How does the abbreviation stand for?

Decoding of ST3PS steel is carried out in accordance with Gosstandart 380-2005:

- St – steel with a predominance of carbon;

- 3 – composition number;

- ps – semi-quiet (level of deoxidation).

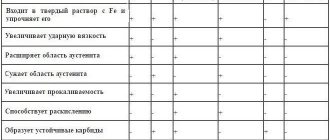

Designations and interpretation of letters of alloying elements of steels

A – nitrogen (indicated in the middle of the mark) B – niobium C – tungsten D – manganese D – copper E – selenium K – cobalt M – molybdenum N – nickel P – phosphorus P – boron C – silicon T – titanium F – vanadium X – chromium C – zirconium Yu – aluminum Ch – rare earth

Alloy structural steels

At the beginning of the stamp there is a two-digit number indicating the carbon content in hundredths of a percent. Alloying elements are listed below. The number following the symbol of the element shows its content as a percentage; if there is no number, then the content of the element does not exceed 1.5%. Steel 30Х2М. This grade of steel contains about 0.30% carbon, 2% chromium, and less than 1% molybdenum.

Alloy tool steels

At the beginning of the brand there is a single-digit number indicating the carbon content in tenths of a percent. If the carbon content is more than 1%, the number is not indicated; then alloying elements are listed, indicating their content.

Decoding the brand

The specifics of decoding any grade of metal are determined by the relevant regulatory documents, as well as GOSTs. For example, according to GOST 380, the following types of metal are available: steel St3SP, St3PS and St3KP.

Indexes are mandatory for any marking. This is an important note for the preparation of any documentation and descriptions in this type of activity.

When deciphering a brand, the following principle should be used:

- St is a formal designation used to indicate the common quality of carbon steel.

- 3 – digital value showing the conventional number of the alloy grade. According to current accepted numbering rules, stamps from 0 to 6 can exist.

- G is a symbol that is not used in all markings. Indicates the presence of manganese impurities.

- Sp is the degree of deoxidation of the material. The most important parameter of steel grade. The additional designation “ps” means “semi-calm”, and “kp” means “boiling”.

It is worth noting that this particular approach to deciphering markings began to be used relatively recently after the introduction of new standards. Before this, other approaches were used to create steel markings, which were additionally divided into various groups.

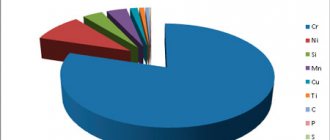

Chemical composition

Decoding the steel grade St3 indicates the main components in its composition - iron (97%) and carbon (0.14-0.22%). The main quality of the alloy—its hardness—depends on the carbon concentration. The steel also contains small amounts of:

- manganese – 0.4-0.65%;

- silicon – 0.15-0.17%;

- nickel and chromium – 0.3% each;

- arsenic – 0.08%;

- copper – up to 0.3%;

- sulfur – 0.05%;

- phosphorus – 0.04%;

- nitrogen – up to 0.008%.

A feature of the St3 alloy is the strict regulation of the content of harmful impurities - sulfur and phosphorus. Phosphorus reduces the plasticity of the metal when exposed to high temperatures, and sulfur, when interacting with iron, forms sulfides, causing the phenomenon of red brittleness. It should be noted that there is an increased concentration of nitrogen, which accounts for almost 0.1%. In accordance with GOST 380-2005, the alloy is marked with accompanying indices that indicate the degree of deoxidation, for example, St3Gsp:

- the first two letters indicate carbon steel of ordinary quality;

- the number “3” means the serial number of the brand according to this GOST;

- the sign “G” indicates a modification with a high manganese content;

- “sp”, “kp”, “ps” – degrees of deoxidation.

Substitutes for steel grade St3 can be:

- C245, according to GOST 27772-88;

- C285;

- VSt3Sp.

Foreign analogues are labeled according to different rules:

- A57036, K01804 – USA;

- 40B, 722M24, HFS4 – UK;

- 1.0038, DC03 – Germany;

- E24-2, E24-4 – France;

- SS330, SS400 – Japan;

- Fe360B, Fe360C – Italy;

- G235C – China;

- RSt360B – Austria;

- Fe235D – Hungary.

The product range includes:

- long and shaped steel according to GOST 2591-2006;

- sheets of various thicknesses and stampings;

- pipes and fittings, according to GOST 10705-80;

- tapes and strips that are produced in accordance with GOST 14918-80;

- wire of different sections.

Main details

St3 steel is currently one of the most in demand due to its operational features. It is most widespread in the industry of manufacturing pipes for heating systems, as well as many other items for everyday use.

Galvanized circle made of steel St3

In most cases, St3 steel is classified as ordinary quality carbon steel.

Purpose of steel grade 3

It is thanks to the advantages of the material that metal processors and builders are eager to buy st3 for their work. Simplicity of welding, strength and ease of use make St3 steel an indispensable assistant in the production of many parts and hardware. It is made from:

- Welded and non-welded structures, the production of parts used at positive temperatures (shields, frames, casings, frames) is carried out.

- Rolled products up to 10 mm thick are used to produce frictionless, low-load parts, such as troughs or machine covers.

- Modified steel is used for the manufacture of channels, angles or I-beams, and shaped outer profiles.

The st3 circle can be used to create mounting fittings, meshes, clamps, water and gas pipes, wire and other elements.

Grade 3 steel is non-floczen sensitive, has no tendency to temper brittleness and has unlimited weldability. The affordable price of St3 also plays a role.

How to harden a metal knife

Heat treatment of iron knives, scissors or surgical instruments can be carried out in a muffle furnace. Such a furnace is ideal for small-sized products made of 40x steel. Some craftsmen also use a gas burner for this purpose, but this method is not very safe, because a fire can occur.

The main advantage of a muffle furnace is that it can perform not only hardening, but also tempering. You can construct this simple device for heat treatment of the alloy with your own hands. Hardening steel at home in a muffle furnace is a non-hazardous method of increasing the hardness of the alloy without the introduction of chemicals (for example, nitrogen). To harden a knife made of 40x steel, it must be placed in the oven while it is still warm.

- Set the oven to gradual heating mode to the desired temperature;

- Cut the sealing wax a couple of times with an iron knife;

- Do the same, but with a gradual decrease in temperature;

- When the knife has cooled, carefully clean it of any remaining melted sealing wax.

This method is often used by doctors to harden iron scalpels at home. Also, a muffle furnace is often used to strengthen iron parts used in the assembly and repair of cars and trucks.

Hardening an alloy is an excellent method to extend the shelf life of an iron product. Naturally, it is better to immediately obtain hardened parts and tools. But if there is no such ability, you can simply increase the hardness of the material without the help of others. Given certain abilities and basic knowledge in the field of metallurgy, a good owner will easily cope with this fundamental task for us. The main thing is to follow preservation techniques and not forget about such a fundamental hardening step as tempering or annealing.

Characteristics of steel ST3

All characteristics of steel st3 are regulated by GOST 380-71 standards. Its composition can include from 0.14 to 0.22% carbon. Steel 3 has quality properties, which are determined by weldability, mechanical properties and corrosion resistance. The mechanical characteristics determine which group the steel belongs to: high-strength, regular or high-strength.

Chemical composition of steel ST3

| steel grade | Mass fraction of elements, % | Carbon Manganese | Silicon |

| ST3kp | 0,14-0,22 | 0,30-0,60 | No more than 0.5 |

| ST3ps | 0,14-0,22 | 0,40-0,65 | 0,5-0,15 |

| ST3sp | 0,14-0,22 | 0,40-0,65 | 0,15-0,30 |

| ST3Gps | 0,14-0,22 | 0,80-1,10 | no more than 0.15 |

| ST3Gsp | 0,14-0,20 | 0,80-1,10 | 0,15-0,30 |

Impact strength of rolled steel ST3

| Steel grade* | Rolled thickness | Impact strength, J/cm2, not less | ||||

| KCU | KCV | |||||

| +20°С | -20°С | after mechanical aging | +20°С | 20°C | ||

| ST3ps ST3sp ST3Gps ST3Gsp | 3,0-5,0 | — | 49 | 49 | — | 9,8 |

| 5,1-10,0 | 108 | 49 | 49 | 34 | — | |

| 10,1-26,0 | 98 | 29 | 29 | 34 | — | |

| 26,1-40,0 | 88 | — | — | — | — | |

| * For ST3kp steel, impact strength is not standardized | ||||||

Mass fraction of steel elements St3sp according to GOST 380-2005

| C (Carbon) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulphur) | Cr (Chrome) | Ni (Nickel) | Cu (Copper) | As (Arsenic) | Fe (Iron) |

| 0,14 — 0,22 | 0,15 — 0,3 | 0,4 — 0,65 | < 0,05 | < 0,05 | < 0,3 | < 0,3 | < 0,3 | < 0,08 | rest |

In open-hearth and converter smelting, the share of nitrogen is 0.01%. An increase in N < 0.013% is allowed, provided that the mass fraction of P is reduced by no less than 0.005% for each increase in the mass fraction of nitrogen by 0.001%. TU 14-1-5283-94: at the request of the consumer P < 0.035, S < 0.04.

How to properly harden an alloy at home?

When making various products from steel or alloys, from time to time the question arises about how to properly harden the alloy at home. The master sets a goal ahead of himself - to obtain a part that has a certain strength. It is not always possible to perform hardening, even with the necessary equipment. There are several circumstances. In almost all options, you can overcome obstacles and achieve the desired result.

Wanting to create similar blanks, they manufacture small-sized technological equipment. It can be used to perform heat treatment of iron products.

Introduction to Metallurgy

The technology of heat treatment of steels provides for a number of thermal action methods. As a result, the grain size changes. This changes the hardness.

The systematization of the compound – iron-cementite – has been adopted in the following meanings:

- 0.0...2.18% carbon is steel;

- 2.14...6.67% carbon – cast iron.

Steels also have other differences:

- 0.0…0.8 – low-carbon steels;

- 0.8…2.14 – carbon steels.

Diagram Fe – Fe₃C. Depending on the temperature and concentration of iron and carbon, different types of compounds are formed. They determine the mechanical characteristics of the alloy:

Heat treatment

Heat treatment of the alloy is carried out to change the features of the iron-carbon alloy.

Annealing is a heat treatment whose purpose is to reduce the strength parameters of steel. It is done by heating to a temperature above the austenitic state, followed by slow cooling (up to 6...8 hours) in the chamber where the heating was carried out.

Normalization is a variant of annealing performed to reduce stress inside the alloy. Normalization is usually done by heating to 727 ⁰C and higher with leisurely cooling (up to 1...2 hours) with the doors of the heating furnace open.

Hardening is a method of changing grain sizes during sudden cooling of an alloy from the austenite state to ambient values.

Tempering is a heat treatment that results in the removal of internal stresses in the alloy. There are: small, medium and high vacation. Everyone has their own temperature values.

Hardness test

The hardness of metals is determined in 2 ways:

- According to Brinell, an iron ball is pressed into the alloy.

- According to Rockwell, it consists of pressing a small cone from a strong pyramid (diamond).

When determining Brinell hardness, the size of the mark left by a ball when pressed with force is determined, the magnitude of which depends on the expected hardness and the ball used. In the tests, balls of various diameters (1, ... 10 mm) are used. Recalculation of readings is done according to the formula:

Where F is the force applied on the device, N; D – diameter of the ball used to test hardness, mm; d – diameter of the print. It is measured under a microscope, which has a special ruler. Measurement accuracy up to 0.01 mm.

This method is recommended for determining hardness of no more than 300...320 units. If you need to find the hardest objects, then use the Rockwell device. On this scale, information is denoted by HRC and numerical value.

Based on countless research works, it has been established that for knife steel, an HRC of 55...63 will be quite high. When designing gears and manufacturing gears, the surface of the teeth is also hardened. Designers set hardness to HRC 52…58. Metal-cutting tools (cutters, drills, cutters, milling cutters) have a hardness of HRC 60...65.

Quenching and tempering

Hardening is created by heating to a temperature above the production of austenite. For some steels, a certain amount of overheating is recommended, which is necessary to obtain a fluidized state throughout the entire mass of the alloy.

Advantages and disadvantages

Among the strengths of this brand:

- Has excellent weldability under any heat treatment.

- Tolerances for the use of elements make it possible to obtain a large variation in mechanical properties.

- Low cost with wide application variations.

- Possibility of hardening with high frequency current (one of the most effective and economical technologies).

- Not prone to temper brittleness.

- Not flake sensitive.

The disadvantage that the St3 steel grade has, which is inherent in the entire class of carbon analogues, is the tendency to corrosion. Even surface treatment gives temporary results. Among other disadvantages:

- As a rule, the steel structure has a coarse or medium-grain structure. Also, when carburizing and nitriding is carried out, the grain is prone to rapid growth and increased fragility.

- Cannot be used for open use in northern climates.

Testing the alloy for properties at home

(*3*)

First, after purchasing an iron item, you need to check its properties. You can create this using a regular soldering iron. The end of the soldering iron is passed over the alloy to find out the shortcomings when developing the tool. If the soldering iron sticks to the surface, it means the steel is not hardened, and with frequent use the tool will become deformed. If, on the contrary, the end of the soldering iron passes smoothly over the steel and practically bounces off it, it means that the alloy is very hardened. In this case, it is necessary to create a heat treatment for the iron tool to increase its strength.

Assortment

Steel grade St3 contains carbon in an amount of 0.14-0.22. Such rolled metal is produced in 2 ways: hot (heating up to 1100 ° C) or cold. The advantage of hot rolling is the absence of stress in the structure due to tempering from rolling heating. During cooling, cold hardening resulting from plastic deformation is naturally removed. Cold rolling is used to produce products with a thickness or diameter of less than 4 mm (due to the formation of scale during heating).

Hot-rolled sheet steel grade St3 (GOST 19903-2005) is intended for the manufacture of welded pipes and casing products. Good machinability by cutting and joining with all types of welding allows the production of products of any shape and size.

Steel grade C255 is an analogue of St3. Heavy-duty products are made from it by hot-rolling: beams, versatile angles, I-beams, rails.

Smooth-bore or periodic profile fittings, 2-4 strength classes, are rolled from ST3sp with a maximum percentage of chemical. elements for this brand: carbon content of 18-22%, manganese - 50-58%, silicon - 18-20%.

If hot-rolled steel sheet grade St3 undergoes additional drawing, its strength increases greatly.

How to properly harden an alloy at home?

The need to harden steel may appear at any time.

There are a huge number of different tools sold on the market that may not have been hardened during manufacture or, on the contrary, were overdone with the temperature during heat treatment. For example, you can remember the well-known drill bits. If the steel is not properly hardened, it will bend. In the case when the steel is very hardened, the drill will most likely begin to crumble. A similar description applies to any iron materials. Naturally, you won’t be able to check the alloy in a store. In this case, there is only one option left, we are talking about hardening steel at home.

Chemical and physical properties

Without steel grade St 3, in our time it is impossible to build, construct above-ground and underground communications, produce vehicles, units and machine tools.

Impurities in steel of this grade are no more than:

- chromium - 0.30 percent;

- nickel - 0.30 percent;

- copper - 0.30 percent;

- sulfur - 0.005 percent;

- phosphorus - 0.04 percent;

- nitrogen - 0.10 percent.

Steel deoxidation

The steel deoxidation process is a chemical process that removes oxygen from the molten raw material. In this case, it is determined by an impurity that worsens the mechanical and physical properties of the alloy.

According to the deoxidation process, St3 steel is divided into the following types:

- Calm - deoxidation occurs with the use of manganese, silicon and aluminum.

- Boiling - deoxidation using only manganese.

- Semi-calm - deoxidation using aluminum and manganese.

The level of deoxidation is indicated in the marking of steel with the letters “kp”, “sp” and “ps”; their modification with an increased percentage of manganese is also indicated. For example – St3Gsp or St3Gps.

Boiling steel differs in chemical composition from calm steel in that the silicon content in it is very low, less than 0.05 percent. Calm steel contains more silicon, ranging from 0.16 to 0.30 percent. Since boiling steel contains more oxygen than calm steel, its quality is much worse than calm steel.

Semi-quiet steel occupies a middle position in quality between calm and boiling steels.

For the deoxidation process, elements such as silicon, manganese, and aluminum are used. The strength of their impact on steel varies. So, the “strongest” is aluminum, and the “weak” is manganese.

Quiet Steel is the most expensive steel in terms of cost. It lacks oxygen and is characterized by a homogeneous (homogeneous) structure, which, due to its nature, is designed to give the alloy maximum protection from environmental influences in the form of corrosion and ductility. Calm steel alloy St3 in accordance with GOST 380-2005 adopted in 2005, is used during the construction of rigid trusses and other metal structures, non-load-bearing and load-bearing elements. This grade of steel is used to make:

- sheet and packaged rolled products (steel sheet St 3);

- blanks for fittings and parts for pipelines (square pipe St 3);

- main and secondary elements for railway facilities, overhead and ground tracks, etc.

Semi-quiet steels occupy a neutral position between boiling and calm types of raw materials. In this form, a percentage of oxygen is already present, which gives the alloy less pronounced characteristics of ductility and hardness.

The chemical composition of this type of steel cannot be considered homogeneous. This grade of steel is used to produce rolled pipes and sheets, such a popular product as the St 3 beam. Semi-quiet steels are also used for the production of circles and strips, angles and squares, embedded parts and hexagons.

If we talk about boiling steels, then these are the most popular and affordable structural steel alloys. The production cost is low, but at the same time, blanks made from this steel (slabs, ingots, finished rolled sheets) lend themselves well to various processing under different thermal conditions.

The density of grade 3 steel of this modification is completely heterogeneous, however, subject to proper use and appropriate requirements, it is one of the most popular and inexpensive, practical types of alloys.

According to GOST 380-2005, it is stated that the manufacturer has the right to independently indicate the degree of deoxidation of raw materials if the customer has not determined it.

Mechanical performance

Mechanical indicators of the properties of St3 steel, which are used to control the properties of rolled raw materials:

- resistance that occurs temporarily - all categories;

- fluidity and its limit - all except the first category;

- bending under external influence in a cold state - all except the first category;

- relative lengthening - all existing categories are here;

- KCU (impact strength) at ambient temperature +20 °C – third category;

- KCU (impact strength) at an ambient temperature of –20 °C – fourth category;

- KCU (impact strength) after mechanical aging – fifth category;

- KC V (impact strength) at ambient temperature +20 °C – sixth category;

- KC V (impact strength) at an ambient temperature of –20 °C – seventh category.

Mechanical properties according to GOST 380-2005 standard

| Yield strength, σ0.2, MPa | Tensile strength, σв, MPa | Elongation at break, δ5, % |

| 205 — 255 | 370 — 490 | 23 — 26 |

Mechanical properties according to GOST 535-2005 standard

| Thickness, mm | Yield strength for residual deformation, σt, MPa | Tensile strength, σв, MPa | Elongation at break, δ5, % | Bend until the sides are parallel* |

| to 10 | > 255 | 380 — 490 | > 26 | d=a |

| 11 — 20 | > 245 | 370 — 480 | > 26 | d=a |

| 21 — 40 | > 235 | 370 — 480 | > 25 | d=2a |

| 41 — 100 | > 225 | 370 — 480 | > 23 | d=2a |

| more than 100 | > 205 | 370 — 480 | > 23 | d=2a |

By agreement with the consumer, for shaped steel with a thickness of more than 20 mm, the yield strength may be reduced by 10 MPa. The relative elongation may be reduced by 1% (by agreement with the consumer). The upper limit of tensile strength may be exceeded by 49 MPa, and by agreement with the consumer - without limiting the upper limit. limit of temporary resistance, provided that other standards are met. At the request of the consumer, exceeding the upper limit of temporary resistance is not allowed. * a - sample thickness, d - mandrel diameter Impact strength standards KCU, J/cm2

| Thickness, mm | At +20 °C | At -20°C | After mechanical aging |

| Steel category 3 (St3sp3)** | |||

| 3 — 9,9 | > 108 | — | — |

| 10 — 25 | > 98 | — | — |

| 26 — 40 | > 88 | — | — |

| Steel category 4 (St3sp4) | |||

| 3 — 9,9 | — | > 49 | — |

| 10 — 25 | — | > 29 | — |

| Steel category 5 (St3sp5) | |||

| 3 — 9,9 | — | > 49 | > 49 |

| 10 — 25 | — | > 29 | > 29 |

** Steel categories: 3 - steel with testing of mechanical properties for tensile strength on samples made from normalized blanks of the size specified in the order, but not more than 100 mm 4 - steel with testing of mechanical properties for tensile strength and impact strength on samples made from heat-treated (hardening + tempering) of workpieces of the size specified in the order, but not more than 100 mm 5 - steel with tensile testing of mechanical properties on samples made of steel in a cold-worked or heat-treated state (annealed or highly tempered)

Mechanical properties according to GOST 8696-74 standard

| Yield strength for residual deformation, σt, MPa (kgf/mm2) | Tensile strength, σв, MPa (kgf/mm2) | Elongation at break, δ5, % |

| > 245 (25) | > 372 (38) | > 23 |

Impact strength standards KCV, J/cm2 (kgf⋅m/cm2)

| Steel category* | At +20 °C | At -20°C | After mechanical aging |

| 3 (St3sp3) | > 59 (6) | ||

| 4 (St3sp4) | — | > 29,4 (3) | — |

| 5 (St3sp5) | — | > 29,4 (3) | > 29,4 (3) |

Mechanical properties according to GOST 10706-76 standard

| Assortment | Tensile strength, σв, MPa | Yield strength for residual deformation, σt, MPa | Elongation at break, δ5, % |

| Pipes | > 372 | > 245 | > 20 |

| Thickness, mm | Test temperature, °C | Impact strength KCU, J/cm2 |

| Steel category 3 (St3sp3)* | ||

| 5 — 9 | +20 | > 59 |

| 9 — 25 | +20 | > 49 |

| more than 25 | +20 | > 29 |

| Steel category 4 (St3sp4)* | ||

| 5 — 9 | -20 | > 20 |

| 9 — 25 | -20 | > 15 |

For main heating networks

| Tensile strength, σв, MPa | Yield strength for residual deformation, σt, MPa | Elongation at break, δ5, % | Test conditions | Impact strength KCU, J/cm2 |

| Steel category 4 (St3sp4)* | ||||

| > 372 | > 245 | > 23 | -20 °C | — |

| Steel category 5 (St3sp5)* | ||||

| > 372 | > 245 | > 23 | -20 °C | > 30 |

| > 372 | > 245 | > 23 | mechanical aging | > 29 |

* Steel categories depending on the standardized characteristics: 3 - steel with tensile mechanical properties tested on samples made from normalized workpieces of the size specified in the order, but not more than 100 mm 4 - steel with tensile and impact strength mechanical properties tested on samples, made from heat-treated (hardening + tempering) workpieces of the size specified in the order, but not more than 100 mm 5 - steel with tensile testing of mechanical properties on samples made from steels in a cold-worked or heat-treated state (annealed or highly tempered)

Mechanical properties according to GOST 10705-80 standard

| Assortment | Diameter, mm | Thickness, mm | Tensile strength, σв, MPa | Yield strength, σ0.2, MPa | Elongation at break, δ5, % |

| Heat-treated products | |||||

| Pipes | All | All | > 372 | > 225 | > 22 |

| Without heat treatment | |||||

| Pipes | from 10 to 19 | no more than 0.06*D | > 441 | > 216 | > 13 |

| Pipes | from 19 to 60 | no more than 0.06*D | > 392 | > 216 | > 13 |

| Pipes | from 10 to 19 | more than 0.06*D | > 441 | > 216 | > 5 |

| Pipes | from 19 to 60 | more than 0.06*D | > 392 | > 216 | > 5 |

| Pipes | from 60 to 152 | All | > 372 | > 216 | > 20 |

| Pipes | from 152 to 377 | no more than 6 | > 353 | > 216 | > 17 |

| Pipes | from 152 to 377 | more than 6 | > 353 | > 216 | > 14 |

| Pipes | more than 377 | no more than 6 | > 353 | > 216 | > 19 |

| Test temperature, °C | Impact strength KCU, J/cm2 (kgf⋅m/cm2) |

| +20 | 78,4 (8) |

| -20 | 39,2 (4) |

| +20 (after mechanical aging) | 39,2 (4) |

Mechanical properties according to GOST 5781-82 standard

| Assortment | Strength class | Diameter, mm | Tensile strength, σв, MPa** | Yield strength, σ0.2, MPa | Elongation at break, δ5, % | Cold bend test* |

| Armature | A-I (A240) | 6 — 40 | > 373 | > 235 | > 25 | 180 °C; c=d** |

* c - thickness of the mandrel, d - diameter of the rod ** For reinforcing steel with a diameter of 20 to 40 mm, cold bending test at 180 °C: c=2d

Weldability of steel grade St3

Consumers enjoy working with this grade of steel. Its technical characteristics, taking into account modifications, are very universal. One of the most important advantages of this brand is its excellent weldability.

Steel allows the use of automatic arc and manual welding methods, as well as contact-spot and electroslag methods. St. 3 is also used for the manufacture of forged parts (fences, various gratings, etc.).

Technological properties St3sp

This steel is considered universal in its qualities.

It is not subject to brittleness after tempering, does not form flakes, and is characterized by excellent weldability using any technology.

Is it possible to harden stainless steel

Hardening refers to the heat treatment of metal, during which intense heating is first carried out, and then sudden cooling in a liquid. During this technological procedure, the ductility and elasticity of the product decreases, but its strength increases. How to properly harden stainless steel items at home?

Types of hardening

Humanity has been using hardening technology for many centuries. Agricultural tools and bladed weapons were hardened already in the Middle Ages.

Hardening of stainless steel was thought about in the era of the industrial breakthrough, when steel alloys with anti-corrosion properties were needed.

It was then that a new method of hardening steel was developed, which made it possible to impart unique chemical and physical properties to the materials.

Stainless steel has a needle-like internal structure called martensite, which makes these alloys highly durable and highly resistant to embrittlement. When heat treating such steel, the viscosity coefficient increases, which expands the scope of their application.

Process Features

When hardening steel, continuous monitoring is required for:

How does the steel hardening process take place?

- uniform heating of the edge and middle of the product;

- the appearance of blue and black spots on the surface of the stainless steel, they indicate strong and uneven heating;

- maintaining temperature indicators;

- uniform cooling in liquid.

As such a liquid, ordinary water or machine oil is most often used. The color change during metal hardening is controlled using a special color scheme.

How to harden steel at home?

Rural residents often resort to self-hardening of metal, thus increasing the service life of household items: plow shares, carpentry and plumbing tools, hunting knives, axes. It is more difficult for a city dweller to process stainless steel - a special workshop is required.

Required Tools

In order to harden steel at home, you need to arm yourself with:

- Pliers with an extended handle;

- Hammers of different sizes;

- Files for subsequent processing;

- Electric oven;

- Gas burner;

- Blowtorch.

To create a cooling environment, you will need any container of appropriate size.

Hardening methods

Stainless steel can be hardened in different ways. First of all, the product heats up well. For this use:

- Burner;

- Electric oven;

- Blowtorch;

- A fire on coals.

The last option will be the best; the fire will be able to provide a much higher temperature.

The most commonly used cooling medium is:

When cooling with oil, the part is dipped into it twice with a short interval of a couple of seconds. The first dive takes 3-4 seconds, and the second - 5-6 seconds. Immediately after this procedure, the steel is immersed in water until it cools completely.

In the second cooling method, the part is immersed in wax several times. If the stainless steel no longer penetrates into the liquid medium, the cooling process is considered complete. Simply clean the surface with turpentine.

How to choose a temperature mode?

The choice of temperature mode plays a big role when hardening steel. Overheating is fraught with loss of inherent strength; this occurs due to a quantitative decrease in carbon in the metal structure.

In some cases, after completion of the stainless steel hardening process, residual stresses appear; they are removed through further mechanical processing.

This problem can be prevented if the product being hardened is cooled in stages, with a measured decrease in temperature conditions.

This step-by-step hardening technique is used in the manufacture of parts with very high strength values.

How to gradually lower the temperature of the cooling medium? To do this, prepare several containers with different liquids: saline solution, alkaline solution, mineral oil, synthetic oil. This method allows you to completely eliminate internal stress, which negatively affects the useful properties of steel. A small disadvantage of the technique is the high cost of implementation.

Master class on hardening a kitchen knife

After hardening, the knife gains strength and elasticity. The procedure does not require a lot of time.

Take:

- Gas burner or electric oven.

- Wax for cooling.

- Turpentine.

- Ticks.

Step by step process:

- Remove the handle from the product.

- Place the blade in the stove compartment. When using a burner, the chamber is made by hand using refractory bricks.

- Turn on the stove (burner). Heat the knife until it acquires a rich red hue. If possible, control the heating by checking the color you purchase against the color chart.

- Soak the stainless steel until it turns bright red and remove from the compartment.

- Immediately immerse the metal in the prepared sealing wax for a couple of seconds. Pull it out. Repeat the procedure many times until the part no longer fits into the sealing wax.

- Clean the stainless steel with turpentine to remove wax residues.

Master class on hardening an ax

Sometimes the manufacturer violates the technology of heat treatment of steel, and the ax turns out to be very soft, quickly begins to dull and form dents, or brittle, then the blade becomes covered with cracks and loses color. The situation can be corrected.

Take:

- Electric oven;

- Wire circle;

- Water;

- Machine oil;

- 2 containers for water and oil.

Step by step process:

- Blunt the cutting edge to 0.1 cm.

- Heat the ax blade to 750-760°C.

- To determine the heating temperature, apply a magnet to the stainless steel; it is not attracted to stainless steel at 768°C.

- Cool slowly to 550°C.

- The cooling procedure takes up to 10 hours. No special cooler is required; just leave the ax in the switched off oven.

- Clean the stainless steel from scale using a wire wheel.

- Heat the blade to 800-830°C until a rich fiery red hue.

- Cool first in water (30°C), lowering for 3-4 seconds. Move the stainless steel quickly in the container, this will help avoid the formation of a steam cushion.

- Cool in machine oil.

- Preheat oven to 300°C. Keep the part in it for an hour.

- Cool outdoors.

On a note

After removing the hot steel from the furnace (burner), it will be elastic and soft, so there is a high probability of damage. To avoid unpleasant consequences, you need to immerse it in a cooling medium smoothly and carefully.

When choosing steel products, pay attention to foreign manufacturers; in their tools, the percentage of stainless metal content exceeds Russian GOST standards.

Long and strong heating of the metal makes the hardening process deeper, resulting in a hard and elastic blade. After this, it will be less strong and gradually lose its cutting qualities.

Annealing modes of carbon steels

The same stainless steel should not be hardened many times: the metal begins to tire and wastes the necessary qualities.

Hardening steel for the first time is a responsible undertaking that requires continuous monitoring. When heated, the product is removed every 3-4 seconds, this allows you to strictly observe the color of the metal. In case of overheating, the steel takes on a white tint; in case of underheating, it becomes dark blue.

To harden stainless steel at home, you must arm yourself with a gas burner, an electric oven, a blowtorch, or light a fire.

In addition, the process cannot be carried out without a coolant (water, sealing wax or machine oil). You will need long-handled pliers and special gloves.

Self-hardening of stainless steel requires constant monitoring of color changes in the material.

on the topic: The hardness of stainless steel and a little about descents

Annealing, hardening and heat treatment of stainless steel

The heating, holding and cooling operations of stainless steel fundamentally affect its structure. After such treatment, the chemical composition remains unchanged, but the stainless steel radically changes its properties. A distinction is made between strengthening and softening heat treatment. Reducing the strength of stainless steel is necessary when the workpiece is to be cut.

Heating

Deep, uniform heating transforms the structure. Heating is carried out directly, gradually or in steps. The heating time depends on the method (furnace, flame or high-frequency electric), on the mass of the metal and the physical properties of the stainless steel type (heat capacity, thermal conductivity). The heating rate is determined by the type of workpiece, the chemical composition of the steel and the temperature range.

Excerpt

The reached temperature ensures the completion of structural transformations. It is important to calculate the optimal time, otherwise the steel will be freed from carbon and scale will form. At high heating temperatures, the holding time should be minimal.

Cooling

Cooling in water exceeds 300 °C per second, but with a furnace it is only 20−30 °C per hour. Cooling occurs faster in air than in an oven. These processes increase the hardness, strength, wear resistance or improve the machinability of the material.

Provider

Are you interested in heat treatment of stainless steel? We offer heat treatment of stainless steel from the supplier Evek GmbH with delivery to any city. Full compliance with modern quality standards. The supplier Evek GmbH offers heat treatment of stainless steel, the price is optimal in this segment of rolled metal.

Buy, favorable price

The supplier Evek GmbH offers heat treatment of stainless steel, the price is determined by the technological features of production without including additional costs.

The company's website displays information about the latest product arrivals. Today you can buy stainless steel at the best price. We have the best price-quality ratio.

In the rare metals segment, Evek GmbH is a profitable supplier.

Mechanical restoration

Parts made from steel grade ST3PS are processed using pre-selected equipment and speed. This ensures that the required performance indicators are maintained, reduces local stresses, etc.

Sharpening and milling is carried out using a cutting tool made of VK8 or T5K10. Internal and external threads are created using taps and dies made of R18 and R6M5 steel. When processing on a machine, it is necessary to use cutting fluids, and when processing manually, castor oil.

The impact strength of ST3PS steel allows products to be processed on machine tools under constant vibration load. The speed depends on the properties of the alloy; other parameters are also selected:

- thickness 6-10 cm – tool holder 16*25 mm;

- cutting depth 3 mm – feed speed 0.7-1.2 mm/rev;

- rotation speed 700 rpm.

Structure of steel after quenching and tempering

Steel in its usual form is a fairly soft and malleable metal.

Some grades do not require special strength (these are the so-called ordinary quality steels, produced in accordance with the requirements of GOST 380): the indicators obtained after smelting are quite sufficient, for example, for sewer manholes or protective gratings.

But there are categories of steels - structural and instrumental - for which the initial strength indicators are not enough. They must be subjected to heat treatment. Its main type is hardening.

Microstructure of steel 45 after annealing and hardening

Hardening and tempering of steel. Colors of heat and tarnish

You may have heard these terms more than once when talking about forged knives, and steels in general. It's time to figure out what they mean.

Hardening, in its essence, is heating the finished product to a certain temperature, followed by cooling at a certain speed, and tempering is additional heating following hardening to lower temperatures with a different cooling mode; exactly which one depends on the grade of steel. The speed is regulated by the so-called. “quenching medium” - a liquid in which the blade is cooled at a certain speed: machine oil, saline solutions, air flow, etc. For example, oil cools at a rate approximately 6 times slower than circulating water.

To get to specific numbers, you need to understand why these two processes are needed at all.

Where and how is it used?

The performance qualities allow the alloy to be used for the manufacture of elements of welded structures operating under load, machine parts and mechanisms. The operating temperature must be above 0 degrees. The fifth category of rolled elements can be used in conditions of negative temperatures -40/-425 C under the action of a variable load.

Complex products require subsequent heat treatment; annealing is most often used. It reduces residual stresses after welding. The scope of application of ST3PS includes the production of At-400S fittings.

The sheets are used to produce parts using cold stamping. The result is pallets for collecting cutting fluids in production, containers of various volumes and purposes, casings, etc.

Equipment and features of the process

To carry out the technological process of processing the material, it is necessary to use certain equipment. Special ovens are used for heating. They can run on electricity, gas or solid fuel. In addition to the heating structure, you need to prepare a container filled with water or oil. It is needed for rapid cooling of the workpiece.

Manufacturing a chamber for hardening metal

The main materials for the manufacture of home furnace bodies for steel hardening are solid refractories in the form of blocks of various sizes and fireclay clay. In such a furnace, a temperature of over 1200 °C is reached, so it is possible to harden products not only from carbon or tool steel, but also from high-alloy steel. When making home stoves from fireclay clay, a cardboard frame is first made according to the shape and size of the working chamber, which is then covered with a layer of fireclay. A heating coil is wound over it, and then the main heat-insulating layer is applied. With this design, the heating area is isolated from the heating element, which is important when it is necessary to harden steel that is sensitive to oxides and carbon burnout.

The most common design of home hardening furnaces are installations whose thermal bodies are made of fireclay bricks or similar refractories. The operating temperature of such materials is more than 1400 °C, so in such furnaces it is possible to harden almost any type of steel and many refractory alloys. Structurally, such a home oven is similar to a conventional wood-burning oven, only it is much smaller in size. The metal in it is heated using an electric spiral placed in grooves along the perimeter of the internal space. If it is necessary to qualitatively harden steel, it must be heated to a precisely specified temperature, so most of these homemade products are equipped with thermostats (they can be freely purchased on Aliexpress).

The video below shows the design of such a home furnace with end loading and a thermostat, which allows you to harden steel with precise temperature conditions. Its thermal body is made of mullite-silica refractory plates ShPT-450.

A detailed description of the design and recommendations for creating a top-loading furnace, in which you can harden products up to 54 cm in length, can be seen in the following video. Here the thermal body of the furnace is made of fireclay bricks (ShB type) and a thermostat is also used. In addition to the top loading, a special feature of this device is a kanthal spiral, which lasts many times longer than traditional nichrome and fechral.

Production Features

The properties of the finished material are determined by the substances that make up its composition and largely depend on what technologies were used in the production of a particular alloy.

The basis of the steel alloy is ferrite. It is a component of iron-carbon alloys. It is, in fact, a solid solution of carbon and alloying components. To increase its strength, the melt is saturated with carbon.

Impurities from which nothing but harm can be expected include phosphorus and sulfur, as well as their derivatives. Phosphorus, reacting with ferrite, reduces the ductility of the alloy when exposed to high temperatures and increases brittleness when exposed to cold. During the melting process, iron sulfide may be formed, which can lead to red brittleness. St3 steel contains no more than 0.05% sulfur and 0.04% phosphorus.

For the production of structural steels, two steelmaking technologies are used:

- open hearth;

- converter

The parameters of the St3 grade, obtained by one or another method, differ little from each other, but the converter technology is simpler and cheaper.

Application of St3sp steel, taking into account characteristics and properties

This type of steel is one of the most popular in construction and industry.

The absence of oxygen in the alloy and a homogeneous structure are factors that increase resistance to corrosion in aggressive environments. These qualities, as well as high ductility, make this steel indispensable in the production of structures and elements that have high rigidity requirements.

These are rolled products - sheet and shaped (channels, I-beams and T-beams, angles), blanks for fittings, pipeline elements (in particular, square pipes), etc.

The characteristics of steel make it possible to construct supporting load-bearing structures and frames from it, the operation of which is carried out in difficult conditions.

Elements and parts are made from St3sp steel without heat treatment, which makes it possible to preserve all the characteristics of the alloy - flanges, tees, transitions.

Steel is also used as a base layer in the production of hot-rolled 2-layer sheets that are resistant to corrosion.

Common media for self-heating

For hardening steel at home, the following cooling media are usually used: air, water and aqueous solutions, mineral oil. 10-15% sodium chloride (table salt) is usually used as aqueous solutions, and mineral oil in home workshops is most often used as a regular engine oil.

To harden individual parts of a product with different hardness, hardening with sequential cooling in two environments is used. Each of these quenching media is characterized by its own cooling rate, which directly affects the structure of the metal being processed.

For example, air cools steel at a rate of 5÷10 °C per second, oil - 140÷150 °C, and water (depending on temperature) - 700÷1400 °C.

In order to properly and without problems harden your product, you need to know the brand of metal from which it is made, since both the heating temperature and the cooling method depend on this. For their products, craftsmen most often use used products made from high-speed and tool steels, which can be hardened in a home workshop, as starting materials.

The table below shows the recommended temperature conditions and cooling environments for various steels.

Hardening metal in oil

Oil conducts heat rather poorly, which contributes to the slower formation of structural elements of steel.

Therefore, if it is hardened in an oil environment, it will acquire strength and elasticity along with hardness. In production, industrial oil I-20 or modern quenching oils such as “Thermoyl”, “Thermo” or “Voltex” are usually used for hardening. In home workshops, craftsmen use what is available. Most often this is new or used motor oil.

To safely quench a part in such oil at home, you need to remember that it has a much lower flash point compared to industrial quenching liquids, and when hot metal is immersed in it, it ignites for a short time, releasing acrid smoke.

Therefore, a hardening container used in a home workshop should have a minimal exposed surface and be used only outdoors or in a ventilated area. In addition to ordinary buckets and cans, one of the most common designs of such containers, which are used by home craftsmen, is an elongated section of pipe of a suitable diameter with a welded bottom.

Analogs

As already noted, the St3 grade is in demand in the production of various structures, and in fact, is the most popular structural steel. This is the reason why it is produced by metallurgical plants located in all parts of the world, for example:

- USA - A284Gr.D, A57036;

- Germany - 1.0038;

- Japan - SS330;

- European Union - Fe37-3FN;

- China - Q235.

Suppliers of steel produced outside our country must submit documents confirming the compliance of imported materials with domestic GOST and TU.

Similar foreign steels

The metal is one of the most common structural steels. Therefore, analogues of ST3PS include foreign products:

- Q235;

- S235J0;

- Fe235D;

- 1.0038;

- K01804 and D.

When purchasing foreign product ranges, you must ensure that they comply with GOST and TU requirements.

Sources

- https://nzmetallspb.ru/stanki/stal-st3-marki-harakteristiki-himicheskij-sostav.html

- https://molotok34.ru/spravochnik/st3ps-rasshifrovka-stali.html

- https://svarkaipayka.ru/material/stal/tehnicheskie-harakteristiki-uglerodistoy-stali-3.html

- https://promkrepez.ru/info/steel-grades/stal-marki-st3/

- https://metal.place/ru/wiki/st3sp/

- https://punktpriema.ru/articles/tehnicheskie-harakteristiki-konstruktsionnoy-stali-st3.html

- https://stanok.guru/stal/fiziko-himicheskie-harakteristiki-staley-st3.html

Other hardening methods

The essence of any hardening is the transformation of austenite into martensite (iron-carbon diagram). Depending on the temperature regime, hardening can be complete or incomplete. The first method is to harden tool steel, and the second is to harden non-ferrous steel.

During hardening, one or more coolants can be used. The method of heat treatment also depends on this. Depending on the cooling medium, heat treatment of the metal can be:

- using one cooler;

- with cooling;

- intermittent;

- stepped;

- isothermal.

Quenching in one cooler

This method is used for heat treatment of simple parts made of alloy and carbon steel. The part is heated to the required temperature and then cooled in liquid. Carbon steel with a diameter of 2 to 5 mm is cooled in water, parts of smaller diameter and all alloy steel are cooled in oil.

Hardening with cooling

When heat treating with a single coolant, thermal and structural internal stress conditions often occur. They develop when the temperature difference reaches a minimum. Tensile stress is formed on the surface of the metal, and compressive stress is formed in the center. To reduce these stresses, before lowering the heated part into the liquid, it is kept in the open air for a short time. The temperature of the part in this case should not be below the 0.8 K line on the iron-carbon diagram.

Intermittent

This hardening is carried out in two environments - water and oil or water and air. A part heated to a critical point is first quickly cooled in water, and then slowly in oil or in the open air. This heat treatment method is used for high-carbon steel. This method is complex, since the cooling time in the first environment is very short and only a highly qualified specialist can determine it.

Stepped

With intermittent heat treatment, the part cools unevenly—thinner surfaces cool faster than others. In addition, it is very difficult to adjust the time the part is in the first medium (water). Therefore, it is better to use step hardening. This method allows the part to be cooled in an environment at a temperature above the martensitic point. The first stage is cooling and holding the part in a given environment until all sections of the part reach the same temperature. The second stage is the final slow cooling (transformation of austenite into martensite).

Isothermal

In isothermal heat treatment, the part is heated to a critical point and then lowered into an oil or salt bath at a temperature of 250 degrees. Leave for half an hour and then cool in the open air. This hardening provides high structural strength and is used for alloy and structural steels in which the decomposition of austenite in the intermediate region does not completely occur. Subsequently, it turns not into martensite, but into bainite + 20% retained austenite, enriched in carbon. With this hardening, high strength and good toughness can be achieved.

Hardening tasks

All heavy-duty carbon steel tools and machine parts, and almost all alloy steel machine parts, are hardened.

- The main purpose of hardening tool steel is to achieve high hardness. The cutting properties of the tool are directly proportional to the hardness of the metal.

- Most machine parts are hardened to achieve high wear resistance. The higher the hardness, the higher the wear resistance and abrasion resistance. For example, spindles, gears, shafts, cams and so on.

- The main purpose of hardening machine parts made from pearlitic grade structural steels is to achieve high yield strength with good toughness and ductility to allow higher operating stresses. But a higher yield strength (and tensile strength) with good toughness and ductility is achieved not during the hardening process, but after high-temperature tempering of hardened steels.

Steel hardening technology is usually applied to finished products rather than raw materials. This is done for a number of reasons. First, hardening an entire block of steel is uneconomical since most of it will be removed during the processing process. In addition, steel after hardening is much more difficult to machine because the hardness of the metal makes it difficult for tools to penetrate.

Cooling medium

Achieving the required properties of stainless materials largely depends on the choice of cooling method.

Different grades of stainless steel undergo cooling differently. If low-alloy steels are cooled in water or its solutions, then for stainless alloys oil solutions are used for these purposes.

Important: When choosing a medium in which to cool the metal after heating, it should be taken into account that cooling occurs faster in water than in oil! For example, water at a temperature of 18°C can cool an alloy by 600°C in a second, but oil by only 150°C.

In order to obtain high metal hardness, cooling is carried out in running cold water. Also, to increase the hardening effect, a brine solution is prepared for cooling by adding about 10% table salt to the water, or an acidic medium containing at least 10% acid (usually sulfuric) is used.

This is interesting: Countersinking and countersinking - how to process metal parts

In addition to the choice of cooling medium, the cooling mode and speed are also important. The temperature decrease rate must be at least 150°C per second. Thus, in 3 seconds the temperature of the alloy should drop to 300°C. A further decrease in temperature can be carried out at any speed, since the structure fixed as a result of rapid cooling will no longer be destroyed at low temperatures.

Important: Cooling the metal too quickly leads to its excessive fragility! This should be taken into account when hardening yourself.

The following cooling methods are distinguished:

- Using one medium, when the product is placed in a liquid and kept there until completely cooled.

- Cooling in two liquid media: oil and water (or saline solution) for stainless steels. Products made of carbon steel are first cooled in water, since it is a fast cooling medium, and then in oil.

- Using the jet method, when the part is cooled with a stream of water. This is very convenient when you need to harden a specific area of the product.

- Using the method of step cooling in compliance with temperature conditions.

Defects during hardening of steel

The cause of defects during steel hardening is a number of physical and chemical factors that arise when there is a deviation from the specified parameters of the thermal process or due to the heterogeneity of the workpiece being hardened. Uneven heating or cooling of the product can lead to its deformation and internal cracks. The same reason can cause uneven phase transformations in different parts of the product, as a result of which the metal will have a structure that is heterogeneous in composition and hardness. Burnout of steel occurs due to the penetration of oxygen into the surface layer of the metal, which leads to the formation of oxides that separate its structural elements and change the physical properties of the surface layer. The reason for decarburization during steel hardening is the burnout of carbon when excess oxygen enters the furnace. These types of defects are irreparable, and the only way to deal with them is to check the tightness of the furnace or hardening in a vacuum and inert gases.

Scales and a critical decrease in carbon concentration during heating

Even a small concentration of oxygen in a hardening furnace leads to the appearance of surface scale, which is a consequence of the oxidation of the metal during its heat treatment. The same reason can cause a decrease in the amount of carbon in the surface layer of the workpiece. It is possible to completely get rid of such phenomena only by using vacuum furnaces, which provide so-called light hardening, as well as by heating the product in a nitrogen or argon environment. To minimize oxidation and decarburization, the hardening furnace must be as sealed as possible, which to some extent limits the flow of oxygen into its working space.

For hardening metals, it is recommended to use transformer or industrial oil I-20. It is not easy for a private owner to get it, so I would like to hear in the comments to this article your opinion on the possibility of using used car oil or other automobile oil for hardening steel.

Sources

- https://www.rocta.ru/info/kak-pravilno-samomu-zakalit-metall-i-stal-v-domashnih-usloviyah/

- https://WikiMetall.ru/metalloobrabotka/zakalka-stali.html

- https://HeatTreatment.ru/zakalka-stalej

- https://WikiMetall.ru/metalloobrabotka/kak-zakalit-metall.html

- https://metalloy.ru/obrabotka/termo/zakalka-metalla-v-domashnih-usloviyah

- https://martensit.ru/termoobrabotka/zakalka-metalla/

- https://plavitmetall.ru/obrabotka/zakalka-stali-v-domashnix-usloviyax.html

- https://metmastanki.ru/kak-zakalit-stal-v-domashnih-usloviyah

- https://www.rinscom.com/articles/kalenyy-metall-kharakteristiki-i-osobennosti-materiala-instrumenty-dlya-obrabotki-primenyaemye-tekhn/