A belt sander is a wonderful tool that effectively allows you to remove significant layers of the surface being treated. It can be used not only in woodworking, but also on plastic (plastic), as well as metal that is coated with paint, putty or simply rust.

Belt sander for wood

Numerous reviews from both amateurs and professionals will help you choose which machine for DIY woodworking is most suitable in a particular case.

Application and working principle of belt sanding machine

In this type of machine, surface treatment is carried out due to the circular movement of the abrasive belt. This process is very similar to the movement of a tractor caterpillar at an accelerated pace. The rated power consumption of the power tool varies from 500 to 1200 W. The higher the surface processing speed and the time of continuous operation of the tool, the greater the power consumption of the belt sander.

Depending on the material being processed, the belt rotation speed can vary within 75–500 m/min, and this feature also makes it possible to take into account the specifics of the type of work being performed. For these purposes, manufacturing companies equip their power tools with adjustable speed control of the sanding belt. The adjustment can be carried out either smoothly or stepwise - as a rule, switching the belt rotation speed is done by turning a special wheel located on the start button.

Belt sander: purpose and scope of application

For ease of use, the wood belt sander can be equipped with various types of adjustable handles. In addition, to improve the quality of work, this type of unit is equipped with a stationary or removable dust collector, the task of which is to remove dust and chips from the working surface into a special bag or vacuum cleaner.

We understand the range of abrasives for grinding machines: sanding and sanding belts

Sanding belts are now widely used among both professionals and amateurs. A large assortment of manual and stationary machines that use them as an abrasive material, a huge number of manufacturers of these products on the Russian market can take an unprepared buyer by surprise.

In this article we will talk about the main types of abrasives and sanding belts, understand their purpose, and talk about the main advantages and disadvantages of these products.

Abrasive tool for belt sander

To process parts using this unit, a special belt for a grinding machine is used - thanks to its fastening device, replacing worn-out sandpaper is easy and quick, and due to the very high precision of manufacturing parts and assemblies of the machine, the belt not only does not fall off the rollers, but it is also possible adjusting its location relative to the edge of the roller. Some of the manufactured models are equipped with automatic centering of the abrasive belt.

Belt for sanding machine photo

In general, sanding belts of different lengths and widths are used for work - this parameter depends on the model and manufacturer. This nuance must be taken into account when deciding how to choose a belt sander. Depending on the quality of the surface treatment, the belt sander is equipped with a belt of the appropriate grain size. The cleaner the processing, the smaller the grain size of the sanding belt that is installed on the machine should be.

Among the belt sanders, the belt file and the brush sander are divided into separate groups. The “file”, due to its design features, allows you to perform surface treatment in places that are inaccessible to a conventional belt sander. A narrow abrasive belt is used for work, which allows the grinding process to be carried out even in corners.

How to choose a belt sander

The brush machine is practically nothing like its belt counterpart; they are united only by the principle of operation. The main difference is that instead of an abrasive tape, a special brush is used for processing. This unit allows you to quickly and efficiently remove old paint, rust and various surface defects.

Tools

0 votes

+

Vote for!

—

Vote against!

Today, the market offers a large number of different tools designed for grinding various surfaces. One of the most popular is the belt sander or simply sander. Those who want to purchase a high-quality and reliable blade for their use will have to choose from a huge assortment. But there are no special secrets or difficulties in how to choose a belt sander. This tool, like any other, has a number of main and secondary characteristics. Knowing and understanding what this or that characteristic is responsible for, you can easily determine which LSM suits you best.

- Purpose of a belt sander

- Main characteristics of a belt sander

- Blade blade power

- LSM belt rotation speed

- LSM weight

- Dimensions of LShM abrasive belt

- Additional functions of the belt sander

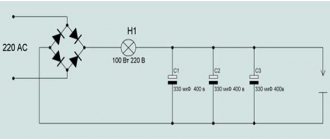

- Power supply for the grinder

- Rotation speed adjustment

- Dust removal method

- Possibility of connection to a vacuum cleaner

- Starting current limitation

- Method for replacing the abrasive belt

- Tape position and tension regulator

- Additional equipment

Purpose of a belt sander

When choosing a belt sander, you need to know in advance how and what it will be used for. Without this, it will be quite difficult to choose the right model. And when you consider that each sander has different performance characteristics, it becomes even more difficult to choose.

The purpose of a belt sander is to sand and remove old paint and varnish coatings from smooth wooden and metal surfaces. The operating principle of this machine is extremely simple and consists of a cyclic movement of an abrasive belt looped on a roller mechanism. Using a blade grinder, you can grind smooth surfaces of both large and small areas. The belt sander is mainly used for coarse and intermediate sanding with the removal of a large layer. Using a belt sander, you can prepare the surface for finer sanding with an eccentric or vibration sander.

Important! For the most part, LBMs are designed to work with flat surfaces. But there are a number of belt sanders designed for processing convex surfaces. Examples of such sanders are the Metabo RB 18 LTX 60 and AGP WS 760. They are positioned as belt sanders for rough grinding, satin finishing and mirror polishing of surfaces.

It is also necessary to decide how often and under what loads the blade will be used. This will determine what type of belt sander you should purchase. So, for rare use with short work cycles, you can purchase a household grinder. They are relatively cheap, but the working life of such blades is designed only for short-term use. The more expensive and at the same time the most reliable sanders, designed to work in difficult conditions, are professional ones.

Main characteristics of a belt sander

When choosing a belt sander, you need to pay special attention to its main performance characteristics. These include power, rotation speed, width and length of the abrasive belt, as well as the weight of the machine. The quality and speed of work execution directly depend on these characteristics.

Blade blade power

The defining characteristic of any power tool is its power. Most manufacturers indicate it in the model name. This parameter affects most other characteristics. The rotation speed, electricity consumption, weight and, most importantly, the quality and period of continuous operation of the grinder depend on it. The power range of belt sanders is from 500 W to 1700 W.

the Makita 9032 belt sander stands out . This sander is sometimes called a power file because it has a narrow belt that allows you to reach narrow and hard-to-reach surfaces. But still, the lion's share of the belt sander market is machines with a power of 700 W to 1500 W. This segment includes belt sanders Makita, Metabo, Bosch, Festul, Interskol and many others. When choosing a particular brand, it will be quite difficult to determine the best sander. If you focus only on the power of the grinder, then the more powerful the grinder, the better. But it is worth remembering about other characteristics, which together will allow you to determine the most suitable belt sander for certain requirements.

LSM belt rotation speed

This is the second most important characteristic for belt sanders. After all, the speed of surface treatment and the quality of work depend on it. The rotation speed of the abrasive belt directly depends on the power of the sander itself. At the same time, in addition to power, the rotation speed is also affected by the width of the belt itself.

LBMs with speeds from 75 m/min to 2000 m/min are available on the market. But it should be noted that high-speed machines use narrow abrasive belts, while low-speed machines use wide belts. Most belt sanders on the market have belt rotation rates ranging from 300 to 500 meters per minute. The optimal indicator for a household grinder is a speed of 400 m/min. One of the machines that combines high rotation speed, wide belt and power is the Fiolent MSHL 1-100 belt sander .

But the downside of high speed and power is rough surface grinding. For comparison, you need to look at surface and eccentric sanders. A surface grinder grinds about 1 gram of processed material per minute, and the power of this tool rarely exceeds 400 W. The eccentric removes 2 - 5 grams, and the power range is 300 - 600 W. But, for example, the Fiolent belt grinder with a power of 1200 and a speed of 550 m/min has a production rate of 12 - 15 grams per minute. Therefore, when choosing a belt sander, it is necessary to adhere to the golden mean in terms of power and belt rotation speed.

LSM weight

A fairly important characteristic is the weight of the grinding machine. This indicator largely affects the convenience and quality of the work performed and depends on the power of the grinder itself. The more powerful the blade, the greater its weight. Of course, in most cases, a blade grinder is used for grinding horizontal surfaces, where it stands securely on the surface. But there are a number of jobs, for example, sanding a door slope or window frame, when the sander needs to be kept suspended. And in this case, a lot of weight will be more of a disadvantage.

Most machines weigh up to 4 kg. And only high-power belt sanders over 1000 W weigh 5 kilograms or more. For example, the Makita 9404 belt sander has a power of 1100 W and a weight of 4.7 kg. Or the Interskol LShM-100/1200E belt grinder with a weight of 5.6 kg. The large weight of these blades is both an advantage and a disadvantage. The fact is that when starting the machine, if it is on the work surface, it can be torn out of the hands at high speed, which will lead to injury to the operator. Therefore, the machine is first turned on and then placed on the surface to be treated. At the same time, for grinding, the large weight of the machine can be an advantage and will be enough for high-quality processing.

Dimensions of LShM abrasive belt

The rotation speed and power of a belt sander are related to another characteristic - the width and length of the abrasive belt. This seemingly simple indicator affects several characteristics at once. Including the quality and productivity of work. The wider the belt, the lower its speed and the more power required to operate. At the same time, machines with a narrow belt have high speed with relatively low power.

The standard tape width is 75 mm, 100 mm, 115 mm. The length is also more or less standardized. In this case, the multiplicity step along the length is 5 mm. But some models of belt sanders have non-standard sizes, which can be 232 mm or 142 mm along the length of the abrasive belt. Which causes certain difficulties when purchasing consumables. A good example is the Skil 1215AA belt sander , whose belt size is 76x457 mm. In contrast to Skil, the Makita belt sander 9404 has dimensions of 100x610, which makes it quite easy to find consumables for it. The dimensions of the tape are quite important. Firstly, it is easier to find consumables for a standard size. Secondly, the greater length and width of the tape will allow you to process a larger surface before the tape is completely worn out. But, remembering the relationship between power, belt rotation speed and its width, you can find a blade grinder with optimal values of these parameters.

Additional functions of the belt sander

Each manufacturer tries to add unique and useful features to their products that will make them stand out from all the others. Such additional options often have a lesser impact on the quality and productivity of work, but make the work noticeably more comfortable. Such additional functions include speed control, the ability to connect a vacuum cleaner, soft start and much more.

Power supply for the grinder

Today, battery-powered construction tools are the norm, and belt sanders are no exception. This approach is very justified, and for those who have to work in conditions without electricity, a cordless sander will come in handy. An example of such a blade is the Metabo RB 18 LTX 60 .

Rotation speed adjustment

One important function of the machine is associated with the rotation speed, namely the ability to adjust it. This additional feature is very useful for a belt sander. By adjusting the rotation speed of the abrasive belt, you can control the quality of the work performed, which allows you to do both rough and finer grinding of the surface. There are various models on the market and some of them do not have this feature. But when choosing one model or another, preference should be given to a blade grinder with the ability to adjust the speed of rotation of the belt. An example is the Makita 9911 belt sander , which allows you to adjust the speed in the range from 75 m/min to 270 m/min.

Dust removal method

The belt sander is unique in that dust is removed by suction from the engine cooling fan. Each manufacturer approached this working moment in its own way. This has led to the fact that some models have one significant drawback - dust settles on the rollers and moving parts, which leads to their rapid wear and the need for replacement or lubrication. When choosing a particular grinder, you need to pay attention to the method of collecting and removing dust. The container or bag itself should not be located near rollers or other moving parts. And if this is what the designers intended, then you should make sure that it is easy to access for cleaning the tool. An example of such a design is the belt grinder Caliber LShM-750 . It should also be noted that if you need to disassemble the blade for repair or lubricate parts, you can lose the warranty on it, which happens quite often. Therefore, before purchasing such a model, ask the seller about the possibility of lubricating and disassembling parts of the unit yourself without losing the warranty.

Possibility of connection to a vacuum cleaner

All grinders of one type or another have a special dust collector, but there are models that are equipped with dust removal using a vacuum cleaner. For example, a Bosch belt sander, model PBS 7 A , has in its arsenal both a dust collector and the ability to connect a vacuum cleaner. When choosing a particular model, you should make sure that this useful option is available, or at least that there is an adapter for the vacuum cleaner. After all, thanks to it, you can increase the period of work without cleaning the bag, which will only have a positive effect on the speed of work.

Starting current limitation

As noted earlier, the belt sander is turned on in midair and then only lowered to the surface. On low-power and light grinders the starting moment is not felt much, but on heavier and more powerful grinders the machine jerks. To eliminate this effect, many manufacturers equip their tools with a starting current limiter, or as it is also called a “soft start” system. It allows the blade to gain momentum gradually, making it much easier to start working with a heavy and powerful tool. When choosing a belt sander, this option will not play a significant role on the quality of the work, but will make it easier to start.

Method for replacing the abrasive belt

In the process of working with blade grinders, you have to change the abrasive belt more than once. To do this, it is sometimes necessary to remove the protective cover or loosen the tension rollers in order to remove the old one and install a new tape. In most cases, this does not take much time, but you don’t really want to keep a pair of keys on hand and fiddle with them when replacing the tape. Of course, manufacturers found a way out of this situation and created machine models where the belt can be replaced without any additional tools. When choosing a belt sander, you should pay attention to the method of replacing the abrasive so that it is as comfortable as possible for you and does not complicate the process of working with the blade.

Tape position and tension regulator

When considering the size of the tape, we mentioned the possibility of adjusting its tension. This option, despite the fact that it is additional, is important when choosing a LSM. Many quick change belt models do not have any manual adjustments for belt tension or alignment. And not every user knows how to properly adjust the tape tension. Therefore, manufacturers have developed automatic centering and belt tension. This greatly simplified the work with such machines and allowed even beginners to use them. When choosing between several models, you should give your preference to a machine with automatic adjustment of the position and tension of the tape.

Additional equipment

In addition to useful additional functions, manufacturers try to highlight their products with the help of various useful accessories. This can be either a branded suitcase for the sander or various removable parts, such as a sanding frame, a clamp or additional handles. But more important is a set of sanding belts, a spare dust bag and a vacuum cleaner adapter. In any case, you should carefully familiarize yourself with the configuration of a particular model. Perhaps it is the presence of some little thing that will make you make the right choice for yourself.

One of the most successful blade grinders with optimal power parameters, belt rotation speed and the ability to adjust it, a wide and long belt, is the Bosch GBS 75 AE Set Professional belt sander . This professional tool, despite its rather high price, boasts excellent performance characteristics and excellent reliability. It should be especially noted that this machine meets such requirements as a dust collection bag removed from the rollers and the ability to connect a vacuum cleaner, automatic centering and belt tension, low weight, speed control and much more. If the Bosch belt sander seems too expensive to you, then it can be used as an example when choosing another, cheaper model.

How to work with a belt sander: features of its use

By and large, almost everyone can master this simple tool. There are practically no nuances in working with it - it is easily installed on the surface to be treated and this surface is just as easily sanded. All you need to do is move the unit evenly over the surface being treated and monitor the quality of the final result.

How to choose sanding belt grit

Difficulties in working with this machine can arise only in two cases: during the process of replacing the abrasive sanding belt and at the time of its adjustment. It's not that difficult to figure this out. To change the used tape, you just need to loosen its tension; for this, there is a special lever on one side of the machine. And to center the abrasive belt, just turn the regulator, which is located on the side of the front roller, rotating it clockwise or counterclockwise, you can move the tape in one direction or another from the edge of the roller. The main thing here is not to overdo it so that the tape does not slip off the tool during operation.

Belt sander: operating principle

In principle, this is the minimum that an ordinary user needs to know about this device. The main thing to remember is that a belt sander is an electromechanical device that can injure a person if handled incorrectly.

Sanding belts. How to choose the right one.

Professionally ground parts are attractive due to the clearly recognizable quality of their surface structure, which is required for reliable operation, ease of cleaning and subsequent processing.

On the path to excellence, the use of the best equipment and high-quality abrasives is critical.

One of the most modern and effective methods of metal processing is the use of a sanding belt.

What is a sanding belt?

Sanding belt

It is a fabric or paper base with abrasive grain applied to it using an adhesive composition and glued into a ring (for this it is often called endless).

Due to the huge variety of materials from which it is made, sanding belts have a huge range of applications:

- rough grinding, aggressive removal of metal and other materials.

- fine grinding, delicate surface treatment, obtaining the required quality.

- giving surface structure.

- polishing surfaces of any materials.

The list of equipment with which the sanding belt is used is also very wide. These include hand-held power tools, pneumatic tools, and stationary grinding machines. Depending on the selected equipment, it is possible to solve a wide variety of problems and process products with simple or complex surface geometry.

Sanding wood with a manual belt machine.

Sanding hard-to-reach areas

with a band file .

Grinding a round stainless steel pipe on

a centerless machine .

As you can see, the uses of sanding belts are very diverse. And to get the perfect result, you need to take into account many factors. We will help you figure it out and tell you what main points you need to consider when choosing

a sanding belt .

Sanding belt size.

No matter how obvious it may seem, this is the first thing you should pay attention to when choosing a tape.

The size of the tape is always selected according to the equipment on which you are using it. Each tool or machine indicates the length and width of the recommended materials (if not indicated on the tool or these inscriptions have been erased, then they are indicated in the manual or technical data sheet). We often encounter situations where a client wants to order a tape, but does not know its size, and the instrument no longer has it and all documents are lost. It is also not always possible to accurately measure the tape, so we recommend that after purchasing the equipment, do not lose its passport or instructions, they will be useful to you.

Criteria for choosing a belt sander

When choosing a belt sander, you first need to focus on the purpose for which it is being purchased. If this is one-time work with small volumes, then almost any hand-held grinder that suits you in terms of price and quality will be suitable for this. If you intend to do extensive repairs or carry out custom work, then you must choose at least a semi-professional model with a good reputation and high performance. When choosing such a power tool, you should first pay attention to the following parameters and operational features:

- Engine power. It is crucial for large volumes of work and is directly related to the width of the belt and the size of the sole. For a budget option, 800 W is enough, for a semi-professional one - from 1000 W.

- Adjusting the linear speed of the sanding belt (motor speed). “According to science,” different materials are polished at different speeds, and a general principle applies: the softer, the lower the speed. For one-time work, you can get by with a grinder without such adjustment.

- Belt width and sole length (grinding area). Grinding performance directly depends on them. In this case, the rule must be strictly observed: the wider the tape, the greater the engine power.

- Duty cycle (T work./T lane). This parameter characterizes the ratio of continuous grinding time to break time (in minutes). Not all manufacturers indicate it in their passports. For budget belt sanders, 10/5 or even 5/5 is sufficient, and for semi-professional ones, at least 15/5.

- Automatic centering of the sanding belt. According to user reviews, one of the main problems of budget models is the low quality of manual alignment mechanisms and the associated belt misalignment. Belt sanders with auto-centering do not have this drawback.

The most common sanding belts in retail chains are 75(76)×457, 75(76)×533 and 100×610 mm. You should definitely pay attention to this so as not to choose a model with a ribbon of some rare size.

Hammer LSM 810

Main characteristics:

- Power - 810 W;

- Belt speed - 380 m/min;

- Tape - 533×75 mm;

- Weight - 3 kg.

Housing and ergonomics. The grinding machine of this brand is distinguished by its compact size and original design. It has a molded body made of durable plastic and rubberized handles that are comfortable for right and left grip. The product weight of 3.5 kg will not cause severe fatigue even during long-term use.

Design features. An abrasive belt measuring 75x533 mm is suitable for this machine. When installing it, a quick tension mechanism, an automatic centering system and an adjusting screw for adjusting the position relative to the edge are activated.

Quick tension mechanism.

You can attach a standard linen bag or a hose from an industrial vacuum cleaner to the dust air removal pipe. There are two through holes in the upper part of the housing for fixing the unit in an inverted position. There are special hatches for quick replacement of motor brushes.

Functionality and capabilities. This model consumes 810 W of energy, which is enough for domestic and professional use. The belt easily accelerates to 380 m/min. The speed limit is adjusted by a rotary wheel on the body in the area of the rear handle. The rotation speed depends on the degree of pressing of the start key, which has a locking button in the on position.

Equipment. The machine comes with a sanding belt and a dust bag.

Pros of Hammer LSM 810

- High performance.

- Compact size and light weight.

- Ability to work close to the wall.

- Comfortable handles.

- A well-thought-out mechanism for replacing and adjusting the position of the tape.

- Speed adjustment.

- Possibility of mounting in an inverted position.

- Acceptable price.

Cons Hammer LSM 810

- Weak rear shaft design.

- Noise.

Makita 9911

Main characteristics:

- Power - 650 W;

- Belt speed - 270 m/min;

- Tape - 457×76 mm;

- Weight - 2.7 kg.

Housing and ergonomics. Unlike previous models, this sander, when well balanced, weighs only 2.6 kg, which is achieved by reducing technical characteristics. It has a plastic body with two handles that fit comfortably in your hands. Working with such a tool, even when suspended, does not cause serious difficulties.

Design features. The machine is fed with an abrasive belt measuring 457x76 mm, which is automatically centered. It is located at the very edge of the platform, which makes it possible to work close to the walls, leaving a minimal untreated area. The product has double insulation of live parts and good cooling of the motor, increasing the period of continuous use.

Functionality and capabilities. The tool has an average power rating of 650 W. Noteworthy is the speed adjustment from a low threshold of 75 m/min with a maximum acceleration of 270 m/min. The start button is secured. It is possible to connect to an industrial vacuum cleaner.

Equipment. When purchasing this model, you will find instructions, sanding tape and a small dust bag in the box.

Pros of Makita 9911

- Convenient handle shape.

- Light weight and compact dimensions.

- Reliability.

- Electrical safety.

- Speed adjustment from low values.

- Acceptable price.

Cons of Makita 9911

- There is no soft start and speed stabilization.

- Short cable only 2.5 m long.