In a previous article, TD Serebro talked about why some metals are considered precious. It turned out that there is a simple explanation for this: they have unique chemical, physical and aesthetic properties.

Each metal is unique in its own way, but our company treats noble silver with special respect. It became the basis of the trading house’s assortment, is one of the main metals in jewelry and is very widely in demand in light and heavy industry. There are amazing facts and several myths associated with silver - we will confirm some, dispel others, and all of this will be interesting.

Disclaimer: We do not try to tell everything, but want to give you a general understanding of those things that will be useful when choosing jewelry. We are a jewelry company. If you want to understand these issues in depth, you might want to consider special education.

Physics

Silver is a white precious metal. Its density is 10.5 g/cm³, temperature 960.5°C, boiling point 2210°C, Brinell hardness in the annealed state (after annealing) 25 kgf/mm². These numbers mean little to a non-specialist, but they are very important for those involved in processing the material. Depending on these indicators, different forces and methods are applied to the metal to give the finished products the desired properties.

Annealing is a high-temperature treatment to give the metal a more stable state, eliminate inhomogeneities, and relieve stress due to deformation. Silver alloys are annealed at a temperature of 600–650°C for up to ten minutes, depending on the mass, and with rapid cooling. Almost all silver jewelry is annealed.

Silver polishes well, is highly reflective, has good malleability and the highest thermal and electrical conductivity of all metals.

Conductivity

The measure of a substance's ability to conduct electric current is called electrical conductivity. The most electrically conductive metal has the highest similar indicator. This characteristic can be determined for any substance or environment instrumentally and has a numerical expression. The specific electrical conductivity of a cylindrical conductor of unit length and unit cross-sectional area is related to the resistivity of this conductor.

The system unit for conductivity is siemens per meter – S/m. To find out which metal is the most electrically conductive metal in the world, it is enough to compare their experimentally determined conductivities. You can determine the resistivity using a special device - a microohmmeter. These characteristics are inversely dependent.

Chemistry

Silver is stable in water, practically does not react with oxygen in the air at room temperature, but due to the presence of hydrogen sulfide in the air, over time it becomes covered with a thin dark coating of silver sulfide. Silver also reacts with ozone, forming a coating of silver oxide. This is the very darkening that is considered the main drawback of this metal.

Copper, which is the most common alloy for silver alloys, also forms a coating of copper sulfide. The higher the copper content in the alloy, the faster the product will darken, and the lower, the less susceptible the alloy is to tarnishing, so alloys from 875 to 960 are considered the most stable.

Ligature is an alloy of two or more components that is added to a precious metal to bring the jewelry alloy to a certain standard, change the color of the alloy, and also impart various useful properties. The process of adding a ligature is called doping.

Silver dissolves in nitric and hot concentrated sulfuric acid. Like gold, it reacts with alkaline solutions of cyanide. You will probably never encounter these things. And if you do, be very careful.

Factors affecting the conductivity of metals

Even the most electrically conductive metal reduces its conductivity if it contains other additives and impurities. Alloys have a different crystal lattice structure than “pure” metals. It is characterized by a violation of symmetry, cracks and other defects. Conductivity also decreases with increasing ambient temperature.

The increased resistance inherent in alloys is used in heating elements. It is no coincidence that nichrome, fechral and other alloys are used to manufacture working elements of electric furnaces and heaters.

The most electrically conductive metal is precious silver, mostly used by jewelers, for minting coins, etc. But its special chemical and physical properties are also widely used in technology and instrument making. For example, in addition to being used in components and assemblies with reduced resistance, silver plating protects contact groups from oxidation. The unique properties of silver and alloys based on it often make its use justified, despite its high cost.

Silver alloys

Pure silver is a heavy (lighter than lead, but heavier than copper and harder than gold), unusually ductile silvery-white metal with a light reflectance of about 100%, therefore, in its pure form, silver is usually used only to cover jewelry made from silver alloys, base metals, etc. component of gold and silver alloys and solders.

In the manufacture of jewelry, in order to increase the hardness and strength of the material, silver is processed in alloys with other metals. Most often these are two-component alloys of silver and copper in varying percentages and with a small amount of impurities.

Silver alloys vary slightly in shade and have approximately the same mechanical properties. Tableware items and decorative table decorations are made from alloys with low silver content. High quality alloys are used to produce jewelry. They are quite flexible and go well with colored stones, pearls and enamel.

Silver samples

The Russian Federation has adopted the metric system of samples. Metric fineness is the number of milligrams of the base noble metal that one gram of the alloy contains.

For example, in a 925 silver alloy, there are 925 milligrams of silver per gram. For simplicity, we can assume that at 925 purity the alloy contains 92.5% silver.

- 800. An alloy with a high copper content, which is why it has a yellowish tint. Suitable for cutlery.

- 830. Properties are identical to the 800th sample. Used for decorative decorations.

- 875. It is used in the industrial production of jewelry and household products - for example, pens.

- 916. Used for the production of tableware items coated with enamel.

- 925. In color and anti-corrosion properties it does not differ from pure silver. This alloy is widely used for making jewelry.

- 960. Used for making filigree products.

- 999. Suitable for storing metal in ingots and silvering, that is, covering jewelry with a thin layer of silver to protect and improve decorative properties.

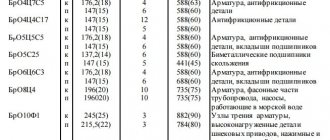

In jewelry production, 875 and 925 are the most common. Modern Russian GOST 30649-99 describes five grades of silver-based alloys. In all, the alloy is copper.

Physical meaning of conductivity

The use of metal conductors has a long history. Scientists and engineers working in fields of science and technology that use electricity have long decided on materials for wires, terminals, contacts, printed circuit boards, etc. A physical quantity called electrical conductivity helps determine the most electrically conductive metal in the world.

The concept of conductivity is the inverse of electrical resistance. The quantification of conductivity is related to the unit of resistance, which is measured in Ohms in the International System of Units (SI). The SI unit of electrical conductivity is siemens. The Russian designation for this unit is Cm, the international designation is S. An electrical conductivity of 1 Cm has a section of an electrical network with a resistance of 1 Ohm.

Coatings of silver products

Currently, the most technologically advanced types and methods of coating silver products are:

- “White” boiling is boiling in sulfuric or hydrochloric acid to reduce the content of copper reacting with hydrogen sulfide in the thin surface layer of the product. The surface acquires a matte tint.

- Electroplating — applying a thin layer of precious metal using the electroplating method. Currently, electroplating is the most popular way to protect and decorate silver jewelry. Depending on the metal that performs the function of the protective layer, the following types of coatings are used:

- Silvering is a coating with a thin layer of pure silver, which reacts weaker than alloys with hydrogen sulfide in the air.

- Rhodium plating is coating with a layer of white and, less commonly, black or yellow rhodium. Rhodium is a precious platinum group metal. It is wear-resistant, does not darken, and has a beautiful mirror-like light-steel shine, which is why in the last 10–15 years it has become one of the most popular coatings on the jewelry market. If repaired by soldering, the rhodium plating turns black and cracks. In this case, the old coating must be removed and a new one applied.

- Gilding is gold plating. It is actively used for complete or partial decoration of silver products.

- Passivation (passivation) — transfer of the top layer of the alloy into a passive state, which sharply slows down corrosion processes. Performs a purely protective function.

- Oxidation is a type of passivation, the creation on the surface of a metal of a dense film of oxides that protects it from corrosion. It is both a decorative and protective coating method.

- Electrophoresis deposition - coating with organic polyurethane foam or acrylic by immersion in an aqueous solution of epoxy or acrylic resin under the influence of tension. Performs only a protective function.

Application

Jewelry, watches, tableware, interior decorations, writing instruments, and decorative elements of weapons are made from silver. Silver can be combined with gold, enamel, niello, precious and semi-precious stones, pearls, corals, and ivory. The metal is widely in demand in the chemical industry, in the production of mirrors, and also as a protective and decorative coating. High thermal and electrical conductivity make silver useful in the production of electronics and electrical equipment.

Myths about silver

- Fake silver turns black, but real (old, high-quality) silver does not turn black

A fake can also turn black for a variety of reasons, but if you carefully read our article, you realized that the formation of a thin layer of silver oxide or sulfide is normal for this metal; this is its chemical feature. And in old jewelry, not copper, but palladium and platinum were used as ligatures. This alloy did not really darken, but it was much more expensive. It's chemistry, nothing personal.

- Silver disinfects

This is true, silver has bacteriostatic properties, slowing down the development of bacteria, and a bactericidal effect, killing bacteria with the help of silver ions. But this manifests itself only in concentration, which can be harmful for you and me, because silver is a heavy metal, it is deposited in the body and can cause poisoning. It is safe to wear, but we do not recommend eating it.

You can also remove spoons, rings and pendants from the water: in this case, so few silver ions are released that they are not able to disinfect anything. This also means you don't have to worry about silverware and cutlery. If you use a special ionizer, there will be an effect, but with it it is easy to exceed the permissible concentration and again get poisoned.

If you are reading in English, here is a WHO report on the use of silver for disinfection, which generally repeats the above conclusions and speaks of the lack of information for far-reaching conclusions in most studies on this topic.

- Silver drives away evil spirits

We invite you to check this myth yourself. Find a vampire and stab him with a silver sword, but take precautions: if the sword is rhodium-plated, the effect may be disappointing.

Top best conductors - metals

4 metals that are of practical importance for their use as electrical conductors are distributed in the following order relative to the value of specific conductivity, measured in S/m:

- Silver - 62,500,000.

- Copper – 59,500,000.

- Gold – 45,500,000.

- Aluminum - 38,000,000.

It can be seen that the most electrically conductive metal is silver. But like gold, it is used to organize the electrical network only in special specific cases. The reason is high cost.

But copper and aluminum are the most common option for electrical appliances and cable products due to their low resistance to electric current and affordability. Other metals are rarely used as conductors.