Grinder is the colloquial name for a power tool designed for abrasive processing of metal or other types of material.

The most important parameter when choosing an angle grinder is the size of the disc . The diameter of the disc determines the depth to which the device will cut the material. Also, do not forget that during operation the disc gradually wears out and becomes smaller, thereby reducing the cutting depth.

Bulgarian

Grinding with a surface grinder and angle grinder (grinder)

An angle grinder (grinder) is a multifunctional device that is also used in the situation under consideration. Special circles are used for this. Petal wheels are made from sandpaper, which is attached to a flat surface. In this case, the circle can be of different diameters, with different grain sizes. When choosing, you can highlight the following recommendations:

- to remove paint, use a coarse-grained wheel;

- if it is necessary to remove a thin layer of wood, you can use an abrasive that has a medium grain size;

- In order to give the wood a special smoothness, you can use a fine-grained abrasive.

However, it should be noted that the surface removal will not be carried out along the fibers. At the same time, it is almost impossible to regulate the rotation speed and feed. You can use an angle grinder in cases where there is no need for a high performance indicator.

In order to sand wood, you can use special equipment called a surface grinder. The features of this include:

- The wood is combed using a reciprocating motion of the abrasive material.

- The sandpaper moves at high speed, which allows you to achieve good results when working.

- Unlike other methods, in this case the grinding machine carries out processing along the fibers, which determines the high quality of the product.

The design is quite simple, allowing you to achieve good quality. But when changing large surfaces, the grinder has low efficiency. Certain models have a fairly large surface to which the skin is attached, but in this case it is quite difficult to provide the necessary force.

Belt type sander

The belt sander is the most productive tool that can be used for processing wood with high productivity. The inkjet technique also has high productivity.

DeWalt Belt Sander

The work of the structure is carried out using a round sanding belt, which can have varying degrees of grain size. The design removes material along the fibers. However, do not forget that it is impossible to polish the corners using this design. The tape can be used for a large volume of work: floors, walls, furniture, and so on.

Despite the greater automation of work, it is possible to provide mechanical action manually. This is due to the fact that fiber removal can be done in the desired direction. It is also possible to process corners. However, in order to achieve the desired result, you need to have certain skills. The work is very difficult and time consuming. Therefore, hand tools are very popular only in certain cases.

FreWind (FW-RAS5) D125 – P80

For example, in order for the luminous flux to be equal to 250lm, an incandescent lamp must have a power of 20W, and an LED lamp must have a power of 2-3W. At the same time, they do the same “work”.

With the advent of LED lamps, they began to indicate on packaging. that 2W (LED lamp) = 20W (incandescent lamps). But it happens that you buy lamps of the same power, then their brightness is different. Therefore, it is better to choose lamps not by power, but by luminous intensity (luminous flux).

The situation is similar with power tools. The power consumption may be the same, but the performance may be different. Therefore, when choosing a power tool, you should not rely only on the “W” value.

Pros and cons of wood sanding tools

Wood processing is carried out using a variety of abrasive devices. When working with them, traces remain. Each of them has its own characteristics. This must be taken into account when choosing a grinding attachment. Among the most popular grinding devices I would like to highlight the following:

Bulgarian

An angle grinder is a multifunctional device. The design of the tool is equipped with circles of different diameters with an abrasive surface.

When choosing a wheel, it is recommended to take into account the criteria on which the quality of processing depends. For example, for what purpose is the processing carried out:

- removing a layer of paint - a circle with coarse grain is suitable;

- removing the top layer of small thickness - it is recommended to use an abrasive wheel with medium grit;

- giving the wood smoothness - a fine-grained wheel will come in handy.

When working with a grinder, it is necessary to take into account the fact that processing is carried out across the fibers at different speeds of rotation of the abrasive wheel.

Drill

Using a drill for grinding is possible with attachments made of different materials. When working, the tool must be positioned at a certain angle. Otherwise, the formation of burrs and scratches cannot be avoided.

When working with a drill, you can use the manual grinding method, which makes it possible to process wood in hard-to-reach places. The possibility of using a fixed method of work cannot be ruled out. This guarantees high quality grinding, but the mobility of the tool is limited.

Belt sander

One of the most effective devices for processing wood is considered to be a belt sander. The design of the equipment is equipped with sanding belts with different degrees of grain.

The work is carried out according to the arrangement of the wood fibers. It is worth noting that an angle grinder is not suitable for grinding the corners of a workpiece. The equipment is effectively used when processing floors, walls or large furniture.

Vibrating sander

This type of equipment is used for polishing purposes. You can also achieve high results using a vibrating sander when removing the paint layer.

The work process is carried out using sheets or wheels with an abrasive surface. Clips or Velcro can be used to attach them to the sole.

Orbital sander

The design of an orbital sander is equipped with a round sole on which an abrasive disk or paper of varying degrees of grain is attached.

Grinding is performed as a result of VP movements of the sole of the machine. In this case, the movement is carried out in a spiral.

Rules for sanding wood

You can achieve high results when sanding a wooden surface if you follow certain rules. Among the most significant are the following:

- Before starting work, the surface must be well moistened with warm water.

- If there are large irregularities or depressions on the working surface, they must be leveled using a primer. Sanding can only begin after the primer has completely dried.

- It is recommended to use medium or coarse abrasive at the first stage of work, and then fine. Thanks to this, you can achieve a smooth working surface.

The correct choice of tools and compliance with work rules allows you to achieve high results in wood processing.

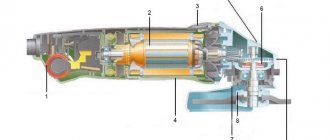

What is a grinder

An angle grinder is colloquially called an angle grinder. The instrument first appeared in the Soviet Union in the seventies of the last century. It was imported from Bulgaria, hence the common name of the device. It is used in construction, wood and metal processing. The axes of the tool’s engine are at right angles to each other, the body is cylindrical, and the handle is most often located on the side.

To process materials with a grinder, abrasive wheels of different thicknesses are used, which are attached to the shaft. Most often, angle grinders are used to cut metal, tiles, bricks, ceramics, concrete, and granite. Flap end discs are used for grinding surfaces.

Comparative analysis of electrical appliances

As can be seen from the above description of electrical appliances, the functions of these tools are 98% identical . Both devices are used for cutting, grinding and polishing metal, wood, plastic and other materials.

Grinding machines have a wider range of divisions of work areas (flat surface, corner). Also, many models have a vacuum cleaner function, which the grinder does not have.

Often, a grinder is used as a tool for cutting various materials, while a grinder is more intended for cleaning surfaces and subsequent polishing.

Repair and constructionComment

Sander

This is a professional tool that allows you to efficiently process large surfaces during finishing. The principle of operation is that sandpaper of varying degrees of abrasiveness is attached to the base of the sole.

When you turn on the device, the sole starts to move - due to this, the surface is polished. Grinders are:

- Eccentric. Can be used for polishing parquet floors and even car bodies. With their help, you can very delicately and extremely accurately sand a wooden surface, with the exception of corners and small recesses where the disc cannot reach.

- Vibro-grinding. They can process not only wood, but also plastic and stone surfaces due to the ability to regulate speed. It has a rectangular sole, ideal for processing large areas.

- Delta grinder. The triangle-shaped soleplate allows for precise finishing sanding of corners and edges of products.

- Multifunctional. This type of tool can be used for large volumes of work and for processing hard-to-reach areas and corners. Additional attachments to the soleplate in the form of an iron allow you to sand even the profile.

There are also belt machines for roughing and polishing machines to give an absolutely smooth surface.

Grinder or grinder - what's the difference?

Both devices are variations of the same electric tool - an angle grinder. They vary in power and actual capabilities. So, while some models are used primarily for cutting, others are more suitable for grinding.

The grinder in the form in which most consumers imagine it has relatively low power and simple functionality. During prolonged continuous operation, the 1.5 kW motor overheats and has to be turned off. It can be successfully used exclusively for domestic needs; such a tool cannot cope with large volumes of work.

Professional grinders are equipped with a much more powerful motor of 1.8 to 2.5 kW, which ensures long continuous operation. In such tools you can adjust the speed, they have greater productivity.

Grinders have a soft start function, unlike household grinders, which pick up speed immediately after switching on. At low speeds they “fade out”, while professional machines continue to work at the set frequency thanks to the available load compensator.

Brush OSBORN P60

Household

Obviously, this group includes a tool that is not intended for intensive work in industrial production conditions. Household grinders have less power and size. The last criterion is especially important when you have to decide how to choose an angle grinder for your home, since the size of the attachment attachment directly determines what diameter of the circle is suitable for the selected tool. So, for home, not too frequent use, a grinder with a minimum circle diameter of 115 mm is quite suitable, but a professional will probably choose a large tool (up to 230 mm), not only because of its power, but also because those who came to change Nozzles with a larger diameter will fail much less often.

READ How to properly insert a disc into an angle grinder

In addition, household angle grinders are not characterized by high productivity, since due to a lack of power and design simplicity, they quickly begin to overheat and when working with them, you have to take frequent pauses to cool them down.

Why you can’t polish with a grinder (my opinion) What is the difference between a grinder and a polisher

What is the difference between a grinder and a grinder?

The two devices that are used for sanding wooden products have significant differences. Not only in terms of the operating principle, but also in the final result. Experts say that an angle grinder will never be able to achieve perfection, unlike a well-chosen grinder.

Before starting work, it is important to set your expectations for the process. The choice of device will depend on this.

Features of the grinder

An angle grinder or angle grinder is a multifunctional device that is used to implement various projects. Depending on the selected attachment, you can process surfaces, saw, cut, peel, and more.

When processing wood, use a flap sanding wheel or an attachment with sandpaper. At high speeds, the grinder rotates the disk, resulting in the processing of the log. The surface will become smooth and even, but only approximately. It will be possible to achieve the desired parameters for each beam only with the help of a grinder.

Note that the grinder works much faster. The disadvantage is the need to keep the machine suspended. In addition, the process generates a huge amount of dust and cuttings that fly towards the operator. You will need protective clothing, a respirator and goggles.

Characteristics of the grinder

Carpentry experts recommend using a sanding machine. There are three types of this device:

- orbital;

- tape;

- vibration.

Orbitals are used for finishing to achieve a smooth finish. They rotate around their axis with a slight displacement. Tape strips are used at the first stage to carry out rough processing and remove a thick layer of wood. They look like two rollers that drive a special tape glued together indefinitely.

Vibratory grinders are used for intermediate grinding. The sole moves in a circle, grinding the material. Experienced carpenters use all types of devices.

Nozzles

The scope of its application directly depends on which attachment is installed on the grinder. Different attachments are designed for each type of material being processed and the nature of the work performed. Their main types are discs or circles and various types of brushes, fixed perpendicular to the body of the angle grinder on the spindle using a threaded connection. Both of them have a fairly large number of modifications and types. Thus, circles differ from each other primarily in the type of materials processed.

There are different circles for: steel, stone, paving and ceramic tiles, various alloys and so on. Although there are universal cutting wheels that apply, if not to all, then to most materials. Cutting wheels vary in diameter, as mentioned above, as well as in thickness. In addition to cutting wheels, there are also end flap grinding wheels, as well as abrasive discs, which require a separate attachment or flange. grinding is attached to it using so-called Velcro .

The brushes used on angle grinders also depend on the material being processed. Thus, we can distinguish brushes whose bristles are made of steel, used mainly for stripping rust and paint from metal surfaces. Brass brushes have approximately the same scope of application. They are softer than steel and fail faster, but they do not spark and leave fewer scratches on the metal surface. There are brushes with nylon bristles. Their area of application is mainly wood. In addition, brushes are divided into cup-shaped and disk.