The development of metallurgy has led to the emergence of new types of steels with special performance characteristics. They are used in the production of certain products and parts that have high demands. A similar example is steel ШХ15. Its main purpose is the manufacture of bearings, but its performance indicators are also actively used in knife production.

Steel strips ШХ15.

Steel for quality knives

ShKh15 was first created as a production tool steel, but over time it gained greater versatility and turned into one of the best alloys for making knives.

The metal lends itself well to heat treatment, which allows it to be actively used in the production of cutting tools. After heat treatment, the strength and wear resistance of knives increases significantly.

Blades made of ШХ15 have a long service life , since resistance to external loads allows them to hold an edge for a long time. They withstand the influence of the external environment well.

However, due to the low chromium content, this alloy is to some extent susceptible to corrosion processes.

Blade made of steel ШХ15.

ShKh15 steel for knives is used in the production of tactical, gift, hunting and kitchen models. Such products cope with cutting meat, chopping bones and branches, cutting thick ropes, and all household tasks without any problems. This knife will be a godsend for an avid cook. And if you carefully monitor and care for your instrument, it will last a long time.

Methods for determining bearing hardness

The hardness of a bearing determines its load-carrying capacity, stability and strength in rolling contacts. Measurements are carried out using three main methods: Brinell, Rockwell and Vickers. You can find their detailed description in the article “Brief description of hardness measurement methods.”

Control is performed using stationary or portable hardness testers. Let's take a closer look at how to measure the hardness of bearings using an ultrasonic hardness tester of the TKM series produced by NPP Mashproekt.

Characteristic

ShKh15 steel received its wide industrial distribution due to its special performance properties, which are ideal for the manufacture of blades and bearings. Characteristics of ШХ15 consists of the following parameters:

- High hardness index . Bearings and blades are subjected to high loads during use, resulting in rapid wear. To prevent this from happening, the product must have additional hardness.

- Wear resistance , that is, the surface of ShKh15 is not subject to abrasion, which allows it to maintain its original working properties for a long time.

- Poor resistance to corrosion . Due to the small content of such an important element as chromium in the chemical composition, this alloy rusts when exposed to moisture, but this process does not occur very quickly due to other alloying components.

- Resistance to high shock and external mechanical loads . This metal practically does not form dents from precise impacts.

- Plasticity and toughness in the alloy in question are at an average level due to its high hardness.

- The steel structure lends itself well to heat treatment . Quenching and annealing make it possible to improve strength at the molecular level.

- Tendency to temper brittleness, which means that there is a small chance that the metal may become more brittle after quenching due to structural defects. But strict adherence to all technologies allows you to avoid this.

- Poor weldability . The alloy achieves high hardness due to its high carbon content, an element that negatively affects weldability.

pros

Having studied in detail the characteristics of steel grade ШХ15, we can draw intermediate results. Among the advantages of this alloy, the following qualities clearly stand out:

- homogeneity of structure;

- high contact endurance;

- easy to process;

- great hardness;

- excellent wear resistance;

- thin edge when sharpening;

- resistance to crushing;

- plasticity and viscosity.

Minuses

Any steel, no matter how good it is, has drawbacks - it has not yet been possible to obtain a metal that is ideal in all respects. However, the disadvantages of the ShKh15 are not numerous, among them the following can be distinguished:

- above average fragility;

- relatively low corrosion resistance;

- Difficult sharpening of cutting tools.

There are many different grades of steel. Each of them has its own advantages and disadvantages. ShKh 15, in turn, is a very versatile steel, suitable for almost any type of knife. At the moment it is one of the most popular brands with low cost and is used mainly in private forging of blades.

Knife Berkut, steel ШХ15, oxidation coating.

A product made from such steel can give the desired result from the work, while significantly saving the budget due to its low cost.

Classification of bearing housings

Bearing housing is a part or assembly unit designed to fix one or a group of bearings and install them in a machine. Their classification includes the following types:

- according to the principle of fastening - on feet, flanged, with special types of fastenings, for example, for linear movement (T), for rotation;

- by the number of bearings per one, two, group;

- by material - cast iron, steel, aluminum, stainless steel, plastic;

- by type of workpiece - welded, cast, stamped, forged, from a solid billet;

- detachable and non-detachable;

- standardized, purchased serial, designed for a specific machine.

For large-scale production, the most rational and cheapest method is to obtain housing blanks for bearings by casting. Gray cast iron casting is more often used, providing rigidity and strength at low cost.

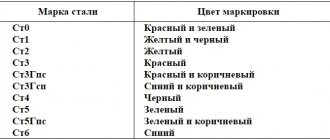

For special requirements, steel and aluminum castings are used. However, casting requires costs for molds and foundry equipment. In single or small-scale production, such costs are not recouped. In this case, welded blanks are used. The material is usually low carbon steel St3 or steel 20.

In the food industry, when there is a possibility of contact with the product, the need for sanitary treatment, and washing, stainless steel is used, for example 12Х18Н10Т. Bearing supports made of plastic are mainly made by injection molding. Housings made of durable chemical-resistant plastic and stainless steel are used in chemical equipment in addition to the food industry.

For tension supports, gray cast iron is often used as a material, forming a good friction pair with steel guides.

From solid rolled products, for example, a circle of support, they are made in small sizes.

Regardless of the type of workpiece, the housings are subjected to rough and finishing machining. Usually, the support feet are processed first by milling the plane or turning the flange. Using the supporting surfaces as a base, bore a hole for the bearing. If necessary, the ends for the covers are machined, grooves are made for spring thrust rings, and surfaces for sealing devices. Mounting holes are drilled on the flanges, feet, and holes for the covers. Threaded holes for grease fittings, channels and lubricant supply holes are made. Often, to allow for adjustment, grooves, rather than holes, are made on the paws.

Bores for bearings are usually made cylindrical for passage.

In some cases, sharpening is performed for axial fixation of bearings.

Chemical composition

ShKh15 steel has an unusual chemical composition , which determines its working properties. This brand belongs to low-alloy chromium alloys, which is due to a large number of base additives, which impart the same strength and wear resistance. The composition includes the following elements:

- Carbon (0.95-1%) – its fairly high concentration allows one to achieve increased hardness of the structure.

- Manganese (0.2-0.4%) is present in almost all steels. It is used to remove oxygen and sulfur from steel. It also has a beneficial effect on the ductility and weldability of steels.

- Silicon (0.17-0.37%) - used in steel smelting, has a positive effect on strength and improves the effect of other components. In combination with manganese or molybdenum, silicon provides higher hardenability of steel.

- Chromium (1.35-1.65%) – chromium ensures the alloy’s resistance to rust, but only if its content exceeds 13%. Therefore, ШХ15 is characterized by low corrosion resistance. A small amount of chromium determines that it does not form its own carbides, remains in solid solution and can be part of cementite. The structure is characterized by homogeneity with small carbides. It is this property that leads to increased wear resistance.

Decoding

At first glance, it may seem that the name of the alloy “ShKh15” is a simple set of beech. However, this is not at all true; these letters are abbreviation symbols and carry a semantic load. A person who knows at least a little about metal markings can extract some useful information from this name:

- Ш - according to GOST, all bearing steels are marked with this letter;

- X – means the presence of chromium in the chemical composition of steel;

- 15 – this is the percentage of chromium (1.5%).

GOST

State standards regulate the production stages, characteristics, properties of all steels, ShKh15 is no exception. All detailed information about bearing steels is contained in GOST 801-78. The permissible limit of elements in the chemical composition, correct hardening, correct labeling, application, etc. are indicated here. Also, for each individual product for the production of which ShKh15 is used, it has its own GOST. Types of material supply:

| B22 – Long and shaped rolled products | GOST 2590-2006; GOST 2591-2006; |

| B23 - Sheets and strips | GOST 103-2006; |

| B32 – Long and shaped rolled products | GOST 14955-77; GOST 7417-75; GOST 801-78; |

| B62 — Steel pipes and connecting parts for them | GOST 800-78; |

| B73 — Alloy steel wire | GOST 4727-83; |

Standardized and purchased enclosures

There are standardized bearing housings in accordance with GOST, the use of which allows you to speed up the design process, avoid errors, and reduce production costs. Cast housings type ШМ according to GOST 13218.1-80 are used for bearing diameters 47 ... 150 mm. These are wide bodies on feet with a through-type boring. They are non-detachable. For axial fixation of the bearings, places are provided for fastening the covers at the ends.

The ShM series for diameters 160...400 mm is determined by GOST 13218.2-80.

State standard 13218.3-80 defines the dimensions and technical requirements of a one-piece narrow body of the UM type on feet, with a bore through for outer ring diameters of 80...150 mm. For the size range 160...400 mm, the design parameters of the UM series are determined by GOST 13218.4-80.

Standardized wide cast large supports ШБ with fastening with paws and through boring for rolling bearings are determined by GOST 13218.5-80 for borings of 80...150 mm and GOST 13218.6-80 for diameters of 160...400 mm.

Dimensions and requirements for narrow large bodies with UB claws are specified by GOST 13218.7-80 for diameters of 80...150 mm and GOST 13218.8-80 for bores of 160...400 mm.

The design and dimensions of detachable wide RU housings on feet with boring through for rolling bearings with outer diameters of 110...400 mm are determined by GOST 13218.9-80, and for a series of split narrow RU - GOST 13218.10-80.

Standardized bearing housings are usually used in pairs to secure a long shaft using a floating bearing arrangement. The choice of support is made according to the diameter, width of the rolling bearing, and load level. The ends of the supports are closed with blind covers or with shaft seals. The bearing is placed in the floating support with gaps on the sides, and in the fixing support you can install spacer rings or make covers with sharpenings of the appropriate size. If it is difficult to ensure strict alignment, use spherical self-aligning ball or roller bearings that allow slight misalignment of the shaft axis.

For such supports, standardized end caps with reinforced cuff seals are suitable:

- low GOST 13219.5-81 for diameters 47...100 mm;

- low GOST 13219.6-81 for diameters 110...400 mm;

- medium GOST 13219.7-81 for diameters 47...100 mm;

- medium GOST 13219.8-81 for diameters 110...400 mm;

- high GOST 13219.9-81 for diameters 47…100 mm;

- high GOST 13219.10-81 for diameters 110...400 mm.

Specifications

The working properties of ShKh15 steel have already been discussed above. That information is a simple explanation that follows from the following characteristics of this alloy:

- brand: ШХ15;

- class: structural bearing steel;

- specific gravity : 7812 kg/m3

- heat treatment: annealing 800oC, oven, 15 oC/h;

- forging temperature, °C: beginning 1150, end 800. Sections up to 250 mm are cooled in air, 251-350 mm - in a pit;

- hardness : HB 10 -1 = 179 - 207 MPa (61-63 HRC);

- temperature of critical points: Ac1 = 724, Ac3(Acm) = 900, Ar3(Arcm) = 713, Ar1 = 700, Mn = 210;

- machinability by cutting: in the hot-woven state at HB 202 σв=740 MPa, K υ solid. spl=0.9 and Kυ b.st=0.36;

- weldability: welding method KTS;

- flake sensitivity: sensitive;

- tendency to temper brittleness : prone;

- grindability: good.

Processing Features

Heat treatment is an important technological process that allows one to increase the basic qualities of the metal. Usually, finished products are hardened, which makes their surface layer more durable.

Hardening ShKh15 has some difficulties. Since the properties of the metal initially include great hardness, and after processing it increases slightly, sharpening cutting tools becomes much more difficult. Hardened steel is difficult to cut, so parts are calcined only after they have been given their final shape. Thermal regimes largely depend on the temperature of critical points. In this case, the alloy cannot be cooled in water, as this will lead to structural deformations.

Annealing of ShKh15 takes place at 800 degrees Celsius , it eliminates internal stresses, which are common causes of chips and cracks. Cooling can be carried out in two ways: if the product is large - in the air, if small - in a pit.

Why do you need to measure the hardness of bearings?

There are a lot of manufacturers and suppliers of bearings for various purposes and of varying quality on the market.

Large and small bearings are an indispensable structural element in hydroelectric turbines, railway equipment, industrial equipment, cars, bicycles, scooters and many other machines and mechanisms. When purchasing large quantities of bearings, you should check their quality and compliance with GOST standards. This will avoid financial losses from purchasing low-quality (counterfeit) components, which can lead to interruptions in the operation of equipment, and will also protect the reputation of your company if you are a supplier.

Analogs

ШХ15 has a large number of analogues around the world . This is due to the fact that bearing steels are subject to the same requirements. The result is a similar chemical composition, production technology, and characteristics. Below is a table with similar alloys from different countries of the world, but it is worth considering that their properties, and even more so their cost, are not identical, but simply have many similarities.

| Foreign analogues of steel grade ШХ15 | |

| USA | 52100, G52986, J19965 |

| Germany | 1.3505, 100Cr6, 102Cr6 |

| Japan | SUJ2, SUJ4 |

| France | 100C6, 100Cr6, 100Cr6RR |

| England | 2S135, 534A99, 535A99 |

| China | GCr15 |

Application

The use of ShKh15 is largely due to its high strength indicators and wear resistance - the main advantages of this brand. The scope of application is quite wide , the alloy is used to obtain:

- rollers with a diameter of up to 23 mm;

- discharge valves;

- pusher rollers;

- plungers;

- balls for bearings.

Bearings made of steel ШХ15.

Although this steel is defined as bearing steel, its use is not limited to this. It is actively used in the production of knives and other cutting tools because it has the necessary basic set of useful qualities.

Owner reviews

Georgiy, 47 years old, Kyiv: “My NSK Serkh from shx15 survived 4 days of wet weather during the hike. The only (out of principle) care that he was subjected to was lubricating him 1-2 times a day with lard from SK sausage. A couple of weak spots, harmoniously aging the blade to a “combat” state. He did all the work that a machete and chain saw couldn’t do. He kept the sharpening well.”

Sergey, 34 years old, Ufa: “Numerous negative comments about ShKh15 forced me to write this review. I consider knives made from this steel to be workhorses. Yes, they rust, but take good care of them and you will be happy. But it rarely needs sharpening; it copes with all tasks from slicing sausage to opening canned food. I am pleased and do not share your indignation.”

Previous

KnivesKnife Gyurza 2 Kizlyar - a beautiful hunting product

Next

KnivesSteel 420j2