Temperature coefficient of linear expansion of steel

Tables of values of the average temperature coefficient of linear expansion of steels TCLR (or TKR) of common grades (more than 300 steel grades) are presented at various temperatures in the range from 27°C to that indicated in the tables. For negative temperatures, the values of the true linear expansion coefficient are given.

The temperature coefficient of linear thermal expansion of steel is numerically equal to the relative change in its linear dimensions with an increase (decrease) in the temperature of this alloy by 1 degree Celsius or Kelvin.

With a positive value of TCLE during heating, the steel increases in size (expands); with a negative value of this coefficient, it contracts. Steel has a negative TCLE at ultra-low temperatures approaching absolute zero (-273.15°C). Under these conditions, the coefficient of linear expansion of steel has a small negative value and is practically equal to zero.

At temperatures from 27 to 100°C, the temperature coefficient of linear expansion of steel averages from 10 to 18·10 -6 deg -1. Steel in a heated state (depending on the type) at 900-1000°C can have a TCLE of up to 24.6·10 -6 deg -1.

Let's calculate the linear elongation of a beam made of stainless steel 12Х18Н10Т with a length of 0.5 meters when its temperature increases from 27 to 1027°C. According to the table, the average coefficient of linear expansion of steel 12Х18Н10Т in the temperature range 27…1027°С is equal to 22.3·10 -6 deg -1. Let's perform the calculation: 22.3·10 -6 ·(1027-27)·0.5=0.0111. We get the linear elongation of the beam to be 0.0111 m.

Temperature coefficient of linear expansion of metals, solids, liquids (Table)

Temperature coefficient of linear expansion of metals and alloys

The table shows the average values of the temperature coefficient of linear expansion ɑ of metals and alloys in the range from 0 to 100 °C (unless a different temperature is indicated).

| Metal, alloy | Linear expansion coefficient ɑ, 10-6°С-1 |

| Aluminum | 2,4 |

| Bronze | 13-21 |

| Tungsten (in the temperature range from 0 to 200 °C) | 4,5 |

| Duralumin (at t = 20 °C) | 23 |

| Gold | 14 |

| Iron | 12 |

| Invar* | 1,5 |

| Iridium | 6,5 |

| Constantan | 42339 |

| Brass | 17-19 |

| Manganin | 18 |

| Copper | 17 |

| Nickel silver | 18 |

| Nickel | 14 |

| Nichrome (from 20 to 100 °C) | 14 |

| Tin | 26 |

| Platinum | 9,1 |

| Platinite** (at t = 20 °C) | 41920 |

| Platinum-iridium*** (from 20 to 100 °C) | 8,8 |

| Lead | 29 |

| Silver | 20 |

| Carbon steel | 43009 |

| Zinc | 32 |

| Cast iron (from 20 to 100 °C). | 41952 |

| * This alloy has a very low linear thermal expansion coefficient. Used for the manufacture of parts for precision measuring instruments. ** Conductor material, the coefficient of linear expansion of which is the same as that of glass; used in the manufacture of electric lamps. *** The prototypes of the kilogram and meter were made from this alloy. | |

Temperature coefficient of linear expansion of solids

The table shows the average values of the temperature coefficient of linear expansion ɑ of solids in the range from 0 to 100 °C (unless a different temperature is indicated).

| Substance | Linear expansion coefficient ɑ, 10-6°С-1 |

| Diamond | 1,2 |

| Concrete (at t = 20 °C) | 41913 |

| Granite (at t = 20 °C) | 8 |

| Graphite | 7,9 |

| Wood (at t = = 20 °C): | |

| - along the fibers | 5,5-5,5 |

| - across the fibers | 34-60 |

| Fused quartz (at * = 40 °C) | 0,4 |

| Brick (at t = 20 °C) | 41885 |

| Ice (in the temperature range from -20 to 0 °C) | 51 |

| Paraffin (from 16 to 48 °C) | 70* |

| Oak (from 2 to 34 °C): | |

| - along the fibers | 4,9 |

| - across the fibers | 54,4 |

| Pine (from 2 to 34 °C): | |

| - along the fibers | 5,4 |

| - across the fibers | 34 |

| Laboratory glass | 41885 |

| Window glass (from 20 to 200 °C) | 10 |

| Porcelain | 2,5-4,0 |

| Slate (at t = 20 °C) | 10 |

| * coefficient of volumetric expansion of paraffin. | |

Temperature coefficient of volumetric expansion of liquids

The table shows the average values of the temperature coefficient of volumetric expansion β of liquids at a temperature of 20 °C (unless otherwise indicated).

| Liquid | Volumetric expansion coefficient β, 10-6°С-1 |

| Petrol | 1240 |

| Water | 200 |

| Water (in the range from 10 to 20 °C) | 150 |

| Water (20 to 40 °C) | 302 |

| Liquid air (from -259 to -253 °C) | 12600 |

| Glycerol | 505 |

| Kerosene | 960 |

| Oxygen (from -205 to -184 °C) | 3850 |

| Oil | 900 |

| Salt solution (6%) | 300 |

| Mercury | 181 |

| Sulfuric acid | 570 |

| Turpentine | 940 |

| Alcohol | 1080 |

| Ether | 1600 |

| Chlorine (in the temperature range from -101 to -34.1 °C) | 1410 |

| Note. The relationship between the coefficients of volumetric (β) and linear (a) expansion is determined by the following relation: β = 3a | |

Carbon steels

The table shows the values of the linear expansion coefficient of carbon steel in the temperature range from -173 to 1000°C. When such steel is heated, its TCLE increases and can reach 19.8·10 -6 deg -1 (for U8 steel) in the temperature range 27-650°C.

Since carbon steel consists almost entirely of iron and does not contain nickel or chromium additives, its thermal expansion coefficient is largely determined by the coefficient of linear expansion of this main component. For example, the maximum coefficient of linear expansion of steel 20, like that of iron, is 14.8·10 -6 deg -1 in the temperature range from 27 to 700°C.

Linear expansion coefficients of carbon steel

| 5,5…10,1…11,8 | ||

| Steel 08KP | 100…200…300…400…500…600…700 | 11,6…12,3…13,2…13,7…14,2…14,6…15 |

| Steel 10 | 100…200…300…400 | 11,6…12,6…13,0…14,6 |

| 15 | 100…200…300…400…500…600…700…800…900…1000 | 12,2…12,3…13,1…13,5…14,3…14,3…15,3…14,1…13,2…13,3 |

| 20, 20KP | 100…200…300…400…500…600…700…800 | 11,1…12,1…12,8…13,4…13,9…14,4…14,8…12,9 |

| 25 | 100…200…300…400…500…600…700 | 12,2…12,7…13,1…13,5…13,9…14,4…14,9 |

| 25L | 100…200…300…400…500…600 | 11,5…12,9…13…13,2…13,5…13,8 |

| 30 | 100…200…300…400…500…600…650 | 12,9…14,5…15,8…15,8…16,7…16,2…16,4 |

| 35 | 100…200…300…400…500 | 11,1…11,9…13,4…14…14,4 |

| 40 | 100…200…300…400…500…600…700…800…900…1000 | 11,2…13…13…13,6…14,1…14,6…14,6…11,9…12,7…13,6 |

| 45 | 100…200…300…400…500…600…700…800…900…1000 | 11,6…12,3…13,1…13,7…14,2…14,7…15,1…12,5…13,6…14,5 |

| 50 | -173…-73…27…100…300…500…700…900…1000 | 4,9…9,3…10,9…12…12,9…13,7…14,3…12,9…14 |

| U8 | 100…200…300…400…500…600…650 | 12,1…14…12,8…16,1…16,8…17,8…19,8 |

| U9 | 100…200…300…400…500…600…650 | 12,1…13,7…15,3…16,4…17,3…17,2…17,6 |

| U12 | 100…200…300…400…500…600…650 | 11,7…13,3…15,4…16,2…17,1…18,3…18,9 |

When heated, metal expands or contracts

The table shows the values of the coefficient of thermal expansion of metals (coefficient of linear expansion of metals) depending on temperature.

The values of the coefficient of thermal expansion of metals are given for the following metals: aluminum Al, beryllium Be, bismuth Bi, tungsten W, gallium Ga, iron Fe, gold Au, iridium Ir, cadmium Cd, cobalt Co, magnesium Mg, manganese Mn, copper Cu, molybdenum Mo, nickel Ni, tin Sn, platinum Pt, rhodium Rh, lead Pb, silver Ag, antimony Sb, titanium Ti, chromium Cr, zinc Zn.

The coefficient of linear thermal expansion of metals in the table is given with a multiplier of 106. For example, the value of the coefficient of thermal expansion of metals in the table for aluminum at 0°C is indicated as 22.8, and taking into account the multiplier of 106, this value is 22.8 10-6 1/ hail

It should be noted that metals with a low coefficient of expansion include metals such as tungsten, molybdenum, antimony, titanium and chromium. Tungsten experiences the smallest linear elongation when heated - the coefficient of linear expansion of this metal ranges from 4.3·10-6 at 0°C to 5.8·10-6 1/deg at a temperature of 2100°C.

The metal that expands the most when heated is zinc - its coefficient of thermal expansion ranges from 22·10-6 to 34·10-6 1/deg. Metals such as aluminum, cadmium and magnesium also expand well when heated.

Note: the temperature coefficients of linear expansion of steels (more than 300 grades) are presented in this article.

Industrial ovens. Reference manual for calculations and design. 2nd edition, expanded and revised, Kazantsev E.I. M., “Metallurgy”, 1975. - 368 p.

Thermal expansion of metal

It is known that all metals expand when heated and contract when cooled. The degree of increase or decrease in the original size of the metal with a change in temperature of one degree is characterized by the coefficient of linear expansion.

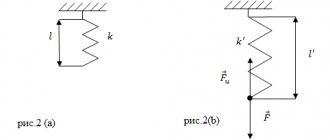

Thus, the length l0 of some part after heating to temperature t° will be:

where a is the linear expansion coefficient.

When observing the change in volume of a part, the coefficient of volumetric expansion is used, which is defined as triple the coefficient of linear expansion.

Materials with a high expansion coefficient are used in instrument making for parts of automatically operating mechanisms. At a certain temperature, such parts, lengthening, can turn on or open an electrical circuit.

The Fe-Ni alloy, called Invar, has the minimum coefficient of linear expansion. Its expansion coefficient is 8 times less than iron.

Thermal conductivity of metals

Various parts of heating equipment - car and airplane radiators, internal walls of working chambers of refrigeration units, boiler walls, etc. - must have the ability to conduct heat well.

Parts and tools that are subjected to local heating during operation must also quickly release this heat so that melting does not occur.

The ability to conduct heat is called thermal conductivity

Pure metals have the best thermal conductivity, such as:

Resistivity

Electrical resistivity is a value that determines the electrical resistance of a reference sample of a material. The Greek letter “p” is used to denote this quantity. Formula for calculation:

p=(R*S)/l.

This value is measured in Ohm*m. You can find it in reference books, in resistivity tables or on the Internet.

Free electrons move through the metal within the crystal lattice. Three factors influence the resistance to this movement and the resistivity of the conductor:

- Material. Different metals have different atomic densities and numbers of free electrons;

- Impurities. In pure metals the crystal lattice is more ordered, therefore the resistance is lower than in alloys;

- Temperature. Atoms are not stationary in their places, but vibrate. The higher the temperature, the greater the amplitude of vibrations, which interferes with the movement of electrons, and the higher the resistance.

In the following figure you can see a table of the resistivity of metals.

Metal resistivity

Interesting. There are alloys whose electrical resistance drops when heated or does not change.

Conductivity and electrical resistance

Since cable dimensions are measured in meters (length) and mm² (section), the electrical resistivity has the dimension Ohm mm²/m. Knowing the dimensions of the cable, its resistance is calculated using the formula:

R=(p*l)/S.

In addition to electrical resistance, some formulas use the concept of “conductivity”. This is the reciprocal of resistance. It is designated “g” and is calculated using the formula:

g=1/R.

Conductivity of liquids

The conductivity of liquids is different from the conductivity of metals. The charge carriers in them are ions. Their number and electrical conductivity increase when heated, so the power of the electrode boiler increases several times when heated from 20 to 100 degrees.

Interesting. Distilled water is an insulator. Dissolved impurities give it conductivity.

Electrical resistance of wires

The most common metals for making wires are copper and aluminum. Aluminum has a higher resistance, but is cheaper than copper. The resistivity of copper is lower, so the wire cross-section can be chosen smaller. In addition, it is stronger, and flexible stranded wires are made from this metal.

Thermal properties of cast iron

An important category of physical properties of a material is its thermal properties. These include:

- Heat capacity.

- Thermal conductivity.

- Thermal diffusivity.

- Thermal expansion coefficient.

They all depend on the composition, structure, and therefore on the grade of the alloy. In addition, these properties of the metal change with changes in its temperature (the so-called displacement rule). The nature of this dependence and the main physical properties are given in the table.

Heat capacity (s)

This is the amount of heat that must be supplied to the body in order for its temperature to increase by one Kelvin (hereinafter all values are converted to degrees Celsius).

The heat capacity depends on the composition of the alloy, as well as on temperature (T). The higher T, the greater the heat capacity. If the temperature is above T for phase transformations, but below T for melting, then

c = 0.18 cal/(G˚С)

at T exceeding the melting point:

c = 0.23±0.03 cal/(G˚С)

Volumetric heat capacity (the ratio of heat capacity to the volume of a substance) for approximate calculations is accepted:

- cast iron in solid state c' = 1 cal/(cm3G˚C)

- molten c' = 1.5 cal/(cm3G˚C)

Thermal conductivity (λ)

This is a quantitative characteristic of a body's ability to conduct heat. The displacement rule does not apply to thermal conductivity. The temperature of the material increases – λ decreases. It depends on the composition of the alloy, and to a greater extent on its structure. Substances that increase the degree of graphitization increase thermal conductivity, and substances that prevent the formation of graphite decrease it.

By the way, the thermal conductivity of molten cast iron is much less than that of solid cast iron. But due to convection it is greater than λ of the solid metal.

Thermal conductivity for different brands lies within:

λ =0.08…0.13 cal/ (cm·sec oC)

Thermal conductivity and other thermophysical properties depending on the temperature of the alloy are given at the end of the section.

Thermal diffusivity (α)

This is a physical quantity that shows how quickly body temperature changes. Equal to the ratio of thermal conductivity to volumetric heat capacity.

For approximate calculations you can take:

α=λ for solid metal (equal to its thermal conductivity);

α=0.03 cm2/sec for liquid.

Melting temperature

This alloy has good casting properties. Better than steel. The fluidity is high and the shrinkage is low (about 1%). It can be melted at a temperature 300-400 degrees lower than steel. Cast iron melting point:

What is it like?

The structure of cast iron is an iron base with graphite (carbon) inclusions. This material is distinguished not by its composition, but by the form of carbon in it:

- White cast iron (BC). Contains carbide (cementite) - this is a form of carbon, the same as in steel. It has a whitish color when scrapped. Very hard and brittle. In its pure form it is almost never used.

- Gray cast iron (GC). Contains carbon in the form of flake graphite. Such inclusions have a bad effect on the quality of the material. To change the shape of graphite grains, there are special methods of melting and further processing. Graphite in midrange can also be in the form of fibers (“worm-shaped” form) - the so-called vermicular graphite (from the Latin word vermiculus - a worm, like vermicelli).

- Highly durable. Spherical shape of graphite grains. It is obtained by introducing magnesium into the alloy.

- Malleable cast iron. To obtain it, warheads are annealed. Graphite grains in the form of flakes.

As a result, the main difference between it (apart from white) and steel is the presence of a graphite structure. And different forms of graphite determine the properties of different grades.

Conventionally, graphite grains are voids and cracks, and cast iron is steel riddled with microscopic cracks.

Accordingly, the more voids, the worse the quality of the metal. The shape and relative position of the inclusions also matters.

However, graphite grains should not be accepted as exclusively harmful. Due to the presence of graphite, this material is easier to machine and the chips become more brittle. In addition, it resists friction well also due to the graphite.

Impurities

Of course, this metal contains more than just iron and carbon. It contains the same elements as steel alloys - phosphorus, manganese, sulfur, silicon and others. These additives indirectly affect the characteristics of the alloy - they change the course of graphitization. The quality of the material depends on this parameter.

- Phosphorus. Has little effect on the formation of graphite. But it is still needed, because it improves fluidity. Solid inclusions of phosphorus provide high hardness and wear resistance of the metal.

- Manganese. It interferes with graphitization and, as it were, “bleaches” cast iron.

- Sulfur. Like silicon, it promotes bleaching of the metal, and also impairs fluidity. The amount of sulfur in the alloy is limited. For small castings no more than 0.08%, for parts more - up to 0.1-0.12%.

- Silicon. Strongly affects the properties of the material, increasing graphitization. The metal can contain from 0.3-0.5 to 3-5% silicon. By varying the amount of silicon, an alloy with different properties is obtained - from white to high-strength.

- Magnesium. Helps to obtain material with spherical grain shape. The boiling point of magnesium is low (1107˚C). For this and other reasons, introducing magnesium into the alloy is difficult. To avoid its boiling, the material is smelted using various methods of introducing magnesium.

In addition to the usual impurities, cast iron may contain other substances. This is the so-called alloyed material. Chromium, molybdenum, vanadium interfere with the process of graphite formation. Copper, nickel and most other substances contribute to graphitization.

Self-smelting technology

Non-industrial smelting of cast iron is a very labor-intensive process. It is impossible to smelt factory-quality castings with your own hands in artisanal conditions.

https://www.youtube.com/watch?v=6uDL-KX7Tqwu0026t=128s

You cannot smelt this metal at home. You need a separate ventilated room - a garage, for example. Melting is carried out in furnaces. In industry, blast furnaces, cupola furnaces and induction furnaces are used.

A blast furnace is an industrial unit capable of melting metal on a huge scale. Iron ore raw materials can be smelted in it. After launch, it works without interruption for up to 5-6, or even up to 10 years.

Then it is stopped, serviced and started again. Melting of the metal takes place in the presence of gases to improve the quality of the material. Such ovens are not suitable for small and medium-sized production.

Fuel - coke.

A cupola furnace is a shaft-type furnace, like a blast furnace. It differs from the latter in that it does not maintain a special composition of gases. It is not ore that is smelted in it, but scrap iron. It is more suitable for small production.

To an engineer about aluminum

The most attractive physical property of aluminum for engineers is its density of 2.7 g/cm3, which is only a third of the density of steel.

Corrosion resistance of aluminum

The second most important property is its good corrosion resistance, although aluminum is not a very noble metal from a chemical point of view.

This is because "fresh" aluminum (and aluminum alloys) reacts with oxygen and water vapor in the air to form a thin, dense oxide film that protects the underlying metal from further interaction with the environment.

Therefore, commercial aluminum and most of its alloys without copper alloying show very good corrosion resistance in liquids with a pH in the acid range from 5 to 8, which corresponds to most atmospheric environmental conditions.

Thermal expansion of aluminum

The linear thermal expansion of aluminum and its alloys is 24·10-6 per 1 degree Celsius - twice as much as that of steels.

This must be taken into account in many designs in which it is necessary to ensure free thermal expansion of elements.

When thermal expansion (or contraction) is limited in an aluminum element, due to the lower modulus of elasticity, stresses arise that are 2/3 of the stresses that would arise in a similar steel element.

Modulus of elasticity of aluminum

The elastic modulus of aluminum is 70,000 MPa, only a third of the elastic modulus of steel. This entails significant consequences for the geometry of the structure, since the deflections of the beams, the load-bearing capacity of the columns, i.e. their lateral buckling or local buckling directly depends on the elastic modulus.

Rigidity of aluminum profiles

In many building structures, a critical parameter of profiles is their rigidity.

If a steel profile is replaced with an aluminum one while maintaining its rigidity, then thickening all the walls three times is not entirely economical, since aluminum is exactly the same three times lighter than steel.

However, lightweighting structures through the use of aluminum is a natural desire, both for physical and economic reasons.

When designing beams, there is a practical and proven rule: increase all dimensions except the width by 1.4 times and you will get a cross section with a moment of inertia almost three times greater. Then for a profile with the same stiffness (E · I) you will save about 50% of the weight.

In this case, the loss of rigidity in relation to lateral buckling is compensated to some extent. Taking into account the fact that often standard steel profiles are not very optimal, you can save more than 50% of the weight. This can be clearly seen from Figure 1.

If there are no height restrictions and lateral buckling is not a design parameter, weight savings of up to 60% can be achieved.

If the rigidity of the element is not important, and the strength of the steel is close to the strength of the aluminum alloy, then savings can be up to 70%, but this is the final limit of possible weight savings.

Picture 1

These considerations lead to a second important point. If the moment of inertia of the profile increases three times with an increase in the height of the profile only by 1.4 times, then the moment of resistance of the section will increase accordingly by 3: 1.4 = 2.1 times.

Therefore, the stresses in an aluminum beam compared to a steel beam will be more than two times less.

Now it is clear why the designer does not need to immediately “grasp” high-strength aluminum alloys, and why less alloyed aluminum alloys 6060 and 6063 (AD31) are so popular.

Heating aluminum

Like other metals, the strength of aluminum decreases with increasing temperature. Up to some temperatures, this phenomenon is reversible, that is, after cooling, the material returns to the same properties as before heating.

Up to a temperature of about 80 °C, the drop in strength can be neglected for all alloys and states. Above 80°C, some design situations may require consideration of the creep effect.

Thermally strengthened alloys begin to lose strength at temperatures above 110 °C, and the extent of this phenomenon depends on the duration of heating.

Alloys that are not hardened by heat treatment begin to lose strength in cold-worked states at temperatures above 150 °C and also depending on the duration of heating. After heating non-thermally hardenable alloys in the annealed “O” state, no irreversible loss of strength occurs.

It is believed that short heating of thermally strengthened aluminum profiles to a temperature of 180-200 °C for 10-15 minutes, which occurs when powder paints are “melted,” does not lead to a serious loss of strength.

Welding of aluminum alloys

Much more serious is the loss of strength of aluminum alloys during welding. Here the temperature rises so high due to local melting that the drop in strength near the weld must be taken into account. Alloys that are not thermally hardenable lose all of their strength obtained during cold hardening and return to the annealed “O” state.

Heat-hardening aluminum alloys in the T6 condition lose approximately 40% of their strength (Figure 2) with the exception of alloy 7020, which loses only 20%. All these alloys do not reach the state of complete annealing, since a certain hardening effect is inevitable when the weld cools.

Requirements for the strength characteristics of the material in the weld zone are established and controlled based on the results of testing samples.

Chromium-nickel low- and medium-alloy steels

The table shows the temperature coefficients of linear expansion of low- and medium-alloy chromium-nickel steels of common grades at temperatures from -268 to 1000°C.

The highest TCLE of the grades considered in the table is possessed by chromium-nickel steel 12Х2Н4А and 12ХН3А, which in the range of 27-600°С is equal to 15.6·10 -6 deg -1.

Linear expansion coefficients of chromium-nickel steel

| steel grade | Temperature, °C | TCLE 10 6 1/deg |

| 12Х2Н4А | 100…200…300…400…600 | 11…12…13…14,7…15,6 |

| 12ХН2 | 100…200…300…400 | 12,6…13,8…14,8…14,3 |

| 12ХН3А | 100…200…300…400…500…600 | 11,8…13…14…14,7…15,3…15,6 |

| 18Х2Н4МА | -268…-263…-243…-173…-73 | -0,06…-0,064…0,32…6,5…10 |

| 18Х2Н4МА | 200…300…400…500…600…700 | 11,2…12,5…13,1…13,7…13,8…13,8 |

| 18HNVA | 100…200…300…400…500…600 | 11,7…12,2…12,7…13,1…13,5…13,9 |

| 20ХН3А | 100…200…300…400…500…600 | 11…12…13…13,5…14…14,5 |

| 30ХН2МФА | -203…-173…-73…27 | 5…7,4…9,3…12,3 |

| 30ХН3 | 100…200…300…400…500…600…700…800…900…1000 | 11,2…11,8…12,4…12,7…13,2…13,5…13,9…10,8…12,1…13,1 |

| 33ХН3МА, 34ХН3М | 100…200…300…400…500…600 | 10,8…11,6…12,5…13,3…13,5…13,7 |

| 34ХН3МА | -203…-173…-73…27 | 5…7,6…9,5…11,6 |

| 35ХН3МФ | 100…200…300…400…500…600 | 11,8…12,1…12,6…13…13,4…13,7 |

| 35ХНМ, 34ХН1М | 100…200…300 | 11,7…12,2…12,7 |

| 40ХН, 45ХН | 100…200…300…400 | 11,8…12,3…13,4…14 |

| 40ХНМА | 100…200…300 | 11,7…12,2…12,7 |

Cast iron. KLTR.

The true TCLE during cooling has negative values, but in absolute value it practically coincides with the TCLE of high-strength cast iron during heating. Thus, when cooling the thermal expansion coefficient of cast iron in the temperature range of 1000...Ar3 is –22.0·10–6 1/deg. In the intercritical temperature range Аr3…Аr1 it is minimal and amounts to only 3.1·10–6 1/deg. LTEC of austenite decomposition products in the temperature range Ar1...600C is –13.0·10–6 1/deg. As the temperature decreases, the TCLE decreases and in the temperature range 300...200C it is 11.2·10–6 1/deg.

The average temperature coefficient of linear expansion (TCLE) of high-chromium cast iron, consisting of eutectic cementite, martensite and retained austenite (Fig. 1, b), in the temperature range 50...100C is 10·10–6 1/deg. In the temperature range 500...900С due to the phase transformation of the initial structure into austenite, it decreases to 11.1·10–6 1/deg. When heated to a maximum temperature of 1000C, it increases due to an increase in the proportion of austenite and is equal to 12.0·10–6 1/deg. The true coefficient of linear expansion of this cast iron when heated in the temperature range 50...100C is 10·10–6 1/deg. With an increase in heating temperature to 5000C, it increases to 13.6·10–6 1/deg. In the temperature range 500...600C due to the processes of tempering the martensitic structure, it decreases to 12.5·10–61/deg. The decomposition of retained austenite into a ferrite-carbide mixture in the temperature range 600 – 700C leads to an increase in LTEC to 17.2·10–6 1/deg. With further heating to Ac1 (770C), due to a decrease in the rate of decay of retained austenite, the thermal expansion coefficient decreases to 10.9 10–6 1/deg. In the temperature range Ac1... 805C, due to the phase transformation of the initial structure into austenite, the TCLE drops sharply and is equal to 3.7 10–6 1/deg. Due to the increase in the rate of transformation to austenite in the temperature range 805...Ac3, the temperature coefficient of linear expansion takes on a negative value and is equal to –2.2·10–6 1/deg.

The true coefficient of linear expansion of this cast iron during cooling has negative values and decreases down to the temperature of the onset of martensitic transformation equal to 250C.

Thus, in the temperature range 100 – 900C it is equal to –21.5·10–6 1/deg. With further cooling it decreases and in the temperature range 300 – 250C it is only –13.6·10–6 1/deg. The decomposition of supercooled austenite into martensite in the temperature range 200–100C leads to expansion of the sample and the LTEC in this case is + 3.7 10–6 1/deg. A further increase in the rate of decomposition of austenite into martensite leads to a further increase in the LTEC of cast iron to +5.3·10–6 1/deg. Modified December 15, 2022 by desti

Chrome steels

Chromium steels have a coefficient of linear expansion on average from 10 to 13·10 -6 deg -1. Additionally, it is worth noting steel ShKh15 and 40Kh, the value of TCLE of which is 13.4...15.7·10 -6 deg -1.

Linear expansion coefficients of chromium steel

| steel grade | Temperature, °C | TCLE 10 6 1/deg |

| Steel 15Х, 15ХА, 20Х | 100…200…300…400…500…600 | 11,3…11,3…12,3…13,2…13,7…14,2 |

| Steel 30Х | 100…200…300…400…500…600…700…800…900…1000 | 12,5…13…13,4…13,8…14,2…14,6…14,8…12…12,8…13,8 |

| 38ХА, 40Х | -268…-263…-253…-223…-173…-73 | -0,002…0,02…0,2…1,7…6,6…11,5 |

| 08Х13 | 100…200…300…400…500…600…700…800 | 10,5…11,1…11,4…11,8…12,1…12,3…12,5…12,8 |

| 08Х17 | 100…200…300…400…500…600…700…800 | 10,4…10,5…10,8…11,2…11,4…11,6…11,9…12,1 |

| 12Х13 | 100…200…300…400…500…600…700…800…900…1000 | 10,2…11,2…11,4…11,8…12,2…12,4…12,7…13…10,8…11,7 |

| 15Х28 | 100…500…600…700…800…900 | 10…11,1…11,3…11,5…12…12,4 |

| 20Х13 | 100…200…300…400…500…600…700…800 | 10,2…11,2…11,5…11,9…12,2…12,8…12,8…13 |

| 30Х13 | 100…200…300…400…500…600…700…800…900…1000 | 10,2…11…11,1…11,7…12…12,3…12,5…12,6…10,6…12,2 |

| 40X | 100…200…400…600 | 13,4…13,3…14,8…14,8 |

| 40Х13 | 100…200…300…400…500…600…700…800 | 10,7…11,5…11,9…12,2…12,5…12,8…13…13,2 |

| 95Х18, 95Х18Ш | 100…200…300…400…500…600…700…800 | 11,7…12,1…12,4…12,9…13,3…11,8…12,1…12,4 |

| ШХ15 | 100…200…400…600 | 14…15,1…15,5…15,7 |

Chrome-nickel steels with nickel content up to 20%

The table shows the linear expansion coefficients of chromium-nickel steels with a nickel content of up to 20%. This type of steel includes a significant variety of grades that have a wide range of thermal expansion coefficients - from 8 to 17.5·10 -6 deg -1 at temperatures up to 100°C and from 10 to 24.6·10 -6 deg -1 in the range up to 1000°C.

Linear expansion coefficients of chromium-nickel steel with nickel content up to 20%

| steel grade | Temperature, °C | TCLE 10 6 1/deg |

| 03Х13Н8Д2ТМ | from -196 to 27…from -253 to 27 | 10,2…8,5 |

| 03X20N16AG6 | -269…-253…-233…-173…27 | 0,01…0,06…0,6…8,3…16,1 |

| 04Х18Н10 | -253…-223…-173…-73…27 | 3…8…10,8…15,4…15,5 |

| 07Х16Н16 | 200…300…400…500 | 11,7…12,1…12,5…12,9 |

| 07X21N5AG7 | from -253 to 27...from -196 to 27...from -100 to 27 | 9,3…11,5…14,6 |

| 07X21N5AG7 | 100…200…300…400…500…600…700 | 15,7…16…16,8…17,3…18…18,4…18,5 |

| 08Х12Н16БС4 | 100…200…300…400…500…600…700…800…900 | 16,5…16,7…17,4…17,7…17,9…18,1…18,3…18,6…18,7 |

| 08Х15Н15М3 | 100…200…300…400…500…600…700…800…900 | 16,9…17,7…18,1…18,5…18,8…19,1…19,5…19,7…19,9 |

| 08Х15Н15М3Б | 100…200…300…400…500…600…700…800…900 | 16,4…17,1…17,4…17,7…17,7…17,9…18,3…18,6…18,8 |

| 08Х15Н7М2У | 100…200…300…400…500…600…700…800…900 | 9,9…10,8…11,1…11,5…11,7…11,4…10,3…11,2…11,9 |

| 08Х16Н13М2Б | 400…500…600…700…800 | 17,1…17,4…17,8…18,2…18,6 |

| 08Х17Н13М2Т | 100…200…300…400…500…600…700 | 15,7…16,1…16,7…17,2…17,6…17,9…18,2 |

| 08Х17Н4 | 100…200…300…400…500…600…700…800…900 | 9,7…10,2…10,6…10,9…11,2…11,3…9,6…9,6…10,2 |

| 08Х17Н4М2 | 100…200…300…400…500…600…700…800…900 | 10,6…11…11,4…11,6…11,9…11,7…11,1…11,7…12,3 |

| 08Х18Н12Б | 100…200…300…400 | 16…18…18…19 |

| 08Х18Н15Р4 | 100…200…300…400…500…600…700…800…900 | 16,5…17,4…17,8…18,1…18,5…18,9…19,2…19,5…19,8 |

| 08Х18Н15Р7 | 100…200…300…400…500…600…700…800…900 | 16,8…17,4…17,7…18,1…18,2…18,6…19…19,4…19,8 |

| 08Х18Н7У1 | 100…200…300…400…500…600…700…800 | 15,6…16,5…17,3…17,9…18,1…18,4…18,5…18,7 |

| 08Х21Н6М2Т | 100…200…300…400…500…600…700…800…900 | 9,5…13,8…16…16…16,3…16,7…17,1…17,1…17,4 |

| 09Х14Н16Б | 100…200…300…400…500…600…700…800 | 15,2…16,5…17,1…17,6…18…18,4…18,9…20,6 |

| 09X14N19V2BR1 | 100…200…300…400…500…600…700…800 | 15,2…16,3…17,2…17,6…18…18,1…18,6…18,6 |

| 10Х13Н16Б | 100…200…300…400…500…600…700…800…900…1000 | 16…16,9…17,7…18,3…18,6…18,8…19…19,3…19,6…19,7 |

| 10Х13Н2С2 | 100…200…300…400…500…600…700 | 10,8…11,4…11,8…12,3…12,7…13,1…13,3 |

| 10Х14Н14В2М | 100…200…300…400…500…600…700…800…900 | 17…17,8…18,3…18,8…19…19,2…19,4…19,9…20,1 |

| 10Х14Н14В2МТ | 100…200…300…400…500…600…700…800 | 17,2…17,2…17,5…18…18,5…18,6…18,9…19,3 |

| 10Х14Н18В2Б | 100…200…300…400…500…600…700…800…900 | 16,5…17,4…17,6…18…18,1…18,2…18,5…19…19 |

| 10Х15Н9С3Б1 | 100…200…300…400…500…600…700…800 | 17,4…18,7…19,7…20,2…20,5…21…21,6…21,8 |

| 10Х16Н16В3МБР | 100…200…300…400…500…600…700…800…900 | 17,1…17,1…17,1…17,9…18,2…18,5…18,8…19,1…19,2 |

| 10Х18Н15М3В2БК13 | 300…400…500…600…700…800 | 16,7…16,7…16,8…17…17,3…17,4 |

| 10Х18Н18У4Д | 100…200…300…400…500…600…700…800…900 | 15,5…16,5…17…17,4…17,7…18,2…18,4…18,8…18,6 |

| 10Х18Н9ВМ | 300…400…500…600…700…800 | 16,7…17,2…17,5…17,8…18…18,2 |

| 12Х18Н9 | 100…200…300…400…500…600…700…800…900…1000 | 16,5…17,2…17,7…18,1…18,3…18,6…18,9…19,3…19,7…20,2 |

| 12Х18Н9В | 200…300…400…500…600…700…800…900…1000 | 16,5…17,1…17,6…18…18,4…18,8…19…19,2…19,4 |

| 12Х18Н9М | 100…200…300…400…500…600…700 | 17,3…17,5…17,8…18…18,3…18,5…18,8 |

| 12Х18Н9М2С2 | 100…200…300…400…500…600…700…800…900…1000 | 16,6…17…17,4…17,7…18…18,4…18,8…19,1…19,4…19,8 |

| 12Х18Н9С2 | 100…200…300…400…500…600…700 | 16,2…17,1…17,8…18,6…19,2…19,2…20,5 |

| 12Х18Н9Т | -253…-223…-173…-73…27 | 0,8…3,3…8,4…14,3…16,7 |

| 12Х18Н9Т | 100…200…300…400…500…600…700…800…900…1000 | 16,6…17…17,6…18…18,3…18,6…18,9…19,3…19,5…20,1 |

| 12Х18Н9ТЛ | 100…200…300…400…500…600…700 | 14,8…16…16,9…17,1…17,6…18…18,4 |

| 12Х18Н10Т | 127…227…427…727…1027 | 17,6…18…19,4…21,1…22,3 |

| 12Х18Н12Т | 100…200…300…400…500…600…700…800…900 | 16,6…17…17,2…17,5…17,9…18,2…18,6…18,9…19,3 |

| 12Х21Н5Т | -173…-73…27 | 7,9…10,4…11 |

| 12Х21Н5Т | 100…200…300…400…500…600…700…800…900 | 10,2…14,4…16,8…16,8…17,4…17,5…17,7…18…18,5 |

| 12X25N16G17AR | 100…200…300…400…500…600…700…800 | 16,6…16,2…16,8…17,4…18…18,5…18,7…18,9 |

| 13Х12НВ2МФ | 100…200…300…400…500…600 | 11…11,3…11,6…12…12,3…12,5 |

| 14Х17Н2 | 100…200…300…400…500 | 10,3…10,4…10,7…11,1…11,8 |

| 20Х13Н2 | 100…200…300…400…500…600 | 10,5…10,6…10,6…10,8…11,1…11,3 |

| 20Х14Н14В2СТ | 100…200…300…400…500…600 | 16,1…16,7…17,2…17,4…17,8…18,2 |

| 20Х17Н1 | 100…200…300…400…500…600 | 8,1…8,8…10,3…10…10,5…10,5 |

| 20Х17Н2 | 100…200…300…400…500…600 | 10,5…10,7…10,9…10,8…11,2…11,3 |

| 20Х20Н11 | 100…300…500…600 | 17,3…17,8…18,4…18,7 |

| 20Х20Н14С2 | 100…600…700…800…900…1000 | 16…18,1…18,3…18,5…18,8…19 |

| 20Х23Н18 | 100…200…300…400…500…600…700 | 14,9…15,7…16,6…17,3…17,5…17,9…17,9 |

| 30Х18Н9В2ФТ | 100…200…300…400…500…600…700…800…900…1000 | 15,4…15,6…15,9…16,3…16,6…17…17,4…17,8…18,4…19 |

| 31Х19Н9МВБТ | 100…200…300…400…500…600…700…800…900…1000 | 16,7…16,9…17,2…17,5…17,8…18,2…18,5…18,9…19,3…19,7 |

| 37Х12Н8Г8МФБ | 100…200…300…400…500…600…700 | 16…16,9…17,7…18,5…19,5…19,9…20,2 |

| 45Х14Н14В2М | 300…500…700…900 | 17…18…18…19 |

| 4X15NG7F2MS | 100…200…300…400…500…600…700…800…900…1000 | 17…17,7…18,4…19,1…20,5…20,8…22,8…22,8…23,3…24,6 |

| Х13Н12М2В2Б1К10 | 100…200…300…400…500…600…700…800…1000 | 15,6…15,8…16,5…16,9…17,1…17,3…17,7…18…18,6 |

| Х13Н13В2Б | 100…200…300…400…500…600…700…800…900 | 16,8…17,3…17,9…18,3…18,7…18,9…19,1…19,3…19,6 |

| Х13Н13В2М2Б3К10 | 100…200…300…400…500…600…700…800…900…1000 | 15,6…15,8…16,5…16,9…17,1…17,3…17,7…18…18,3…18,6 |

| Х14Н14М2В2ФБТ | 400…500…600…700…800 | 16,7…17,1…17,4…17,8…18,1 |

| Х14Н14МВФБ | 100…200…300…400…500…600…700 | 15,1…15,9…16,9…18…18,2…18,4…19 |

| X14N18V2BR | 100…200…300…400…500…600…700…800…900 | 15,9…16,5…17,2…17,6…18…18,3…18,6…18,7…19 |

| Х15Н15М2К3ВТ | 100…200…300…400…500…600 | 15,8…16,6…17,2…17,6…18,3…18,6 |

| Х16Н14Б | 100…300…500…800 | 16…18…18…19 |

| Х16Н16В3МБ | 100…200…300…400…500…600…700…800 | 15,8…16,8…17,3…17,6…17,8…17,9…18,1…18,2 |

| Х16Н9М2 | 100…200…300…400…500…600…700 | 17…17,5…18…18,4…18,9…19,3…19,5 |

| Х17Н5М2 | 100…200…300…400…500…600 | 12,1…13,7…14,3…14,6…14,8…14,8 |

| Х18Н11Б | 100…200…300…400…500…600…700…800…900 | 16,8…17,7…18,2…18,5…18,9…19…19,4…19,7…19,9 |

| Х18Н12 | 100…200…300…400…500…600…700 | 16,8…17,2…17,6…17,8…18,2…18,5…18,8 |

| Х18Н12М2Т | 100…200…300…400…500…600…700 | 15,7…16,1…16,7…17,2…17,6…17,9…18,2 |

| Х18Н12М3 | 100…300…500…600…1000 | 16…16,2…17,5…18,6…20 |

| X18N12MFTR | 100…200…300…400…500…600…700…800…900 | 15,9…16,9…17,6…17,8…17,9…18,4…18,8…19…19,2 |

| Х18Н14М2Б1 | 400…500…600…700 | 17,6…17,8…18,2…18,7 |

| Х18Н15М3БУР2 | 100…200…300…400…500…600…700…800…900 | 15…16,1…16,8…17,1…17,5…17,8…18,2…18,4…18,3 |

| Х18Н15М3БУР4 | 100…200…300…400…500…600…700…800…900 | 15,1…15,8…16,4…17,2…17,4…17,6…17,9…18,1…18,5 |

| Х19Н10М2Ф3БК47 | 100…200…300…400…500…600…700…800…900 | 14,8…15…15,1…15,2…15,3…15,9…16,4…16,8…17,2 |

| Х19Н14Б2 | 100…200…300…400…500…600…700 | 17…17,2…17,4…17,6…17,9…18,6…18,8 |

| Х22Н9 | 400…800 | 17,5…18,5 |

| Х25Н13АТ, Х25Н13Т | 500…900 | 17,1…18,1 |

Chrome-nickel steels and alloys with a nickel content of more than 20%

Chromium-nickel steels with a nickel content of more than 20% have a linear temperature expansion coefficient of up to 19.8·10 -6 deg -1 (KhN46B alloy). The steel of this type with the lowest TCLE value is 04KhN40MDTYu; its average coefficient of linear expansion at temperatures up to 100°C is 8.2·10 -6 deg -1 .

Linear expansion coefficients of chromium-nickel steel with a nickel content of more than 20%

| steel grade | Temperature, °C | TCLE 10 6 1/deg |

| 0Х17Н39Б | 100…200…300…400…500…600…700 | 14,2…16…17,2…17,2…17,2…17,5…17,8 |

| 0Х18Н20С3М3Д3Б | -263…-243…-203…-73…27 | -0,25…0,61…6…14,3…15,8 |

| 0Х20Н60Б | 100…200…300…400…500…600…700…800…900 | 12,6…13,6…14,4…14,8…15,1…15,5…15,6…16,2…16,7 |

| 0Х21Н40БР | 100…200…300…400…500…600…700…800 | 14,3…15,4…15,8…15,9…16…16,3…16,8…17,1 |

| 04ХН40МДТУ | 100…200…300…400…500…600…700…800 | 8,2…11…12…12,8…13,6…14,1…19,9…16,2 |

| 08Х15Н24В4ТР | -269…-243…-203…-173…27 | -0,12…-0,42…5,2…8,5…15,6 |

| 10Х11Н20Т3Р | from -100 to 27…100…200…300…400…500…600…700 | 8,2…15,9…16,4…17,2…17,9…18,4…18,9…19,2 |

| 10Х11Н23Т3МР | -268…-243…-223…-173…27 | 0,03…0,14…1,5…9,1…16 |

| 1Х15Н30Т2 | 400…500…600…700 | 16,1…16,7…16,9…17,5 |

| 1Х16Н25М6 | 100…200…300…400…500…600…700 | 15…15,7…15,9…16,3…16,6…16,9…17,1 |

| 1X16N36MBTYUR | 100...from 100 to 200...from 400 to 500...from 700 to 800 | 17,7…14…17…25 |

| 3Х20Н20М4В4К45 | 300…400…500…600…700…800…900…1000 | 11,8…12,4…12,7…13…13,5…14…14,4…15 |

| 36Х18Н25С2 | 100…200…300…400 | 13…13,6…14,7…16,1 |

| Х10Н56К20М5Т4У5 | 100…500…900 | 11,7…14…16,2 |

| Х11Н54К2М5УТ2 | 100…200…300…400…500…600…700…800…900…1000 | 12,4…13,1…13,6…14…14,3…14,5…15…15,7…16,8…18,1 |

| Х11Н55М5К20Т1 | 100…1000 | 12,4…18,8 |

| Х12Н42МБТ3 | 100…500…from 27 to 750 | 14…15,1…17 |

| Х13Н71М5Б2Т1УБ | 100…500…900 | 11,9…12,6…14,5 |

| Х15Н24В4Т | 100…200…300…400…500…600…700…800 | 14,5…15,5…16,3…16,8…17,2…17,3…17,9…18,5 |

| Х15Н24Т2 | -203…-173…-73…27 | 3,6…5,9…14,3…16,4 |

| X15N35V2M2TR | 100…400…500…600…700…800 | 13…15…16…16,2…16,9…16,9 |

| Х15Н35В3ТК4 | 200…300…400…500…600…700 | 14,8…15,2…15,7…16,1…16,5…17,1 |

| X15N35V5TR | 100…400…500…600…700…800 | 14,1…15,8…16,2…16,2…16,7…16,9 |

| Х15Н45К28М3Т2У3 | 100…500…900 | 12,3…14,3…17 |

| Х15Н51К20М5У5 | 100…500…900 | 11,9…14,3…17,7 |

| Х15Н58М16 | 100…1000 | 11,3…15,3 |

| Х15Н70В5М4У2ТР | 100…200…300…400…500…600…700…800…900 | 12,2…12,6…13,2…13,6…14,1…14,5…15,1…15,8…16,5 |

| Х15Н70В6М3Т2УР | 100…200…300…400…500…600…700…800…900…1000 | 12,4…12,8…13,1…13,3…13,6…14…14,6…15,3…16,1…17,4 |

| Х15Н73Т2У1Б | 300…400…500…600…700…800 | 13,1…14…14,5…14,9…15,6…16,4 |

| Х15Н73Т3У1Б1 | 100…200…300…400…500…600…700…800…900 | 13,7…13,9…14,2…14,4…14,6…15…15,4…16,2…16,8 |

| Х16Н38В3Т | 100…200…300…400…500…600…700…800…900 | 13,7…14,5…15,7…16,2…16,3…16,6…17,1…17,1…17,3 |

| Х16Н57М17В4 | 500…900 | 13,3…11,8 |

| Х16Н60У3 | 100…200…300…400…500…600…700…800…900 | 12,3…13,1…13,4…14,2…14,4…14,6…15,1…15,2…15,9 |

| Х16Н80ТБУ | 100…200…300…400…500…600…700…800…900…1000 | 13,3…13,5…13,9…14,2…14,5…14,9…15,5…16,2…16,7…17,8 |

| Х18Н22В2Т2 | 100…200…300…400…500…600 | 15,3…16…17…17,1…17,2…17,5 |

| Х18Н67В5М5Т2УР | 100…200…300…400…500…600…700…800…900 | 10,4…11,1…11,7…12…12,5…12,8…13,6…13,8…14 |

| Х19Н55К10М10Т2У1 | 100…500…900 | 14…14,7…16 |

| Х20Н20Б1М3К20 | 400…500…600…700…800…950 | 15,7…16,1…16,7…17,2…17,6…17,8 |

| Х20Н54К16Т2У1 | 100…500…900 | 12,4…14,7…17,4 |

| Х20Н56К18Т2У1.5 | 100…200…300…400…500…600…700…800…900 | 11,6…12,6…12,7…13,5…13,7…14,2…15…16…17 |

| Х20Н58М10К10 | 100…500…900 | 12,5…14,3…16,5 |

| Х20Н59К16Т2У1 | 100…500…900 | 12,8…15,1…17,9 |

| X20N75TYU | 100…200…300…400…500…600…700…800…900 | 12,2…13…13,4…13,8…14,1…14,7…15,4…15,5…16 |

| Х20Н77Т2У | 100…200…300…400…500…600…700…800…900 | 11,9…12,7…13…13,5…13,7…14…14,5…15,1…15,8 |

| Х20Н80 | 1000 | 17,6 |

| Х20Н80Т | 100…200…300…400…500…600…700…800…900 | 11,8…12,9…12,9…14,4…14,8…15,8…16,1…16,5…16,8 |

| Х20Н80Т3 | 100…200…300…400…500…600…700…800…900 | 11,9…12,7…13…13,5…13,7…14…14,5…15,1…15,8 |

| Х22Н45М9 | 100…1000 | 13,9…16,3 |

| Х22Н47М9 | 100…500…900 | 13,8…14,9…16,8 |

| Х25Н20С2 | 100…600…700…800…900…1000 | 16,1…17,8…17,8…18,1…18,5…18,8 |

| X25N25TR | 100…200…300…400…500…600…700…800…900 | 13…14,4…15,2…15,7…16,2…16,5…17,3…17,3…17,8 |

| Х26Н20Л | 300…400…500…600…700…800 | 15,5…15,6…15,9…16,2…16,6…17,2 |

| Х26Н36К30МБ | 300…400…500…600…700…800…900 | 13,5…13,9…14,3…14,7…15,1…15,5…16 |

| Х27Н70У3 | 1000 | 18 |

| ХН30МБУ | -269…-263…-223…-173…20 | -0,14…0,2…1,9…8,2…14,5 |

| ХН32Т | 100…200…300…400…500…600…700…800 | 13,7…15,6…17,2…18…18…18,4…18,9…19 |

| ХН35ВТ | 100…200…300…400…500…600…700…800 | 14,8…15,1…15,5…15,9…16,1…16,6…16,9…17,7 |

| ХН35ВТУ | 100…200…300…400…500…600…700…800…900 | 12,7…14,1…15…15,4…15,8…16…16,6…16,8…18,4 |

| ХН45У | 100…200…300…400…600…800…900 | 15,8…15,9…16…16,6…16,6…19…19,7 |

| ХН46Б | 100…200…300…400…500…600…700…800 | 13,3…14,2…16…17,7…17,7…18,5…19,5…19,8 |

| ХН55ВМКУ | 100…200…300…400…500…600…700…800…900…1000 | 11,8…12,2…12,7…13,1…13,4…13,6…14,1…14,8…15,7…17 |

| KHN55VMTKYU | 100…200…300…400…500…600…700…800…900 | 10,8…11,7…12,4…12,8…13,4…13,8…14,1…14,5…15,5 |

| ХН55МБУ | from -253 to 27...from -73 to 27...from -13 to 27 | 10…13,6…14,1 |

| ХН55МБУ | 300…400…500…600…700…800…900 | 14,1…14,3…14,5…15,1…15,5…16,3…16,3 |

| ХН55МВУ | 100…200…300…400…500…600…800…900 | 13,4,…14,2…14,9…15,2…15,8…16,2…17,3…18,8 |

| ХН56МВТУ | 100…200…300…400…500…600…700…800…900 | 11,7…12…12,4…12,7…13…13,5…13,8…14,5…15,2 |

| ХН57МВТУ | 100…200…300…400…500…600…700…800…900 | 12,6…13,6…14,7…15…15,3…15,8…16,2…17,3…18,2 |

| ХН60В | 100…200…300…400…500…600…700…800…900…1000 | 12,7…13,2…13,6…14,1…14,5…15,5…15,7…16…16,2…16,8 |

| ХН60КМВУБ | 100…200…300…400…500…600…700…800…900 | 11,3…12…12,6…13,2…13,5…13,8…14,4…15,3…16,1 |

| ХН60У | 100…200…300…400…500…600…700…800…900 | 12,3…13,1…13,4…14,2…14,2…14,6…15,1…15,2…15,9 |

| KHN62VMKTYUB | 100…200…300…400…500…600…700…800 | 13,5…13,5…13,5…13,6…13,6…13,9…14,5…15,6 |

| ХН62МБВУ | 100…200…300…400…500…600…700…800…900…1000 | 12…12,8…13,3…13,5…13,8…14,5…14,8…15,5…16,4…17,3 |

| KHN62MYUK10 | 100…200…300…400…500…600…700…800…900…1000 | 11,5…12,6…13…13,4…13,7…14…14,3…14,8…15,6…16,9 |

| ХН65ВМТУ | 100…300…400…500…600…700…800…900 | 11,5…12,3…12,8…13…13,2…14…14,3…15 |

| ХН67ВМТУ | 100…200…300…400…500…600…700…800 | 12…12,3…13,5…13,6…14,4…14,8…15,2…16,2 |

| ХН70ВМТУ | 100…200…300…400…500…600…700…800…900 | 12…12,5…13,5…13,9…14,3…14,8…15,8…16,3…16,7 |

| KhN70VMTUF | 100…200…300…400…500…600…700…800…900 | 10,4…11,7…12,4…12,9…13,2…13,6…14…14,5…15 |

| ХН70ВМУ | 100…200…300…400…500…600…700…800…900…1000 | 10,2…11,3…12…12,2…12,4…12,6…13,1…13,2…14…15,1 |

| ХН70ВМУТ | 100…200…300…400…500…600…700…800 | 12,2…12,7…13,2…13,6…14,1…14,6…15,1…15,8 |

| ХН77TYUR | 100…200…300…400…500…600…700…800…900…1000 | 12,7…12,9…13,3…13,8…14,2…14,6…15,1…15,5…16,2…16,8 |

| ХН78Т | 100…200…300…400…500…600…700…800 | 12,2…13…13,4…13,8…14,1…14,7…15,7…15,5 |

Directory

| Material | Coefficient of linear thermal expansion | |

| 10-6 °С-1 | 10-6 °F-1 | |

| ABS (acrylonitrile butadiene styrene) thermoplastic | 73.8 | 41 |

| ABS - fiber reinforced glass | 30.4 | 17 |

| Acrylic material, pressed | 234 | 130 |

| Diamond | 1.1 | 0.6 |

| Diamond technical | 1.2 | 0.67 |

| Aluminum | 22.2 | 12.3 |

| Acetal | 106.5 | 59.2 |

| Acetal, glass fiber reinforced | 39.4 | 22 |

| Cellulose acetate (CA) | 130 | 72.2 |

| Cellulose acetate butyrate (CAB) | 25.2 | 14 |

| Barium | 20.6 | 11.4 |

| Beryllium | 11.5 | 6.4 |

| Beryllium-copper alloy (Cu 75, Be 25) | 16.7 | 9.3 |

| Concrete | 14.5 | 8.0 |

| Concrete structures | 9.8 | 5.5 |

| Bronze | 18.0 | 10.0 |

| Vanadium | 8 | 4.5 |

| Bismuth | 13 | 7.3 |

| Tungsten | 4.3 | 2.4 |

| Gadolinium | 9 | 5 |

| Hafnium | 5.9 | 3.3 |

| Germanium | 6.1 | 3.4 |

| Holmium | 11.2 | 6.2 |

| Granite | 7.9 | 4.4 |

| Graphite, pure | 7.9 | 4.4 |

| Dysprosium | 9.9 | 5.5 |

| Wood, fir, spruce | 3.7 | 2.1 |

| Oak wood, parallel to the grain | 4.9 | 2.7 |

| Oak wood, perpendicular to the grain | 5.4 | 3.0 |

| Wood, pine | 5 | 2.8 |

| Europium | 35 | 19.4 |

| Iron, pure | 12.0 | 6.7 |

| Iron, cast | 10.4 | 5.9 |

| Iron, wrought | 11.3 | 6.3 |

| Gold | 14.2 | 8.2 |

| Limestone | 8 | 4.4 |

| Invar (iron-nickel alloy) | 1.5 | 0.8 |

| Inconel (alloy) | 12.6 | 7.0 |

| Iridium | 6.4 | 3.6 |

| Ytterbium | 26.3 | 14.6 |

| Yttrium | 10.6 | 5.9 |

| Cadmium | 30 | 16.8 |

| Potassium | 83 | 46.1 — 46.4 |

| Calcium | 22.3 | 12.4 |

| Masonry | 4.7 — 9.0 | 2.6 — 5.0 |

| Rubber, hard | 77 | 42.8 |

| Quartz | 0.77 — 1.4 | 0.43 — 0.79 |

| Ceramic tiles (tiles) | 5.9 | 3.3 |

| Brick | 5.5 | 3.1 |

| Cobalt | 12 | 6.7 |

| Constantan (alloy) | 18.8 | 10.4 |

| Corundum, sintered | 6.5 | 3.6 |

| Silicon | 5.1 | 2.8 |

| Lanthanum | 12.1 | 6.7 |

| Brass | 18.7 | 10.4 |

| Ice | 51 | 28.3 |

| Lithium | 46 | 25.6 |

| Cast steel grating | 10.8 | 6.0 |

| Lutetium | 9.9 | 5.5 |

| Cast Acrylic Plastic Sheet | 81 | 45 |

| Magnesium | 25 | 14 |

| Manganese | 22 | 12.3 |

| Copper-nickel alloy 30% | 16.2 | 9 |

| Copper | 16.6 | 9.3 |

| Molybdenum | 5 | 2.8 |

| Monel metal (nickel-copper alloy) | 13.5 | 7.5 |

| Marble | 5.5 — 14.1 | 3.1 — 7.9 |

| Soapstone (steatite) | 8.5 | 4.7 |

| Arsenic | 4.7 | 2.6 |

| Sodium | 70 | 39.1 |

| Nylon, universal | 72 | 40 |

| Nylon, Type 11 | 100 | 55.6 |

| Nylon, Type 12 | 80.5 | 44.7 |

| Nylon cast, Type 6 (Type 6) | 85 | 47.2 |

| Nylon, Type 6/6, molding compound | 80 | 44.4 |

| Neodymium | 9.6 | 5.3 |

| Nickel | 13.0 | 7.2 |

| Niobium (Columbium) | 7 | 3.9 |

| Cellulose Nitrate (CN) | 100 | 55.6 |

| Alumina | 5.4 | 3.0 |

| Tin | 23.4 | 13.0 |

| Osmium | 5 | 2.8 |

| Palladium | 11.8 | 6.6 |

| Sandstone | 11.6 | 6.5 |

| Platinum | 9.0 | 5.0 |

| Plutonium | 54 | 30.2 |

| Polyallomer | 91.5 | 50.8 |

| Polyamide (PA) | 110 | 61.1 |

| Polyvinyl chloride (PVC) | 50.4 | 28 |

| Polyvinylidene fluoride (PVDF) | 127.8 | 71 |

| Polycarbonate (PC) | 70.2 | 39 |

| Polycarbonate - glass fiber reinforced | 21.5 | 12 |

| Polypropylene - glass fiber reinforced | 32 | 18 |

| Polystyrene (PS) | 70 | 38.9 |

| Polysulfone (PSO) | 55.8 | 31 |

| Polyurethane (PUR), hard | 57.6 | 32 |

| Polyphenylene - glass fiber reinforced | 35.8 | 20 |

| Polyphenylene (PP), unsaturated | 90.5 | 50.3 |

| Polyester | 123.5 | 69 |

| Glass fiber reinforced polyester | 25 | 14 |

| Polyethylene (PE) | 200 | 111 |

| Polyethylene - terephthaly (PET) | 59.4 | 33 |

| Praseodymium | 6.7 | 3.7 |

| Solder 50 - 50 | 24.0 | 13.4 |

| Promethium | 11 | 6.1 |

| Rhenium | 6.7 | 3.7 |

| Rhodium | 8 | 4.5 |

| Ruthenium | 9.1 | 5.1 |

| Samarium | 12.7 | 7.1 |

| Lead | 28.0 | 15.1 |

| Lead-tin alloy | 11.6 | 6.5 |

| Selenium | 3.8 | 2.1 |

| Silver | 19.5 | 10.7 |

| Scandium | 10.2 | 5.7 |

| Mica | 3 | 1.7 |

| Hard alloy K20 | 6 | 3.3 |

| Hastelloy alloy C | 11.3 | 6.3 |

| Steel | 13.0 | 7.3 |

| Austenitic stainless steel (304) | 17.3 | 9.6 |

| Austenitic stainless steel (310) | 14.4 | 8.0 |

| Austenitic stainless steel (316) | 16.0 | 8.9 |

| Ferritic stainless steel (410) | 9.9 | 5.5 |

| Showcase glass (mirror, sheet) | 9.0 | 5.0 |

| Pyrex glass, pyrex | 4.0 | 2.2 |

| Refractory glass | 5.9 | 3.3 |

| Construction (lime) mortar | 7.3 — 13.5 | 4.1-7.5 |

| Strontium | 22.5 | 12.5 |

| Antimony | 10.4 | 5.8 |

| Thallium | 29.9 | 16.6 |

| Tantalum | 6.5 | 3.6 |

| Tellurium | 36.9 | 20.5 |

| Terbium | 10.3 | 5.7 |

| Titanium | 8.6 | 4.8 |

| Thorium | 12 | 6.7 |

| Thulium | 13.3 | 7.4 |

| Uranus | 13.9 | 7.7 |

| Porcelain | 3.6-4.5 | 2.0-2.5 |

| Phenolic-aldehyde polymer without additives | 80 | 44.4 |

| Fluoroethylene propylene (FEP) | 135 | 75 |

| Chlorinated Polyvinyl Chloride (CPVC) | 66.6 | 37 |

| Chromium | 6.2 | 3.4 |

| Cement | 10.0 | 6.0 |

| Cerium | 5.2 | 2.9 |

| Zinc | 29.7 | 16.5 |

| Zirconium | 5.7 | 3.2 |

| Slate | 10.4 | 5.8 |

| Plaster | 16.4 | 9.2 |

| Ebonite | 76.6 | 42.8 |

| Epoxy resin, cast rubber and unfilled products thereof | 55 | 31 |

| Erbium | 12.2 | 6.8 |

| Ethylene vinyl acetate (EVA) | 180 | 100 |

| Ethylene and ethyl acrylate (EEA) | 205 | 113.9 |

| Ether vinyl | 16 — 22 | 8.7 — 12 |

Note: Reference data is sourced from online publications and may not be considered "official" or "completely accurate." As a rule, Internet directories do not provide links to scientific works that are the basis of published data. We try to take information from the most reliable scientific sites. However, if anyone is interested in links to experiments, we advise you to conduct an in-depth search on the Internet yourself. We will be grateful for any comments on our reference tables, and especially for clarification of existing information or addition of reference data.

You may also be interested in:

Volume expansion coefficient

TCLE of materials used in electronics

Manganese and chromium-manganese steels

The table presents the average values of the coefficients of thermal linear expansion of manganese and chromium-manganese steels in the temperature range from -269 to 1000°C. It should be noted that 30KhGSA steel has the minimum TCLE at high temperatures.

Linear expansion coefficients of manganese and chromium-manganese steel

| steel grade | Temperature, °C | TCLE 10 6 1/deg |

| Steel 20G | -243…-173…-73…27 | 0,3…5,8…10…11,9 |

| Steel 20GK | 100…200…300…400…500…600 | 10,5…11,8…12,6…13,1…13,7…14 |

| Steel 50G | 100…200…300…400…500…600 | 11,6…11,8…12,8…13,8…14,2…14,6 |

| 03X13AG19 | -263…-233…-173…-73…27 | 0,05…0,4…4…7,4…14,4 |

| 03X13AG19 | 100…200…300…400…500…600…700…800 | 13,9…16,8…18,7…19,4…20,4…21,8…21,8…22,5 |

| 07X13AG20N4 | -253…-196…20 | -0,2…3…15,3 |

| 07X21G7AN5 | -269…-253…-203…-73…27 | -0,03…-0,13…3,1…5,8…15,7 |

| 10Х14Г14Н4Т | -253…-173…-73 | 0,5…5,1…9,2 |

| 10Х14Г14Н4Т | 100…200…300…400…500…600…700…800 | 15,3…15,8…18,9…19,1…19,1…20…20,1…21,1 |

| 12X17G9AN4 | -223…-173…-73…27 | 3,6…9,1…14,1…14,6 |

| 14G2AF | -269…-253…-173…-73…27 | 0,035…0,23…9…14,4…15,9 |

| 20ХГНР | 200…300…400…500…600…700 | 11,7…12,7…13,5…14…14,3…15,2 |

| 25ХГСА | 100…200…300…400…500…600…700 | 13,2…13,9…14…14,3…14,9…14,9…15,1 |

| 30G2 | 100…200…300…400…500…600…700…800…900…1000 | 11,9…12,7…13,4…13,9…14,3…14,7…15,1…13,6…13,7…14,5 |

| 30ХГСА | -223…-173…100…200…300…400…500…600 | 7,6…9,5…12…12,5…12,9…13,2…13,6…13,9 |

| 65G | 100…200…300…400…600 | 11,1…11,9…12,9…13,5…14,6 |

| G13 | 100…200…300…400…500…600…700…800…900…1000 | 18…19,4…20,7…21,7…20,8…19,9…20,5…21,9…23,5…23,2 |

| Х12Г20Ф | 100…200…300…400…500…600…700 | 15,4…16,9…17,5…18,2…18,9…19,7…20,5 |

| Х14Г14Н3Т | 100…200…300…400…500…600…700 | 16…16,8…17,6…18,3…19…19,5…20,1 |

| Х15Г21Т | 100…200…300…400…500…600…700…800 | 15,3…16,6…17,8…18,9…19,6…20,3…20,9…21,5 |

Thermal expansion

The vast majority of substances expand when heated. This is easily explained from the perspective of the mechanical theory of heat, since when heated, the molecules or atoms of a substance begin to move faster. In solids, atoms begin to vibrate with greater amplitude around their average position in the crystal lattice, and they require more free space. As a result, the body expands. Likewise, liquids and gases, for the most part, expand with increasing temperature due to an increase in the speed of thermal movement of free molecules ( see.

Boyle-Marriott's law, Charles's law, Equation of state of an ideal gas).

The basic law of thermal expansion states that a body with linear dimension L

in the corresponding dimension, with an increase in its temperature by Δ

T

it expands by an amount Δ

L

equal to:

Δ L

=

αL

Δ

T

where α —

so-called

coefficient of linear thermal expansion.

Similar formulas are available for calculating changes in area and volume of a body. In the simplest case presented, when the coefficient of thermal expansion does not depend on either the temperature or the direction of expansion, the substance will expand uniformly in all directions in strict accordance with the above formula.

For engineers, thermal expansion is a vital phenomenon. When designing a steel bridge across a river in a city with a continental climate, it is impossible not to take into account possible temperature changes ranging from -40°C to +40°C throughout the year. Such differences will cause a change in the overall length of the bridge up to several meters, and so that the bridge does not heave in the summer and does not experience powerful tensile loads in the winter, the designers compose the bridge from separate sections, connecting them with special thermal buffer joints

, which are rows of teeth that engage, but are not rigidly connected, that close tightly in the heat and diverge quite widely in the cold. On a long bridge there may be quite a few of these buffers.

However, not all materials, especially crystalline solids, expand uniformly in all directions. And not all materials expand equally at different temperatures. The most striking example of the latter kind is water. When water cools, it first contracts, like most substances. However, from +4°C to the freezing point of 0°C, water begins to expand when cooled and contract when heated (from the point of view of the above formula, we can say that in the temperature range from 0°C to +4°C the coefficient of thermal expansion water α

takes a negative value). It is thanks to this rare effect that the earth's seas and oceans do not freeze to the bottom even in the most severe frosts: water colder than +4°C becomes less dense than warmer water and floats to the surface, displacing water with a temperature above +4°C to the bottom.

The fact that ice has a specific density lower than the density of water is another (although not related to the previous one) anomalous property of water, to which we owe the existence of life on our planet. If not for this effect, the ice would sink to the bottom of rivers, lakes and oceans, and they, again, would freeze to the bottom, killing all living things.

Chrome-molybdenum steels

Chromium-molybdenum steels, compared to other types, have relatively low TCLE values. The coefficients of linear expansion of steel of this type have a value of 9.7...15.5·10 -6 deg -1 at temperatures up to 1000°C.

Linear expansion coefficients of chrome-molybdenum steel

| steel grade | Temperature, °C | TCLE 10 6 1/deg |

| Steel 12ХМ, 12МХ | 100…200…300…400…500…600…700 | 11,2…12,5…12,7…12,9…13,2…13,5…13,8 |

| Steel 15ХМ | 100…200…300…400…500…600…700…800…900…1000 | 12,2…13…13,3…13,7…14…14,3…14,5…13,4…11,2…12,5 |

| Steel 15M, 16M, 20M | 100…200…300…400…500…600 | 12…12,6…13,2…13,7…14,2…14,7 |

| Steel 20ХМ | 100…200…300…400…500…600 | 11,8…12,5…13…13,6…14…14,3 |

| 1Х2М | 100…200…300…400…500…600 | 12,1…12,3…12,8…13,2…13,8…14 |

| 1Х13М2С1 | 100…200…300…400…500…600…700…800…900…1000 | 10,2…10,8…11,3…11,7…12…12,4…12,6…13…13…13,6 |

| 1Х13М2ФБР | 100…200…300…400…500…600…700…800…900…1000 | 9,7…10,6…11,5…11,6…11,8…12,2…12,2…12,6…12,4…12,6 |

| 10Х7МВФБР | 100…200…300…400…500…600…700 | 10,3…11,6…12,4…12,8…13,3…13,6…13,4 |

| 12Х12МВФБ | 100…200…300…400…500…600…700…800…900 | 10,3…11,6…11,6…11,6…13,9…12,7…15…10,5…13,9 |

| 12X12MVFBR | 100…200…300…400…500…600…700…800…900 | 11,2…11,2…11,4…11,8…12…12,2…12,2…12,7…11,6 |

| 12Х13М2С2 | 100…200…300…400…500…600…700…800…900…1000 | 10,5…11,2…12…12,3…12,5…12,8…13…13,5…14,1…13,9 |

| 12Х1МФ | 100…200…300…400…500…600…700…800…900 | 12,4…13…13,6…14…14,4…14,7…14,9…14,8…12 |

| 12Х2МБ, 1Х2МФБ | 100…200…300…400…500…600 | 12,3…12,4…12,6…12,6…13,3…13,5 |

| 12X2MFSR | 100…200…300…400…500…600…700…800…900 | 11,9…12,9…13,6…14…14,4…14,8…15,2…15,5…12,4 |

| 15Х11МФ | 100…200…300…400…500…600…700…800 | 10,3…10,6…10,8…11,3…11,7…12…12,2…12,4 |

| 15Х1М1Ф | 100…200…300…400…500…600 | 11,2…11,7…12,5…13…13,5…13,7 |

| 15Х1М1ФК1Р | 100…200…300…400…500…600…700 | 12,1…12,5…13,1…13,8…14,6…14,9…14,6 |

| 15Х2М2ФБС | 100…200…300…400…500…600…700…800…900 | 11,5…12,3…12,9…13,4…13,8…14,3…14,6…14,9…13 |

| 15Х5М | 100…200…300…400…500…600 | 11,3…11,6…11,9…12,2…12,3…12,5 |

| 18Х11МФБ | 100…200…300…400…500…600…700…800 | 10,3…10,6…10,8…11,3…11,7…11,8…12…12,4 |

| 20Х1М1Ф | 100…200…300…400…500…600…700…800…900 | 12…12,4…12,9…13,2…13,5…13,8…13,9…14,3…12,7 |

| 20Х1М1Ф1ТР | 200…300…400…500…600 | 12…12,3…12,9…13…13,6 |

| 20HML | 100…200…300…400…500…600 | 10,9…12,4…12,8…13,1…13,6…13,9 |

| 20ХМФЛ | 100…200…300…400…500…600 | 10…11,9…12,9…13,1…13,5…13,8 |

| 25Х1М1Ф | 100…200…300…400…500…600…700 | 10,9…12…12,7…13,7…13,7…13,8…14 |

| 25Х1МФ | 100…200…300…400…500…600 | 11,3…11,7…12,8…13,2…14,2…14,4 |

| 25Х2М1Ф | 100…200…300…400…500…600 | 12,5…12,9…13,3…13,7…14…14,7 |

| 30ХМ, 30ХМА | 100…200…300…400…500 | 11,6…12,5…13,2…13,8…14,3 |

| 34ХМ, 35ХМ | 100…200…300…400…500…600 | 12,3…12,6…13,3…13,9…14,3…14,6 |

| 35HMFA | 100…200…300…400…500…600…700 | 11,8…12,5…12,7…13…13,4…13,7…14 |

| 38ХМУА | 100…200…300…400…500…600 | 12,3…13,1…13,3…13,5…13,5…13,8 |

| X3MVSE | 100…200…300…400…500…600…700…800…900…1000 | 10,6…11,5…12,3…12,7…13,1…13,3…13,4…13,1…11,5…10,4 |

Chrome tungsten and chrome vanadium steels

The table shows the average linear expansion coefficients of chrome-tungsten and chrome-vanadium steels for the temperature range from 27 to 1000°C. The table shows that these types of steel have similar TCLE values.

Linear expansion coefficients of chrome-tungsten and chrome-vanadium steel

| steel grade | Temperature, °C | TCLE 10 6 1/deg |

| Chrome tungsten steels | ||

| 15Х12ВНМФ | 100…200…300…400…500…600…700…800…900…1000 | 10…10,5…10,7…11…11,2…11,5…11,6…11,8…10,7…11,7 |

| 18Х12ВМБФР | 100…200…300…400…500…600…700…800 | 11,5…11,1…11,4…11,8…12…12,5…12,7…11,6 |

| 20Х3ВМФ | 400…500…600 | 12,3…12,8…13,8 |

| 28ХВФЦ | 100…200…300…400…500 | 11,8…12,1…12,8…12,9…13,2 |

| 38ХВФУА | 100…200…300…400…500…600…700…800…900 | 12,3…12,9…13,1…13,4…13,8…14,1…14,5…14,1…11,6 |

| 3ХВ8Ф | 100 | 11,2 |

| 4Х4ВМФС | 100 | 11,4 |

| 4Х4ВМФСШ | 100 | 11,6 |

| Х11В2НМФ | 100…200…300…400…500…600 | 10,5…11,2…11,9…12,6…12,8…13,1 |

| Х12В2МФ | 100…600 | 10,8…13,5 |

| Chrome vanadium steels | ||

| 12Х2ФБ | 100…200…300…400…500…600…700 | 11,5…12,2…12,4…12,9…13,2…13,4…13,5 |

| 15HF | 100…200…300…400…500…600…700 | 11,9…12,4…13,1…13,7…14,2…14,5…14,9 |

| 40HFA | 100…300…600 | 11…12,9…14,5 |

| 50HFA | 100…200…300…400…500…600 | 11,8…12,4…13,1…13,6…13,9…14,1 |

| 70Х4Ф1В18 | 100…200…300…400…500…600…700…800…900…1000 | 11,3…11,7…12…12,2…12,4…12,6…12,8…12,9…11,4…12,5 |

Silicon, titanium and other steels and alloys

The table contains the values of the average linear expansion coefficient of titanium, silicon and other steels and alloys in the temperature range from 27 to 1000°C.

The steel types considered have a relatively low TCLE, which, for example, for E16 steel is only 7·10-6 deg-1 at a temperature of 27-100°C. Linear expansion coefficients of silicon, titanium and other steels and alloys

| steel grade | Temperature, °C | TCLE 106 1/deg |

| Silicon steels | ||

| 15HSMB | 100…200…300…400…500…600 | 10,1…11,7…12,2…12,6…14…13,7 |

| 15HSMF | 100…200…300…400…500…600 | 11,8…12,1…12,4…12,6…12,9…13,1 |

| 30ХС, 37ХС, 40ХС | 100…200…300…400…500…600 | 11,7…12,7…13,4…14…14,4…14,5 |

| 50S2G | 100…200…300…400…500…600…700…800…900…1000 | 11,2…12,2…12,9…13,4…13,7…14,1…14,4…13,6…13,7…14,5 |

| 60С2А | 100…200…400…500 | 12…12,8…13,5…13,4 |

| СХ6М | 100…500…600…700 | 11…12…12,2…12,4 |

| Titanium and other steels and alloys | ||

| 15Х25Т | 200…300…400…500…600…700…800…900…1000 | 10…10,6…10,8…11,3…11,5…11,6…11,6…12,2…12,2 |

| 48TS-1, 48TS-2, 48TS-3 | 27-300 | 11,9-12,6 |

| HVG | 100…200…300…400…500…600 | 11…12…13…13,5…14…14,5 |

| E (Armco) | 200…300…400…500 | 11,7…13…13,7…14,2 |

| E1 | 100…200…300…400…500…600…700 | 10,8…12,6…13,8…14,6…14,8…14,3…14,3 |

| E14 | 200…300…400…500…600…700 | 11,7…12,7…13,7…14,7…15,6…15,4 |

| E16 | 100…200…300…400…500…600…700 | 7…10,7…13,1…14,3…14,6…14,3…13,2 |

| E5 | 100…200…300…400…500…600…700 | 10,6…11,8…13…14…14,7…15,3…15,6 |

Sources:

- Novitsky L.A. Thermophysical properties of materials at low temperatures.

- Physical properties of steels and alloys used in energy. Directory. Ed. Neymarka B.E. M.-L.: Energy, 1967.

- Tables of physical quantities. Directory. Ed. I.K. Kikoina. M.: Atomizdat, 1976.

- Kuzminov Yu.S. Ferroelectric crystals for controlling laser radiation. M.: Nauka, 1982.

- Solntsev Yu.N., Stepanov G.A. Materials in cryogenic technology. Directory. L.: Mechanical Engineering, 1982.

- Pridantsev M.V. etc. Structural steels. Directory. M.: Metallurgy, 1980.

- Ulyanin E.A., Sorokina N.A. Steels and alloys in cryogenic technology. Directory. M.: Metallurgy, 1984.

Chromium-cobalt steels and alloys

Chromium-cobalt steels have a temperature coefficient of linear expansion of 12...17.7·10 -6 deg -1 at temperatures up to 300°C and 15.5...17.8·10 -6 deg -1 at high temperatures. Of particular note is steel 40K44Kh20N20M4V4B4, the average expansion coefficient of which practically does not change in the range from 300 to 1000°C.

Coefficients of linear expansion of chromium-cobalt steel

| steel grade | Temperature, °C | TCLE 10 6 1/deg |

| Steel 15K, 20K | 200…300…400…500…600 | 12…12,8…13,2…13,5…13,9 |

| Steel 22K, 25K | 200…300…400…500 | 12,2…13…13,3…13,9 |

| 03Х9К14Н6М3Д | -264…-253…-203…-163…27 | -0,08…0,3…4,4…7,4…13,2 |

| 12К51Х20Н10В15 | 300…500…600…700…800 | 13,7…14,7…15,3…15,9…16,3 |

| 15К20Х20Н20М3В2Б | 300…400…500…600…700…800 | 15,6…16…16,3…16,7…17,1…17,6 |

| 25К65Х25Н2М5 | 300…400…500…600…700 | 14,1…14,3…14,6…14,9…15,4 |

| 40К19Х14Н20М4В4Б4 | 300…400…500…600…700…800 | 14,3…14,5…14,8…15,1…15,4…15,8 |

| 40К20Х20Н20М4В4Б4 | 300…400…500…600…700…800…900 | 15,2…15,3…15,4…15,5…15,7…16,1…16,7 |

| 40К30Х20Н20М8В4 | 300…400…500…600…700…800…900 | 13,7…14,2…14,7…15,1…15,5…16…16,6 |

| 40К44Х19Н10В15 | 300…400…500…600…700…800…900 | 14,5…14,7…14,9…15,3…15,7…16,3…16,9 |

| 40К44Х20Н20М4В4Б4 | 300…400…500…600…700…800…900 | 17,7…17,6…17,6…17,6…17,6…17,7…17,8 |

| 40К51Х24Н16М6 | 300…400…500…600…700…800…900 | 13,9…14,1…14,2…14,4…14,7…15,1…15,5 |

| 40К55Х25Н10В8 | 300…400…500…600…700…800…900 | 14,1…14,4…14,9…15,5…16,4…16,7…16,8 |

| 40К65Х23Н2В6 | 300…400…500…600…700…800 | 13,7…14,2…14,6…15,1…15,7…16,3 |

| 75К41Х23Н20В12 | 300…400…500…600…700…800 | 14,2…14,3…14,6…14,9…15,3…15,9 |

| 125К65Х27В4С3 | 300…400…500…600…700…800 | 14,5…14,7…14,9…15,3…15,7…16,3 |

| V3K stellite | 600…1000 | 14…16 |

Coefficient of linear expansion of concrete and iron

| Thermal expansion coefficient | |

| β = 1 V ( d V d T ) p {displaystyle eta ={frac {1}{V}}left({frac {dV}{dT}} ight)_{p}} | |

| Dimension | −1 |

| Units | |

| −1 | |

| GHS | −1 |

Coefficient of thermal expansion

- a physical quantity characterizing the relative change in the volume or linear dimensions of a body with an increase in temperature by 1 at constant pressure. Has the dimension of inverse temperature. There are coefficients of volumetric and linear expansion.

Coefficient of linear thermal expansion

α L = 1 L ( ∂ L ∂ T ) p ≈ Δ LL Δ T {displaystyle alpha _{L}={frac {1}{L}}left({frac {partial L}{partial T}} ight)_ {p}approx {Delta L over {LDelta T}}} , К−1 (°C−1) - a relative change in the linear dimensions of a body resulting from a change in its temperature by 1 K at constant pressure.

In general, the coefficient of linear thermal expansion may be different when measured along different directions. For example, anisotropic crystals and wood have linear expansion coefficients along three mutually perpendicular axes: α x ; αy ; α z {displaystyle alpha _{x};alpha _{y};alpha _{z}} .

For isotropic bodies α x = α y = α z {displaystyle alpha _{x}=alpha _{y}=alpha _{z}} and α V = 3 α L {displaystyle alpha _{V}=3alpha _{L }} .

For example, water, depending on temperature, has a different coefficient of volumetric expansion:

- 0.53·10−4 K-1 (at a temperature of 5–10 °C);

- 1.50·10−4 K-1 (at a temperature of 10–20 °C);

- 3.02·10−4 K-1 (at a temperature of 20–40 °C);

- 4.58·10−4 K-1 (at a temperature of 40–60 °C);

- 5.87·10−4 K-1 (at a temperature of 60–80 °C).

For iron, the coefficient of linear expansion is 11.3×10−6 K−1[1].

For steels

Table of linear expansion coefficient values α, 10−6K−1[2]

| steel grade | 20—100 °C | 20—200 °C | 20—300 °C | 20—400 °C | 20—500 °C | 20—600 °C | 20—700 °C | 20—800 °C | 20—900 °C | 20—1000 °C |

| 08kp | 12,5 | 13,4 | 14,0 | 14,5 | 14,9 | 15,1 | 15,3 | 14,7 | 12,7 | 13,8 |

| 08 | 12,5 | 13,4 | 14,0 | 14,5 | 14,9 | 15,1 | 15,3 | 14,7 | 12,7 | 13,8 |

| 10kp | 12,4 | 13,2 | 13,9 | 14,5 | 14,9 | 15,1 | 15,3 | 14,7 | 14,8 | 12,6 |

| 10 | 11,6 | 12,6 | — | 13,0 | — | 14,6 | — | — | — | — |

| 15kp | 12,4 | 13,2 | 13,9 | 14,5 | 14,8 | 15,1 | 15,3 | 14,1 | 13,2 | 13,3 |

| 15 | 12,4 | 13,2 | 13,9 | 14,4 | 14,8 | 15,1 | 15,3 | 14,1 | 13,2 | 13,3 |

| 20kp | 12,3 | 13,1 | 13,8 | 14,3 | 14,8 | 15,1 | 20 | — | — | — |

| 20 | 11,1 | 12,1 | 12,7 | 13,4 | 13,9 | 14,5 | 14,8 | — | — | — |

| 25 | 12,2 | 13,0 | 13,7 | 14,4 | 14,7 | 15,0 | 15,2 | 12,7 | 12,4 | 13,4 |

| 30 | 12,1 | 12,9 | 13,6 | 14,2 | 14,7 | 15,0 | 15,2 | — | — | — |

| 35 | 11,1 | 11,9 | 13,0 | 13,4 | 14,0 | 14,4 | 15,0 | — | — | — |

| 40 | 12,4 | 12,6 | 14,5 | 13,3 | 13,9 | 14,6 | 15,3 | — | — | — |

| 45 | 11,9 | 12,7 | 13,4 | 13,7 | 14,3 | 14,9 | 15,2 | — | — | — |

| 50 | 11,2 | 12,0 | 12,9 | 13,3 | 13,7 | 13,9 | 14,5 | 13,4 | — | — |

| 55 | 11,0 | 11,8 | 12,6 | 13,4 | 14,0 | 14,5 | 14,8 | 12,5 | 13,5 | 14,4 |

| 60 | 11,1 | 11,9 | — | 13,5 | 14,6 | — | — | — | — | — |

| 15K | — | 12,0 | 12,8 | 13,6 | 13,8 | 14,0 | — | — | — | — |

| 20K | — | 12,0 | 12,8 | 13,6 | 13,8 | 14,2 | — | — | — | — |

| 22 | 12,6 | 12,9 | 13,3 | 13,9 | — | — | — | — | — | — |

| A12 | 11,9 | 12,5 | — | 13,6 | 14,2 | — | — | — | — | — |

| 16GS | 11,1 | 12,1 | 12,9 | 13,5 | 13,9 | 14,1 | — | — | — | — |

| 20X | 11,3 | 11,6 | 12,5 | 13,2 | 13,7 | — | — | — | — | — |

| 30X | 12,4 | 13,0 | 13,4 | 13,8 | 14,2 | 14,6 | 14,8 | 12,0 | 12,8 | 13,8 |

| 35X | 11,3 | 12,0 | 12,9 | 13,7 | 14,2 | 14,6 | — | — | — | — |

| 38ХА | 11,0 | 12,0 | 12,2 | 12,9 | 13,5 | — | — | — | — | — |

| 40X | 11,8 | 12,2 | 13,2 | 13,7 | 14,1 | 14,6 | 14,8 | 12,0 | — | — |

| 45X | 12,8 | 13,0 | 13,7 | — | — | — | — | — | — | — |

| 50X | 12,8 | 13,0 | 13,7 | — | — | — | — | — | — | — |

/ About Concrete / Coefficient of linear expansion of concrete and iron

The table shows the values of the coefficient of linear expansion of building materials (CTLE) and some metals at temperatures up to 100°C. The dimension of the expansion coefficient in the table is m/(m °C) or 1/deg (K -1).

The table considers: aluminum Al, copper Cu, steel, granite, basalt, quartzite, sandstone, limestone, wall brick, clinker brick, sand-lime brick, lightweight concrete stones, aerated concrete blocks, concrete, reinforced concrete, cement mortar, lime mortar, complex plasters, wood, parallel to the grain, glass.

Of these building materials, clinker brick has the lowest coefficient of thermal linear expansion (its CTE is 3.5·10 -6 1/deg), as well as wood, plasters, wall bricks and basalt.

It should be noted that a high coefficient of thermal expansion is characteristic of metals such as aluminum, copper or steel.

For example, the coefficient of linear expansion of aluminum is 24·10 -6 1/deg, which is 2 times more than that of steel.

The coefficient of thermal linear expansion shows how much (relative to the size of the body) the material will elongate when its temperature increases by 1 degree.

To calculate the increase in the linear dimensions of a material due to thermal expansion, it is necessary to multiply the value of the temperature coefficient of linear expansion by the linear dimension of the material and by the temperature difference in degrees Celsius or Kelvin. For example, a wall brick (CTLR = 0.000006 deg -1) with a length of 240 mm will elongate by 0.144 mm when heated by 100 degrees.

From the values of the coefficients of thermal expansion in the table, it can be seen that the indicated building materials and metals have a positive coefficient of linear expansion, that is, they increase their size (expand) when heated.

source

Tables of values of the average temperature coefficient of linear expansion of steels TCLR (or TKR) of common grades (more than 300 steel grades) are presented at various temperatures in the range from 27°C to that indicated in the tables. For negative temperatures, the values of the true linear expansion coefficient are given.

The temperature coefficient of linear thermal expansion of steel is numerically equal to the relative change in its linear dimensions with an increase (decrease) in the temperature of this alloy by 1 degree Celsius or Kelvin.

With a positive value of TCLE during heating, the steel increases in size (expands); with a negative value of this coefficient, it contracts. Steel has a negative TCLE at ultra-low temperatures approaching absolute zero (-273.15°C). Under these conditions, the coefficient of linear expansion of steel has a small negative value and is practically equal to zero.

At temperatures from 27 to 100°C, the temperature coefficient of linear expansion of steel averages from 10 to 18·10 -6 deg -1. Steel in a heated state (depending on the type) at 900-1000°C can have a TCLE of up to 24.6·10 -6 deg -1.

Let's calculate the linear elongation of a beam made of stainless steel 12Х18Н10Т with a length of 0.5 meters when its temperature increases from 27 to 1027°C. According to the table, the average coefficient of linear expansion of steel 12Х18Н10Т in the temperature range 27…1027°С is equal to 22.3·10 -6 deg -1. Let's perform the calculation: 22.3·10 -6 ·(1027-27)·0.5=0.0111. We get the linear elongation of the beam to be 0.0111 m.

The table shows the values of the linear expansion coefficient of carbon steel in the temperature range from -173 to 1000°C. When such steel is heated, its TCLE increases and can reach 19.8·10 -6 deg -1 (for U8 steel) in the temperature range 27-650°C.

Since carbon steel consists almost entirely of iron and does not contain nickel or chromium additives, its thermal expansion coefficient is largely determined by the coefficient of linear expansion of this main component. For example, the maximum coefficient of linear expansion of steel 20, like that of iron, is 14.8·10 -6 deg -1 in the temperature range from 27 to 700°C.

Linear expansion coefficients of carbon steel

| steel grade | Temperature, °C | TCLE 10 6 1/deg |

| Steel 3, steel 3KP | -173…-73…27 | 5,5…10,1…11,8 |

| Steel 08KP | 100…200…300…400…500…600…700 | 11,6…12,3…13,2…13,7…14,2…14,6…15 |

| Steel 10 | 100…200…300…400 | 11,6…12,6…13,0…14,6 |

| 15 | 100…200…300…400…500…600…700…800…900…1000 | 12,2…12,3…13,1…13,5…14,3…14,3…15,3…14,1…13,2…13,3 |

| 20, 20KP | 100…200…300…400…500…600…700…800 | 11,1…12,1…12,8…13,4…13,9…14,4…14,8…12,9 |

| 25 | 100…200…300…400…500…600…700 | 12,2…12,7…13,1…13,5…13,9…14,4…14,9 |

| 25L | 100…200…300…400…500…600 | 11,5…12,9…13…13,2…13,5…13,8 |

| 30 | 100…200…300…400…500…600…650 | 12,9…14,5…15,8…15,8…16,7…16,2…16,4 |

| 35 | 100…200…300…400…500 | 11,1…11,9…13,4…14…14,4 |

| 40 | 100…200…300…400…500…600…700…800…900…1000 | 11,2…13…13…13,6…14,1…14,6…14,6…11,9…12,7…13,6 |

| 45 | 100…200…300…400…500…600…700…800…900…1000 | 11,6…12,3…13,1…13,7…14,2…14,7…15,1…12,5…13,6…14,5 |

| 50 | -173…-73…27…100…300…500…700…900…1000 | 4,9…9,3…10,9…12…12,9…13,7…14,3…12,9…14 |

| U8 | 100…200…300…400…500…600…650 | 12,1…14…12,8…16,1…16,8…17,8…19,8 |

| U9 | 100…200…300…400…500…600…650 | 12,1…13,7…15,3…16,4…17,3…17,2…17,6 |

| U12 | 100…200…300…400…500…600…650 | 11,7…13,3…15,4…16,2…17,1…18,3…18,9 |

Negative coefficient of thermal expansion

Main article: Negative thermal expansion

Some materials, when the temperature increases, do not exhibit expansion, but rather contraction, i.e., they have a negative coefficient of thermal expansion.

For some substances this manifests itself in a rather narrow temperature range, such as for water in the temperature range 0...+3.984 °C, for other substances and materials, for example scandium(III) fluoride, zirconium tungstate (ZrW2O8)[3], some The range of carbon fiber reinforced plastics is very wide. Conventional rubber also exhibits similar behavior.

At ultra-low temperatures, quartz, silicon and a number of other materials behave in a similar way. There are also Invar alloys (ferro-nickel) that have a thermal expansion coefficient close to zero in a certain temperature range.

3.2. Thermal expansion of solids, liquids and gases

The relative change in the length of solids and the volume of solids, liquids and gases with an increase in temperature by ΔT is characterized, on the one hand, by the average linear expansion coefficient:

on the other hand, the average coefficient of volumetric expansion:

Here l0 and V0 are the length and volume of the body at temperature T0, l and V are the same quantities at temperature T.

The limiting values at ΔT>0 are called the true linear expansion coefficient:

and the true coefficient of volumetric expansion:

Dimensions of linear and volumetric expansion coefficients: K–1, °С–1.