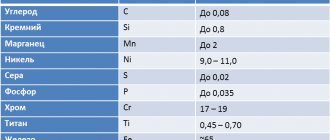

Chemical composition of steel

10KhSND (old name 10KhSND-Sh) belongs to the class of low-alloy alloys intended for the construction of welded structures.

Decoding the steel grade indicates that the material contains such chemical elements as:

- chromium - up to 0.9%;

- carbon - up to 0.12%;

- nickel - up to 0.5%;

- copper - up to 0.6%.

GOST

The chemical composition of steel is defined in GOST 19281 - 89. Domestic manufacturers of metallurgical products produce the following types of products:

- rolled products of different classes and sizes: GOST 19282-73, GOST 2590-2006;

- sheets GOST 19282-73, GOST 5521-93;

- strip GOST 19281-89, GOST 82-70, GOST 103-2006;

- forgings and forged products GOST 1133-71;

- pipes OST 14-21-77.

All applied products must be marked with the indication of the manufacturer, production date, heat number, etc.

The elements included in the composition of 10HSND steel allow it to be used for the production of metal structures designed to work in conditions with aggressive environments and a wide temperature range from -70 to +450 degrees Celsius.

Analogs

Among the domestic steels that can replace 10HSND can be called 16G2AF. Among the imported analogues we can name the following brands:

Bulgaria - 10ChSND;

physical characteristics

| Temperature | E, GPa | l, W/(m °С) |

| 100 | 197 | 40 |

| 200 | 201 | 39 |

| 300 | 195 | 38 |

| 400 | 188 | 36 |

| 500 | 180 | 34 |

| 600 | 169 | 31 |

| 700 | 156 | 29 |

| 800 | 135 | — |

| 900 | 125 | — |

Technological features of steel application

As already noted, 10HSND steel is low-alloy. This means only one thing - it can be welded without restrictions. But the presence of alloyed elements can cause the appearance of hardened structures in the welding zone. As a result, this may result in reduced crack resistance. In addition, alloying elements can provoke an increased tendency to brittle fracture. If steel of this type has undergone heat treatment, in particular, improvement, which may lose strength in different areas of heating and cooling. This class of steel requires the welder to have certain knowledge and skills.

The technologist, when choosing a method of electric welding and subsequent heat treatment, must take into account the conditions under which the structure will be operated. By the way, some of the difficulties that arise when performing welding work on this steel require the manufacturer to pay special attention to the quality of the work performed.

When processing on turning and milling equipment, there is no need to select any special tool or special cutting modes.

Hand over alloy 10HSND (GOST 19281 - 89) in St. Petersburg

Steel 10HSND is a low-alloy structural steel, which is used for the manufacture of welded metal structures of increased strength and corrosion resistance. This material is produced in accordance with the requirements of the standards DSTU 8817, GOST 6713, DSTU 8541, GOST 19281

Classification: Low-alloy structural steel for welded structures.

Products: Thick plates, wide strips, strips, long and shaped rolled products

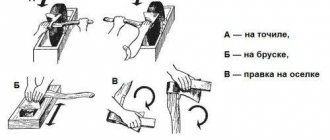

Heat treatment of welded parts

The main task that heat treatment solves is the removal of residual stresses that arise during welding. As a result of this treatment, the structure of the metal and the properties of the weld should improve.

This treatment is carried out immediately after completion of welding work. In this case, it is very important to prevent overcooling of the welded workpieces. The minimum permissible temperature should not fall below the heating temperature. In the event that it is not technically possible to perform heat treatment, then it makes sense to perform thermal rest.

To perform heat treatment operations, certain preparations are required. In particular, parts intended for processing must be placed on a special pallet in accordance with the requirements of the technological map. After laying, the pallet is placed in the oven.

At the time of loading, the oven must be either cold or heated to a temperature of 300 ºC. The parts should be in the oven for about 1 - 2 hours. After this time, the oven can be heated further. The maximum temperature should not exceed 590 ºC, and the heating rate should be 70 ºC per hour. The parts must remain at a temperature of 590 ºC for at least three hours. Cooling must be done at a rate of 50 ºC per hour to 250 ºC.

Serious enterprises operate a quality control system. That is, the entire heat treatment process is recorded in special logs and the furnace parameters are constantly recorded. Measurements are carried out using a pyrometer. This approach allows us to obtain high quality products.

Material 10HSND Ekaterinburg

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells 10HSND material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, 10HSND material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Coursework: Development of technology for welding a section of a ship's hull

St. Petersburg State Marine Technical University

Department of Welding of Ship Structures

DEVELOPMENT OF WELDING TECHNOLOGY

Section dimensions - S=16mm; A=7000mm; B=3500mm

Wall thickness of the transverse set S=10mm

The distance between the bulbs is 350, between the transverse brands - 850mm

1. Characteristics of steel 10HSND.

2. Features of welding steel 10HSND.

As already mentioned above, 10HSND steel belongs to the group of structural low-alloy steels.

This group of steels behaves in the same way when welding as low-carbon steel, but there are differences in the action of thermal cycles:

1. There is a greater tendency for grain growth in the heat-affected zone, especially when overheated.

2. The possibility of the formation of hardening structures, which will cause the formation of cold cracks.

3. Reduction in the impact toughness of the metal in the heat-affected zone of the HAZ of the welded joint.

4. The resistance of the weld metal against the formation of hot cracks is lower due to the presence of alloying elements.

5. Sensitivity to stress concentrators and even thermal “burns”.

Low alloy steels can be welded well by all fusion welding methods. Usually there are no difficulties associated with the possibility of the formation of cold cracks caused by the formation of hardening structures in the weld or heat-affected zone. However, in steels containing upper limit carbon and a high content of manganese and chromium, the likelihood of cold cracks forming in these zones increases, especially with increasing cooling rate (increasing metal thickness, welding at subzero temperatures, welding with small-section seams, etc.). Under these conditions, prevention of cracks is achieved by preheating to 120 0 -200 0 C. Preliminary and subsequent heat treatment of steels used in critical structures serves this purpose, and also allows one to obtain the necessary mechanical properties of welded joints (high strength or ductility, or their required combination).

Therefore, when welding low-alloy steels, more stringent requirements are imposed on the welding mode parameters than when welding unalloyed low-carbon steels. Welding is limited to narrow limits of changing the mode parameters in order to simultaneously ensure the minimum occurrence of hardening structures and reduce overheating.

This technological process was written using the modern Vertikalv3 program, which made it possible to determine and calculate welding modes with higher accuracy, select the necessary equipment, welding materials, edge cutting, etc.

2.1 Clean parts for welding to bare metal

3. Covered electrode arc welding

3.2 Grasp the sheets along the entire length of the joints.

Electrodes UONII-13/55-4 GOST 9466-75

Seam=C8, Isv=150-210A, Ud=23V, L=14m, Lpr=35mm, Npr=41

4.1 Clean the weld from slag and metal splashes

4.2 Clean the weld bead flush with the base metal

5. Submerged arc welding

5.1 Weld the deck flooring sheets in the lower position on a copper slider in accordance with GOST-8713-79. Flux OSTS-45, wire 4.0 Sv-08A (according to RD5R.9083-92). Seam=C8, Isv=830-860A, Ud=38-40V, Vsv=15-17m/h, Reach=25-45, L=14m

6. Assembly (a longitudinal set is installed to the panel)

7.1 Clean parts for welding to bare metal

8. Arc welding with coated electrode

Electrodes UONII-13/55-4 GOST 9466-75, Seam=T8 8 25 200, Ist=150-210A, L=63m, Lpr=25mm, Npr=253

9.1 Clean the weld from slag and metal spatter

9.2 Clean the weld bead flush with the base metal

10. Carbon dioxide arc welding with solid wire

Seam=T8 6, Iw=300A, Ud=28-30V, Vw=17m/h, L=56m, welding wire Sv-08A-1.6mm, carbon dioxide GOST 8050-76

12.1 Clean parts for welding to bare metal

Electrodes UONII-13/55-4 GOST 9466-75, Seam=T8 6 25 100, Ist=150-210A, L=28m, Lpr=25mm, Npr=161

14.1 Clean the weld from slag and metal spatter

14.2 Clean the weld bead flush with the base metal

15. Submerged arc welding

15.1 Weld T-beams according to GOST-8713-79. Flux OSTS-45, wire 4.0 Sv-08A (according to RD5R.9083-92). Seam=T8 6, Isv=830-860A, Ud=38-40V, Vsv=15-17m/h, Reach=25-45, L=56m

16. Assembly (welding the T-bar set to the panel)

17.1 Clean parts for welding to bare metal

18. Arc welding with coated electrodes

Electrodes UONII-13/55-4 GOST 9466-75, Seam=T8 6, Ist=150-210A, L=28m, Lpr=25mm, Npr=161

19.1 Clean the weld from slag and metal spatter

19.2 Clean the weld bead flush with the base metal

20. Carbon dioxide arc welding with solid wire

Seam=T8 6, Iw=300A, Ud=28-30V, Vw=17m/h, L=56m, welding wire Sv-08A-1.6mm, carbon dioxide GOST 8050-76

21. Control of the appearance of welds, the presence of marks - 100%

22. Ultrasonic testing of welds according to GOST 14782-86. - 50%

| Characteristic name | Meaning |

| Supply voltage | 2 x 380V |

| Rated frequency, Hz. | 50 Hz |

| Electrode diameter | 2-5mm. |

| PV at 300A | 40% |

| PV at 200A | 100% |

| Welding current adjustment range | 60- 300A |

| Open circuit voltage | from 25 V - 50 V |

| Power consumption | 9kW |

| Primary protection current | 25A |

| No-load current | no more than 1.6A. |

| Power cord length | 3m |

| dimensions | 410x140x400 mm |

| Weight | 42 |

Nominal operating mode, % 60

Power consumption, kW 60-500

Overall dimensions, mm 1050×760×960

Supply voltage, V 380

regulation limits 100-500

feed speed, m/h 120-1200

| Parameter name | VDU-1001 |

| Rated voltage of the three-phase current supply network, V at a frequency of 50 Hz | 380 |

| Primary power, kVA, no more | 82 |

| Open circuit voltage, V, no more | 85 |

| Welding current control limits, A (PVC/ZHVH) | 100-1001120-1000 |

| Rated operating voltage, V | 56 |

| Operating voltage regulation limits, V | 24-56 20-56 |

| (PVC/ZVC) | |

| Nominal operating time, duty cycle, % | 100 |

| Efficiency, %, not less | 79 |

| Weight, kg, no more | 500 |

Technical data of welding tractor

GOST 5264-80 “Manual arc welding. Welded connections. Basic types, structural elements and dimensions"

GOST 14771-76 “Arc welding in shielding gas. Welded connections. Basic types, structural elements and dimensions"

GOST 8713-79 “Submerged arc welding. Welded connections. Basic types, structural elements and dimensions."

GOST 14782-86 “Non-destructive testing. Welded connections. Ultrasound methods"

RD5R.9083-92

“Steel ship hulls. Welding of carbon and low-carbon steels"

Common grades of low-alloy steels used in welding metal structures

Low-alloy steels, from which building structures are welded, contain no more than 0.25% carbon and no more than 3% alloying elements.

For the manufacture of metal structures for industrial and civil buildings, the most suitable steel grades are 15HSND, 14G2, 09G2S, 10G2S1, 10G2S1D, 16GS, 14G2AF, 16G2AF, etc.

Steel grades such as 18G2S, 25G2S, 35GS, 20KhG2Ts, etc. are well suited for the manufacture of welded gas pipes. The same grades are also used in the manufacture of reinforcement for reinforced concrete slabs.

Hand over alloy 10HSND (GOST 19281 - 89) in St. Petersburg

Steel, low-alloy structural for welded structures

10KhSND is a metal alloy based on iron (Fe) , its content in 10KhSND must be at least 95.5%. The 10HSND alloy must contain silicon, chromium, manganese, nickel, and copper. The permissible amount of impurities is determined in the chemical composition table.

- Urgently! Alloys AMS5537 (L-605), AMS5536 (Hastelloy X)

- Urgently! Nickel N-1 (cathode sheets)

- Urgently! Railway rails - scrap, liquid scraps

- purchase non-ferrous metals and alloys

- purchase ferrous metals, steels and alloys

- purchase non-ferrous metals and alloys

- purchase ferrous metals, steels and alloys

- sell ferrous metals, steels and alloys

- sell ferrous metals, steels and alloys

- purchase ferrous metals, steels and alloys

- purchase ferrous metals, steels and alloys

- sell non-ferrous metals and alloys

- sell non-ferrous metals and alloys

- sell petroleum products and their waste

- purchase non-ferrous metals and alloys

- sell non-ferrous metals and alloys

- sell semiconductors, non-metals and their compounds

- sell non-ferrous metals and alloys

All ads + Add yours Useful tools

- Determine the brand Determine the alloy by composition

- Pipe or angle weight Metal calculator

- For scrap acceptors Calculation of the profitability of the transaction

Determine the alloy by chemical composition Determine the mass by the shape of the product Calculate the profitability of the transaction