Honing is a process of treating a metal surface using diamond chips. It is mainly used for grinding conical and cylindrical parts. This operation is convenient when making holes. The resulting surface roughness value corresponds to the level of fine turning or grinding with a coarse-grained abrasive wheel. Only the honing method can achieve the desired result when working with a cylinder block. At the interfaces between parts there must be lubricant, which is held in place by a specially applied honing mesh.

The honing tool used is called a hone. These are bars or stones that are placed around the perimeter of the base. During operation, they are erased, so the design of the clip allows for the possibility of replacing them.

Special machines are used for the honing process. These are devices with a horizontal or vertical arrangement in the spindle space. Each of them has its own purpose depending on the work being done. Honing equipment is specialized for narrow profiles. The production of universal machines is a thing of the past.

Processing tool

For processing, a special honing tool is used - honing. Honing heads are classified according to the following characteristics:

- according to the method of fastening the abrasive tool: rigid;

- floating;

according to the method of ensuring the size:

- adjustable;

self-unclosing.

The honing head consists of:

- housings;

- abrasive bars;

- rod;

- control coupling.

The body has milled grooves into which abrasive stones are installed. A collet mechanism is provided inside the body, ensuring simultaneous and smooth ejection of the bars.

The coaxiality of the motor sleeve and the tool is ensured by the rod. The resulting hole diameter is adjusted using a coupling.

How to process non-round holes

A characteristic feature of honing machines is their ability to process any surface.

These can be deep or blind holes, keyways, grooves. Conical elements and non-circular holes can also be processed. This happens due to the fact that in honing machines the stones are located in a special housing, the design of which consists of the following elements:

- pneumatic chamber;

- two couplings: movable and fixed;

- pads

The housing has grooves through which air is supplied. During operation, the pressure of the air flow from the pneumatic chamber presses the tool to the workpiece surface. The pads have the ability to rotate to the required angle. Thanks to this, any surface can be honed, regardless of its configuration. By changing the force of the air flow, the amount of pressure of the honing tool to the workpiece is controlled.

Another way is to use flexible brushes that are attached to elastic threads. As a result, it is possible to process the surface of any contour.

What car owners say about cylinder honing

- Honing on old engines Honing the cylinder block at Soviet enterprises in the 60–80s. was absent in principle. Automobile, boat and motorcycle engines were, as a rule, the result of side activities of the defense industry. Therefore, there was no incentive to introduce new technologies and improve existing products. People bought what was available and did not complain about the quality, because there was always a shortage and long queues for almost any product, including cars. The complication of technological operations was not welcomed in mass production, and in the absence of competition, the plant did not care how long its engine went through before a major overhaul.

- Non-factory honing A homemade hone may be no worse than a factory one, but the difficulty is that there is no information anywhere about the depth of the grooves, the honing angle, and the permissible surface roughness.

These parameters greatly affect the quality of lubrication and oil consumption. Oil starvation, as well as high consumption, will not make the engine long-lived. Increasing the honing pitch can lead to a reduction in oil film thickness and rapid engine wear. Therefore, car services, when honing a cylinder block, make certain average indicators that are suitable for a given type of engine (3L V6, for example). A lot depends on the machine equipment used. In boxer engines, the cylinder axis is horizontal, and therefore there is logic in changing the grid pitch and hone angle at the top and bottom of the cylinder. - Advantage of factory honing Repair honing of cylinders is significantly worse than factory honing. Flat-top honing can only be achieved in automotive production conditions. Car repair shops will not be able to handle such equipment, and the manufacturer has no interest in doing major repairs efficiently. When cutting a furrow with a hone, a turning and boring machine squeezes out a layer of metal on each side, which wears out the rings much faster during engine break-in.

- Honing Wear Uniformity Hon wears unevenly. Maximum wear occurs at the position of the upper compression ring at TDC of the piston. Above it, wear is significantly less.

- Same hone or different The honing angle is different for each engine and each manufacturer. It’s difficult to find exact numbers; you often have to look at how it’s done on similar engines. Once I was rebuilding the engine on a RAV4 using a manual hone. In appearance it is much worse than the factory one, but it still gives the effect. After manually honing the cylinder block and replacing the rings, oil consumption practically disappeared.

Caseless engines

Hone treatment differs on liner and linerless engines. If you need to process a linerless cylinder block, there should not be any particular difficulties.

Read also: Why is there a diamond with slots on the backpack?

The solid metal structure is securely fixed to the machine table immediately after the boring process. You should make sure that the sleeves are positioned strictly vertically and that no displacements will occur during the reciprocating movement of the cartridge - otherwise there will be no benefit from the processing.

When machining linerless cylinders, only a few machine passes are required.

In this case, it is necessary to strictly control the resulting dimensions and surface roughness. An indicator bore gauge (monitors dimensions) and a profilometer or optical device for measuring the level of roughness will help with this.

general description

Honing (honing, honing, honing polishing) is the treatment of the surface of metal products using diamond chips . It has received priority use in grinding cone-shaped and cylindrical-shaped products. The resulting surface roughness value corresponds to the quality of finishing turning or grinding with a fine-grained grinding wheel. Only by honing can the desired effect be achieved when working with a cylinder block. Lubricant must be present at the points of contact of the parts, held in place by a specially created honing mesh.

The tool used for honing polishing is called a hone. These are stones or bars that are located along the contour of the base. During operation, they wear out, and therefore the structure of the clip suggests the possibility of their rotation.

Specialized units are used to apply hone. These are devices with a horizontal or vertical spindle axis. Each of them has its own purpose, taking into account the work performed.

Honing equipment is narrow-profile. Creating multifunctional machines is a thing of the past.

Carrying out work

To obtain a high-quality result, a honing machine is required. Such equipment is used in large specialized auto repair shops that repair diesel and gasoline engines.

The cylinder block is positioned and secured on the machine table so that the holes or liners are positioned strictly vertically. This is the main condition. The honing head is placed inside. The clutch adjusts the desired hole size.

The processing process is carried out using working fluids. Kerosene is used to process cast iron, and a mixture of kerosene and oil is used to process steel. Coolant emulsions are increasingly being used. For example, 7% aqueous solution of NSC-5.

Interestingly, during honing, the surface is hardened to a depth of 0.06 mm. When the pressure of the abrasive bars is equal to 5 kgf/cm2, the hardness increases by 10−15%. When processing alloy steels and a pressure of 70 kgf/cm2, the hardness value increases to 70%.

Overview of species

Taking into account the design features, there are the following types of honing units.

By spindle axis location:

To perform special honing, specialized inclined modifications are practiced.

By number of spindles:

Honing of ordinary products is done on single-spindle units, while multi-spindle units are used for processing parts of complex configurations.

These units are used in most cases for machining holes in gears, connecting rods, cylinder blocks, liners and other parts. The honing procedure involves processing parts with a roughness parameter Ra = 0.32-0.04 µm and corrects configuration deviations (tapering, ovality error, etc.).

Parts are processed using coolant (emulsion, mineral oil, kerosene). As we already know, machines are manufactured for honing internal, less often external, surfaces with horizontal and vertical placement of one or several spindles.

Machines with horizontal spindle placement

Horizontal honing units are used for honing long pipe-type workpieces. Honing length is up to 10 thousand millimeters, the outer diameter of the part is up to 1 thousand millimeters. In most cases, these parts are figures of rotation, however, their precise processing on ordinary turning units is problematic due to the high ratio of length to diameter.

With vertical spindle placement

Vertical honing units are used for processing parts in which the holes are located vertically, in addition, for parts with a small hole depth or small diameter, which is convenient to place in a vertical position.

The machines are ideal for mass and serial production, as they can be easily integrated into an automatic line.

Source

But why "Mechanics"?

We mentioned above - and for good reason. He is a recognized expert in engine repair. And here are the arguments.

Automotive engines are changing rapidly. The power increases while the size of the unit is reduced. Thermal and mechanical stress on parts is increasing. This means that structural materials for piston rings, pistons and cylinder blocks are being improved. The rings themselves also change - their height decreases, and the number of rings decreases.

You need to know all this, continuously monitor all industry news, and above all, innovative solutions from engine manufacturers.

So, Mekhanika employees keep their finger on the pulse of the global automotive industry. But classical technologies are not forgotten either. Therefore, both the good old naturally aspirated engine and the newest turbocharged unit, born under the downsizing banner, will be repaired here.

As already mentioned, accurate diagnostics are carried out here. This means choosing the right repair technology.

This company has an excellent machine fleet, including modern Sunnen honing machines. And experienced craftsmen work for them. These will not “loose” tolerances; they feel the metal intuitively.

(photo: BC honing machine)

The tools - honing stones and brushes - are imported here. Cutting fluid (coolant) of the highest quality. It washes the instrument and block during the operation, is immediately filtered and again supplied to the working area.

Boring and honing stages

The problems described above entail repair of the power unit. If this is not done on time, the condition of the cylinders may adversely affect the performance of other mechanisms, which will lead to more serious breakdowns. There are cases when, as a result of postponing repairs, it was necessary to replace the entire crank mechanism.

The repair takes place in several stages:

- The worker bores all the liners in accordance with a certain repair size. If repairs have never been performed before, boring is done to the first size. Be sure to allow a few millimeters of allowance.

- Honing is performed to give the liners the correct shape and to reduce roughness.

Boring and honing is carried out in stages:

- First, rough processing occurs. It is made using coarse abrasive materials. The original form is returned.

- The cylinder is bored using a special abrasive. Honing occurs using diamond or ceramic coated timber. The stone is located on the honing head, which rotates and performs upward and downward movements. This device makes it possible to have high accuracy during the honing process. Scratches are removed from the surface of the cylinders using abrasive materials, so an acceptable degree of roughness occurs.

- At the end of honing, the surface of the treated cylinder is cleared of debris.

- Some specialists clean the surface using a special paste.

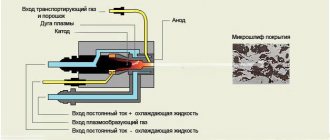

Description of the honing process and its types

During the honing process, an abrasive effect occurs on the surface of the workpiece. The goal is to obtain the desired surface roughness and achieve the required dimensional accuracy using a honing tool. A diamond block acts in this capacity. Often the diamond chips are located on a ceramic bond. Ceramic honing is used along with bakelite. The resulting parts minimize friction losses when working in conjunction with other structural elements.

There are several types of honing:

- Dry. In this process, no lubricating fluid is involved.

- Vibration. This is a method in which vibration provides additional assistance.

- Electrochemical. Not only mechanical forces are involved in the process, but also an electrochemical factor.

- Extrusion honing. The video shows the whole process, which is literally mesmerizing while watching.

- Flat-topped, or plateau honing.

Video recording of extrusive honing:

Platohoning has its own characteristics compared to conventional ones. Used for machining cylinder blocks.

There is a gap between the cylinders and rings, which is filled with oil. It is formed automatically during the first time the engine is running. To do this, using plate honing, the surface layer of the mating parts is made loose. During operation, it is erased, and the parts fit securely to each other. The minimum remaining gap is filled with oil.

Professional Services

If the wear is already significant (for example, when the ellipse of the cylinder exceeds 0.1 mm and the taper exceeds 0.2 mm), it is necessary to bore the cylinders to repair size. In this case, you need to buy special pistons, the diameter of which is larger than the standard ones. The cylinder block must be bored in a specialized workshop. It is impossible to perform this operation in a garage environment. Accuracy tolerances are very strict - tenths of a millimeter. Only professionals equipped with modern equipment can perform this work efficiently.

How is boring done?

At the first stage, the sleeve is bored at low speed. Due to the high strength of the alloy, high speeds are contraindicated - accuracy will suffer. When processing metal at low speeds, the top layer is subject to structural damage, so it must be removed. This is why honing is needed. This technological operation allows you to correct minor flaws that are inevitable when boring. Honing treatment allows you to bring the cylinder bore to a perfectly round shape (with proper honing, the ellipse is no more than 0.03 mm).

Honing after boring is performed in two stages. First, the walls are treated with coarse abrasive. Then finishing is done with fine-grained stones. The engine and machine are securely mounted on a special stand. Cooling and lubricating fluid is continuously supplied to the working area. At the final stage, the treated surface must be washed with soapy water to remove chips and abrasive particles. Diamond hones are almost universally used in professional equipment - they are more economical than ceramic ones.

To reduce wear of parts when running in the piston ring-liner assembly, it is recommended to use the Active Plus engine additive from . This tribological composition is specially designed to create conditions for comfortable operation of the power unit. The composition optimizes the gaps in piston-liner pairs, thereby equalizing compression across the cylinders. Suprotec Active Plus also increases the efficiency of hydraulic compensators by improving the lubrication of operating components. All these factors make it possible to avoid excessive wear of parts during the running-in stage. Also, the Active Plus tribo composition can be used to prevent scuffing on any gasoline engines, including those equipped with turbines. This is cheaper than repairing a worn cylinder-piston group.

Specifications

Main technical characteristics that honing units must have.

Accuracy classes. There are 5 of them in total - from N (normal accuracy) to C (ultra-high accuracy). Many models of honing units are manufactured in H and B (normal and high) accuracy classes.

Honing dimensions . In this case, these are the largest and smallest diameters of the hole being machined.

Honing length. This characteristic is taken into account only if the intended machined holes are too long.

Features of honing tools

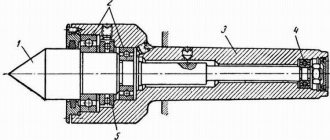

The honing tool is the head. It contains the adjusting rod 1. By changing its length (tightening or unscrewing the nuts), the position of the abrasive bars is changed.

A double-sided conical adjustable rod 1 is mounted inside the head, through which the radial rods together with the abrasive bars move apart, adjusting the diametrical size and compensating for the wear of the abrasive bars 4. Movement is possible up to 0.5...2.8 mm. As wear occurs, the turning size must be restored, so the machine operator has the opportunity to obtain the desired size without replacing the bars.

Special cylindrical clamps 5 do not allow changing the set size. The processing accuracy corresponds to class 1-2. You can achieve a mirror-like shine of the resulting surface.

The honing head is used with a special machine 3G833. It has a vertical rigid shaft. It allows you to obtain rigid rotation of the tool without signs of runout.

Design of the honing head: 1 – rod for changing the outer diameter of the hone extension; 2 – workpiece; 3 – spindle; 4 – abrasive bars; 5 – cylindrical clamp

External honing is performed on a fixture that can be mounted on lathes. For large machines such as DIP-300 or DIP-400, an external honing head KhNP-150 is used. It allows external polishing of parts with a diameter of up to 150 mm.

External honing head KhNP-150: 1, 2, 7 and 8 – abrasive stones; 3, 6 – locking expansion pads; 4, 5 – brackets for fixation

The part is installed into the machine spindle. A honing device is located on the caliper. The rotating part is in the zone of action of the bars, which grind the surface. The tool is fed longitudinally in different directions.

equipment requirements

The application of hone to the cylinder is carried out using a special metalworking unit - a honing machine. It consists of a surface on which the workpiece is fixed, a control unit, and a drive. Characteristics by which equipment is distinguished:

- Spindle location. The hone is held by a spindle; depending on its location, the machine is considered vertical or horizontal, and for specialized honing, an inclined machine is used.

- Number of spindles. To process complex, multi-level parts, multi-spindle machines are used to make working with objects easier. Honing of simple elements is carried out on equipment with one spindle.

- Availability of an automation system. The machine can be automated to make it easier for the technician to work with complex parts.

Program control controls the processing, ensures the stability of grinding, calculates the exact amount of oil for irrigation, and is responsible for calculating the cleanliness of polishing.

Equipment and materials used

To carry out the process, it is necessary to have equipment into which bars are inserted to process parts.

This is the honing tool. During operation, a lubricating fluid is used, which significantly speeds up the operation. The number of inserted bars ranges from 5–8 pieces. The more of them, the higher the roughness class of the treated surface.

Honing machines

The honing machine used is of 2 types:

- Honing horizontal type. It performs external operations with long parts.

- Vertical honing type.

On vertical honing machines, work is carried out only on internal surfaces, and the workpieces are of short length.

In the classic version, there are the following machine components:

- Frame. It is a welded pipe structure. There is a protective cover on top.

- Linear guides with installed limit switches. They are necessary to control the movement of the carriage within specified limits.

- Moving carriage.

- Honing tool.

- Liquid cooling pump.

- Clamping device.

- Electrical part.

- Control Panel.

VIEW Hole Honing Tool on AliExpress →

Honing stones

Honing stones are available on ceramic and bakelite bases. The following abrasive materials are used:

- white electrocorundum;

- green silicon carbide;

- elbor;

- diamond.

Honing diamond stones are the most widely used. If ceramics are used as a binder, the instrument material becomes porous and brittle. During operation, due to its softness, the bar self-sharpenes and small particles break off from it. These microelements fall on the surface of the workpiece and cause scratches.

VIEW Honing stone on AliExpress →

Bakelite bonded honing stones do not have such disadvantages. They are more durable and elastic. During the honing process, the tool has no chips, and the volume of metal removed is 20–60% higher.

When selecting the hardness of the honing stone, the following rules are followed:

- A solid honing tool is used to machine rough surfaces.

- When processing a short workpiece, you should use a harder block.

- Reducing the width of the bar should be accompanied by an increase in its hardness.

- As the hardness of the material of the workpiece increases, the softness of the bar should increase.

An increase in the hardness of the bar is accompanied by a decrease in its porosity. This makes it difficult to position the chips. There is a risk of metal sticking to the honing tool.

Honing for internal combustion engine parts

When repairing an engine, as was said earlier, most of the internal cylindrical surfaces - holes - are honed. These are the bushings of the upper connecting rod head, the holes of the lower connecting rod head, the rocker arm bushings of the valve mechanism drive, the crankshaft beds and, of course, the engine cylinders.

Hong head with hon bars in the cylinder |

If we consider that cylinders are the heart of the engine, then knowledge about honing, the properties of the resulting surface and methods for obtaining it is cardiology.

For normal operation of piston rings (everyone can come up with a cardiac analogue for themselves), it is necessary to provide a certain surface microprofile on the cylinder wall - a set of intersecting marks. The depth and relative position of these scratches largely determines such operational parameters as compression, power, oil consumption, fuel consumption, wear of the cylinder-piston group and engine life. The application of these marks occurs precisely during the operation of the honing head with bars installed in it along the surface of the cylinder. The simultaneous rotation of the tool and its reciprocating movements (this is not for you to go back and forth with a drum machine:) determines the angle of mutual intersection of the marks on the surface of the cylinder - the honing angle. The type of abrasive used, its grain size and bond determines the roughness of the cylinder surface, the depth and size of the marks. Accordingly, it is not difficult to guess that it is necessary to distinguish between rough and fine honing, and therefore the stones used for honing. The “trend setter” in this matter, the company KOLBENSCHMIDT (KS), gives clear recommendations for performing this operation. Therefore, I decided not to take a moment in the workshop to film the honing process and did not even go to the warehouse to get the whetstones. I just scanned the pictures from the KS booklet. So, the recommendations apply to the use of abrasives and lubricants, equipment setup, processing allowances and, most importantly, methods for quality control of the work performed. To control roughness, the Germans use a Hommel tester with the ability to print a microprofile diagram and roughness parameters in evaluation units. To control the honing angle, a special template film is used. In the photo it is attached to the cylinder wall.

Template film for checking hone lines and a visual drawing of the lines themselves from KS recommendations |

Hommel roughness tester |

Processing tool

For processing, a special honing tool is used - honing. Honing heads are classified according to the following characteristics:

according to the method of fastening the abrasive tool: rigid;- floating;

- according to the method of ensuring size: adjustable;

The honing head consists of:

- housings;

- abrasive bars;

- rod;

- control coupling.

The body has milled grooves into which abrasive stones are installed. A collet mechanism is provided inside the body, ensuring simultaneous and smooth ejection of the bars.

Abrasive stones are made from sintered composites or matrix diamond elements. The grain size does not exceed several tens of microns.

The coaxiality of the motor sleeve and the tool is ensured by the rod. The resulting hole diameter is adjusted using a coupling.

Self-unclosing hones are made in the form of a brush that used to be used to wash milk bottles. Small abrasive stones are attached to the ends of the spring legs. This device is intended for use in conjunction with a hand-held electric drill or screwdriver.

Processing with such a head is close to fine grinding or polishing. The absence of rigid fastening does not allow the correction of surface defects after boring, but reduces the roughness to a value of Ra 0.25.

Tags

honing of engine cylinders Cylinders of worn-out boring of cylinders before, however, the cylinders are again boring of cylinders. The cylinder walls and in the cylinders are carried out at the points of the engine cylinders. The cylinder walls are formed processing of the internal combustion engine cylinders. Toyota engine characteristics Engine cylinders Linerless engines Liner timing engines engine internal Worn out engine requires Linerless engines linerless engines. Linerless engines D engine and

car friction mirror article is the best necessary walls operation by hands friend shape smooth read