One type of metal utensils is utensils made of aluminum. For many years, housewives have been using these kitchen items with pleasure. Today, such dishes have changed their appearance and properties. These are no longer those gray pots and pans familiar to us from Soviet times. Manufacturers of aluminum cookware are increasing their range, as the demand for products is not decreasing, but, on the contrary, increasing every year.

The variety of products needed in the kitchen made of aluminum is great. What the manufacturer does not produce:

- pots, pans;

- bowls, mugs;

- boilers, cauldrons;

- spoons forks;

- colanders, duck pots and much more.

It’s no wonder why this dishware is so popular among housewives.

It is light, the dish cooks faster, since the material conducts heat well. Food doesn't burn.

The manufacturer is increasing the production of aluminum cookware and expanding its range, since the material is not too expensive, is resistant to corrosion, lightweight, and has a low melting point. These properties of the metal ensure the production of inexpensive products.

Consumption in industry and life

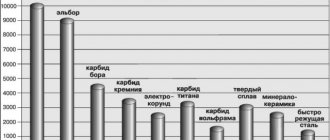

The figure below shows eight industrial and construction sectors in which aluminum is being used particularly strongly. The percentage shares of various industrial sectors in total consumption are presented according to statistics from the International Aluminum Institute for 2007. Since then, I think the picture as a whole has not changed, and these data are quite relevant.

Application of aluminum in finished industrial products [1]

The main industries that actively use aluminum are:

- Construction

- Product packaging

- Electrical industry

- Transport engineering

- Manufacturing of machinery and equipment

- Production of goods for everyday life

- Powder metallurgy

- Deoxidation of steel in ferrous metallurgy

Aluminum and aluminum alloys

Aluminum products include products and semi-finished products made of unalloyed aluminum and aluminum alloys, wrought and cast, as well as raw materials for their production - primary and secondary aluminum in the form of liquid aluminum, ingots, billets, etc.

Unalloyed aluminum is aluminum without alloying elements, in which the aluminum content is at least 99.00%.

Aluminum alloy is aluminum that contains alloying elements, the aluminum content being greater by weight than any of the other elements in the alloy, and the aluminum content being at least 99.00%.

An alloying element is a metallic or non-metallic element that is controlled within upper and lower limits to impart certain special properties to the aluminum alloy.

An impurity is a metallic or non-metallic element present in a metal, the minimum content of which is not controlled.

Detailed information about aluminum and aluminum alloys:

Aluminum and Aluminum Alloys/ed. JR Davis – ASM International, 1993

Introduction to Aluminum Alloys and Tempers – J. Gilbert Kaufman

Construction

Aluminum windows and facades

The main aluminum alloys that are used in the construction industry are alloys 6063 and 6060, as well as alloy 6082 (in Europe) and alloy 6061 (in North America). They have fairly high strength (6082 and 6061 - up to 400 MPa) and good corrosion resistance.

Window aluminum profiles with thermal decoupling (alloys 6060/6063)

The most important structural characteristics of aluminum, which determine the use of aluminum as a material for window and door frames:

- strength for rigidity and safety;

- the ability to take complex shapes (provided by extrusion);

- attractive appearance;

- corrosion resistance;

- minimal need for maintenance.

Curtain facade with aluminum frame (alloys 6060/6063)

Post-transom facade

Aluminum roofing and aluminum cladding of buildings

Decorative and protective profiled cladding materials are often made from rolled aluminum sheets. Various types of decorative and protective coatings make them ideal materials for use as roofing materials.

Application for roofing and cladding of buildings provides the following properties of aluminum:

- low weight due to low density;

- resistance to water;

- corrosion resistance;

- decorative look.

Aluminum roofing

Automotive industry

In cars it is appropriate to use metals of high strength and low weight. At the same time, they must be resistant to corrosion and have a decorative surface. A substance such as aluminum, which car bodies are made from, meets these criteria. Thanks to it, manufacturers are able to reduce the weight of vehicles, make them more economical and increase loading capacity, and high resistance to corrosion significantly increases the service life of the vehicle.

Beams and frames of heavy trucks can also be made from alloys.

Transport

Aluminum in passenger cars

The average weight of aluminum in passenger cars in Europe in 2006 was about 118 kg and continued to increase. Its share in various components and parts of cars is (in kilograms per car):

- engine cylinder blocks: 40.3

- transmission: 16.3

- Chassis, suspension and handling: 12.5

- wheels: 17.7

- heat exchanger: 12.3

- brakes: 3.7

- body: 6.8

- heat shields: 1.4

- bumpers: 2.8

- other components: 3.9.

Aluminum car engine block

Aluminum car wheel rim

The use of aluminum for the manufacture of automotive parts is due to its following properties:

- low density;

- strength;

- rigidity;

- viscosity;

- price;

- corrosion resistance.

Aluminum car frame

Aluminum alloys for trucks

Aluminum alloys for automobile tanks [5]

Production of aluminum automobile tanks [5]

Aluminum alloys for dump truck bodies [5]

Production of aluminum dump truck bodies [5]

Aluminum alloys for car vans [5]

Aluminum alloys for truck chassis [5]

Aluminum in carriage building

Construction of the Intercity Express high-speed train from extruded aluminum profiles - Germany, 1992

Aluminum urban rail car [7]

Aluminum freight car for coal transportation [7]

Aluminum in shipbuilding

Aluminum patrol boat

Cruise ship with aluminum superstructure [5]

Aluminum catamaran yacht [5]

Aluminum alloys for aircraft

The Wright brothers' first airplane in 1903 was primarily made of wood with an aluminum engine.

Among the aluminum alloys used in aircraft construction, high-strength wrought alloys dominate, such as alloy 2024 (containing copper and magnesium) and alloy 7075 (containing magnesium, zinc and some copper). Most aluminum alloys used in aircraft construction are non-weldable and are joined mainly with rivets.

The figures below show the use of 2xxx series alloys for the manufacture of aircraft fuselage and 7xxx series alloys for wings.

(a)

(b)

The use of aluminum alloys in aircraft construction: a – alloys of the 7xxx series for the fuselage and b – alloys of the 2xxx series for the wings [2].

Airbus A380

Basic requirements for aluminum alloys in the aerospace industry:

- low density;

- high strength;

- precision machining;

- corrosion resistance;

- price.

Types of aluminum cookware

Speaking about the variety of aluminum cookware, about what types exist, let’s make a simple table.

| Difference parameters | Kinds |

| According to the manufacturing method. | Cast and stamped |

| By "purity" | Made from pure aluminum and with the addition of alloys, for example, duralumin. |

| According to the form. | Pots, pans, baking sheets, bowls, etc. |

| With coatings. | External and internal. |

With color coating

Many manufacturers have started producing aluminum kitchen products with color coating. They look beautiful and attractive. Methods for finishing aluminum pots and pans: anodizing (creating a protective film), applying durable enamel, varnish or painting with organic paint (acrylic or polyamide). The most common method is the application of porcelain slurry. This finishing on the outside gives the dishes an elegant look and is a protective outer layer.

- First, the product is cleaned in preparation for applying a protective layer.

- The colored coating is applied by sprayers that coat the dishes with a porcelain slurry. Porcelain is a clay-like material. Hardens when fired.

- The kiln fires porcelain at temperatures above 500 degrees.

- The intense heat transforms the porcelain into a durable, beautiful outer coating that won't burn or scratch.

- After cooling, a non-stick layer is applied to the inner walls.

Manufacturers of aluminum cookware will improve their products.

With thickened bottom

To increase their service life, they make dishes with thicker walls and double or triple bottoms. Metal refractory disks are built into it. Such kitchen items become heavier, but they are preferred when purchasing. Thickened bottom:

- prevents overheating;

- distributes heat evenly;

- prevents food from sticking to the walls and bottom.

Products with thick walls and bottom are more stable. They are less susceptible to mechanical stress.

Frying pans with grooved bottom

Another new product from aluminum cookware manufacturers is frying pans with uneven, grooved bottoms. They are called grill pans. The main difference from the usual frying pan is that the bottom is not smooth, but striped: longitudinal or transverse - corrugated. Every housewife who loves to pamper her loved ones with something delicious needs such an item. A dish cooked on a grill pan has a special taste. Reminds me of the smoke of a fire, of a picnic at the dacha. This kitchen gadget allows you to cook steaks, meat, fish, and vegetables the same way as on a grill or barbecue. The products do not lose their beneficial qualities. They come into contact with the surface of the pan only on the raised ribs. Excess fat flows into the spaces between them. Due to this, the food will not burn and will cook quickly enough.

With stone or marble coating

Today, one of the best coatings is stone. It is also called marble. This is a special development of engineers from Germany. Frying pans, saucepans, pots - this is not the entire list of stone-coated items. It consists of several layers interspersed with stone chips and a high mineral content. Made from natural stone mined in the Alpine mountains.

- The coating itself is considered safe, as it does not contain harmful substances, but consists of natural minerals.

- Manufacturers claim that their dishes are made for people who decide to lose weight. Or those who are forced to eat on a diet.

- According to experts, the cookware uses the reserves of the food itself, without requiring oil or fat. Due to this, budget savings occur.

- The guaranteed service life of such utensils is at least 15 years.

- The coating does not require additional careful care.

- Food does not burn. You can use metal accessories without fear of scratching the surface.

Utensils for the oven: how to choose the right one

The price for such dishes is high. But the quality is excellent.

Ceramic coating

It is considered environmentally friendly and safe. Made from natural materials: clay and sand. It replaced Teflon. Housewives are very fond of kitchen products.

The coating technology is complex. Silicon and chlorine compounds and various hardeners are used. It is impossible to talk about the complete safety of ceramics on aluminum cookware. You shouldn’t be scared either: the compounds of harmful substances are insignificant.

Non-stick coating

One of the first is Teflon (tetrofluoroethylene). Teflon is a white, transparent substance in a thin layer, reminiscent of paraffin or polyethylene. It, applied to the bottom of the cookware, gives it non-stick properties. Teflon is not wetted by water or grease. Withstands temperatures from minus 70 to 170 degrees. If you heat it to 300 degrees, the Teflon evaporates. This means that this non-stick coating cannot withstand high temperatures.

When heated above 160 degrees, Teflon releases perfluorooctanoic acid into the air. It can cause flu-like symptoms: headache, runny nose, nasal congestion. Doctors called this flu polymer. Perfluorooctanoic acid is a persistent compound that accumulates in the body. Negatively affects the liver, endocrine system and reproductive function. In accordance with the Stockholm Convention on Persistent Organic Compounds, PFOA has been banned from widespread use. Russia signed and ratified the convention in March 2011. Must follow its implementation. Europe has banned the use of Teflon for making cookware.

Disposable aluminum tableware

Convenient, practical, no need to wash. At first it was used only in aviation. Lunch was served to passengers in aluminum foil pans. Later it became widespread in all areas related to food and products. Manufacturers produce products that vary in shape, purpose and size. It is very convenient to use when preparing dishes in the oven. Wrap it in foil or place it in a form made from it, and the dish will not burn and will retain its beneficial qualities and taste.

Foil is safe, since microbes do not live in it. It is practical, convenient, and does not contain harmful substances. Products do not spoil longer and retain their shelf life if placed in aluminum foil or a container.

Advice. Do not store acidic foods in aluminum foil. Additional oxidation occurs, and aluminum enters the human body.

Space technology

The first person to understand the enormous potential of aluminum for space was the great novelist Jules Verne. In his novel “A Trip to the Moon,” he described in detail an aluminum rocket back in 1865.

Aluminum alloys for spacecraft

The body of the first Soviet satellite, which was launched in October 1957, was made of aluminum-magnesium alloy AMg6 with a magnesium content of 6%. Aluminum-magnesium alloys remain the main material for the manufacture of rocket bodies. Duralumin aluminum alloys are also used in the internal compartments of missiles.

The first artificial space object - Soviet Sputnik 1

In the last decades of the 20th century, aluminum-lithium alloys began to be used in spacecraft. The density of lithium is only 0.533 g/cm3 - it is lighter than water. Additions of lithium to aluminum in amounts up to 2.5% reduce the density of the aluminum alloy and also increase its elastic modulus. Thus, alloy 8090 has a density 10% lower and a modulus of elasticity 11% higher than that of alloys 2024 and 2014, popular in aircraft construction. The figure below shows the Curiosity rover wheel made of aluminum alloy 7075.

Curiosity rover wheel made of aluminum alloy 7075-T7351

Aluminum is also used as a binder material in boron-aluminum composites, which are currently also used in space technology.

Boron-aluminum composite (40% boron fibers)

Powdered aluminum - a component of rocket fuel

The high chemical activity of aluminum makes it possible to use it as a component of rocket fuel for solid rocket boosters in the space launch system (SLS) being developed by NASA.

In rocket boosters, aluminum powder and ammonia perchlorate are bonded together using a special binder. This mixture, similar to eraser material, is then placed in a steel casing [3].

When this mixture ignites, the oxygen from the ammonia perchlorate combines with the aluminum to form aluminum oxide, aluminum chloride, water vapor and nitrogen gas, and release enormous amounts of energy.

Aluminum is a component of solid fuel for NASA rocket boosters [3]

Operating rules

Follow the basic rules for handling aluminum cookware.

- Do not wash dishes with hard sponges or abrasive cleaning agents.

- Use only for cooking and do not store food.

- Wash immediately after use.

- Do not cook foods containing acids.

How to prepare for first use

Before using a new aluminum pan or frying pan, prepare it properly for use. There are many methods for preparing dishes for use.

- Wash with hot water using laundry soap or detergent such as Feri or AOC, wipe dry.

- If it's a saucepan, fill it with water, boil it and drain the water. If dark spots form on the wall, wipe them with a cotton swab dipped in a solution of vinegar and water in a 1:1 ratio.

- If you are preparing a frying pan, bake it after washing and wiping it. To do this, pour in vegetable oil to cover the bottom. Add 1 tablespoon of salt and heat over low heat for 10-15 minutes until black smoke appears.

- Let cool, drain and rinse thoroughly with hot water without using detergents.

- Can be calcined without oil or salt.

Grease the pan on both sides with a cotton swab dipped in vegetable oil. Place the frying pan upside down in an oven preheated to 180 degrees and heat for an hour. After cooling, rinse with hot water.

Important. These preparation methods apply to aluminum cookware without ceramic or stone coatings. It is enough to wash them with warm water and laundry soap or detergent.

Can I put it in the microwave or oven?

You can cook in the oven in an aluminum pan. Even bake Easter cakes. But there is no need to store food after cooking; it is better to pour or pour the cooked dish into an enamel bowl.

Aluminum frying pans, if the handle is removed, can also be used for stewing and baking in the oven.

Important. Do not place any metal products in the microwave oven.

This means that aluminum products cannot be placed in a microwave oven.

Use on induction hob

Aluminum cookware is not suitable for induction cookers. The main indicator for use is the ability to magnetize. Aluminum does not have this feature.

Although there are so many new products in stores. Manufacturers make dishes with bottoms from various alloys. It is better to read the instructions or consult with the seller before purchasing.

Product packaging

Rolled aluminum – strips and foil – are used in the packaging of bulk and liquid products. Aluminum packaging accompanies us everywhere in our lives - for example, aluminum cans and bottles, foil in food and medicine packaging. Aluminum has low density, food and beverage compatibility, and an attractive appearance. This makes it an ideal material for various types of packaging: hard (cans) and soft (foil).

Aluminum cans for food packaging [6]

Aluminum cans

Aluminum is used to make 75% of beverage cans and 15% of aerosol containers. Aluminum cans provide a significant reduction in packaging weight compared to similar steel cans.

The can body is made of 3000 series alloy (aluminum-manganese alloys), which, after deep upsetting, is rolled out to a wall thickness of 0.27 mm.

The lid of the jar makes up 25% of its weight. It is made from a more durable aluminum-magnesium alloy. The “opener” lever built into the can, which is attached to the can with an integral rivet, consists of a different aluminum-magnesium alloy. This rivet is rolled from the body of the cap during its manufacture.

Aluminum can for packaging beer and soft drinks

Requirements for aluminum alloys for the packaging industry:

- low density;

- strength;

- good formability;

- compatibility with food and drinks;

- decorativeness (the ability to apply drawings and inscriptions);

- price.

Packaging foil

Aluminum foil is usually made from 1000 series grades of commercial aluminum. The properties of aluminum that make it suitable for use as a foil material are as follows:

- strength and impermeability to liquids and gases with small thickness;

- low density;

- thermal conductivity;

- heat resistance;

- resistance to penetration of gases and liquids;

- compatibility with food and drinks;

- aesthetic and decorative potential.

Aluminum Packaging Foil

Production of household items

There are countless things in everyday life that are made from this metal. In particular, aluminum stairs are popular - they are found in almost every home and garage. Kitchen utensils, TV brackets - all these elements can be made of aluminum, not to mention smaller items.

Aluminum ladders, by the way, have confidently replaced iron ones, since the latter are very difficult to move from place to place. This once again demonstrates the advantage of this metal. The list of household items made from it could take a very long time.

Wires and cables

The high electrical conductivity of the 1000 series aluminum grades, as well as the 8000 series aluminum alloys, makes them very suitable for the manufacture of electrical conductors. Aluminum conductors are used in the following cases:

- electrical distribution substations;

- power systems of high-rise buildings;

- high-voltage power lines;

- most underground power lines;

- power cables for industrial applications.

Most aluminum in the electrical industry is used in the form of cables (8 out of 13%). However, it is also used in the form of electrical busbars for equipment with high current strength, as well as for powering large buildings. In addition, cables for industrial, commercial and residential buildings may contain many insulated conductors, which are placed in a common protective aluminum sleeve.

Requirements for aluminum used for electrical applications:

- reasonable cost;

- sufficiently high electrical conductivity;

- corrosion resistance;

- strength.

Minerals, deposits...and native aluminum?

Aluminum reserves in nature are enormous. Among metals, it holds first place in prevalence. But the “sociability” and activity of the element have led to the fact that the metal is practically absent in its pure form.

Aluminum production in millions of tons

There are many minerals containing aluminum:

- bauxite;

- aluminas;

- feldspars;

- nephelines;

- corundum.

So extracting aluminum raw materials is not difficult.

If all reserves on Earth are depleted (which is doubtful), then aluminum can be extracted from seawater. There its content is 0.01 mg/l.

Anyone who wants to see native aluminum will have to descend into the craters of volcanoes.

The origin of such a metal is from the very depths of our planet.

cars and equipment

Heating and ventilation systems

Aluminum alloys of the 3000, 5000 and 6000 series have good thermal conductivity. Combined with high strength, these alloys are a good choice for heating and ventilation applications. These systems include the following components using aluminum alloys:

- compressors;

- condensers/evaporators;

- expansion valves;

- fans;

- pipes.

Properties of aluminum that are important for heating and ventilation systems:

- high thermal conductivity;

- high contact coefficient;

- low density;

- high corrosion resistance.

Electrics

Aluminum and a number of alloys based on it are used in electrical engineering due to their good electrical conductivity, corrosion resistance, low specific gravity, and, importantly, lower cost compared to copper and its conductor alloys.

Depending on the value of electrical resistivity, aluminum alloys are divided into conductive and alloys with increased electrical resistance.

The specific electrical conductivity of electrical aluminum grades A7E and A5E is about 60% of the conductivity of annealed copper according to the international standard. Technical aluminum AD0 and electrical aluminum A5E are used for the manufacture of wires, cables and buses. Low-alloy aluminum alloys of the Al-Mg-Si system AD31, AD31E are used in the electrical industry.

Aluminum alloys, which increase its strength and improve other properties, are obtained by introducing alloying additives into it, such as copper, silicon, magnesium, zinc, and manganese.

Duralumin

Duralumin (duralumin, duralumin, from the name of the German city where industrial production of the alloy began) is an alloy of aluminum (base) with copper (Cu: 2.2 - 5.2%), magnesium (Mg: 0.2 - 2.7 %) manganese (Mn: 0.2 – 1%). Subject to hardening and aging, often clad with aluminum. It is a structural material for aviation and transport engineering.

Figure 6 – Duralumin sheet

Silumin

Silumin - light casting alloys of aluminum (base) with silicon (Si: 4 - 13%), sometimes up to 23% and some other elements: Cu, Mn, Mg, Zn, Ti, Be). Parts of complex configurations are made from it, mainly in the automotive and aircraft industries.

| Figure 7 – Silumin | Figure 8 – Magnalia |

Magnalia

Magnalia are alloys of aluminum (base) with magnesium (Mg: 1 – 13%) and other elements that have high corrosion resistance, good weldability, and high ductility. They are used to make shaped castings (casting magnals), sheets, wire, rivets, etc. (deformable magnals).

In terms of breadth of application, aluminum alloys occupy second place after steel and cast iron [4].

Consumer goods

Aluminum is used in large quantities in the manufacture of various components, parts and housings of many consumer products that surround our lives - household products, for example, refrigerators, freezers, dishwashers. Refrigerators and freezers contain refrigeration units, which, as mentioned above, also contain significant amounts of aluminum. Important properties of aluminum for consumer products are:

- aesthetic properties;

- corrosion resistance;

- strength;

- high thermal conductivity (for refrigeration units).

Caring for aluminum cookware

If you use and care for aluminum cookware every day, it is not difficult to keep it clean.

Universal advice

To prevent pots and pans from deteriorating over time, it is better to wash them immediately after cooking. The only condition is to let it cool. If a drop of cold water falls on a hot frying pan, the pan may become deformed.

When the pan is washed immediately, no special effort is required. For washing, use warm water and mustard powder instead of chemicals. If it doesn’t work right away, and the leftover food has already dried, then fill the dishes with warm water with the addition of laundry soap or detergents and leave for 1 hour. Contaminants can be easily washed off.

How to remove blackness

With the onset of warm days, who doesn’t like to relax outside the city in nature. Smoke from the fire, barbecue, hot tea. Or fishing, fish soup, which is also cooked over a fire. Aluminum pots, saucepans, and kettles turn black after a fire. Don't be alarmed. It is not difficult to clean it. Wine vinegar or citric acid will help.

- Use a cloth soaked in vinegar or citric acid to rub the outside of the dishes and rinse thoroughly with warm water.

- If blackness has formed inside the dish, pour warm water into it, add 7-8 tablespoons of wine vinegar or squeeze out lemon juice, as much as you like.

- Boil, let cool. Drain the solution.

- Rinse with warm water using a soft sponge.

Folk remedies for washing dishes - benefits, savings or a waste of time

The dishes will become clean again.

Using hard scourers for cleaning

Under no circumstances should you clean aluminum cookware with hard sponges, much less steel or iron ones.

Firstly, they destroy the protective film of aluminum cookware, which prevents metal from getting into the food.

Secondly, hard washcloths leave wide scratches into which dirt will subsequently get clogged. It is almost impossible to wash it there.

How to clean pots and pans from burning and grease

If the dishes are very dirty and you are sorry to part with them, then use the advice on how to clean a pot or frying pan from burning and grease.

- Fill a large container with water.

- Grate or cut with a knife 1 piece of laundry soap. Pour in 300 grams of silicate glue.

- Bring the solution to a boil and place the dishes that need to be cleaned there.

- Boil over low heat with the lid closed for 1 hour.

- Remove the product from the container, being careful not to burn yourself. A soft flannel cloth or sponge can easily remove grease and carbon deposits.

- Rinse thoroughly with water.

After such a bath, your pots and pans will thank you.

How to remove scale from an aluminum surface

Using the same method that was used to remove burning and grease, you can remove scale. In addition, ammonia or vinegar will help remove it.

Dilute 8-11 drops of ammonia in a small amount of water, rub with 1/3 of a piece of laundry soap. This solution will remove a small layer of scale.

- Pour water and 5-6 tablespoons of vinegar into the container you want to descale,

- Boil the water for 10 minutes.

- Drain and rinse thoroughly with warm water.

It is not recommended to wash aluminum products in the dishwasher. They lose their shine.

How to restore shine to dishes

If your aluminum kitchen items have lost their shine and darkened, these tips will help you restore their shiny appearance.

- If it darkens inside, pour in kefir or sour milk and leave for 30-40 minutes. Rinse with warm water. Lemon or apple juice will help prevent darkening on the outside. Rub half a lemon or sour apple onto the darkened walls, leave for 1 - 3 hours and rinse with warm water.

- Instead of fruit juice, you can use 6 - 9% vinegar. The technology is the same.

- Cut the onion into several pieces, place in a bowl, add water and boil for 10 minutes.

- Rub the wetted surface with tooth powder and leave for 11 hours. Rinse thoroughly with warm water.

Your dishes will shine like new.

Cleansing with soda and sand

It is not recommended to clean aluminum cookware with these products. Aluminum is a soft metal. Soda contains alkali, and it is detrimental to the protective film. Soda will destroy it completely.

Sand in its structure consists of small particles. If you clean an aluminum surface with sand, it will leave scratches, not too big, but deep. Then dirt will get clogged there. In addition, the protective film in places of scratches will not be restored.

Advice. Do not use baking soda or sand to clean aluminum products.

Removing dark plaque

If the rules for using aluminum cookware are violated, dark spots and stains appear on its walls. Apparently, jacket potatoes, beets, and sour cabbage soup were cooked in the saucepan. It is unpleasant to use such utensils. How can I return it to its previous appearance? Regular onions will help remove this nuisance.

- Take 2 medium-sized onions and place them in the container you want to peel.

- Pour water and boil for half an hour.

Grate the laundry soap, add water and boil for 20-25 minutes.

After all procedures, thoroughly rinse the dishes with warm water and wipe dry.

Try to clean off dark spots on the walls that are not too old with an apple or lemon.

Cut the fruit in half and rub the halves into the dark areas. After this, rinse with warm water and dry.

Removing Burnt Food

To prevent food from burning, the housewife must control the cooking process, stir in time and ensure that the food does not “run away”. Then you won’t need any effort to wash the pot or pan. If it turns out that for some reason the hostess didn’t pay attention, and the food managed to burn, then don’t panic. Salt will deal with the remains of burnt food.

- Soak the pan - pour cool water into it and leave for a while.

- Drain the water and add as much salt as you like. Leave for 3-4 hours.

- Clean with a soft sponge and rinse with warm water.

If milk is burnt, activated carbon is effective.

- Grind 10 tablets into powder, pour into the bottom of the dish and leave for 1 hour.

- Pour in cool water and let the solution sit for another 30-40 minutes.

- Wash the pan with regular dishwashing detergent. Will wash off easily.

The main rule that must be followed is that if food is burnt, do not put off cleaning until later.

Medicine

Equipment and tools

Anodized aluminum is widely used for products and parts in medical and dental equipment, including:

- Interior decoration of hospital wards and medical offices

- Instruments that can withstand regular autoclave sterilization

- Hospital beds, stretchers, strollers and other means for moving patients

- Medical Oxygen Equipment

- Dental equipment and instruments

- X-ray machines

- Dialysis equipment.

Medicine packaging

Aluminum foil is an unrivaled barrier that reliably protects medications from microorganisms, sunlight, oxygen and other gases. Therefore, this foil is the main material for protective packaging of medicines and pharmaceutical materials.

Medicinal tablets in aluminum packaging

Selection of suitable raw materials

Due to the fairly large number of problems that arise when melting aluminum at home when using powder as a raw material, aluminum ingots or wire are subjected to heating. In this case, the wire can be purchased at a relatively low price, after which it is cut and compressed to reduce the area of contact with air.

If melting is carried out to obtain a workpiece or product of low quality, then scrap can be used as a raw material, for example, cans or scraps of aluminum profiles. To simplify the smelting process, scrap should also be cut into small pieces.

When looking for raw materials, many people pay attention to the fact that it may be colored or have other unnecessary components. During the heating process, all foreign impurities, as a rule, go away in the form of slag. However, paint and other chemicals during combustion can cause the release of toxic fumes, which should be taken into account when carrying out work.

Various fluxes are responsible for removing harmful impurities from the composition. It is recommended to purchase them in a specialized store ready-made, but if necessary, you can build them yourself. The flux consists of 10% cryolite and 45% potassium and sodium chloride.

How to cast metal?

Metal

poured into a rotating metal mold, during rotation it is pressed against the walls of the mold, and this allows you to obtain high-precision castings.

Electroslag casting. One of the modern methods is electroslag casting. metal

is first obtained by electroslag remelting.

Interesting materials:

Why are electrical installations divided into up to and above 1000V? Why do pipes hum when the tap is closed in a private house? Why is the floor in the house cold? Why did they start building panel houses? Why can’t I call another subscriber? Why doesn't Kalanchoe bloom at home? Why doesn't Kalanchoe bloom at home? Why can’t you keep loach flowers at home? Why can't you keep geraniums in the house? Why can't you keep cacti in your house?

Melting aluminum in a ladle

The author of the method of melting aluminum on a gas stove uses a stainless steel ladle as a crucible. The melting point of aluminum is 660 degrees. A gas stove cannot provide such heating. First, the crucible with its contents is heated for 15 minutes, then the gas burner is turned on, which provides the temperature necessary to melt the aluminum. Ready-made melting furnaces in this store.

Attention! Do not use a crucible as unstable as the one in this video. Be sure to use a hood, leave the window open, and do not frequently work with molten aluminum at home.

What can be done using such melting furnaces? For example, as in another article on our website, you can make an aluminum model of a weapon. To do this you need polystyrene foam, sand and a smelter. By the way, the article also contains a link to an analogue of the smelter, which is presented here.

Where is aluminum used?

Aluminum is a lightweight metal that is widely used in various industries.

It has good thermal conductivity and also conducts electricity. Oxide films are formed on its surface, which have high strength and durability, so the material is impervious to corrosion and does not rust, even with prolonged contact with moisture. The material is widely used in:

- aviation and space industry;

- automotive industry;

- sea and river transport;

- construction;

- production of various household items.

Manufacturers choose this material for the optimal combination of safety, reliability and cost.

Aluminum producing countries.

In 2022, global aluminum smelting reached 60 million tons, distributed by country as follows:

- China – 33 million tons.

- Russia – 3.71 million tons.

- India – 3.68 million tons.

- Canada - 2.9 million tons.

- UAE – 2.6 million tons.

- Australia – 1.6 million tons.

- Norway – 1.35 million tons.

- Bahrain – 0.995 million tons.

- Saudi Arabia - 0.916 million tons.

- USA – 0.89 million tons.

Aluminum occupies a leading position among the non-ferrous metals produced on the planet, second only to steel in the general metallurgical list.

Source

How to smelt aluminum in survival conditions

Having the survival skills at your fingertips becomes incredibly invaluable! One skill that has unfortunately fallen by the wayside in recent years is the art of blacksmithing. Knowing how to melt aluminum is an important survival skill to master. You can't trust someone else to do it for you in the indefinite future... you have to know how to create your own materials.

Here's how to melt aluminum in your backyard.

Backyard. Blacksmithing: How to Melt Aluminum

The term “DIY survival” can be easily understood if you take it literally. This simply means that you can do most things yourself.

Read also: Introductory course on argon arc welding

Having your own crucible will allow you to create a small-scale metalworking industry in your backyard (or bomb shelter). Aluminum alloys can be difficult to make on their own. But having a stack of ingots made from molten aluminum can provide you with a large amount of raw material to build tools.

Luckily, with a little time, effort, and a few household items, you can build your own! Before the melting starts, you need to make a foundry. With your own foundry, you can melt metals such as aluminum and transform them into the tools you need. We have step-by-step instructions on how to set up your own mini foundry and how to melt aluminum.

Check out the video tutorial below to learn how: Once you create this smelter, you can do all sorts of things with it! Check out this short instructional video below that shows how to turn scrap aluminum into cupcakes. Basically, the cupcakes are made from molten aluminum. After melting your aluminum cans, you can turn them into many great things that can be used for survival purposes.

Warning: This foundry can reach temperatures over 1200 degrees Fahrenheit! Before attempting to use the foundry, be sure to use all necessary safety equipment.