Information about the manufacturer of the semi-automatic cylindrical grinding machine 3M175, 3M174, 3M173

Manufacturer of semi-automatic cylindrical grinding machine 3M175, 3M174, 3M173 - Lubny Machine Tools

.

founded in 1915 and in 1918 received the name “Kommunar”.

Since 1957, the plant has specialized in the production of universal and special cylindrical grinding machines with various levels of automation, from manual machines to modern CNC machines.

Machine tools produced by the Lubensky machine-tool plant Kommunar

- 3A130

- universal semi-automatic cylindrical grinding machine Ø 280 × 700 - 3A423

- cylindrical grinding machine for regrinding crankshaft journals Ø 580 × 1600 - 3B423

- cylindrical grinding machine for regrinding crankshaft journals Ø 580 × 1600 - 3D4230

- cylindrical grinding machine for regrinding crankshaft journals Ø 580 × 1600 - 3M131 (3M132, 3M133)

- universal semi-automatic cylindrical grinding machine Ø 280 × 700 - 3M174 (3M173)

- universal semi-automatic cylindrical grinding machine Ø 400 × 2000 - 3M175

- universal semi-automatic cylindrical grinding machine Ø 400 × 2800 - 3U131

- universal semi-automatic cylindrical grinding machine Ø 280 × 700 - 3U132

- universal semi-automatic cylindrical grinding machine Ø 280 × 1000 - 3U133

- universal semi-automatic cylindrical grinding machine Ø 280 × 1400 - 3U142

- universal semi-automatic cylindrical grinding machine Ø 400 × 1000 - 3U143

- universal semi-automatic cylindrical grinding machine Ø 400 × 1400 - 3U144

- universal semi-automatic cylindrical grinding machine Ø 400 × 2000 - 3131

— universal semi-automatic cylindrical grinding machine Ø 280 × 1400

3M175 universal semi-automatic cylindrical grinding machine. Purpose and scope

Semi-automatic cylindrical grinders 3M175 , 3M174, 3M173 are designed for external grinding of cylindrical and flat conical surfaces in single, serial and large-scale production.

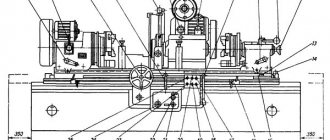

Operating principle and design features of the 3M175 machine

Machine accuracy class P according to GOST 11654-65.

Roughness of the processed surface according to GOST 2789-59-VI0.

Grinding on semi-automatic machines 3M175 is carried out in fixed centers.

The upper part of the table is rotatable, which ensures grinding of conical surfaces.

The hydraulic drive of the longitudinal movement of the table allows you to smoothly adjust the speed of movement and change the delay values in the extreme positions of the table. There is a mechanism for manual movement of the table.

The spindle of the grinding head is mounted in self-aligning hydrodynamic bearings, which ensure a stable position of the spindle under heavy loads.

The grinding head moves on roller guides. The feed mechanism of the grinding wheel uses a helical rolling pair, which ensures high feed accuracy.

Semi-automatic machines 3M175 are equipped with a mechanism for balancing the grinding wheel on the move and a device for measuring the amount of vibration.

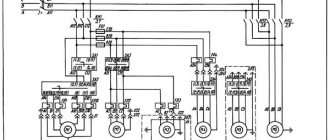

On semi-automatic machines 3M175, plunge-in and longitudinal grinding methods are automated with changes in the transverse and longitudinal feeds and rotation speeds of the product during the grinding process. Grinding can be carried out in a semi-automatic or manual cycle.

High precision and cleanliness of processing is ensured.

Reservoirs for oil and coolant are located outside the frame to eliminate thermal deformations. Provides cleaning of oil and coolant.

Reliable locking prevents the activation of the drives for rotating the grinding wheel spindle and moving the table in the absence of lubrication, as well as the retraction of the tailstock quill when the grinding headstock is connected.

Semi-automatic machines 3M175 are easy to operate and maintain. Starting the table movement, turning on the rotation of the product, cooling and quickly bringing the grinding wheel to the product are done with one handle.

The tailstock quill moves from an electromechanical drive.

Fast installation movement of the grinding head is ensured. Semi-automatic machines are equipped with a hinged indicator bracket for measuring the grinded diameter of the product.

By special order, semi-automatic machines can be equipped with a device for automatic wheel dressing with compensation for its wear and an active control device.

The high rigidity of semi-automatic machines, sufficient dimensions of the grinding wheel and its powerful drive ensure high productivity.

Semiautomatic 3M175 cylindrical grinder for plunge-cut and longitudinal grinding

Lubensky Machine Tool Plant Semi-automatic machine 3M175 is designed for external grinding of cylindrical and flat conical surfaces in single, serial and large-scale production. The accuracy class of the machines is P. Grinding on semi-automatic machines is carried out in fixed centers. The upper part of the table is rotatable, which ensures grinding of conical surfaces. The hydraulic drive of the longitudinal movement of the table allows you to smoothly adjust the speed of movement and change the delay values in the extreme positions of the table. There is a mechanism for manual movement of the table. The spindle of the grinding head is mounted in self-aligning hydrodynamic bearings, which ensure a stable position of the spindle under heavy loads. The grinding head moves on roller guides. The feed mechanism of the grinding wheel uses a helical rolling pair, which ensures high feed accuracy. Semi-automatic machines are equipped with a mechanism for balancing the grinding wheel on the move and a device for measuring the amount of vibration. On semi-automatic machines, plunge-in and longitudinal grinding methods are automated with changes in the grinding process of transverse and longitudinal feeds and rotation speeds of the product. Grinding can be carried out in a semi-automatic or manual cycle. High precision and cleanliness of processing is ensured. Reservoirs for oil and coolant are located outside the frame to eliminate thermal deformations. Provides cleaning of oil and coolant. Reliable locking prevents the activation of the drives for rotating the grinding wheel spindle and moving the table in the absence of lubrication, as well as the retraction of the tailstock quill when the grinding headstock is connected. Semi-automatic machines are easy to operate and maintain. Starting the table movement, turning on the rotation of the product, cooling and quickly bringing the grinding wheel to the product are done with one handle. The tailstock quill moves from an electromechanical drive. Fast installation movement of the grinding head is ensured. Semi-automatic machines are equipped with a hinged indicator bracket for measuring the grinded diameter of the product. By special order, semi-automatic machines can be equipped with a device for automatic wheel dressing with compensation for its wear and an active control device. The high rigidity of semi-automatic machines, sufficient dimensions of the grinding wheel and its powerful drive ensure high productivity.

Technical characteristics of the 3M175 machine

| Parameter name | 3M173 | 3M174 | 3M175 |

| Main settings | |||

| Accuracy class according to GOST 8-82 | P | P | P |

| Largest diameter of the workpiece, mm | 400 | 400 | 400 |

| Maximum length of the workpiece, mm | 1400 | 2000 | 2800 |

| The largest grinding diameter in a steady rest/without a steady rest, mm | 120/ 400 | 120/ 400 | 120/ 400 |

| Smallest grinding diameter with a worn wheel, mm | 130 | 130 | 130 |

| Distance from the axis of the headstock spindle to the table mirror (height of centers), mm | 210 | 210 | 210 |

| Maximum mass of the processed product, kg | 1000 | 1000 | 1000 |

| Cone of the headstock spindle and tailstock quill according to GOST 2847-67 | Morse 4 | Morse 4 | Morse 5 |

| End of the grinding spindle according to GOST 2323-67 (taper 1:5, nominal diameter), mm | |||

| Diameter of the front support journal of the grinding spindle, mm | 110f7 | 110f7 | 110f7 |

| Machine work table | |||

| Maximum table movement length, mm | 1400 | 2000 | 2800 |

| Manual movement of the table per revolution of the flywheel, mm | 2 | 2 | 2 |

| Table movement speed from the hydraulic system, m/min | 0,05..5,0 | 0,05..5,0 | 0,05..5,0 |

| Maximum angle of rotation of the upper table clockwise, degrees | 2 | 2 | 2 |

| Maximum angle of rotation of the upper table counterclockwise, degrees | 5 | 5 | 4 |

| Upper table rotation scale division value (taper), deg | 0,2 | 0,2 | 0,2 |

| Grinding head | |||

| Grinding wheel diameter - largest / smallest / landing, mm | 750/ 500/ 305 | 750/ 500/ 305 | 750/ 500/ 305 |

| Diameter of the grinded product with a wheel diameter of 500 mm, mm | 130..400 | 130..400 | 130..400 |

| Diameter of the grinded product with a wheel diameter of 600 mm, mm | 30..400 | 30..400 | 30..400 |

| Diameter of the grinded product with a wheel diameter of 700 mm, mm | 20..400 | 20..400 | 20..400 |

| Diameter of the grinded product with a wheel diameter of 750 mm, mm | 0..400 | 0..400 | 0..400 |

| Maximum height of the installed circle, mm | 80, 100 | 80, 100 | 80, 100 |

| Grinding head spindle rotation speed, rpm | 1270 | 1270 | 1270 |

| Grinding wheel cutting speed, m/s | 35, 50 | 35, 50 | 35, 50 |

| Cross feed mechanism | |||

| Maximum movement of the grinding head along the screw, mm | 365 | 365 | 365 |

| The size of the quick approach of the grinding head, mm | 100 | 100 | 100 |

| Time for rapid approach of the grinding head, s | 3 | 3 | 3 |

| Periodic feed of the grinding head when reversing the table (stepless control), mm | 0,0025..0,05 | 0,0025..0,05 | 0,0025..0,05 |

| Plunge feed speed limits, mm/min | 0,1..4 | 0,1..4 | 0,1..4 |

| Jog feed, mm | 0,001 | 0,001 | 0,001 |

| The price of dividing the dial for the transverse movement of the grinding head, mm | 0,005 | 0,005 | 0,005 |

| The amount of transverse movement of the grinding head per one revolution of the flywheel, mm | 0,5 | 0,5 | 0,5 |

| Headstock | |||

| Product rotation speed (stepless regulation), rpm | 20..180 | 20..180 | 20..180 |

| Center cone according to GOST 13214-67 | Morse 6 | Morse 6 | Morse 6 |

| Tailstock | |||

| The amount of retraction of the tailstock quill, mm | 70 | 70 | 70 |

| Center cone according to GOST 13214-67 | Morse 6 | Morse 6 | Morse 6 |

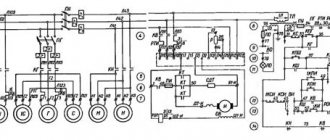

| Drive and electrical equipment of the machine | |||

| Number of electric motors on the machine | 8 | 8 | 8 |

| Grinding head spindle electric motor, kW | 17 | 17 | 17 |

| Product drive electric motor, kW | 1,5 | 1,5 | 1,5 |

| Hydraulic pump electric motor, kW | 2,2 | 2,2 | 2,2 |

| Electric motor of the spindle bearing lubrication system pump, kW | 0,27 | 0,27 | 0,27 |

| Electric motor of the table guide lubrication system pump, kW | 0,08 | 0,08 | 0,08 |

| Electric motor of the cooling system pump, kW | 0,15 | 0,15 | 0,15 |

| Tailstock quill drive electric motor, kW | 0,18 | 0,18 | 0,18 |

| Magnetic separator electric motor, kW | 0,12 | 0,12 | 0,12 |

| Total power of electric motors, kW | 21,5 | 21,5 | 21,5 |

| Overall dimensions and weight of the machine | |||

| Overall dimensions of the machine (length x width x height), mm | 5510 x 2620 x 1860 | 6620 x 2690 x 1850 | 8220 x 2620 x 1850 |

| Weight of the machine with electrical equipment and cooling, kg | 11800 | 13000 | 14700 |

- Alperovich T.A., Konstantinov K.N., Shapiro A.Ya. Design of grinding machines, 1989

- Alperovich T.A., Konstantinov K.N., Shapiro A.Ya. Setup and operation of grinding machines, 1989

- Dibner L.G., Tsofin E.E. Sharpening machines and semi-automatic machines, 1978

- Genis B.M., Doctor L.Sh., Tergan V.S. Grinding on cylindrical grinding machines, 1965

- Kashchuk V.A., Vereshchagin A.B. Grinder's Handbook, 1988

- Kulikov S.I. Honing, 1973

- Lisova A.I. Design, adjustment and operation of metal-cutting machines, 1971

- Loskutov V.V. Metal grinding, 1985

- Loskutov V.V. Grinding machines, 1988

- Lurie G.B. Grinding machines and their adjustment, 1972

- Lurie G.B. Design of grinding machines, 1983

- Menitsky I.D. Universal sharpening machines, 1968

- Mutsyanko V.I. Bratchikov A.Ya. Centerless grinding, 1986

- Naerman M.S., Naerman Ya.M. Guide for training grinders. Textbook for vocational schools, 1989

- Popov S.A. Grinding work, 1987

- Tergan V.S. Grinding on cylindrical grinding machines, 1972

- Shamov B.P. Types and designs of main components of grinding machines, 1965

Bibliography:

Related Links. Additional Information

- Classification and main characteristics of the grinding group

- Repair, restoration and modernization of grinding machines: the American approach

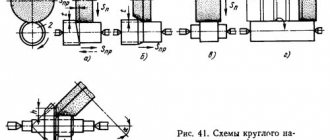

- Cylindrical grinding. Processing on cylindrical grinding machines. Grinding Methods

- Setting up a cylindrical grinding machine when installing parts in centers

- CNC grinding machines

- Marking of grinding wheels

- Testing and checking metal-cutting machines for accuracy

- Grinding machines. Market of grinding machines in Russia

- Manufacturers of grinding machines

- Directory of grinding machines

- Manufacturers of metal-cutting machines

- Articles on the topic

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Cylindrical grinding machine 3M173, 3M174, 3M175

This equipment is intended for external grinding of cylindrical and flat conical surfaces of parts by plunge-cut and longitudinal grinding in conditions of single, serial and large-scale production.

On the 3M173, 3M174, 3M175 cylindrical grinding machine the following are automated and mechanized: plunge-in and longitudinal grinding methods, changing transverse, longitudinal and circular feeds; starting and stopping the product; turning the coolant on and off; quick approach and retraction of the grinding headstock and tailstock quill; driving the grinding head along the screw; balancing the grinding wheel. By agreement with the customer, semi-automatic machines can be produced configured for grinding a specific product. The machines have semi-automatic control and have the possibility of manual control. The semi-automatic cycle is provided by a mechanical device with electro-hydraulic control.

Cylindrical grinding machines 3M173, 3M174, 3M175 3M173 grind the surfaces of the journal and hub part of the RU1Sh railway axle in one installation of the workpiece, both during the manufacture and when performing repairs of wheel pairs.

Technical characteristics of cylindrical grinding machines:

| Model | 3M173 | 3M174 | 3M175 |

| Maximum dimensions of the installed workpiece (diameter/length), mm: | 400/1400 | 400/2000 | 400/2800 |

| Maximum grinding dimensions (diameter/length), mm | 400/1260 | 400/1800 | 400/2520 |

| Maximum weight of the installed workpiece, mm | 1000-15 | 1000-15 | 1000-15 |

| Maximum table movement length, mm | 1400 | 2000 | 2800 |

| Height of centers above table, mm | 210 | 210 | 210 |

| Accuracy class according to GOST 8 | P | P | P |

| Cone in the front spindle and tailstock quill according to GOST 25557 | Morse 6 | Morse 6 | Morse 6 |

| End of the grinding spindle according to GOST 2323 (taper 1:5), mm: | |||

| - nominal diameter | 100h11 | 100h11 | 100h11 |

| - diameter of support journals | 110f7 | 110f7 | 110f7 |

| Maximum dimensions of the grinding wheel, mm: | |||

| — outer/inner diameter | 750/305 | 750/305 | 750/305 |

| - height | 80 (100) | 80 (100) | 80 (100) |

| Grinding head spindle rotation speed, min-1 | 1270 | 1270 | 1270 |

| Workpiece rotation speed (steplessly adjustable), min/max min-1 | 180/20 (360/40) | 180/20 (360/40) | 180/20 (360/40) |

| Peripheral speed of the grinding wheel, m/s | 50 (35) | 50 (35) | 50 (35) |

| Angle of rotation of the upper table (clockwise/counterclockwise), degrees: | 2 / 6 | 2 / 5 | 2 / 4 |

| Total power of electric motors, kW | 26,19 (23,98) | 26,19 (23,98) | 26,19 (23,98) |

| Type of current | AC three-phase | AC three-phase | AC three-phase |

| Voltage, V | 380 (220, 400, 415, 440) | 380 (220, 400, 415, 440) | 380 (220, 400, 415, 440) |

| Current frequency, Hz | 50 (60) | 50 (60) | 50 (60) |

| Overall dimensions with separately located equipment, mm | 5760 x 3690 x 2135 | 6710 x 3690 x 2135 | 8310 x 3690 x 2135 |

| Net weight, kg | 10420 | 11600 | 13850 |

Delivery set (included in price) of cylindrical grinding machine 3M173, 3M174, 3M175.

- Complete machine

- Hydraulic drive station

- Control cabinet

- Cooling installation

- Sludge tank

- Table guard

- Set of plumbing tools

- Angular orientation device

- Linear orientation device

- Lunette

- Grinding wheel dressing device

- Indicator device

- Indicator ICH 10 class 1 GOST 577-68

- Wheel lifting device

- Center

- Lever

- Clamp 15- 100

- Clamp 100-125

- Mandrel

- Shoes

- Documentation set

Additionally, you can buy the following accessories for the 3M173, 3M174, 3M175 cylindrical grinding machine.

- Electronic indicator VBV-005

- Device BV-P.3156-02