directs oil to where it is needed. The system is available on all STIHL saw chains.

Sometimes customers may report a problem such as the chain on a Stihl chainsaw not being lubricated. This is a rare occurrence. Compared to conventional saws without a system without Ematic, STIHL controls the consumption of chain lubrication. A special system reduces consumption by up to 50%, depending on the type of wood and the cutting attachment used. This system includes STIHL Ematic or Ematic S, STIHL Oilomatic.

Each model is equipped with a saw chain and a variable flow or reduced flow oil pump. Virtually every drop of chain lube is delivered exactly to the right place. This system reduces friction and wear and therefore extends the life of the cutting attachment. Oil channels (funnel-shaped) in the saw chain carry oil directly to the rivets and cutting teeth stages. Several recesses into which chain oil can collect are also stamped into both ends of the drive links. This allows for better oil distribution over the sliding surfaces of the guide rods.

Possible problems

Often reviews such as the calm chainsaw does not supply oil to the chain concern the STIHL Rollomatic ES (STIHL EmaticSuper) models. This model consists of a solid and particularly rigid stem with a nose that can be completely replaced. Therefore, it is ideal for the most demanding professionals, various tasks and is used mainly for heavy work. Elliptically shaped, angled oil holes increase chain oil flow rate for optimal lubrication and long guide bar life. Very often, problems with oil supply can be due to improper refueling.

It is important to adhere to the manufacturer's instructions and requirements to avoid problems. To do this, use STIHL oils with 2 cycles

They are high quality, conventional petroleum based motor oils designed to provide the highest levels of engine performance.

The oil provides protection in modern high-performance air-cooled two-stroke engines. The environmental friendliness of chainsaws and power tools is also significantly improved with BioPlus lubricating oil (BlueAngel winner). It is a toxicologically pure oil that is not only biodegradable, but also environmentally friendly.

STIHL 2-cycle oils are designed for the high temperatures and operating conditions of today's innovative and technologically advanced engines. All STIHL 2-cycle oils contain a fuel stabilizer for longer shelf life. STIHL recommends a 50:1 combination of high quality 89 octane unleaded gasoline. This same mixture ratio should be used during a breakdown.

What do people who use a Stihl saw with an oil supply system write about this?

“The most common reason for a system failure is that it is blocked. You have to remove the handle - take out the screws, the external plugs. You will see a hose from the tank - pull it out. If it's broken, you've found the problem. Flush the reservoir, hose and pump inlet.”

Adjusting the carburetor of the Husqvarna 137 chainsaw with your own hands

Regardless of how often and under what conditions the 137th Husqvarna model is used, its proper operation largely depends on the timely adjustment of the standard carburetor

The following malfunctions indicate the need for adjustment of this important unit:

- the chainsaw engine does not start;

- the engine starts and immediately stalls at idle;

- The internal combustion engine operates at idle and low speeds, but stalls at full throttle;

- Fuel consumption has noticeably increased and the volume of processed gases emitted by the engine has increased.

Setting up the carburetor of a Husqvarna 137 chainsaw yourself is quite simple if the operator adheres to the following algorithm of actions:

- First, the owner of the tool will need to set the factory settings of the standard carburetor. To do this, with a cold motor, you need to turn the screws in the manner indicated in the saw’s operating manual;

- Then you need to start the internal combustion engine of the chainsaw and wait a few minutes until it warms up;

- Next, you need to start turning the standard bolt marked “L” in the direction of the clock until the engine reaches its maximum operating speed. After this, screw “L” must be turned 1/4 turn in the opposite direction;

- The next step will require adjusting the idle speed of the Husqvarna chainsaw engine. To do this, you need to alternately turn the screw “T” in different directions until the chain stops on the bar. After this, you need to check the operation of the saw set - it should rotate only when you press the gas trigger;

- Then you need to adjust the engine power and its operation at maximum speed. To do this, you need to connect a tachometer to the built-in ignition system of the saw and set the maximum engine speed. Then the readings on the device must be compared with the instructions in the operating instructions. The indicators on the device and in the manual must match. Otherwise, you need to configure the operation of the chainsaw as required by the manufacturer.

Immediately after setting up the carburetor, you need to check the operation of the engine. To do this, you need to start the garden tool and sharply press the gas trigger several times. If the engine accelerates sharply when you press the trigger, it means that the unit has been configured correctly.

What you need to have for setup

Each carburetor owner must have the necessary tools to adjust this system. There are three adjustment screws that are located on the body of the device. They have their own markings:

- L - screw for correcting low speeds.

- H - screw for adjusting high speed.

- T - regulates idle speed , in most cases it is used for experiments.

Chainsaw air filter

Before adjusting the carburetor, you need to prepare the device:

- The engine warms up, that is, it starts about 10 minutes before repairs, and turns off when starting work (see how to start a chainsaw).

- The air filter is checked and washed.

- The chain is stopped by turning screw T until it stops (see chain oil

To carry out a safe repair, you need to prepare a flat surface where you can carefully place the device and the chain in the opposite direction. Need a tachometer. It determines whether there is a malfunction in the carburetor. When turning the screws, the sound should be perfect and absolutely smooth. If you notice squealing notes, the mixture is oversaturated.

What oil to use to lubricate the chain

This part requires constant lubrication, for which you can fill in special chainsaw oil, and it must be of high quality. It is recommended to choose oil for lubricating chainsaw chains from the manufacturer of the saw itself. Its consumption is small, so you should not save on your purchase. But there is no need to pour liquid on the chain itself. There are entire lubrication systems that help it flow to the tire uninterruptedly.

There are other criteria for choosing a saw lubricant:

- resistance to freezing, because sometimes you have to use the saw in winter, including lubricating it with oil, which means that at subzero temperatures it should not freeze;

- optimal viscosity of chain oil;

- the oil used should not leave residue on candles and other spare parts;

- no impurities.

The chain oil needs to be replaced if the part heats up and various breakdowns occur.

Chain lubrication diagram

The chainsaw chain lubrication system consists of the following elements:

- oil tank, which is located in the engine crankcase;

- filter in the tank;

- oil line, that is, a small diameter hose;

- oil pump.

Chainsaws are equipped with an automatic lubrication system. This means that oil flows to the chain only if it is in contact with the wood. The system operation scheme is as follows. The gear, which is located on the main shaft, drives the oil pump shaft. This creates pressure in the oil line, which forces the oil to move towards the tire.

The oil channel ends at the point where the device tire comes into contact with the chainsaw crankcase. The tension of the chainsaw chain for oil supply does not matter. It still lubricates itself.

No oil getting to the chain

You can tell that oil is not getting to the chain by the following signs:

- dryness of the part and lack of shine;

- its rapid stretching;

- heat;

- no reduction of oil from the tank;

- reduction in cutting efficiency.

If oil stains appear on the surface of the wood, then there is no problem with the oil supply. Feed may need to be adjusted.

The reasons for the lack of oil supply may be:

- Missing thread on the oil pump shaft. In this case, it will need to be replaced.

- Broken oil hose.

- The presence of a defective thread on the pump drive gear.

- Lack of main shaft corkscrew. The problem can be solved by installing a nail of a suitable diameter and the required length.

- Blockage. You can clean the line by blowing it with compressed air or using a thin wire. If the blockage is in the filter or in the pump itself, then it is better to replace these parts.

The main reasons why stihl 180 oil does not arrive

Self-repair of the stihl ms 180 chainsaw. The chainsaw chain is not lubricated. We find and eliminate the cause of samosas.

The first thing to do after you suspect that chain lubricating oil is not being supplied is to check its supply. Diagnostics of the chainsaw chain lubrication system Repair of chainsaw Shtil ms 180 frequent. There are two ways to do this. The first is described in detail in the instructions for the tool and consists in the fact that you need to start the chainsaw, increase the gas as much as possible and point it towards any obstacle.

Currently reading: Chainsaw Ural 2 electron carburetor adjustment

If the lubrication system is working properly, the oil will fly off from the tip of the tire and a strip of oily drops will appear on the surface towards which the tire is pointed. If there are still violations in the system, the surface will remain clean.

The second way is to remove the tire from the chainsaw and start it. When the engine speed increases, oil will flow from the oil channel at the tire shank installation site; if this does not happen, it is necessary to look for the cause of the malfunction.

Why does the chain fly off and break?

If the chain falls off the chainsaw or it breaks, this means that there is some kind of problem with the device; under normal conditions it should not do this. There are three reasons why a chain falls off:

- Tire problems. They lead to loosening of the tension, which can lead to the chain breaking. Most often, this problem occurs in the groove between the outer plate on the chain set housing and the inner plate on the motor housing. The casing with the tire is secured with a bolt, which can become loose during operation of the chainsaw, as a result of which the tire begins to move or vibrate. To solve this problem, you need to find and lower the chain brake, for which you need to turn the tension screw, which is located next to the tire, until it is fully tensioned.

- The chain has stretched. Sagging may indicate a malfunction of the chainsaw mechanism. During operation, the metal is deformed, which means it can become 0.5-1 cm longer. In this case, it is recommended to replace or shorten the chain.

- The drive sprocket is poorly secured. To secure it, you need to remove the engine protective cover and spark plugs, and then pull out the air filter. The spark plug itself also needs to be unscrewed, after which a special stopper is installed in its place to secure the piston. Turn the fastening disk clockwise until the piston stops in the uppermost position. A thick rope folded several times can act as a stopper. After fixing the piston, clamp the drive sprocket. Reassemble the chainsaw, installing all parts in the reverse order.

Read also: Finding hidden wiring and communications

Most problems can be solved by repair. Only in exceptional cases will it be necessary to change it.

Maximum number of revolutions

To limit this indicator, you need to use a screw marked H. To increase the number of revolutions, turn it clockwise , and to reduce them in the opposite direction. The maximum frequency should not exceed 15000 rpm.

If you make this figure larger, the device’s engine will wear out, which will lead to problems in the ignition system. When rotating this screw, you need to take into account the ignition processes of the device. If the slightest malfunctions appear, then the maximum speed value must be reduced.